Organopolysiloxane composition with excellent adhesion and reliability and preparation method thereof

A polysiloxane, reliable technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

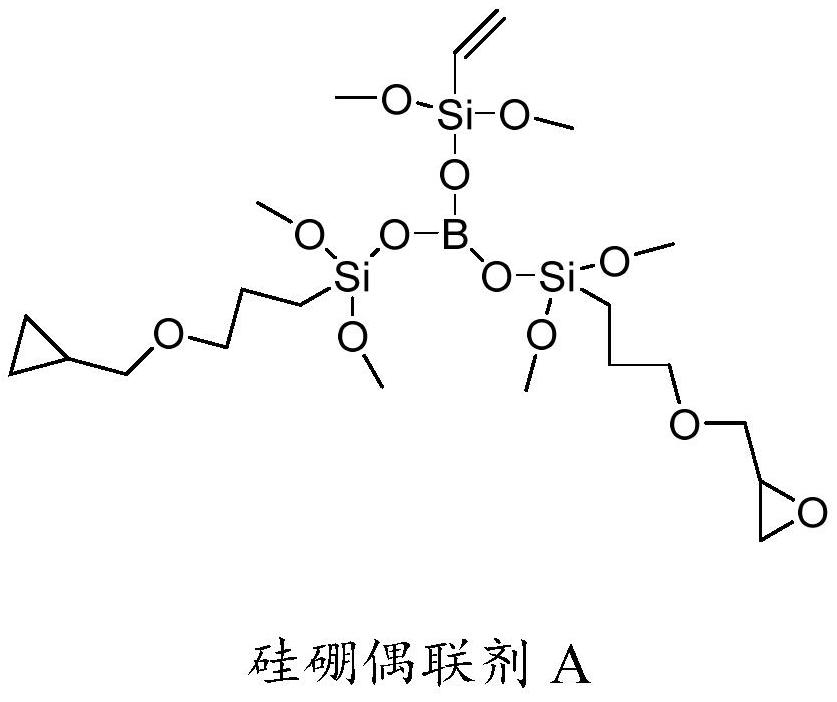

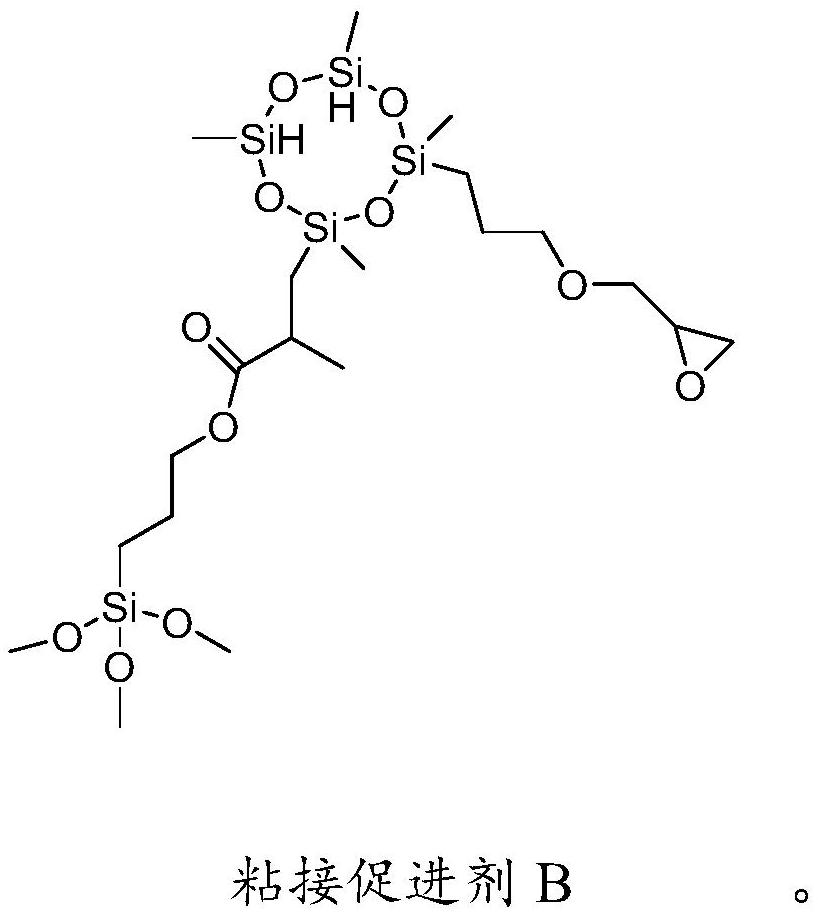

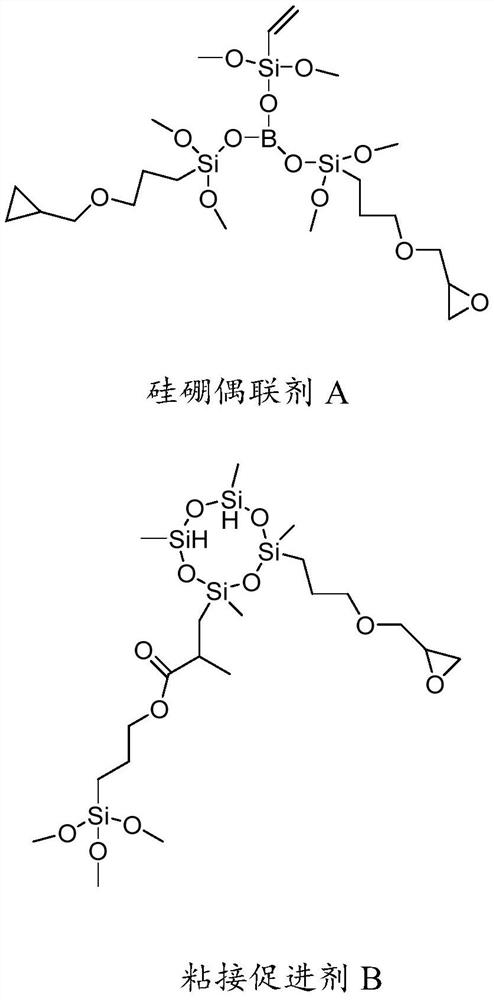

Image

Examples

Embodiment 1

[0027] Example 1 (H(CH 3 ) 2 SiO 1 / 2 ) (SiO 4 / 2 ) 1.5 preparation of

[0028] Add 208.33g of tetramethyldisiloxane (HMMH) and 0.27g of trifluoromethanesulfonic acid into the reaction vessel, heat up to 40°C, add 75g of tetramethyldisiloxane (HMMH), stir and mix well, then heat up to 60°C, then slowly add 15g of water dropwise, after the dropwise addition, set the temperature above 95°C to distill off small molecules with low boiling points until the temperature in the system exceeds 85°C, then stop the reaction. Wash with water until neutral, dry, filter, and vacuum rotary evaporation to remove solvent and small molecular substances, to obtain (H(CH 3 ) 2 SiO 1 / 2 ) (SiO 4 / 2 ) 1.5 .

Embodiment 2

[0029] Example 2 (H(CH 3 ) 2 SiO 1 / 2 )(Me 2 SiO 2 / 2 ) 6 (SiO 4 / 2 ) 1 preparation of

[0030] Add 208.33g tetraethyl orthosilicate (Q) and 2g sulfuric acid into the reaction vessel, raise the temperature to 40°C, and slowly add 1056g Me 2 Si(OOCCH 3 ) 2 , after the dropwise addition was completed, the temperature was raised to 100° C., and the low boiling generated during the reaction was removed. When there is no low-boiling distillation, cool down to below 50°C, add 70g of tetramethyldisiloxane (HMMH), stir and mix well, then raise the temperature to 60°C, then slowly add 26g of water dropwise to it, after the dropwise addition , Raise the temperature of the system to above 110°C to distill off small molecules with low boiling points until the temperature in the system exceeds 85°C, then stop the reaction. Wash with water until neutral, dry, filter, and vacuum rotary evaporation to remove solvent and small molecule substances, to obtain ((H(CH 3 ) 2 SiO 1 / 2 )(Me...

Embodiment 3

[0031] Example 3 (H(CH 3 ) 2 SiO 1 / 2 )(Me 3 SiO 1 / 2 ) (SiO 4 / 2 ) 2 preparation of

[0032] Add 208.33g tetramethyldisiloxane (Q) and 0.4g trifluoromethanesulfonic acid into the reaction vessel, raise the temperature to 45°C, add 75g tetramethyldisiloxane (HMMH) and 81.19g Me 3 SiOSiMe 3 , fully stir and mix evenly, heat up to 60°C, then slowly drop 15g of water into it, after the dropwise addition, set the temperature above 95°C to distill off small molecules with low boiling points, until the temperature in the system exceeds 85°C, stop the reaction . Wash with water until neutral, dry, filter, and vacuum rotary evaporation to remove solvent and small molecular substances, to obtain (H(CH 3 ) 2 SiO 1 / 2 )(Me 3 SiO 1 / 2 ) (SiO 4 / 2 ) 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com