Split-flow convergent type mixer and mixing method

A technology of mixer and splitter plate, which is applied in mixing methods, fluid state mixers, chemical instruments and methods, etc., can solve the problems of difficult turbulent flow area of etching mixer, high energy consumption in mixing process, low mixing efficiency, etc. Simple structure, low production and processing cost, and high mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

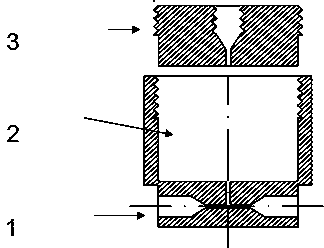

[0039] Embodiment 2 see attached figure 1 , a diversion-confluence type static mixer and method thereof, the mixer tank body is composed of a tee joint 1, a mixing chamber 2, and an outlet adapter 3. The mixing chamber 3 is alternately arranged with dividers 4, 24-channel divider plates 5, 24-channel dividers 6, 24-channel manifolds 7, dividers 8, dividers 4, 24-channel divider plates 5, 24-channel dividers 6, 24 Channel manifold 7, partition 8, please refer to the attached Figure 6 shown. Divider plate 5, partition plate 6, and manifold plate 7 include processing corresponding grooves on both sides of a plate, and the ends of the grooves on both sides are connected with through holes, and the three plates are integrated to realize the integration of manifold plate 5, partition plate 6, and manifold plate 7. effect. The partitions 4, 6, 8, diverter plate 5, and manifold 7 are PEEK plates whose shape matches that of the mixing chamber. Other arrangements are the same as in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com