Anti-corrosion and anti-sticking coating for fire grate segment of garbage incinerator as well as preparation method and application of anti-corrosion and anti-sticking coating

A garbage incinerator and anti-sticking coating technology, which is applied in the direction of anti-corrosion coatings, coatings, fire-proof coatings, etc., can solve the problems of corrosion problems that cannot be effectively solved, difficult to promote, and high cost, and achieve good anti-corrosion and anti-sticking effects. The effect of avoiding coating cracking and simple construction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

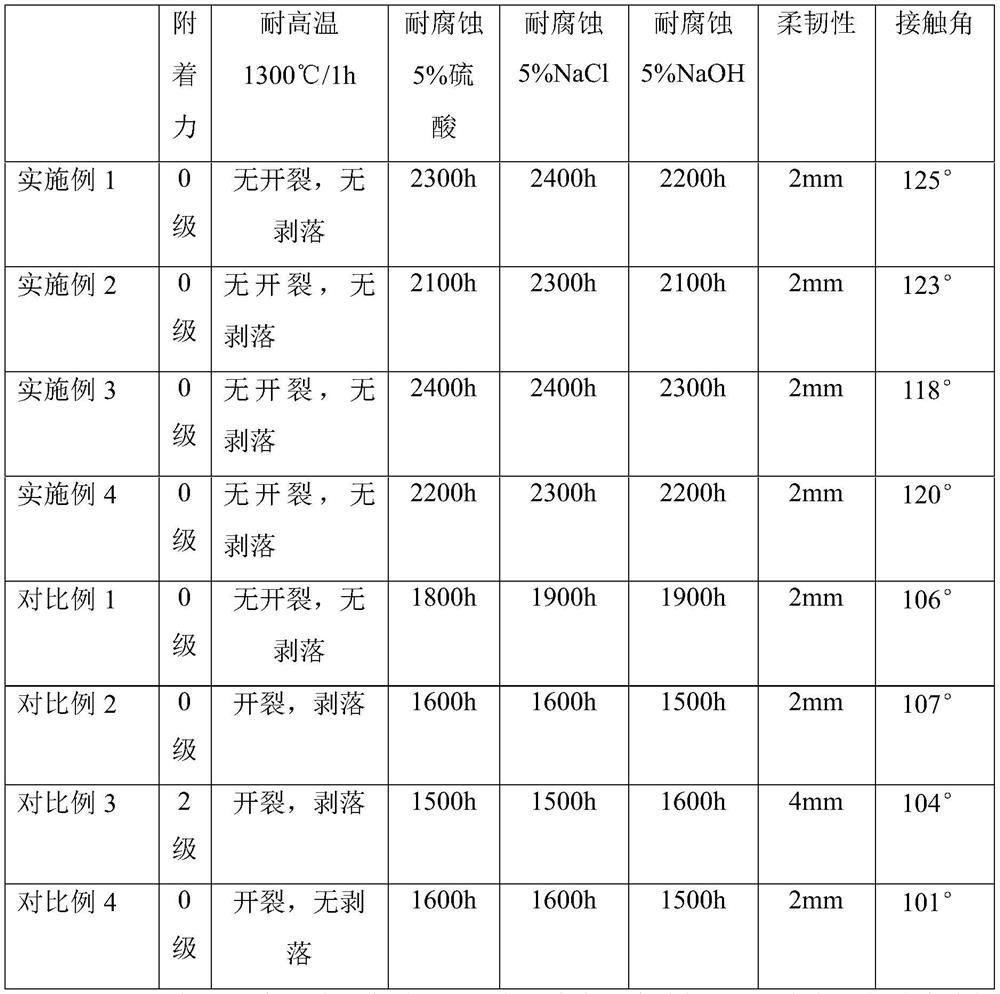

Examples

preparation example Construction

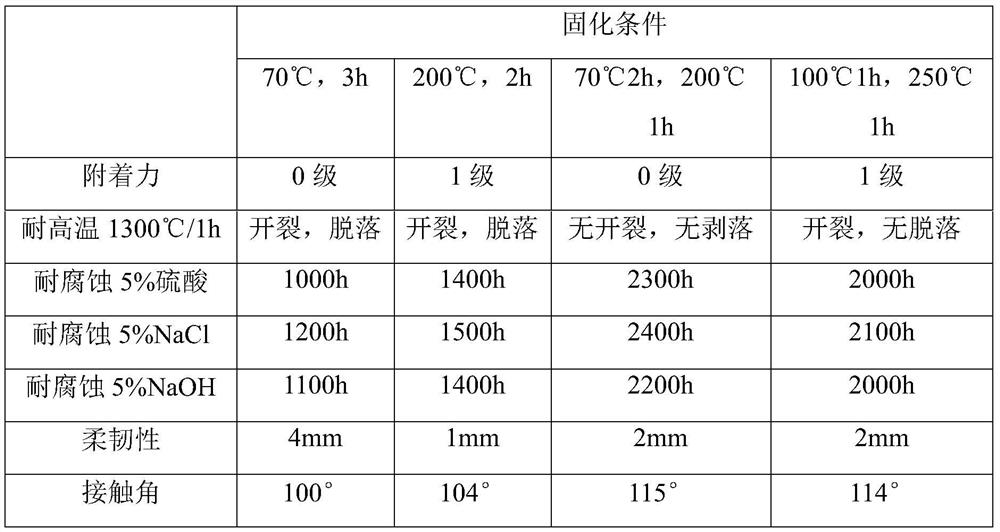

(3) After surface drying in the above construction environment for 0.5-1h, heat up to 50-70°C and dry for 1-2h, then continue to heat up to 200-250°C to dry and cure for 0.5-1h, that is, the anti-corrosion and anti-sticking coating is prepared waste incinerator grate pieces. The thickness of the formed anti-corrosion and anti-sticking coating can be 0.5-1 mm.

[0034] The construction method of the waste incinerator grate sheet of the present invention is simple, and the conventional spraying process can be used, and the curing temperature is not high, which can effectively save energy and reduce costs. At the same time, the present invention adopts a two-step drying method, which can not only ensure the rapid drying of the coating, but also avoid cracking of the coating caused by excessive drying of the coating, which has an unexpected technical effect. The drying method can fully ensure the metal oxidation The full hydrolysis of the material sol and the rapid and sufficient ...

Embodiment 1

[0044] Prepare the following raw materials in parts by weight: 30 parts of titanium oxide sol, 30 parts of zirconia sol, 3 parts of fluorine-doped graphene, 5 parts of boron nitride, 5 parts of tungsten carbide, 2 parts of α-corundum, 3 parts of alumina fiber, 4 parts of silicon carbide fiber, 5 parts of compatibilizer, 2 parts of silane coupling agent, 6 parts of auxiliary agent, and 50 parts of solvent.

[0045] Wherein, the solid content of titanium oxide and zirconium oxide sol is 10-15%, and the particle size is 10-30nm; the fluorine doping amount in the fluorine-doped graphene is 15wt%, and the sheet thickness of graphene is 1-10nm , the length of graphene sheets is 10–100 μm. The nano-ceramic powder is selected from α-corundum, boron nitride and tungsten carbide, with a particle size of 20-40 nm; the diameter of the aluminum carbide fiber and silicon carbide fiber is 5-10 μm.

[0046] The compatibilizer has a structure shown in formula (I): R1(Me)2Si-(O-SiR2R3-)m-(OSiR...

Embodiment 2

[0052] The compatibilizer has a structure shown in formula (I): R1(Me)2Si-(O-SiR2R3-)m-(OSiR2R4-)n-O-Si(Me)2R1, (I); wherein, R1 is A C6 straight-chain alkyl group with a carbon-carbon double bond, R2 and R3 are each independently a C5 alkyl group, R4 is -OSi(Me)3, m is an integer of 60-80, and n is an integer of 3-6. The auxiliary agent is 1 part of wetting and dispersing agent, 0.5 part of leveling agent, 0.5 part of defoamer, and 3 parts of anti-settling agent; the solvent is selected from 20 parts of propylene glycol methyl ether acetate, 20 parts of butanol, three 20 parts of diethylene glycol.

[0053] Preparation of anti-corrosion and anti-stick coating:

(1) Weigh fluorine-doped graphene, nano-ceramic powder, and anti-corrosion filler, add them to the solvent and mix them evenly, add the silane coupling agent dropwise and continue to stir evenly, the rotation speed is 700rpm, and the time is 40min;

(2) Add metal oxide sol, compatibilizer, and additives to the mixtur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com