Low-odor fast UV-LED ultraviolet cross-linked polyethylene insulation material and preparation method thereof

A UV-LED, cross-linked polyethylene technology, applied in the field of insulating materials, can solve the problems of low energy efficiency, high equipment cost, slow cross-linking speed, etc., and achieve good compatibility, less smoke at high temperature, and cross-linking reaction. The effect of increased speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

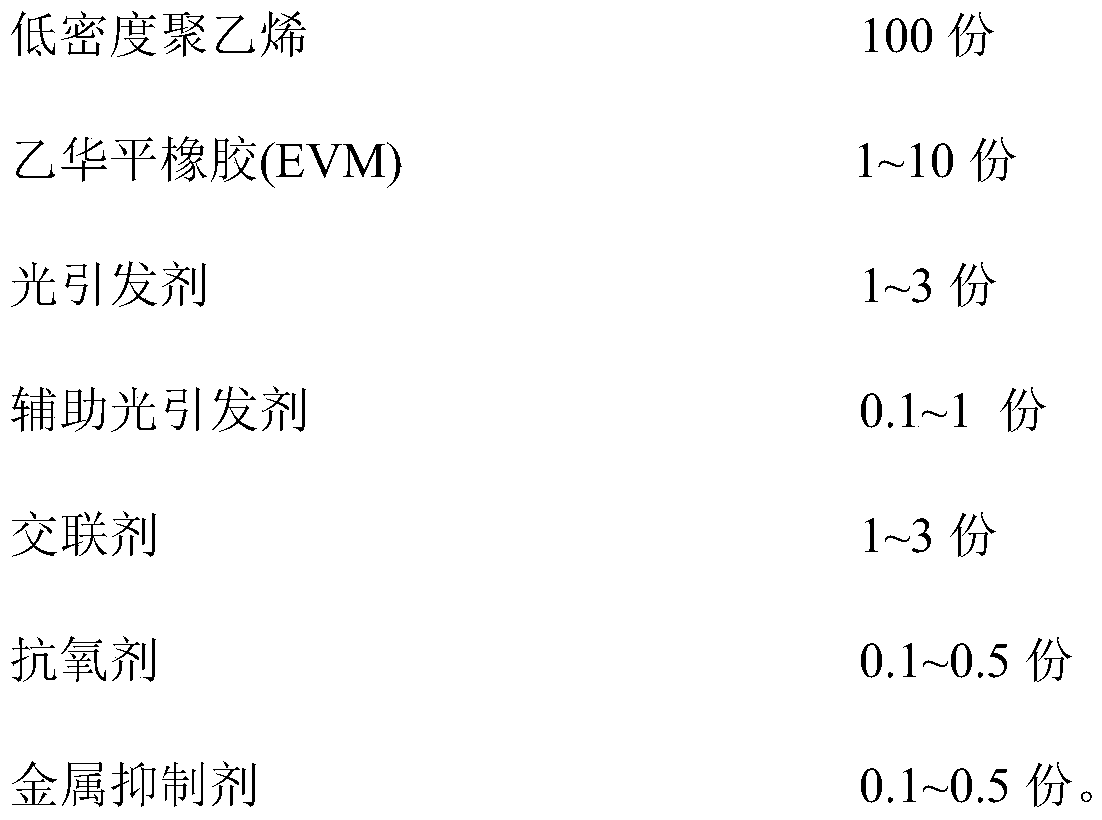

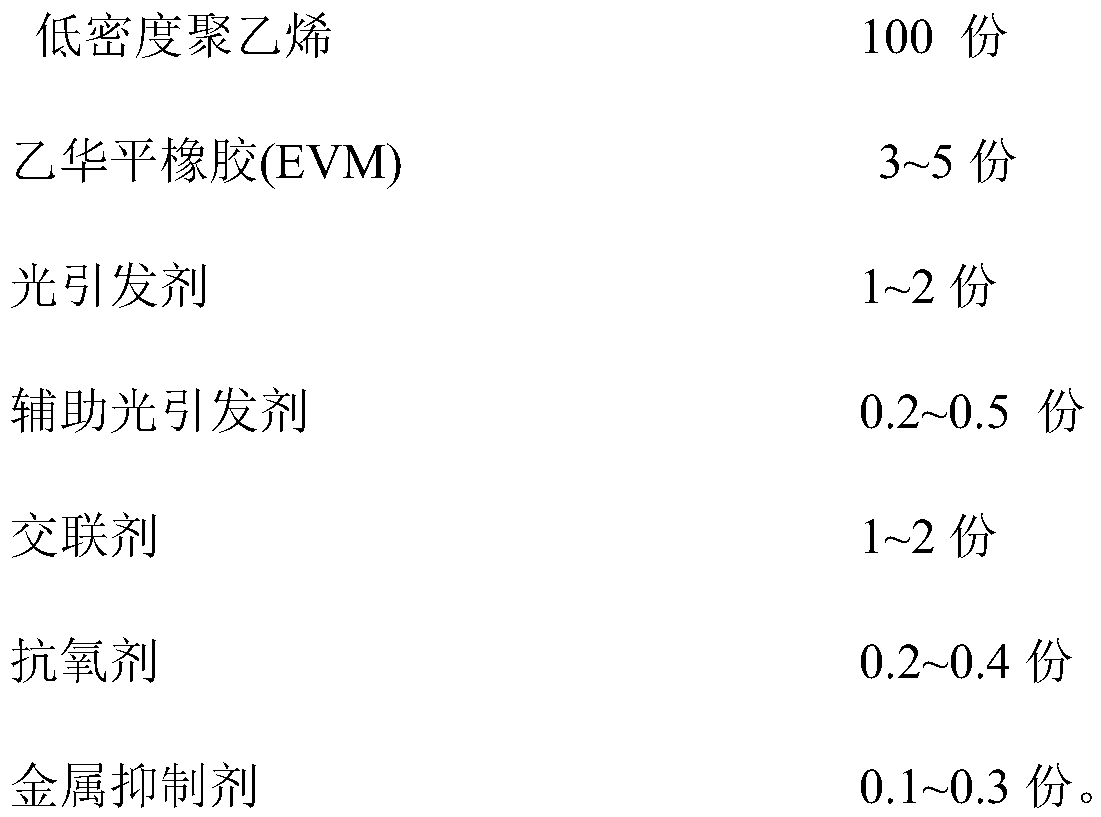

[0019]

[0020]

[0021] The low-density polyethylene is Jinshan Petrochemical J182A, with a density of 0.918 and a melt index of 2.0g / 10min. Evapine rubber (EVM) is an EVM with a VA content of 45%, and a melt index of 3.0 g / 10 min. The metal inhibitor is bis(3,5-di-tert-butyl-4-hydroxyphenylpropionoyl)hydrazine. Extrude and granulate through a twin-screw extruder (length-to-diameter ratio: 40), at a temperature of 150°C, and dry after cooling to obtain a low-odor polyethylene insulating material that can be quickly cross-linked by UV-LED; JB / T10437- 2004 standard for testing, the results are shown in Table 1.

Embodiment 2

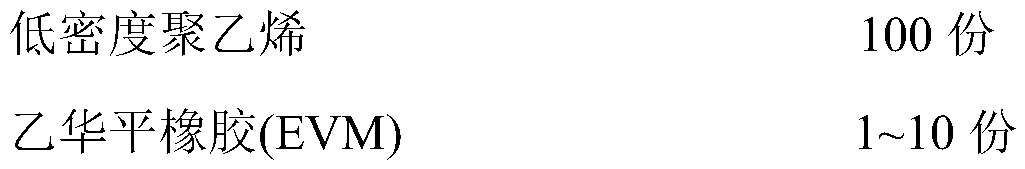

[0023]

[0024] The low-density polyethylene is Jinshan Petrochemical J182A, with a density of 0.918 and a melt index of 2.0g / 10min. The VA content of Evapine rubber (EVM) is 50%, and the melt index is 4.0g / 10min. The metal inhibitor is salicylamidophthalimide. Extrude and granulate through a twin-screw extruder (length-to-diameter ratio: 40), at a temperature of 150°C, and dry after cooling to obtain a low-odor cross-linked polyethylene insulating material that can be quickly cross-linked by UV-LED; JB / T 10437-2004 standard was tested, and the results are shown in Table 1.

[0025] Table 1 Example performance test results

[0026]

[0027]

[0028] Compared with the traditional UV-light cross-linked polyethylene insulating material, the low-odor cross-linked polyethylene insulating material prepared by the above two examples has low odor, low smoke generation, and is non-flammable and non-flammable. Explosive additives, cross-linking speed can be as fast as 1 sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com