Symtriazine-type flame retardant, preparation method and application of symtriazine-type flame retardant

A technology of s-triazine and flame retardant, which is applied in the field of flame retardant and its synthesis and preparation, can solve problems such as difficult adhesion, and achieve the effects of less smoke generation, long-lasting flame retardant performance, and high char formation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Step 1: Full dissolution of cyanuric chloride

[0044] In a 500ml four-necked flask equipped with a stirrer and a thermometer, add 8g (0.043mol) of cyanuric chloride and 250ml (196.13g) of acetone to fully dissolve to obtain a base liquid.

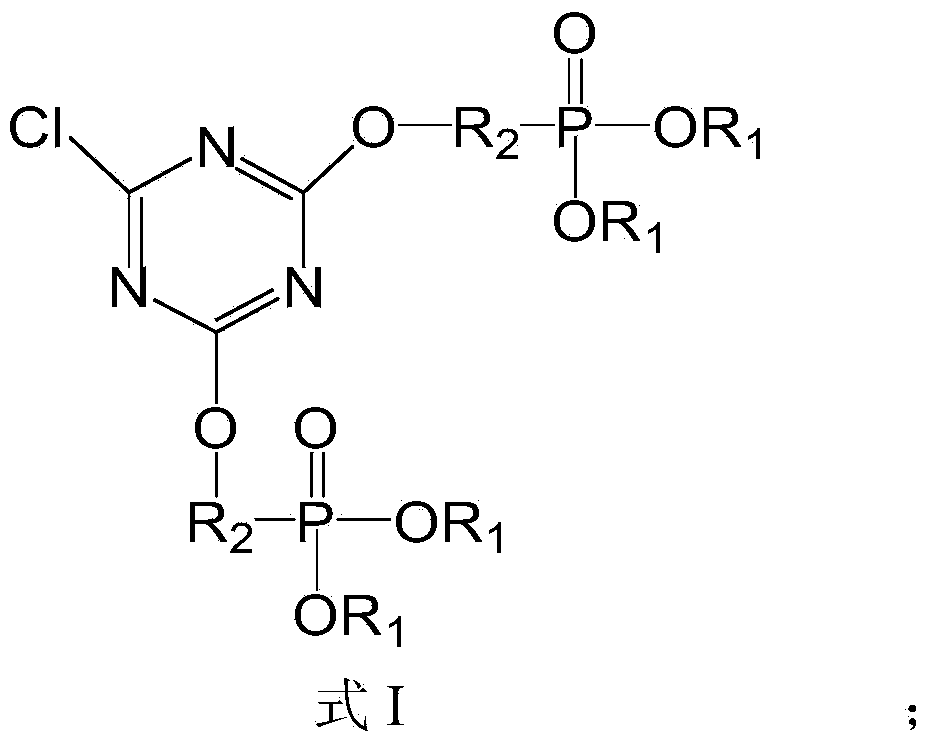

[0045] Step 2: Preparation of s-triazine flame retardant

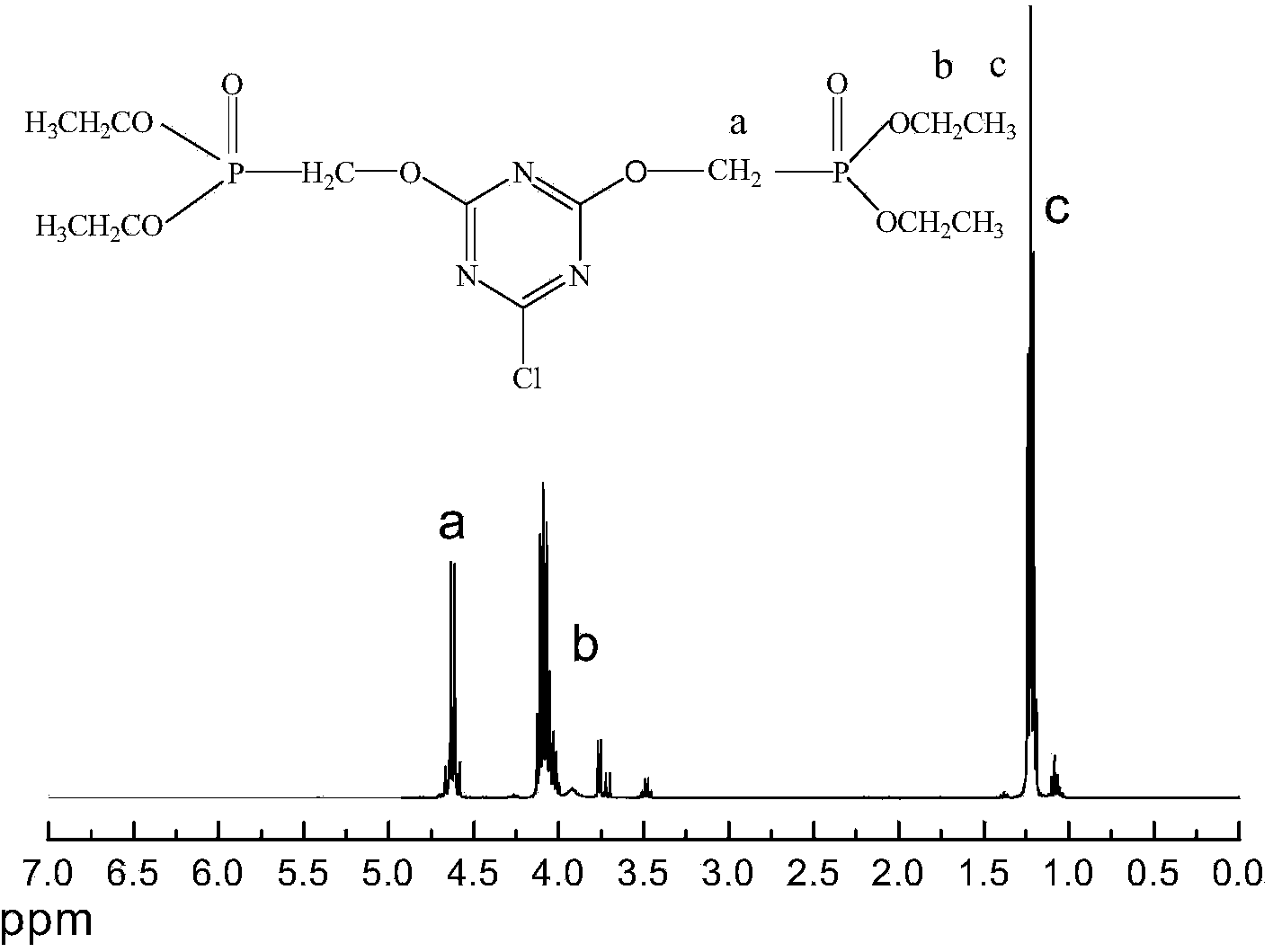

[0046] Move the above base liquid to a temperature of 0°C, and continuously add 15.90 g (0.0946 mol) of diethyl hydroxymethyl phosphate to the base liquid, and the addition is completed in 1 hour; Potassium aqueous solution adjusts pH=5. At different stages of the reaction, draw a small amount of reaction solution, and use thin-layer chromatographic analysis to determine whether the reaction of cyanuric chloride is complete. After the diethyl hydroxymethyl phosphate has been added dropwise, move to room temperature at 25°C for 35 minutes until cyanuric chloride disappears.

[0047] The concrete reaction formula of this step is as follows:

[0048]

[0049] Step 3: Pur...

Embodiment 2

[0057] Step 1: Full dissolution of cyanuric chloride

[0058] In a 500ml four-neck flask equipped with a stirrer and a thermometer, add 8g (0.043mol) of cyanuric chloride and 200ml (156.9g) of acetone to fully dissolve to obtain a base solution.

[0059] Step 2: Preparation of s-triazine flame retardant

[0060] Move the above base liquid to a temperature of -5°C, and continuously add 15.13g (0.090mol) of diethyl hydroxymethyl phosphate to the base liquid dropwise, and the dropwise addition is completed in 1 hour; during this period, 5% by mass of Potassium carbonate aqueous solution adjusts pH=6. At different stages of the reaction, draw a small amount of reaction solution, and use thin-layer chromatographic analysis to determine whether the reaction of cyanuric chloride is complete. After the diethyl hydroxymethyl phosphate has been added dropwise, move to room temperature at 25°C for 30 minutes until cyanuric chloride disappears.

[0061] The concrete reaction formula of...

Embodiment 3

[0067] Step 1: Full dissolution of cyanuric chloride

[0068] In a 500ml four-necked flask equipped with a stirrer and a thermometer, add 8g (0.043mol) of cyanuric chloride and 300ml (235.35g) of acetone to fully dissolve to obtain a base liquid.

[0069] Step 2: Preparation of s-triazine flame retardant

[0070] Move the above base liquid to a temperature of 5°C, and continuously add 14.46g (0.086mol) of diethyl hydroxymethyl phosphate to the base liquid dropwise, and the dropwise addition is completed in 1 hour; Potassium aqueous solution adjusts pH=7. At different stages of the reaction, draw a small amount of reaction solution, and use thin-layer chromatographic analysis to determine whether the reaction of cyanuric chloride is complete. After the diethyl hydroxymethyl phosphate has been added dropwise, move to room temperature at 25°C for 40 minutes until cyanuric chloride disappears.

[0071] The concrete reaction formula of this step is as follows:

[0072]

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com