Full-mold casting paint and preparation method thereof

A solid casting and coating technology, applied in casting molding equipment, coating, casting and other directions, can solve the problems of uneven wear resistance, can not meet the production requirements of large castings, etc., it is difficult to achieve heat resistance, excellent ventilation and quick drying, improving the overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

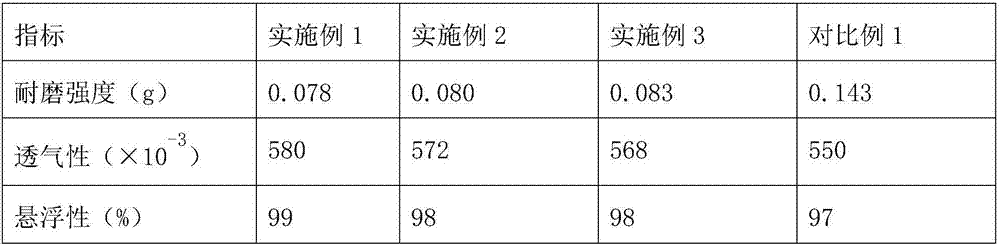

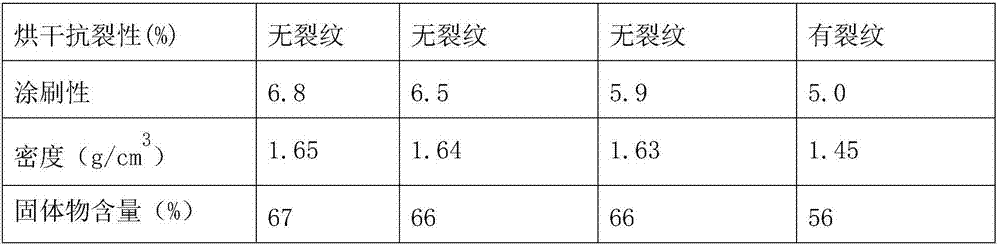

Examples

Embodiment 1

[0035] A full mold casting coating, comprising the following raw materials in parts by weight: 76 parts of quartz powder, 12 parts of olivine powder, 13 parts of corundum powder, 5 parts of sodium bentonite, 1.5 parts of lignosulfonic acid, 2.5 parts of dextrin powder, carboxylate 1.1 parts of sodium methylcellulose, 0.5 parts of sodium benzoate, 1.5 parts of hollow glass microspheres, 8 parts of aluminum sulfate, 5 parts of polyvinyl alcohol, 5.5 parts of silica sol, 0.6 parts of iron oxide powder, 0.05 parts of n-octanol, graphite powder 35 parts, 0.7 parts of zircon powder, 5 parts of attapulgite, 0.8 parts of water reducing agent and 16 parts of water.

[0036] Graphite powder is added to the raw material. Graphite powder has the characteristics of stable chemical properties at room temperature, good fire resistance, good wear resistance, good lubricity, good toughness and good thermal shock resistance.

[0037] Zircon powder is added to the raw material, which has the adv...

Embodiment 2

[0054] A full mold casting coating, comprising the following raw materials in parts by weight: 72 parts of quartz powder, 10 parts of olivine powder, 11 parts of corundum powder, 4 parts of sodium bentonite, 1 part of lignosulfonic acid, 2 parts of dextrin powder, carboxylate 0.8 parts of sodium methylcellulose, 0.4 parts of sodium benzoate, 1 part of hollow glass microspheres, 7.1 parts of aluminum sulfate, 4.4 parts of polyvinyl alcohol, 5 parts of silica sol, 0.5 parts of iron oxide powder, 0.04 parts of n-octanol, graphite powder 30 parts, 0.5 parts of zircon powder, 4 parts of attapulgite, 0.7 parts of water reducing agent and 12 parts of water.

[0055] Graphite powder is added to the raw material. Graphite powder has the characteristics of stable chemical properties at room temperature, good fire resistance, good wear resistance, good lubricity, good toughness and good thermal shock resistance.

[0056] Zircon powder is added to the raw material, which has the advantage...

Embodiment 3

[0073] A full mold casting coating, comprising the following raw materials in parts by weight: 80 parts of quartz powder, 14 parts of olivine powder, 15 parts of corundum powder, 6 parts of sodium bentonite, 2 parts of lignosulfonic acid, 3 parts of dextrin powder, carboxylate 1.4 parts of sodium methylcellulose, 0.6 parts of sodium benzoate, 2 parts of hollow glass microspheres, 8.9 parts of aluminum sulfate, 5.6 parts of polyvinyl alcohol, 6 parts of silica sol, 0.7 parts of iron oxide powder, 0.06 parts of n-octanol, graphite powder 40 parts, 0.9 parts of zircon powder, 6 parts of attapulgite, 0.9 parts of water reducing agent and 20 parts of water.

[0074] Graphite powder is added to the raw material. Graphite powder has the characteristics of stable chemical properties at room temperature, good fire resistance, good wear resistance, good lubricity, good toughness and good thermal shock resistance.

[0075] Zircon powder is added to the raw material, which has the advanta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com