Mixing and stirring mechanism for long tank

A mixing and stirring, long-shaped tank technology, applied in mixers, mixer accessories, shaking/oscillating/vibrating mixers and other directions, can solve problems such as poor effect, influence of mixing effect, and insufficient mixing, and achieve high efficiency and mixing effect. Good, satisfying the effect of mixing needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

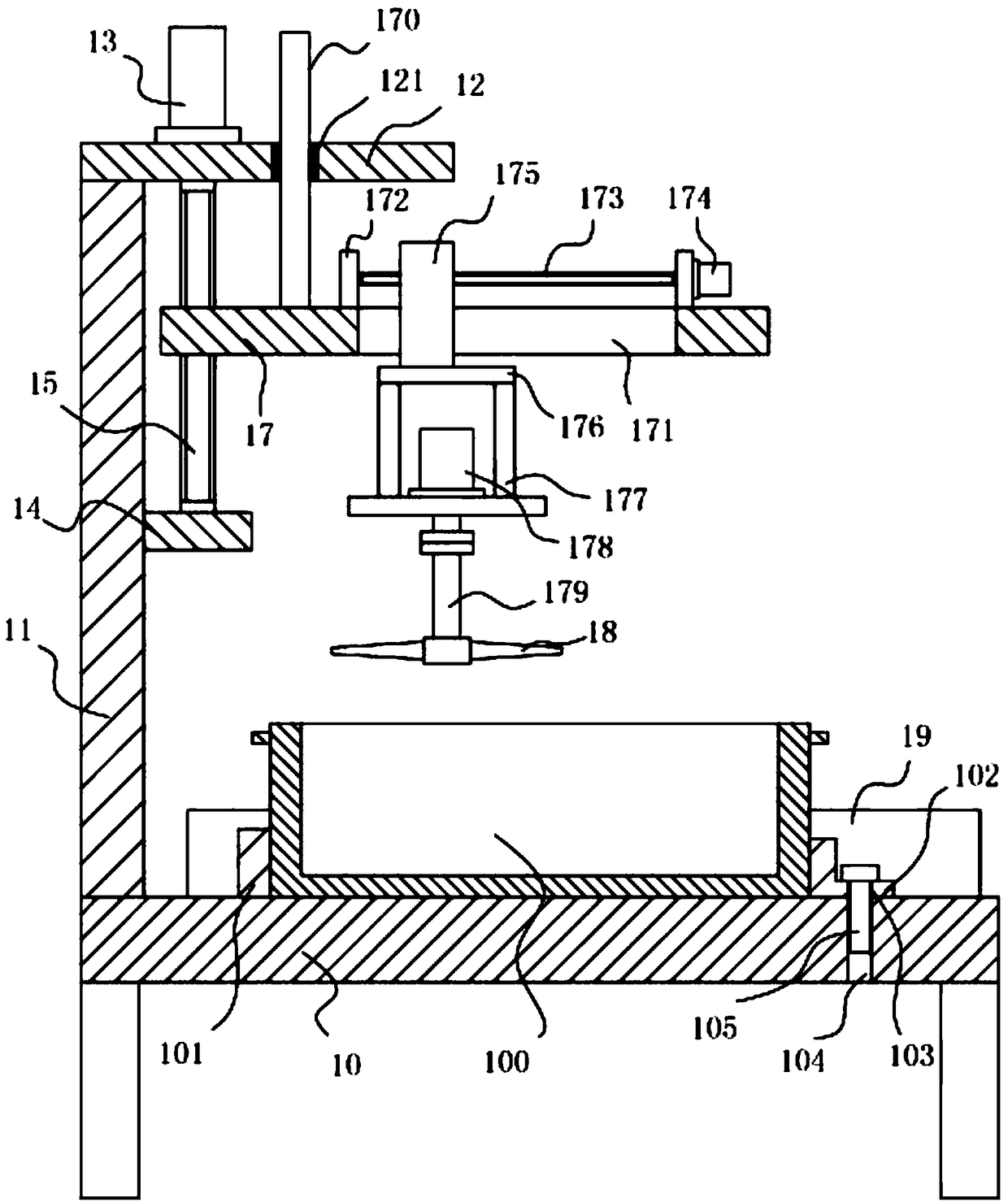

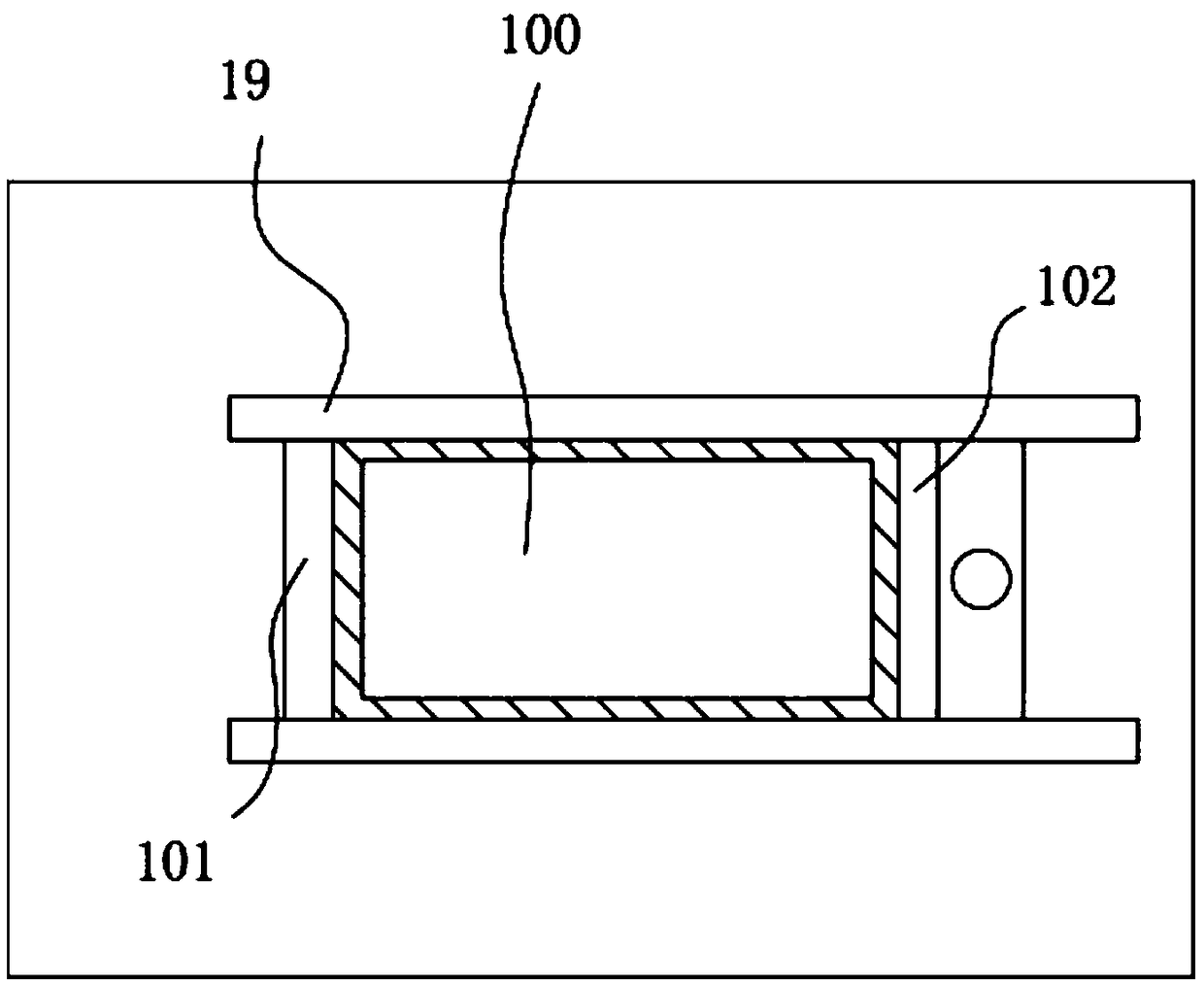

[0018] Example: see Figure 1 to Figure 2 Shown, a kind of elongated tank body is used mixing stirring mechanism, comprises frame 10, and the left top surface of the top plate of described frame 10 is fixed with vertical plate 11, and the top surface of vertical plate 11 is fixed with upper top plate 12 , the upper top plate 12 is directly above the top plate of the frame 10, the top surface of the upper top plate 12 is fixed with a lifting motor 13, the middle inner side wall of the vertical plate 11 is fixed with a middle horizontal plate 14, and the bottom of the vertical lifting screw rod 15 Hinged on the middle horizontal plate 14 through bearings, the top of the vertical lifting screw 15 is hinged on the upper top plate 12 through bearings, the output shaft of the lifting motor 13 is a spline shaft, and the spline shaft is sleeved on the top of the vertical lifting screw 15 In the spline hole that has, the lifting plate 17 is screwed in the vertical lifting screw rod 15,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com