PET film production line mother roll single-layer direct winding and coating technology

A technology of coating process and film production line, which is applied to the device for coating liquid on the surface, coating, pretreatment surface, etc., which can solve the problems of large friction coefficient, short service life, poor impact resistance, etc., and achieve improved The effect of generating speed, smooth and uniform winding, and reducing loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

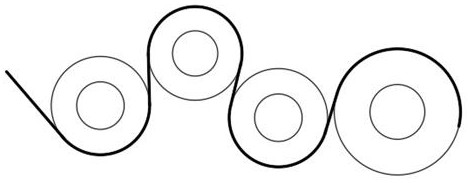

Image

Examples

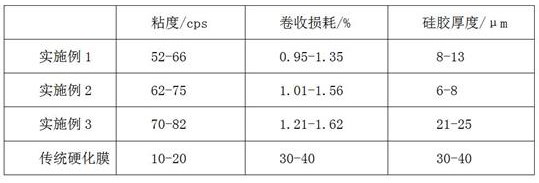

Embodiment 1

[0041] A PET film production line parent roll single-layer direct collection coating process, specifically including the following steps:

[0042] S1: Choose PET film as the base material, and release the PET film with unwinding equipment;

[0043] S2: preparing a silica gel coating liquid, using a three-roller coating head to evenly coat the silica gel coating liquid on the PET film substrate, the thickness of the silica gel coating liquid is 15 μm, and the thickness of the PET film substrate is 20 μm;

[0044] S3: Put the PET film coated with the silicone coating liquid into the rotary machine for UV curing;

[0045] S4: Winding up the cured PET film by a four-roller winder.

[0046] It is worth noting that the viscosity range of the coating liquid in this embodiment is 200 mPa.S.

[0047] In this embodiment, the silica gel coating solution includes the following raw materials in parts by weight:

[0048] 65 parts of vinyl silicone resin;

[0049] 2 parts of photoinitiat...

Embodiment 2

[0059] A PET film production line parent roll single-layer direct collection coating process, specifically including the following steps:

[0060] S1: Choose PET film as the base material, and release the PET film with unwinding equipment;

[0061] S2: preparing a silica gel coating liquid, using a three-roller coating head to evenly coat the silica gel coating liquid on the PET film substrate, the thickness of the silica gel coating liquid is 10 μm, and the thickness of the PET film substrate is 30 μm;

[0062] S3: Put the PET film coated with the silicone coating liquid into the rotary machine for UV curing;

[0063] S4: Winding up the cured PET film by a four-roller winder.

[0064] It is worth noting that the viscosity range of the coating liquid in this embodiment is 200 mPa.S.

[0065] In this embodiment, the silica gel coating solution includes the following raw materials in parts by weight:

[0066] 70 parts of vinyl silicone resin;

[0067] 4 parts of photoinitiat...

Embodiment 3

[0077] A PET film production line parent roll single-layer direct collection coating process, specifically including the following steps:

[0078] S1: Choose PET film as the base material, and release the PET film with unwinding equipment;

[0079] S2: preparing a silica gel coating liquid, using a three-roller coating head to evenly coat the silica gel coating liquid on the PET film substrate, the thickness of the silica gel coating liquid is 30 μm, and the thickness of the PET film substrate is 60 μm;

[0080] S3: Put the PET film coated with the silicone coating liquid into the rotary machine for UV curing;

[0081]S4: Winding up the cured PET film by a four-roller winder.

[0082] It is worth noting that the viscosity range of the coating liquid in this embodiment is 200 mPa.S.

[0083] In this embodiment, the silica gel coating solution includes the following raw materials in parts by weight:

[0084] 50 parts of vinyl silicone resin;

[0085] 1.5 parts of photoinitia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com