A kind of continuous production method of GMA type acrylic resin powder coating

A technology of acrylic resin and production method, which is applied in the direction of powder coating and coating, and can solve the problems of cumbersome preparation process, difficult control of acrylic resin process, easy blockage of pipelines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

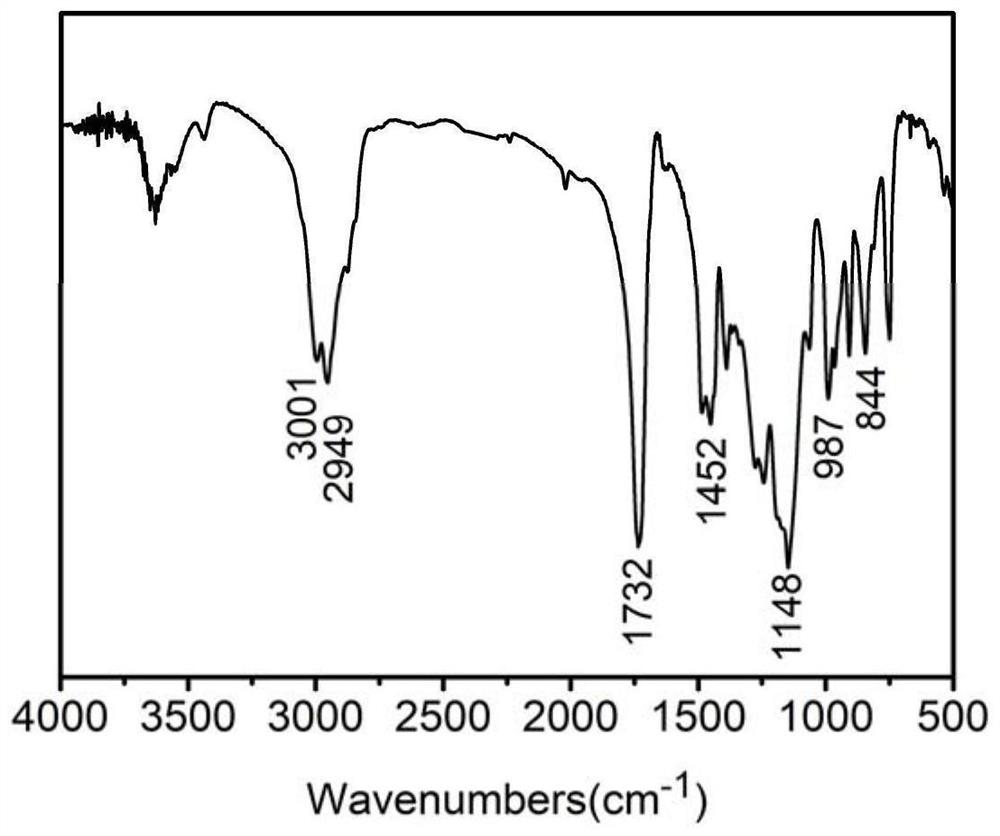

Image

Examples

Embodiment 1

[0028] The preparation method of GMA class acrylic resin powder coating in the present embodiment is as follows:

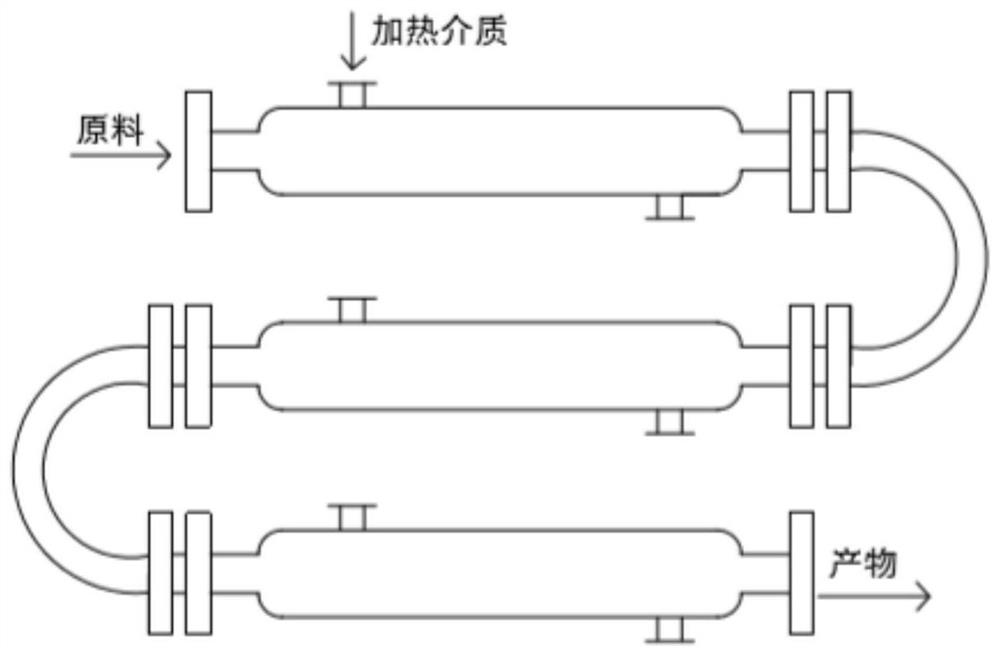

[0029] Step 1: Add 30 parts by mass of GMA, 60 parts by mass of methyl methacrylate, 10 parts by mass of butyl acrylate, 3 parts by mass of azobisisobutyronitrile, and 2 parts by mass of dodecyl mercaptan into the premix tank for mixing Uniform, and then through the high-pressure pump continuously into the tubular reactor for free radical polymerization, in which the tubular reactor is composed of three sections of tubular reactors connected in series, the control temperature is 90°C, 30°C and 150°C in sequence to control the polymerization The concentration of the reactant is 30%, 50% and 70% successively, the pressure in the control reactor is 0.2MPa, the residence time of the control reactant is 6min by adjusting the flow velocity in the tube, and the GMA type acrylic resin solution with a polymer concentration of 70% is prepared.

[0030] Step 2: pump the GMA ...

Embodiment 2

[0033] The preparation method of GMA class acrylic resin powder coating in the present embodiment, comprises the steps:

[0034] Step 1: 25 parts by mass of GMA, 65 parts by mass of acrylic acid, 5 parts by mass of ethyl acrylate, 5 parts by mass of 2-ethylhexyl acrylate, 3 parts by mass of dicumyl peroxide, 1 part by mass of octadecyl The mercaptan is added into the pre-mixing tank and mixed evenly, and then continuously added into the tubular reactor equipped with a static mixing device through a high-pressure pump for free radical polymerization. The temperature is 100°C, 50°C and 130°C in turn, the polymer concentration is controlled to be 40%, 60% and 85% in turn, the pressure in the reactor is controlled to be 0.5MPa, and the flow rate in the tube is adjusted to control the residence time of the reactant to be 5min. A GMA type acrylic resin solution having a polymer concentration of 85% was obtained.

[0035] Step 2: pump the GMA type acrylic resin solution discharged f...

Embodiment 3

[0038] The preparation method of GMA class acrylic resin powder coating in the present embodiment, comprises the steps:

[0039] Step 1: 21 parts by mass of GMA, 36 parts by mass of methacrylic acid, 43 parts by mass of butyl methacrylate, 0.2 parts by mass of di-tert-butyl peroxide, 3 parts by mass of 2,4-diphenyl-4-methyl -1-Pentene is added to the pre-mixing tank and mixed evenly, and then continuously added to the tubular reactor through a high-pressure pump for free radical polymerization, wherein the tubular reactor is composed of three sections of tubular reactors connected in series, and the temperature is controlled in sequence: 120°C, 60°C and 120°C, control the polymer concentration to 40%, 70% and 85% in turn, control the pressure in the reactor to 1MPa, adjust the flow rate in the tube to control the residence time of the reactant to 4min, and obtain the polymer concentration 85% GMA type acrylic resin solution.

[0040] Step 2: pump the GMA type acrylic resin so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com