Preparation technology for pesticide microcapsule

A technology of microcapsules and pesticides, which is applied in the field of preparation of pesticide microcapsules, which can solve the problems of poor product slow release performance and decreased embedding rate of core materials, etc., and achieve the effect of simple capsule particle size distribution, simple mechanical strength, and easy manipulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

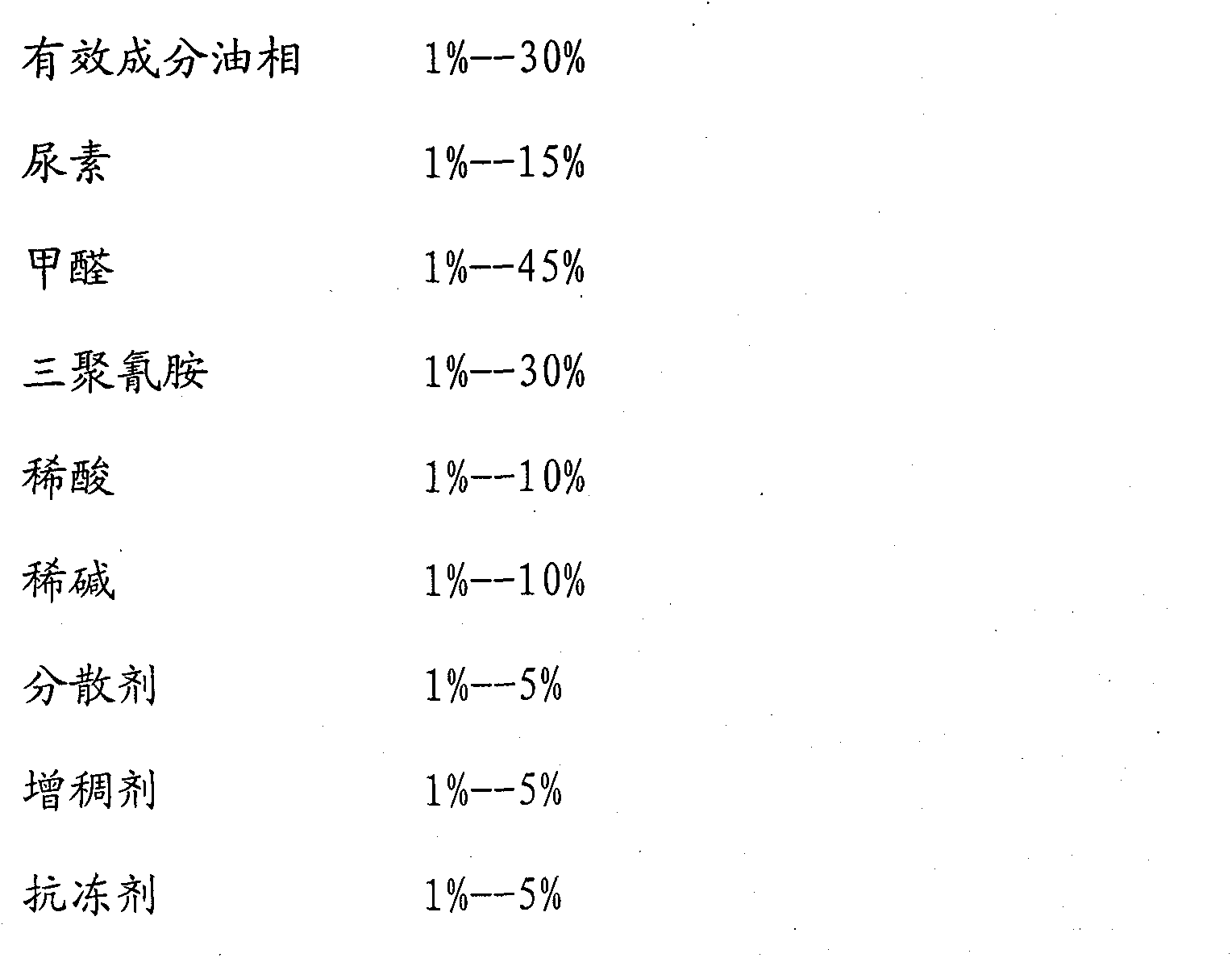

Method used

Image

Examples

Embodiment 1

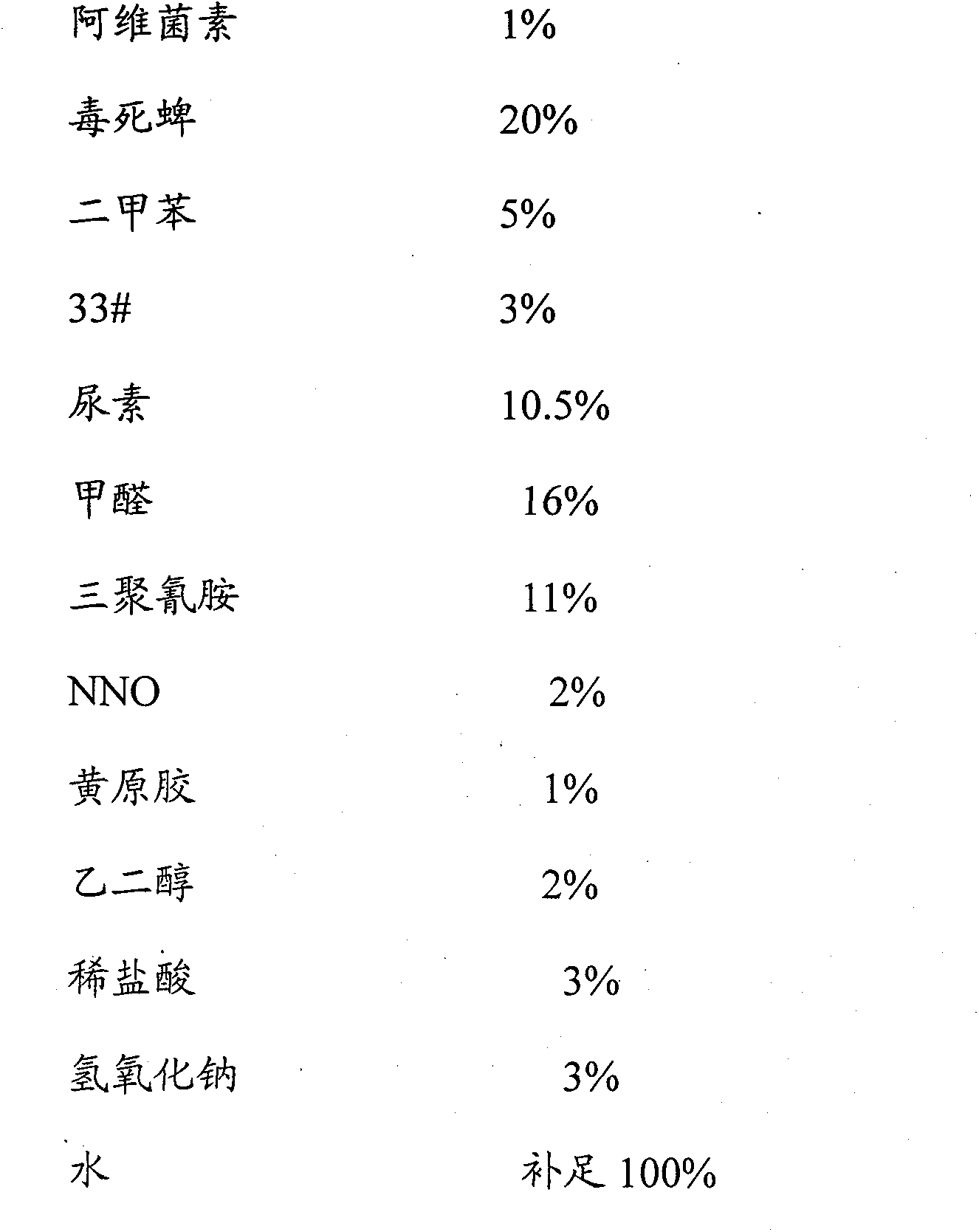

[0033] The preparation method of 16% Avi·du microcapsule suspension

[0034]

[0035] The preparation method is as follows:

[0036] (1) 52.5g of urea, 80g of formaldehyde solution and 55g of melamine were stirred and mixed at a low speed, an appropriate amount of NaOH was added to adjust the pH value to 8, and the temperature was raised to 65°C until the melamine was completely dissolved, then stirred for 10 minutes to obtain cyanuric cyanide-urea - formaldehyde prepolymer.

[0037] (2) Dissolve 5g avermectin and 75g chlorpyrifos in 25g xylene, add 15g33# to 70g water to prepare an aqueous solution, mix the above materials, and stir rapidly for 20 minutes under a mixer at 1000r / min to obtain an oil-in-water milky white mixture liquid.

[0038] (3) Add melamine-urea-formaldehyde prepolymer into the obtained milky white mixture, and then adjust the rotating speed to 600r / min for stirring.

[0039] (4) Slowly drip 20ml of 5% dilute hydrochloric acid into (3) during the sti...

Embodiment 2

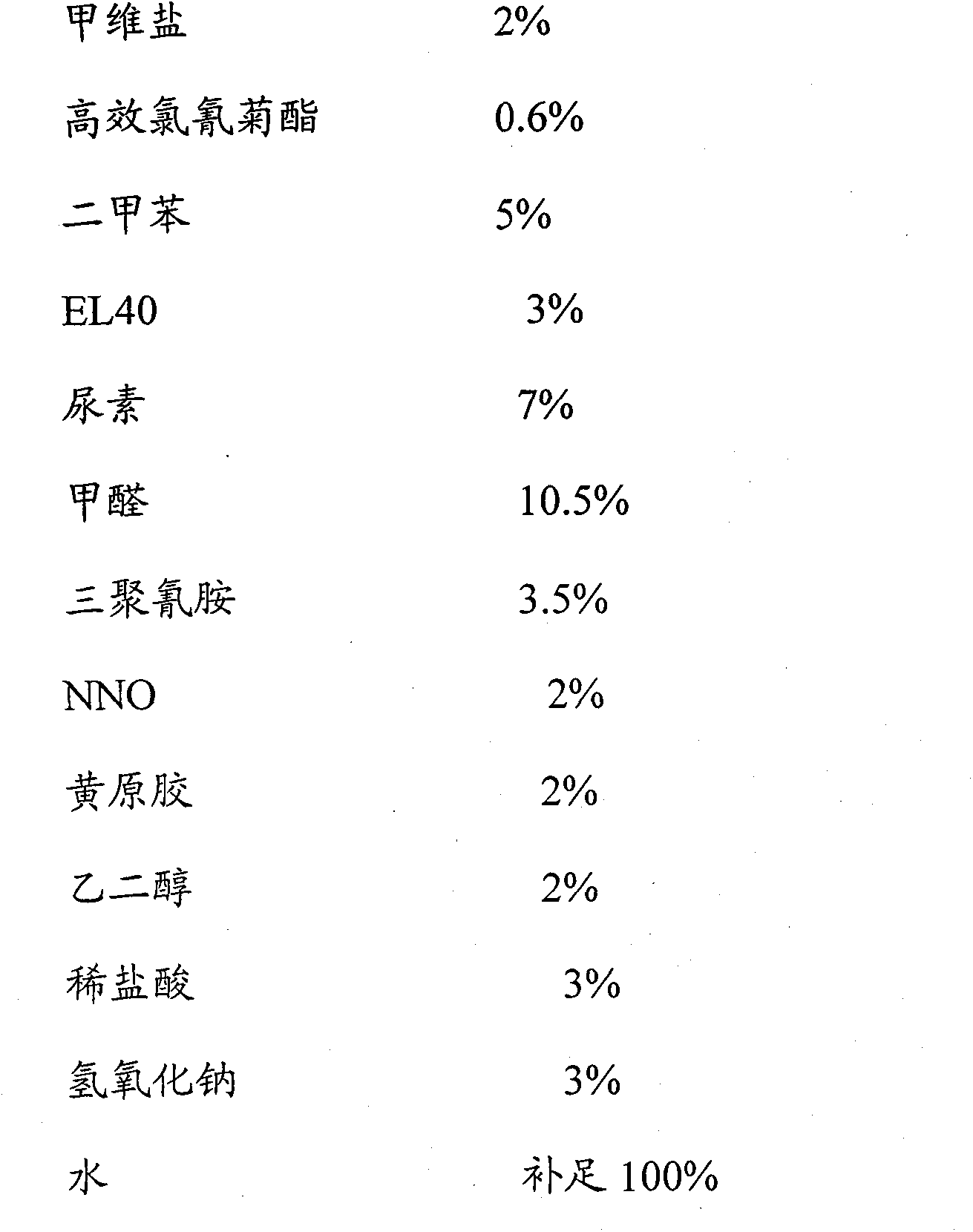

[0046] 2.6% emamectin benzoate · high chlorine microcapsule suspension

[0047]

[0048] The preparation method is as follows:

[0049] (1) 35g urea, 52.5g formaldehyde solution and 17.5g melamine are stirred and mixed at a low speed, add an appropriate amount of NaOH to adjust the pH value to 8, and increase the temperature to 65°C until the melamine is completely dissolved, then stir for 10 minutes to obtain melamine- Urea-formaldehyde prepolymer.

[0050] (2) Dissolve 10g avermectin and 3g beta-cypermethrin with 25g xylene, add 15Gel40 to 100g water to prepare an aqueous solution, mix the above materials, and stir rapidly for 20 minutes under a mixer at 1000r / min to obtain an oil-in-water milky white mixture liquid.

[0051] (3) Add melamine-urea-formaldehyde prepolymer into the obtained milky white mixture, and then adjust the rotating speed to 600r / min for stirring.

[0052] (4) Slowly drip 20ml of 5% dilute hydrochloric acid into (3) during the stirring process, and ...

Embodiment 3

[0059] 10% Kung fu permethrin microcapsule suspension

[0060] 2.6% emamectin benzoate · high chlorine microcapsule suspension

[0061]

[0062]

[0063] The preparation method is as follows:

[0064] (1) 47.5g urea, 70g formaldehyde solution and 47.5g melamine are stirred and mixed at a low speed, adding an appropriate amount of NaOH to adjust the pH value to 8, and raising the temperature to 65°C until the melamine is completely dissolved, stirring for 10 minutes to obtain melamine- Urea-formaldehyde prepolymer.

[0065] (2) Dissolve 50g kungfuthrin with 50g dimethylbenzene, add 15g14# to 100g water and be mixed with aqueous solution, above-mentioned material is mixed, stir rapidly 20 minutes under mixer 1000r / min, obtain the milky white mixed solution of oil-in-water.

[0066] (3) Add melamine-urea-formaldehyde prepolymer into the obtained milky white mixture, and then adjust the rotating speed to 600r / min for stirring.

[0067] (4) Slowly drip 20ml of 5% dilute hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com