Dry reinforced concrete and preparation method thereof

A concrete and mixture technology, applied in the field of dry-strength concrete and its preparation, to achieve the effect of improving quality, resistance to sunlight, and excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

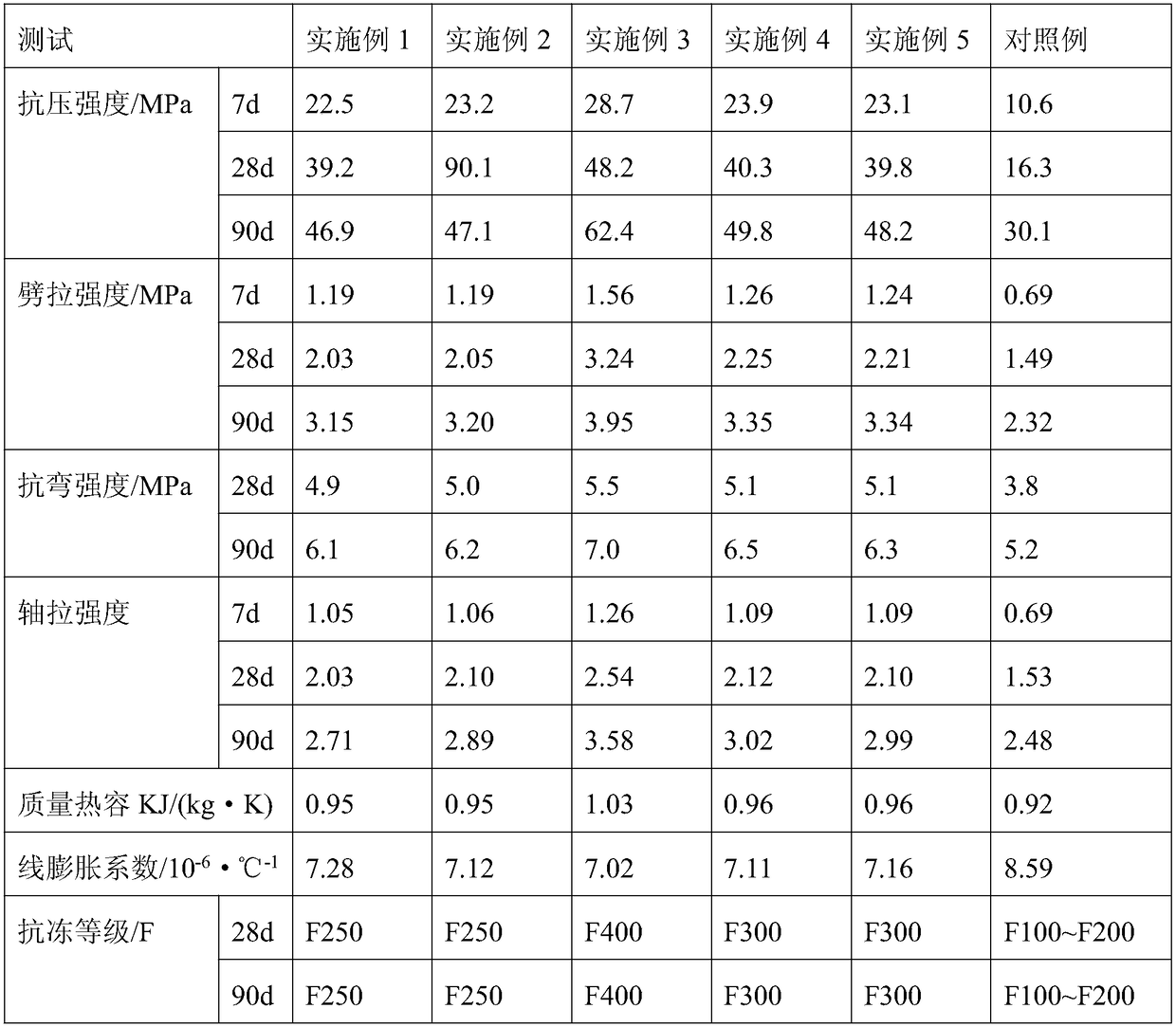

Examples

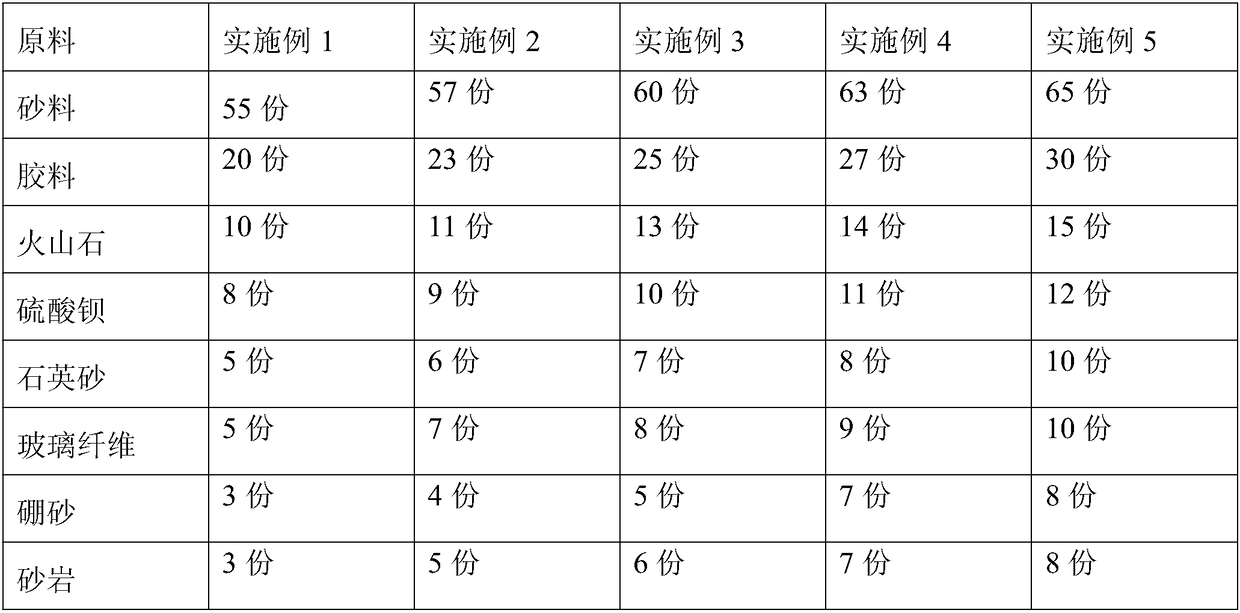

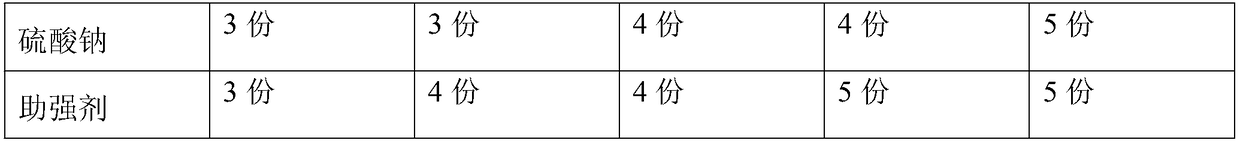

Embodiment 1

[0024] This embodiment provides a dry-strength concrete, including the following raw materials in parts by weight: 55-65 parts of sand material, 20-30 parts of rubber material, 10 parts of volcanic rock, 8 parts of barium sulfate, 5 parts of quartz sand, and 5 parts of glass fiber , 3 parts of borax, 3 parts of sandstone, 3 parts of sodium sulfate, 3 parts of reinforcing agent, wherein, described sand material is the mixture of river sand and mountain sand that weight ratio is 8:3; Described sizing material is that weight ratio is 5:3:1 mixture of cement powder, magnesia clay and rubber powder; the rubber powder is a mixture of old tire rubber powder and resin rubber powder with a weight ratio of 1:3, and the particle size of the rubber powder is 0.1 mm or less; the strengthening agent is a mixture of silicon oxide, allophane and dry strengthening agent in a weight ratio of 7:7:10.

[0025] The present embodiment also provides a method for preparing dry-strength concrete, comp...

Embodiment 2

[0029] This embodiment provides a dry-strength concrete, comprising the following raw materials in parts by weight: 57 parts of sand material, 23 parts of rubber material, 11 parts of volcanic rock, 9 parts of barium sulfate, 6 parts of quartz sand, 7 parts of glass fiber, and 4 parts of borax , 5 parts of sandstone, 3 parts of sodium sulfate, and 4 parts of strengthening agent, wherein the sand material is a mixture of river sand and mountain sand with a weight ratio of 10:3; the rubber material is a weight ratio of 6:4: 1 mixture of cement powder, magnesia clay and rubber powder; the rubber powder is a mixture of old tire rubber powder and resin rubber powder with a weight ratio of 1:2, and the particle size of the rubber powder is below 0.1 mm; The above-mentioned strengthening agent is a mixture of silicon oxide, allophane and dry strengthening agent with a weight ratio of 7:7:10.

[0030] The present embodiment also provides a method for preparing dry-strength concrete, c...

Embodiment 3

[0034]This embodiment provides a dry-strength concrete, comprising the following raw materials in parts by weight: 60 parts of sand material, 25 parts of rubber material, 13 parts of volcanic rock, 10 parts of barium sulfate, 7 parts of quartz sand, 8 parts of glass fiber, and 5 parts of borax , 6 parts of sandstone, 4 parts of sodium sulfate, and 4 parts of strengthening agent, wherein the sand material is a mixture of river sand and mountain sand with a weight ratio of 10:7; the rubber material is a weight ratio of 6.5:4: 2.1 The mixture of cement powder, magnesia clay and rubber powder; the rubber powder is a mixture of old tire rubber powder and resin rubber powder with a weight ratio of 3:2, and the particle size of the rubber powder is below 0.1mm; The above-mentioned strengthening agent is a mixture of silicon oxide, allophane and dry strengthening agent in a weight ratio of 10:8:7.

[0035] The present embodiment also provides a method for preparing dry-strength concre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com