Method for manufacturing anti-insect and anti-mold oriented strand board with full eucalyptus leftover materials

A technology of oriented particle board and leftover materials, which is applied in the pretreatment of molding materials, wood processing appliances, household components, etc., can solve the problems of oriented particle board with anti-insect and mildew-proof functions, warping and deformation of boards, and serious moldy smell, etc. Reduce the content of free formaldehyde, improve the anti-aging performance, and the effect of white color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

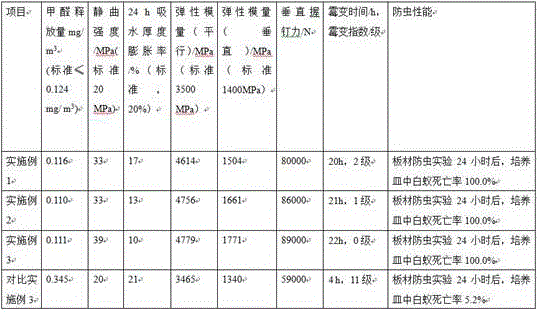

Examples

Embodiment 1

[0076] The method for producing insect-proof and mildew-proof oriented strand board from whole eucalyptus wood leftovers is characterized in that: comprising the following steps:

[0077] 1) The leftovers from the production of eucalyptus boards are separated from metal and stone, chipped, and simply screened, and then sent to the wood chip storage warehouse for transitional storage, and then sent to the veneer longitudinal shearing machine for length slicing by a conveyor, and the above-mentioned leftovers are cut along the longitudinal direction Cut into shavings with a length of 50-80 mm; transport the length-cut shavings to the veneer transverse shearing machine for width slicing, and cut the shavings into 5-20 mm wide shavings along the transverse direction; Transitional storage in the wet shavings silo; the moisture content of the wet shavings should be kept below 20% by weight;

[0078] The leftover material of above-mentioned production eucalyptus plank is the waste ma...

Embodiment 2

[0103] The method for producing insect-proof and mildew-proof oriented strand board from whole eucalyptus wood leftovers is characterized in that: comprising the following steps:

[0104] 1) The leftovers from the production of eucalyptus boards are separated from metal and stone, chipped, and simply screened, and then sent to the wood chip storage warehouse for transitional storage, and then sent to the veneer longitudinal shearing machine for length slicing by a conveyor, and the above-mentioned leftovers are cut along the longitudinal direction Cut into shavings with a length of 50-80 mm; transport the length-cut shavings to the veneer transverse shearing machine for width slicing, and cut the shavings into 5-20 mm wide shavings along the transverse direction; Transitional storage in the wet shavings silo; the moisture content of the wet shavings should be kept below 20% by weight;

[0105] The leftover material of above-mentioned production eucalyptus plank is the waste ma...

Embodiment 3

[0130] The method for producing insect-proof and mildew-proof oriented strand board from whole eucalyptus wood leftovers is characterized in that: comprising the following steps:

[0131] 1) The leftovers from the production of eucalyptus boards are separated from metal and stone, chipped, and simply screened, and then sent to the wood chip storage warehouse for transitional storage, and then sent to the veneer longitudinal shearing machine for length slicing by a conveyor, and the above-mentioned leftovers are cut along the longitudinal direction Cut into shavings with a length of 50-80 mm; transport the length-cut shavings to the veneer transverse shearing machine for width slicing, and cut the shavings into 5-20 mm wide shavings along the transverse direction; Transitional storage in the wet shavings silo; the moisture content of the wet shavings should be kept below 20% by weight;

[0132] The leftover material of above-mentioned production eucalyptus plank is the waste ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com