Microporous membrane containing cross-linked hydrophilic polymer and preparation method thereof

A technology of hydrophilic polymers and microporous membranes, which can be used in general water supply conservation, chemical instruments and methods, and membranes. The effect of water stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

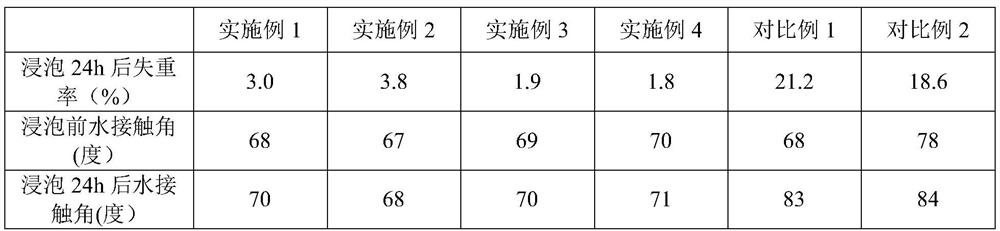

Examples

preparation example Construction

[0027] A preparation method of a microporous membrane containing a cross-linked hydrophilic polymer, comprising the steps of:

[0028] (1) Preparation of a film-making solution: adding the microporous film main material, polyvinyl acetal and a non-solvent for film-making into a solvent, and dissolving to obtain a film-making solution;

[0029] Wherein, the main material of the microporous membrane is selected from one or more of polyvinylidene fluoride, polyvinyl chloride, and polysulfone polymers, and the mass fraction of the main material of the microporous membrane in the membrane-forming solution is 10-20%;

[0030] The polyvinyl acetal is selected from one or more of polyvinyl formal, polyvinyl acetal, polyvinyl methyl acetal and polyvinyl butyral, and in the molecular chain of polyvinyl acetal , the mass content of vinyl alcohol chain segments is not less than 10%, and the mass ratio of polyvinyl acetal to the main material of the microporous membrane is less than 1:1; ...

Embodiment 1

[0036] A preparation method of a microporous membrane containing a cross-linked hydrophilic polymer, comprising the steps of:

[0037] (1) Preparation of film-making solution: add polyvinylidene fluoride, polyvinyl butyral (the mass content of vinyl alcohol segments is 20%) and polyethylene glycol 400 into N,N-dimethylacetamide, After dissolving at 70 DEG C, a film-forming solution is obtained; in the obtained film-forming solution, the mass concentration of polyvinylidene fluoride is 12%, the mass concentration of polyvinyl butyral is 5%; the mass concentration of polyethylene glycol 400 is 13%;

[0038] (2) Film formation: the obtained film formation solution was extruded through an annular gap type spinneret, and an aqueous solution of 40wt% N,N-dimethylacetamide was used as the outer coagulation bath, and 50wt% N,N-dimethylacetamide was used as the outer coagulation bath. The aqueous solution of acetamide is an internal coagulation bath to prepare a polymer hollow fiber m...

Embodiment 2

[0041] A preparation method of a microporous membrane containing a cross-linked hydrophilic polymer, comprising the steps of:

[0042](1) Preparation of film-making solution: add polyvinylidene fluoride, polyvinyl butyral (the mass content of vinyl alcohol chain segments is 10%) and polyethylene glycol 400 into N,N-dimethylacetamide, After dissolving at 70 DEG C, a film-forming solution is obtained; in the obtained film-forming solution, the mass concentration of polyvinylidene fluoride is 10%, the mass concentration of polyvinyl butyral is 8%, and the mass concentration of polyethylene glycol 400 is 12%;

[0043] (2) Film formation: the obtained film formation solution was extruded through an annular gap type spinneret, and an aqueous solution of 40wt% N,N-dimethylacetamide was used as the outer coagulation bath, and 50wt% N,N-dimethylacetamide was used as the outer coagulation bath. The aqueous solution of acetamide is an internal coagulation bath to obtain a polymer hollow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com