Strong abrasion resistant solid casting coating and preparation method thereof

A technology of solid casting and wear resistance, applied in casting molding equipment, coating, mold and other directions, can solve the problems of inability to meet the production requirements of large castings, uneven wear resistance, etc., and achieve excellent air permeability and fast speed. Dryness, uniform fire resistance, good fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

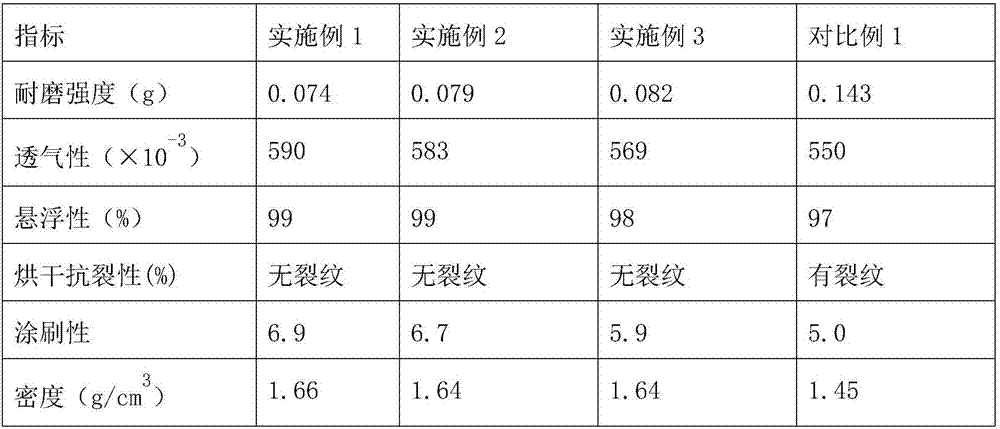

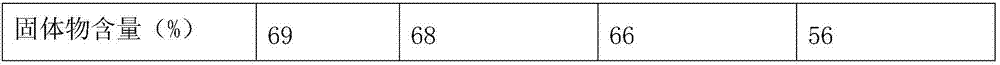

Examples

Embodiment 1

[0035] A solid mold coating with strong wear resistance, comprising the following raw materials in parts by weight: 76 parts of quartz powder, 11 parts of olivine powder, 12 parts of corundum powder, 5 parts of sodium bentonite, 1.5 parts of lignosulfonic acid, and dextrin powder 2.5 parts, 1 part of sodium carboxymethyl cellulose, 0.5 parts of sodium benzoate, 1.5 parts of hollow glass microspheres, 7.9 parts of aluminum sulfate, 1 part of polyvinyl alcohol, 5.5 parts of silica sol, 0.6 parts of iron oxide powder, 0.05 parts of n-octanol 17 parts of nano-attapulgite, 35 parts of nano-ceramic powder, 0.7 part of grass ash, 5 parts of diatomaceous earth, 6 parts of starch paste, 2.5 parts of aluminum phosphate, 0.7 parts of water reducer and 14 parts of water.

[0036] Nano-ceramic powder is added to the raw material. Nano-ceramic powder has the advantages of large specific surface area, compact structure, uniformity and good fire resistance.

[0037] Diatomite is added to the ...

Embodiment 2

[0052] A solid mold coating with strong wear resistance, comprising the following raw materials in parts by weight: 74 parts of quartz powder, 10 parts of olivine powder, 11 parts of corundum powder, 4 parts of sodium bentonite, 1 part of lignosulfonic acid, and dextrin powder 2 parts, 0.8 parts of sodium carboxymethyl cellulose, 0.4 parts of sodium benzoate, 1 part of hollow glass microspheres, 7.1 parts of aluminum sulfate, 4.4 parts of polyvinyl alcohol, 5 parts of silica sol, 0.5 parts of iron oxide powder, 0.04 parts of n-octanol 12 parts of nano-attapulgite, 30 parts of nano-ceramic powder, 0.5 part of grass ash, 4 parts of diatomaceous earth, 5 parts of starch paste, 2 parts of aluminum phosphate, 0.5 part of water reducer and 12 parts of water.

[0053] Nano-ceramic powder is added to the raw material. Nano-ceramic powder has the advantages of large specific surface area, compact structure, uniformity and good fire resistance.

[0054] Diatomite is added to the raw mat...

Embodiment 3

[0069] A solid mold coating with strong wear resistance, comprising the following raw materials in parts by weight: 78 parts of quartz powder, 12 parts of olivine powder, 13 parts of corundum powder, 6 parts of sodium bentonite, 2 parts of lignosulfonic acid, and dextrin powder 3 parts, 1.2 parts of sodium carboxymethyl cellulose, 0.6 parts of sodium benzoate, 2 parts of hollow glass microspheres, 8.7 parts of aluminum sulfate, 5.6 parts of polyvinyl alcohol, 6 parts of silica sol, 0.7 parts of iron oxide powder, 0.06 parts of n-octanol 22 parts of nano-attapulgite, 40 parts of nano-ceramic powder, 0.9 part of grass ash, 6 parts of diatomaceous earth, 7 parts of starch paste, 3 parts of aluminum phosphate, 0.9 part of water reducing agent and 16 parts of water.

[0070] Nano-ceramic powder is added to the raw material. Nano-ceramic powder has the advantages of large specific surface area, compact structure, uniformity and good fire resistance.

[0071] Diatomite is added to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com