Top-insertion type short-cantilever stator-rotor stirring device

A technology of stirring device and stator and rotor, which is applied in the directions of mixer accessories, dissolving, mixer, etc., can solve the requirement of low clearance between the stator and rotor of the higher speed of the difficult rotor, the poor working conditions of the bearing of the long cantilever stirring shaft, and it is difficult to achieve better performance. High homogeneous material mixing and other problems to achieve the effect of improving mixing effect, improving reliability and small gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

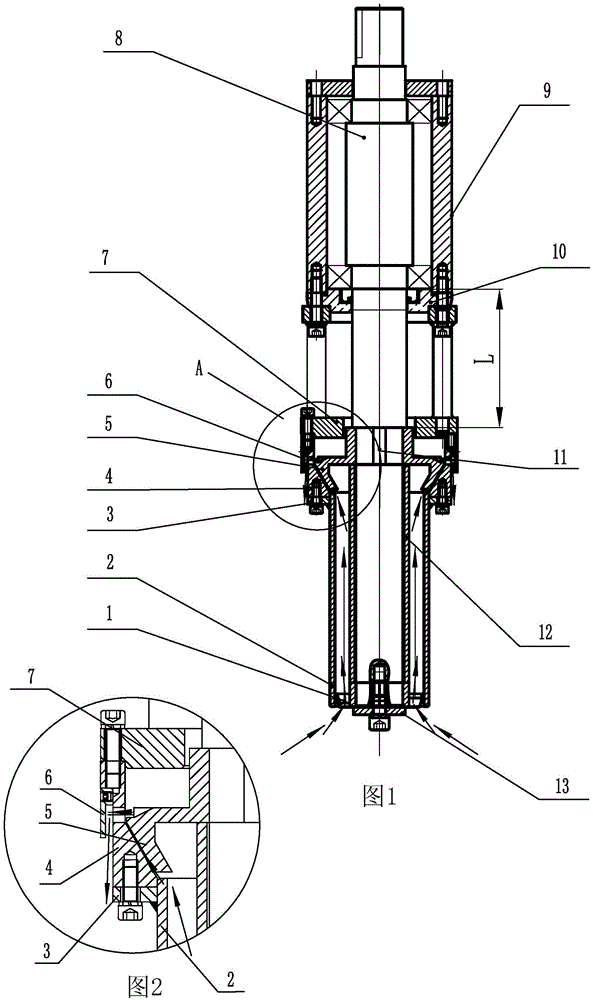

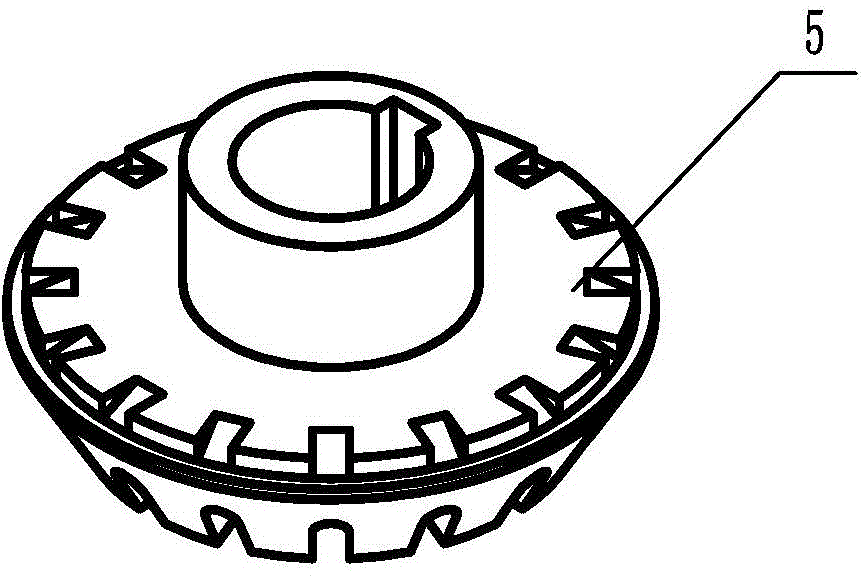

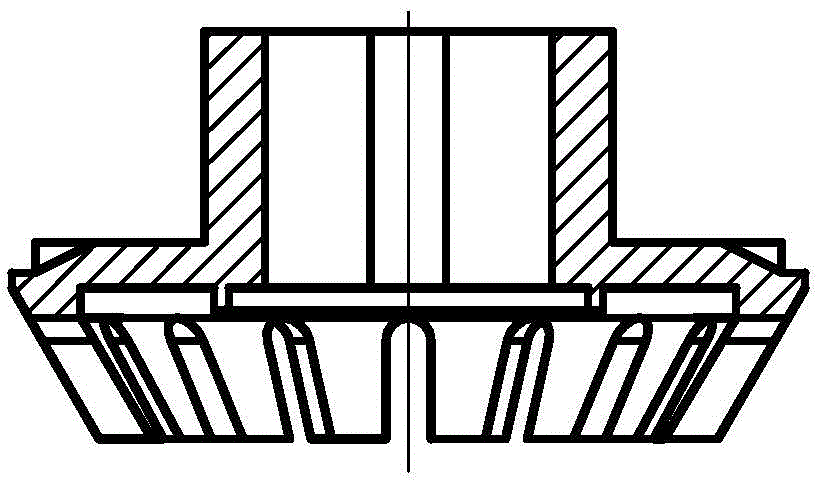

[0031] Embodiment 1: A top-inserted short cantilever stator-rotor stirring device, including a rotating shaft 8, a bearing seat 9, a bearing gland 10, an emulsification support 7, a rotor 5, a stator 4, a sleeve 2 and an inducer 1, the The inducer 1 is composed of a mounting sleeve 101 and 3 blades 102 evenly distributed on the mounting sleeve, the blades are obliquely connected to the mounting sleeve, and the inclination angle β of the blades is 20°. The bearing seat is connected with the emulsification support, the rotating shaft 8 passes through the bearing seat 9 and the emulsification support 7 and is installed in the bearing seat through a bearing, the rotor 5 is installed on the rotating shaft, and the stator 4 Located on the outside of the rotor and connected to the lower end of the emulsification bracket 7, the upper end of the sleeve 2 is fixed with a connecting plate 3, the sleeve 2 is set outside the rotating shaft 8 below the stator and connected to the bottom end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com