Water-based composite adhesive

A composite adhesive and water-based technology, applied in the field of polyacrylate, can solve the problems of complex production process, high cost, difficult industrialized production and promotion, etc., and achieve the effects of improving peel strength, high and low temperature resistance and durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

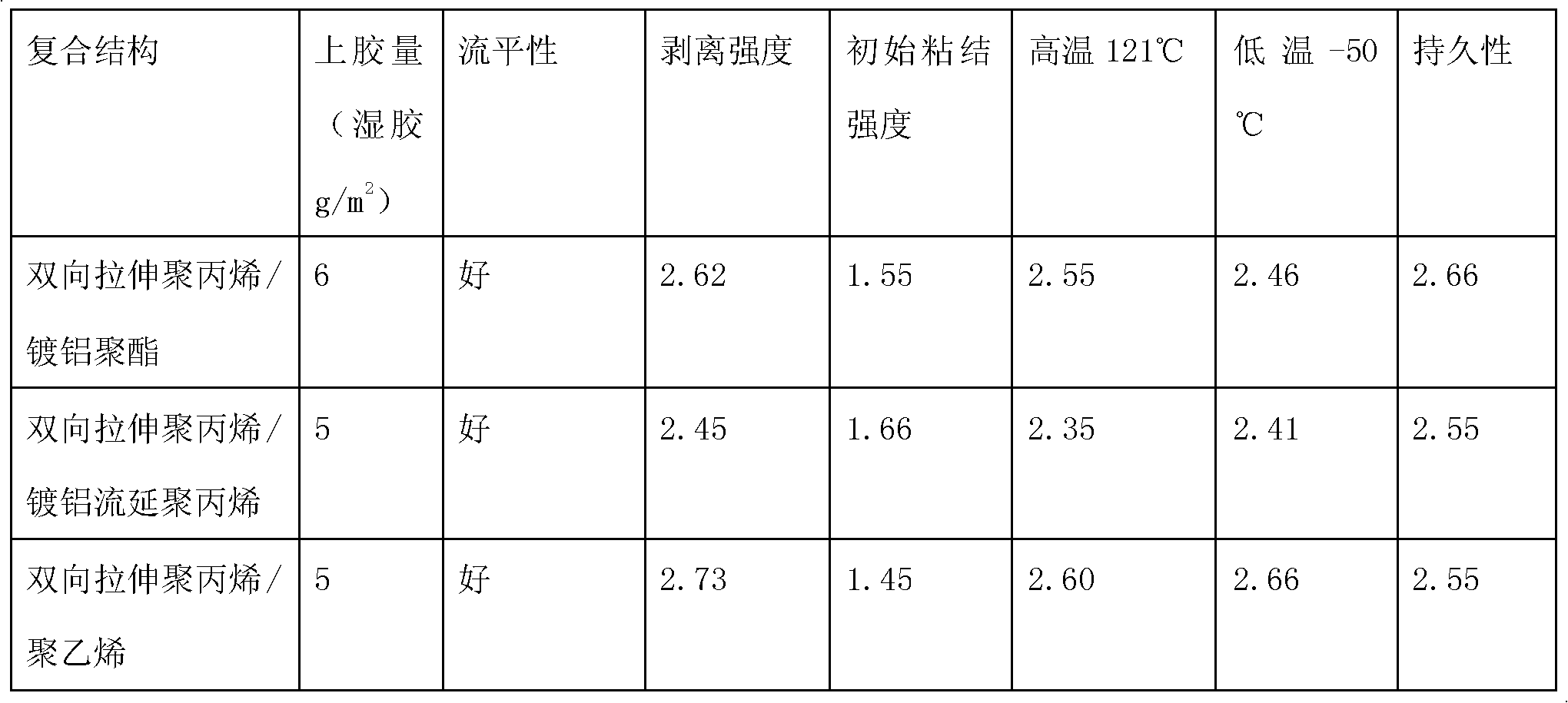

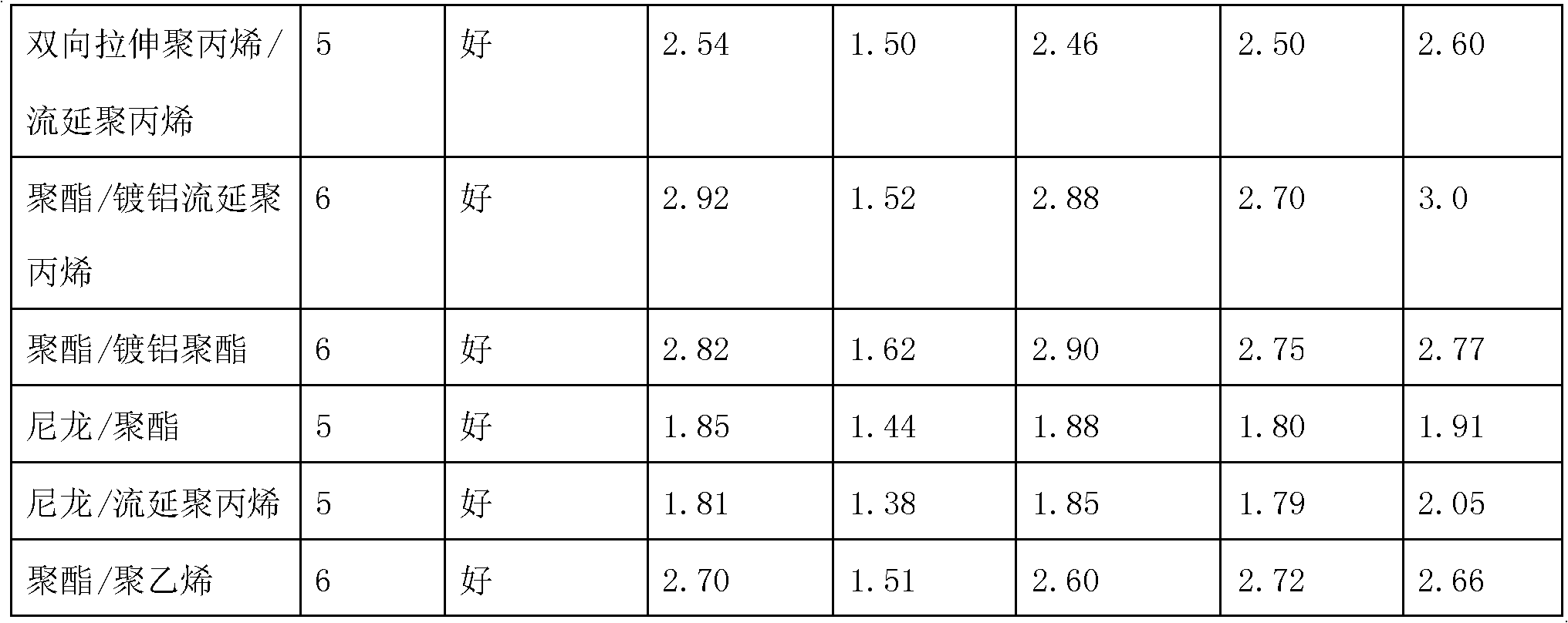

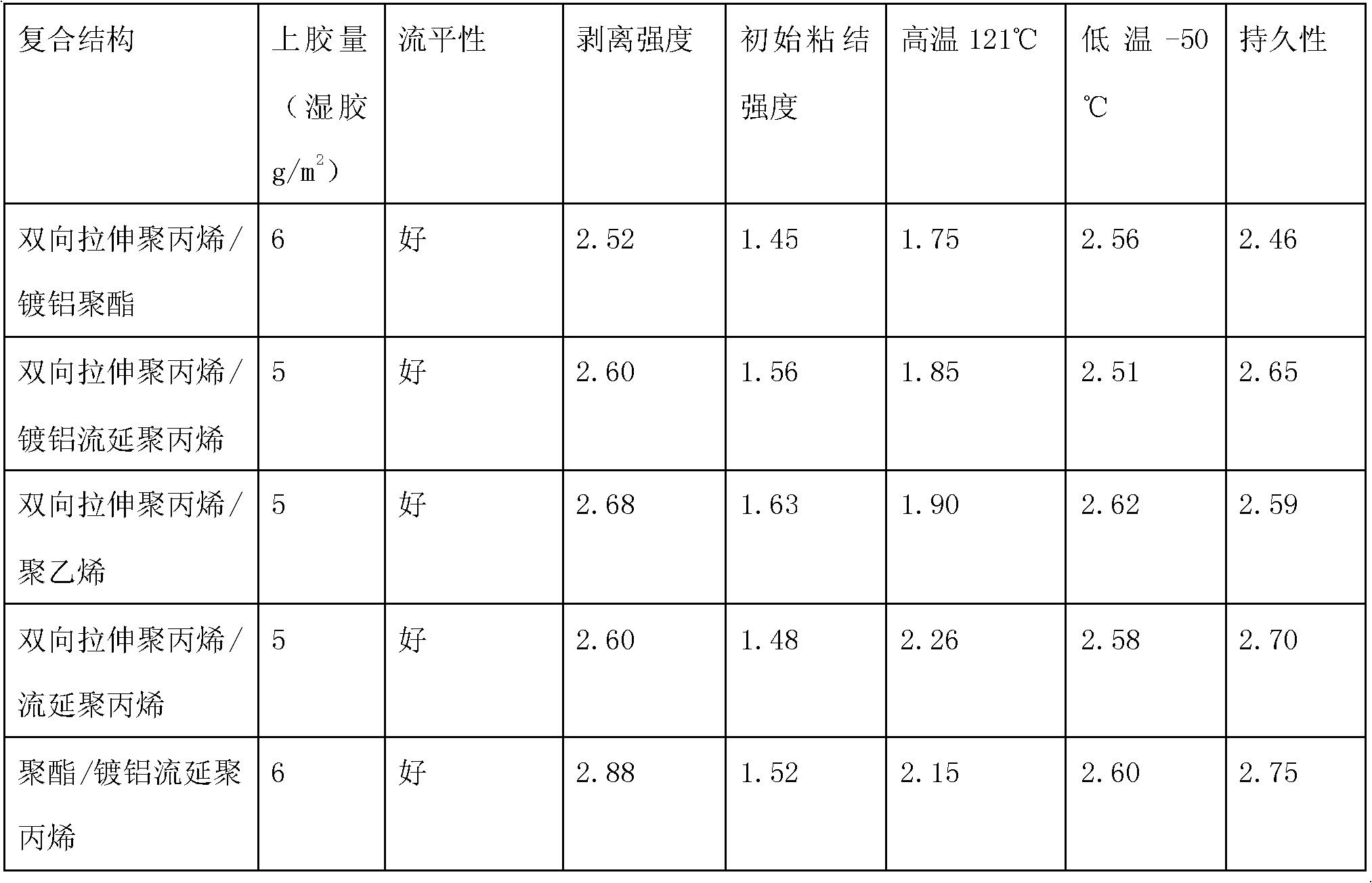

Examples

Embodiment 1

[0027] (I) Acrylate emulsion

[0028] (a) Acrylate emulsion formulation

[0029] Vinyl Hard Monomer: Styrene 30.5kg

[0030] Vinyl soft monomer: butyl acrylate 62.5kg

[0031] Alkenyl carboxylic acid monomer: methacrylic acid 2.5kg

[0032] Alkene functional monomer: 2.5kg of hydroxyethyl acrylate,

[0033] Divinyl monomer: ethylene glycol dimethacrylate 0.1kg,

[0034] Vinyl crosslinking monomer: diacetone acrylamide 1.9kg,

[0035] Emulsifier: sodium alkylbenzenesulfonate 0.3kg, allyloxy fatty alcohol polyoxyethylene ether sulfate 0.5kg, fatty alcohol polyoxyethylene ether 0.375kg, alcohol ether succinic acid monoester sulfonate 0.5kg,

[0036] Initiator: ammonium persulfate 0.6kg

[0037] Deionized water: 120kg

[0038] (b) Preparation method

[0039] (1) 69.9 kg of deionized water, 0.3 kg of sodium alkylbenzene sulfonate, 0.5 kg of allyloxy fatty alcohol polyoxyethylene ether sulfate, 0.125 kg of fatty alcohol polyoxyethylene ether and alcohol ether succinic acid m...

Embodiment 2

[0071] (I) Acrylate emulsion

[0072] (a) Acrylate emulsion formulation

[0073] Vinyl hard monomer: methyl methacrylate 50kg,

[0074] Vinyl soft monomer: ethyl acrylate 40kg

[0075] Vinyl carboxylic acid monomer: acrylic acid 3kg

[0076] Alkenic functional monomer: 1.5kg of hydroxypropyl acrylate,

[0077] Divinyl monomer: diallyl phthalate 1.0kg,

[0078] Vinyl crosslinking monomer: diacetone acrylamide 4.5kg;

[0079] Emulsifier: disodium alkyl dibenzene sulfonate 0.5kg, allyloxy fatty alcohol polyoxyethylene ether sulfate 1.0kg, fatty alcohol polyoxyethylene ether 1.25kg, alcohol ether succinic acid monoester sulfonate 1.0kg,

[0080] Initiator: potassium peroxodisulfate 0.4kg,

[0081] Deionized water: 110kg.

[0082] (b) Preparation method

[0083] (1) 55kg of deionized water, 0.5kg of disodium alkyldibenzenesulfonate, 1.0kg of allyloxy fatty alcohol polyoxyethylene ether sulfate, 0.25kg of fatty alcohol polyoxyethylene ether, alcohol ether succinic acid monoe...

Embodiment 3

[0105] (I) Acrylate emulsion

[0106] (a) Acrylate emulsion formulation

[0107] Vinyl hard monomer: methyl methacrylate 40kg,

[0108] Vinyl soft monomer: butyl acrylate 40kg; isocyl methacrylate 10kg;

[0109] Alkenic carboxylic acid monomer: maleic anhydride 1.0kg

[0110] Alkenic functional monomer: 1.5kg of hydroxypropyl acrylate, 1.5kg of hydroxyethyl acrylate,

[0111] Divinyl monomer: ethylene glycol dimethacrylate 0.5kg, diallyl phthalate 1.0kg,

[0112] Olefinic crosslinking monomer: 4.5kg ethyl acetoacetate methacrylate,

[0113] Emulsifier: disodium alkyl dibenzene sulfonate 1.0kg, allyloxy fatty alcohol polyoxyethylene ether sulfate 1.5kg, fatty alcohol polyoxyethylene ether 3.0kg, alcohol ether succinic acid monoester sulfonate 0.50kg;

[0114] Initiator: ammonium peroxodisulfate 0.1kg, potassium peroxodisulfate 0.1kg,

[0115] Deionized water: 100kg

[0116] (b) Preparation method

[0117] (1) 70kg of deionized water, 1.0kg of disodium alkyldibenzenesulf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com