Production method of moisture-proof modified urea resin adhesive

A urea-formaldehyde resin glue, urea-formaldehyde resin technology, applied in the direction of adhesives, adhesive additives, aldehyde/ketone condensation polymer adhesives, etc., can solve the problems of poor moisture resistance and corrosion resistance, low bonding strength, slow curing speed, etc. Good performance, improve moisture resistance, improve water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

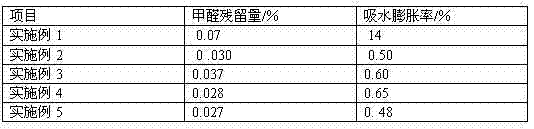

Examples

Embodiment l

[0027] The production of modified urea-formaldehyde resin comprises the steps:

[0028] Initial stage of reaction: add formaldehyde solution to the polymerization reactor at one time, raise the temperature from room temperature to 50°C, adjust the pH value to 7.5-8.0 with NaOH solution, add urea with 12% weight of formaldehyde solution, and complete the addition within 35-45 minutes , heat preservation reaction 50min.

[0029] Middle stage of reaction: After the initial stage of reaction, add formic acid solution to adjust the pH value of the reaction to 4.8-5.2, add urea with 28% weight of formaldehyde solution, finish adding within 40-50min, then add oxidized starch with 5% weight of formaldehyde solution, and heat up the reaction Liquid to 110 ~ 120 ℃, heat preservation reaction 120min.

[0030] Late stage of reaction: the polymerization stage in the middle stage of the reaction is over, adjust the pH value to 7.5 to 8.5 with NaOH solution, add urea with 40% to 50% of the ...

Embodiment 2

[0033]First prepare polyvinyl acetate emulsion, the preparation method of polyvinyl acetate emulsion is: add polyvinyl alcohol solution with a mass fraction of 5.5% in the reactor, and add emulsifier OP-10 with 33% polyvinyl alcohol mass, stir to adjust the temperature To 60°C, add vinyl acetate with 4.5 times the mass of polyvinyl alcohol to the emulsion and add 44% of the mass of polyvinyl alcohol with a mass fraction of 10% ammonium persulfate solution, replace the air with nitrogen, and keep the temperature at 60°C and reflux React for 45 minutes, then raise the temperature to 85-90°C, then add vinyl acetate 17 times the mass of polyvinyl alcohol drop by drop and ammonium persulfate solution with a mass fraction of 66% of the mass of polyvinyl alcohol and 10% ammonium persulfate solution, keep warm After reacting for 60 minutes, lower the temperature to 50°C, adjust the pH to 5-6 with sodium bicarbonate solution, then add dibutyl phthalate 1.7 times the mass of polyvinyl al...

Embodiment 1

[0034] 55 parts of the modified urea-formaldehyde resin obtained in Example 1, add 5 parts of polyvinyl acetate emulsion and 0.5 part of isobutyltriethoxysilane under stirring, after stirring and mixing evenly, add 25 parts of flour, grind with a three-roll mill 30min to obtain a moisture-proof urea-formaldehyde resin adhesive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com