A nanofiber/mofs-based pervaporation membrane with alcohol-preferential permeation and its preparation method

A pervaporation membrane and nanofiber technology, applied in the field of membrane separation, can solve the problems of pervaporation performance improvement, easy agglomeration, and limited load capacity, and achieve high production efficiency, low raw material cost, and increased load capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

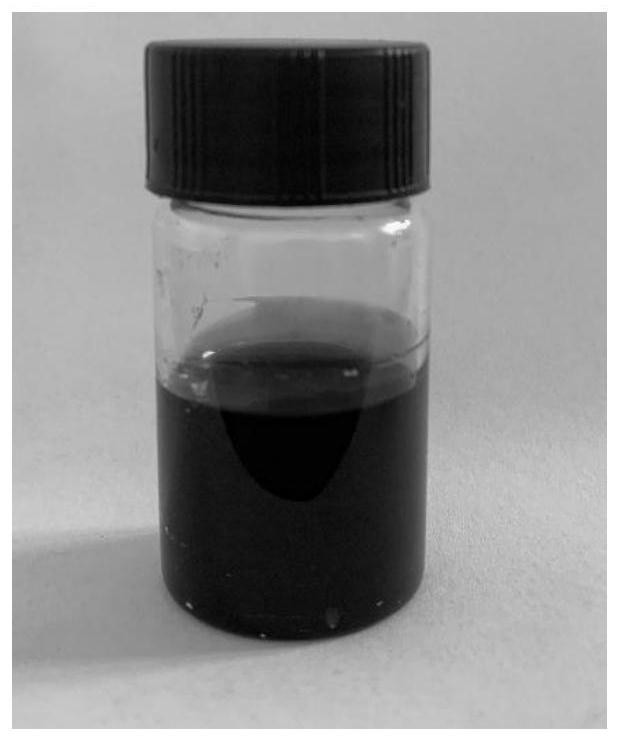

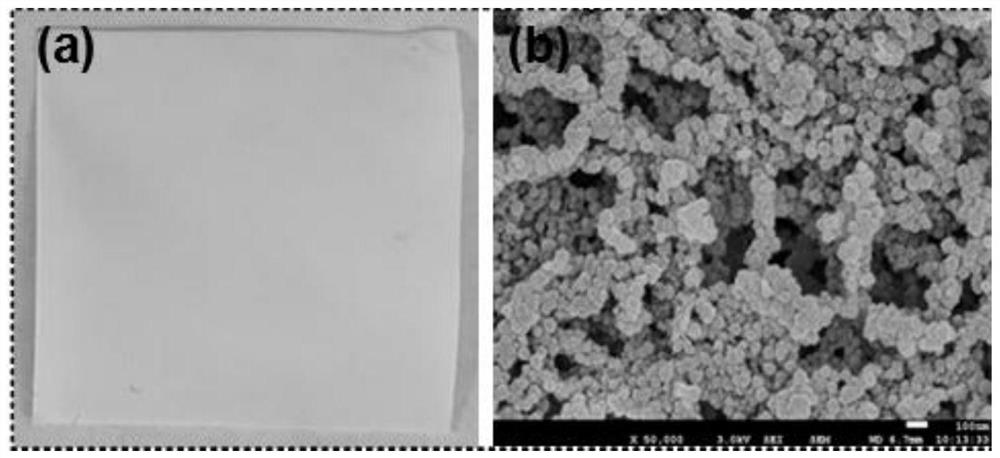

[0033] Embodiment 1: Kevlar yarn is cut into small sections of about 5mm, 5g Kevlar yarn small sections, 200ml dimethyl sulfoxide, 7.5g KOH, 8mL deionized water are successively added in a 400mL beaker, magnetic stirring (600rpm ) 10h to completely dissociate the Kevlar yarn, and centrifuge to remove excess KOH particles to obtain reddish-brown Kevlar nanofiber casting solution ( figure 1 ); Pour the configured casting solution on the smooth side of the glass plate, scrape it evenly and quickly from the bottom line to the top line with a glass rod, then quickly immerse the glass plate in the coagulation bath water, and obtain Kevlar fiber hydrogel membrane ( figure 2 ), then transfer it to deionized water and dialyze for 72h to remove the residual dimethyl sulfoxide in the fibrous hydrogel membrane, so as to avoid affecting the subsequent freeze-drying effect because of its low vapor pressure and difficulty in volatilization.

[0034] The above-mentioned Kevlar fiber hydroge...

Embodiment 2

[0037] Embodiment 2: according to the operation of embodiment 1, wherein, the concentration of the methanol solution of zinc nitrate hexahydrate is increased to 30mg / ml, the concentration of the methanol solution of 2-methylimidazole is increased to 66mg / ml and shaken, and ZIF-8 is obtained @Kevlar hybrid airgel membrane, the loading of ZIF-8 is calculated to be 47wt% by weighing method.

[0038] Add 3% of free radical photoinitiator 2-hydroxy-2-methyl-1-phenylacetone into the acrylate functionalized polysiloxane, and stir evenly to obtain a mixed solution of polysiloxane. Immerse the ZIF-8@Kevlar airgel in the mixed solution of polysiloxane at room temperature for 45 minutes, and absorb and remove the excess polysiloxane solution on the surface after fully soaking. The distance between the UV light source and the film was controlled to be 12 cm, and photopolymerization was carried out for 35 s under a UV light with a power of 220 w and a wavelength of 365 nm to obtain a ZIF-8...

Embodiment 3

[0040] Embodiment 3: According to the operation of embodiment 1, wherein, only the concentration of the methanol solution of zinc nitrate hexahydrate is increased to 50 mg / ml, and the concentration of the methanol solution of 2-methylimidazole is increased to 110 mg / ml for shaking. The loading of ZIF-8 was calculated by weighing method to be 63wt%. The prepared ZIF-8@Kevlar / PDMS mixed matrix membrane was used for the pervaporation separation of butanol aqueous solution. When the feed liquid temperature was 45°C, butanol When the alcohol concentration is 1.0wt%, the separation factor is 56, and the permeation flux is 1894g / m 2 h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation factor | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com