Preparation method of high-saline-absorbency high-water-absorptivity resin

A technology of superabsorbent resin and salt water, which is applied in the production field of functional polymer materials, can solve problems such as poor salt resistance, and achieve the effects of increasing strength, reducing dosage, and using safely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

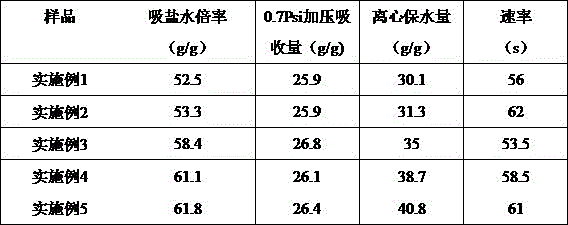

Examples

Embodiment 1

[0023] Weigh 37.5g, 80% (weight) of acrylic acid solution, put it into a beaker, add 25.4g of water into the beaker; weigh 11g of alkali, prepare it into a 30% (weight) solution, and pour it into the acrylic acid solution under stirring Slowly add the alkali solution dropwise, after the dropwise addition is completed, cool to room temperature in an ice-water bath; add 0.3g, 5% (weight) N,N-methylenebisacrylamide solution, and stir well; when the above system is heated to 75°C, Add 0.09 g of ammonium persulfate solution, stir evenly and further heat the system to 95° C., polymerize for 5 minutes to obtain a gel-like substance. After the polymerization is completed, the gel is cut into granules with a particle size of 1 cm, placed in an electric blast drying oven at 195°C for 2 hours to dry to constant weight, then crushed, sieved with 30-80 meshes, and finally Mix the surface cross-linking agent evenly, and dry it in an electric blast drying oven at 140°C for 45 minutes to obta...

Embodiment 2

[0025] Weigh 37.5g, 80% (weight) of acrylic acid solution, put it into a beaker, add 20.4g of water into the beaker; weigh 11g of alkali, prepare it into a 30% (weight) solution, and pour it into the acrylic acid solution under stirring Slowly add the alkali solution dropwise, after the addition is completed, cool to room temperature in an ice-water bath; add 5g, 8% (weight) of inorganic nanosheet water dispersion colloid; add 0.3g, 5% (weight) of N, N-methylenebis Acrylamide solution, stir evenly; when the above system is heated to 70°C, add 0.09g of ammonium persulfate solution, stir evenly, further heat the system to 95°C, and polymerize for 5 minutes to obtain a gel-like substance. After the polymerization is completed, the gel is cut into granules with a particle size of 1 cm, placed in an electric blast drying oven at 195°C for 2 hours to dry to constant weight, then crushed, sieved with 30-80 meshes, and finally Mix the surface cross-linking agent evenly, and dry it in ...

Embodiment 3

[0027] Weigh 37.5g, 80% (weight) of acrylic acid solution, put it into a beaker, add 14.4g of water into the beaker; weigh 11g of alkali, prepare it into a 30% (weight) solution, and pour it into the acrylic acid solution under stirring Slowly add the alkali solution dropwise, after the addition is completed, cool to room temperature in an ice-water bath; add 10g, 8% (weight) of inorganic nanosheet water dispersion colloid; add 0.3g, 5% (weight) of N, N-methylenebis Acrylamide solution, stir evenly; when the above system is heated to 75°C, add 0.09g of potassium persulfate solution, stir evenly, continue to heat the system to 90°C, and polymerize for 5 minutes to obtain a gel-like substance. After the polymerization is completed, the gel is cut into granules with a particle size of 1 cm, and placed in an electric blast drying oven at 100°C for 3 hours to dry to constant weight, then crushed, sieved with 30-80 mesh, and finally Mix the surface crosslinking agent evenly, and dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com