Patents

Literature

33results about How to "Cross-linking reaction is sufficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Blocked isocyanato group-containing polymer, composition containing polymer, and applications thereof

ActiveCN105008411AFull solvent resistanceGood solvent resistanceOptical filtersPolyurea/polyurethane coatingsPolymer scienceAcid value

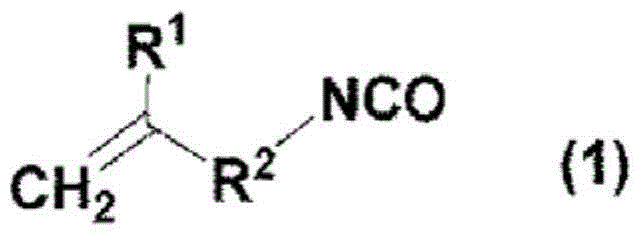

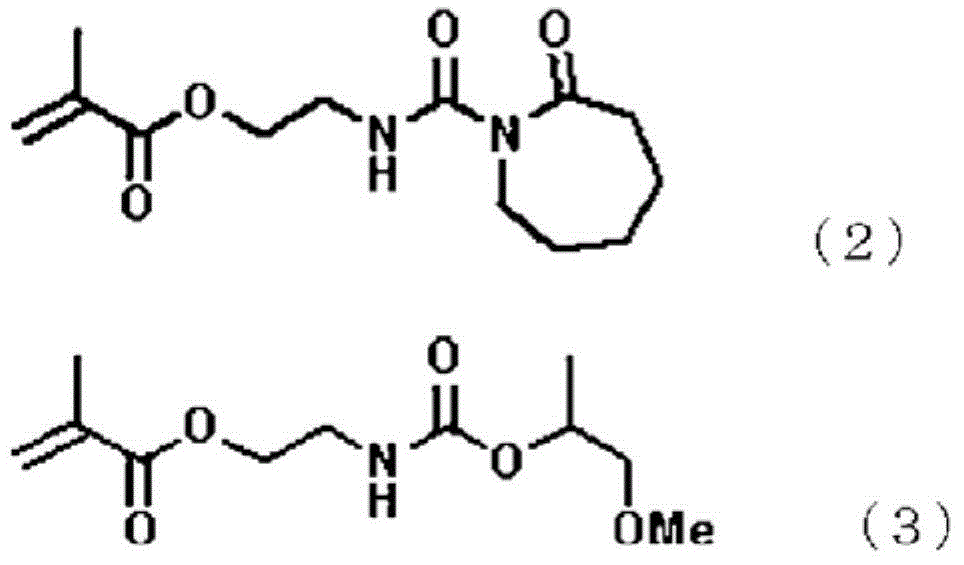

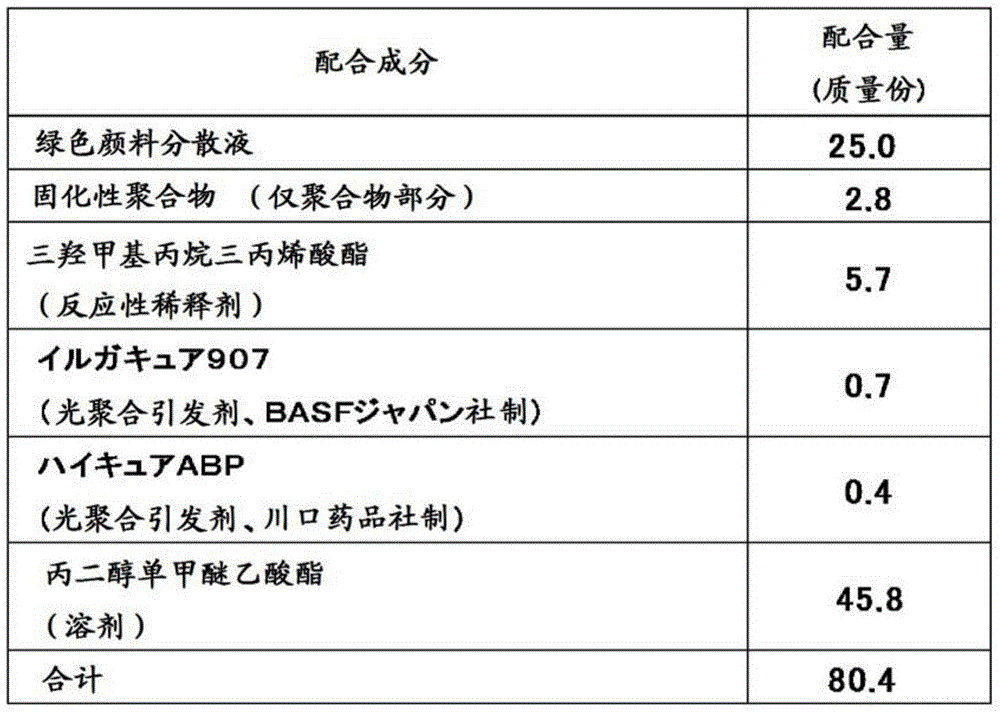

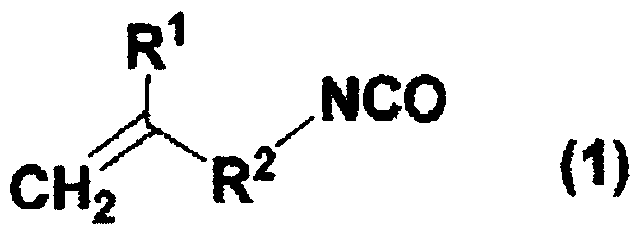

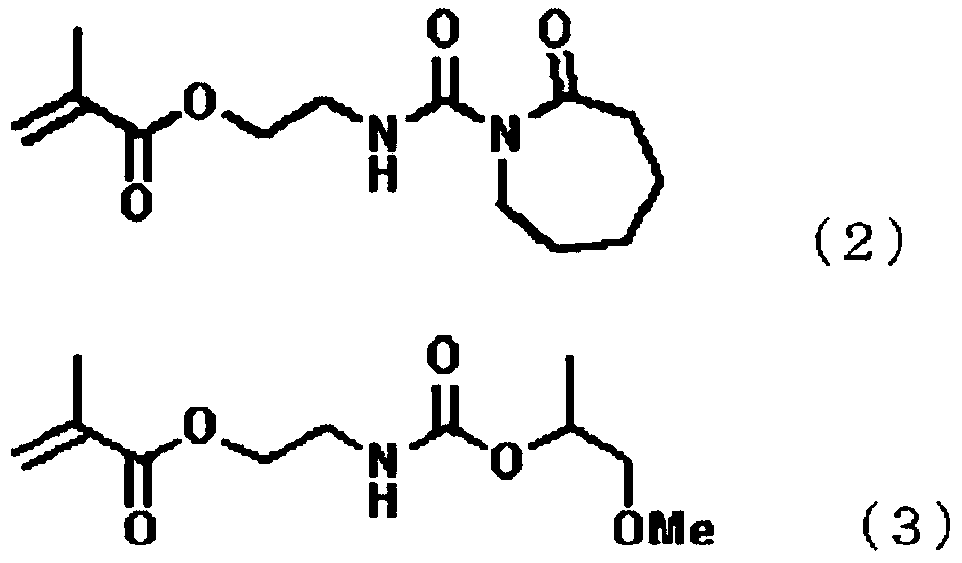

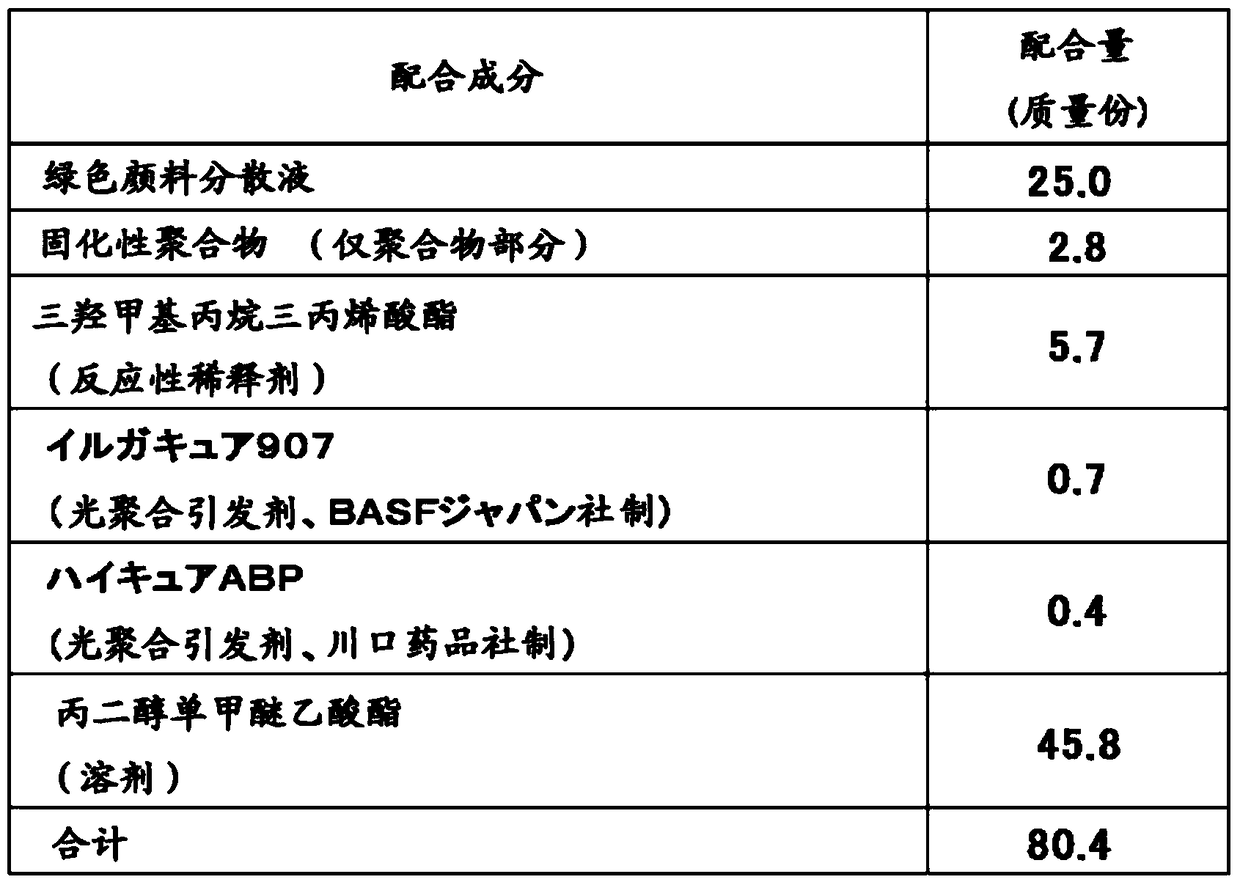

Provided is a curable polymer that contains an acid group, a polymerizable unsaturated group and a blocked <span lang=EN style='font-family:"Courier New"'>isocyanato group. The curable polymer<span lang=EN style='font-family:"Courier New"'> has a weight average molecular weight of 1,000 to 50,000 in terms of polystyrene, and preferably has an acid value of 20 to 300 mg KOH / g, an unsaturated group equivalent of 100 to 4,000 g / mol, and a blocked isocyanato group equivalent of 400 to 6,000 g / mol. After mixing the curable polymer with a solvent, blending in a reactive diluent, a photopolymerization initiator and a colorant to prepare a photosensitive material for a color filter, and using said photosensitive material to form a pattern, a color filter is obtained by preferably baking said pattern at 210°C or less.

Owner:RESONAC CORP

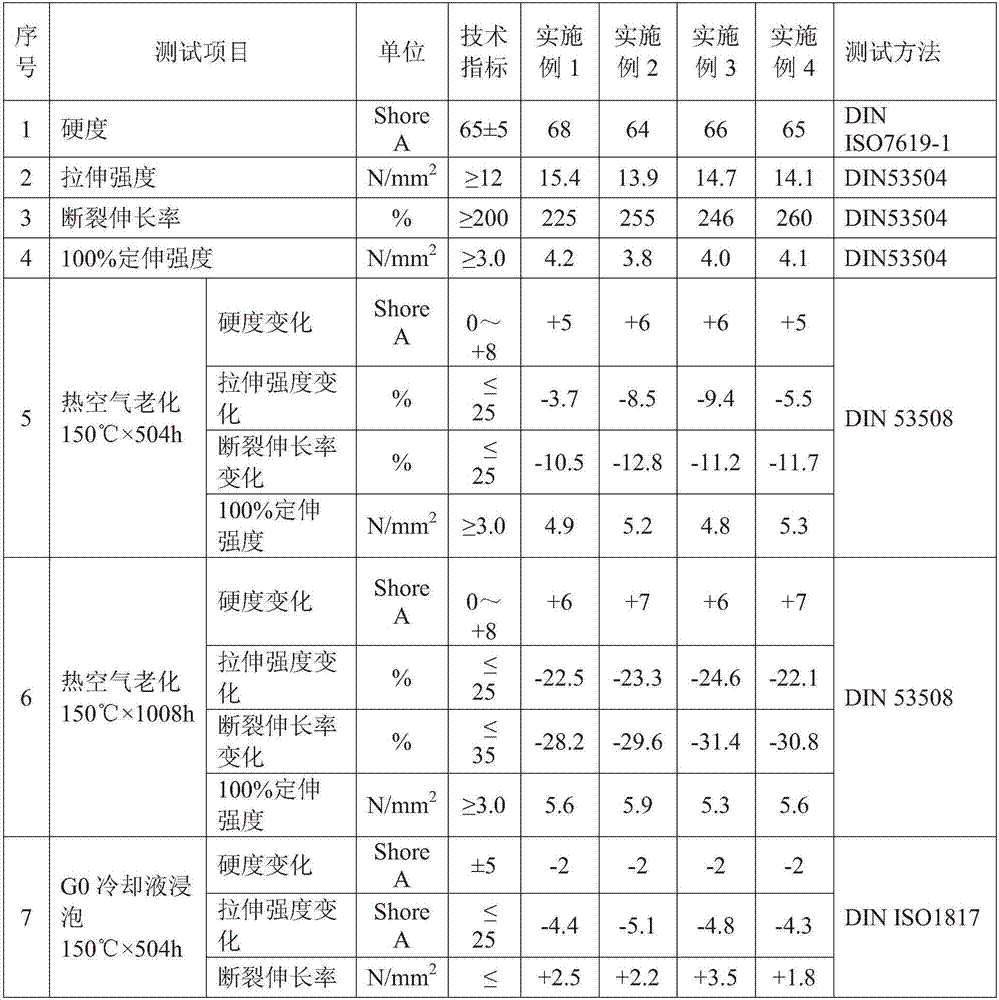

Ethylene propylene rubber material for sealing part of automobile heat dissipation system and production method of ethylene propylene rubber material

InactiveCN107090133AImprove high temperature resistanceLow temperature resistanceCross-linkRubber material

The invention discloses an ethylene propylene rubber material for a sealing part of an automobile heat dissipation system and a production method of the ethylene propylene rubber material and belongs to the technical field of rubber. The rubber material is prepared from the following components in parts by weight: 100 parts of raw ethylene propylene rubber, 5 parts of zinc oxide, 0.5 to 1.5 parts of stearic acid, 3 to 6 parts of an anti-ageing agent, 20 to 30 parts of fast extruding carbon black N550, 10 to 20 parts of semi-reinforced carbon black N774, 3.5 to 7 parts of a cross-linking auxiliary agent Ricon 153D and 5 to 8.5 parts of a vulcanizing agent Perkadox 14-40B-GR. The rubber material disclosed by the invention has excellent high-temperature-resisting performance and can be used for a long time under the condition that the temperature is -50 DEG C to 150 DEG C; meanwhile, the rubber material has remarkable advantages of low temperature resistance and low-compression permanent deformation.

Owner:南京金三力高分子科技有限公司

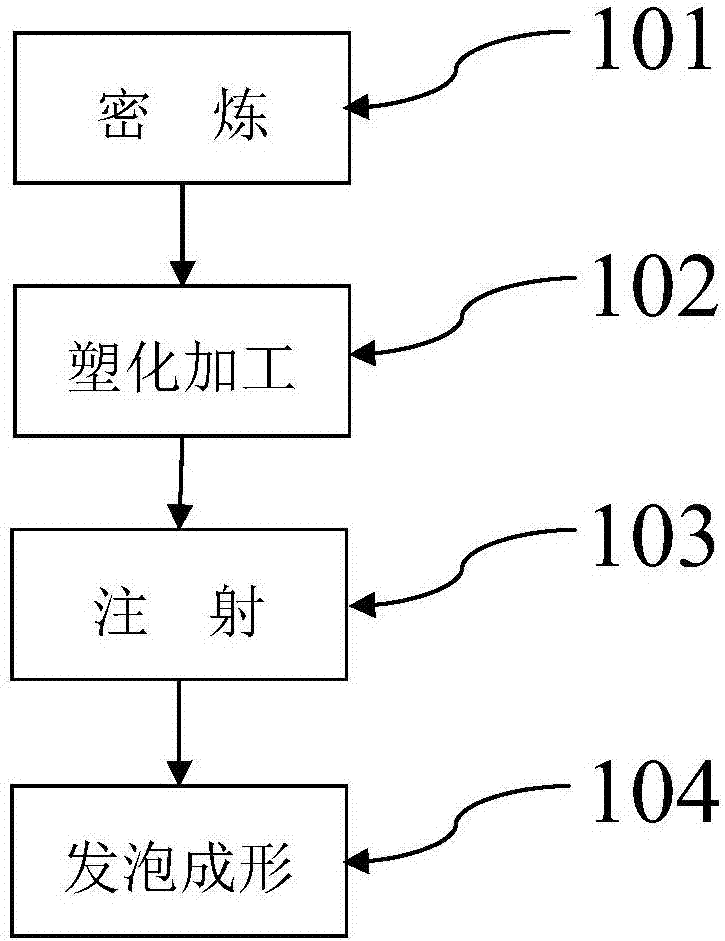

Production formula and preparation method for elastic rotator

The invention discloses a production formula and a preparation method for an elastic rotator, which belong to the technical field of road transportation equipment. The formula comprises the following specific components: 10 to 20 percent of ethylene-octene copolymer (POE), 40 to 60 percent of EVA (ethylene-vinyl acetate copolymer), 10 to 20 percent of ethylene-propylene-diene monomer, 5 to 10 percent of anti-shrinking agent, 1 to 3 percent of filler, 0.6 to 1.6 percent of dispersed lubricant, 1 to 2 percent of zinc oxide, 0.7 to 1.2 percent of cross-linking agent, 1.5 to 2.5 percent of foaming agent, 1.5 to 2.5 percent of flowable agent and 2 to 4 percent of color masterbatch pigment, and the total weight is 100 percent. The POE, the ethylene-propylene-diene monomer and the EVA are mixed and refined, and are added with a variety of additives, so that the three types of materials keep respective properties and complement one another, the elasticity of the prepared elastic rotator is high, moreover, after foaming, the texture is dense, the weight is light, the good anti-aging property of the elastic rotator is ensured, the elastic rotator cannot be easily cracked when receiving impact force, and the service life of the elastic rotator is effectively prolonged.

Owner:江苏恪铭智慧交通科技有限公司

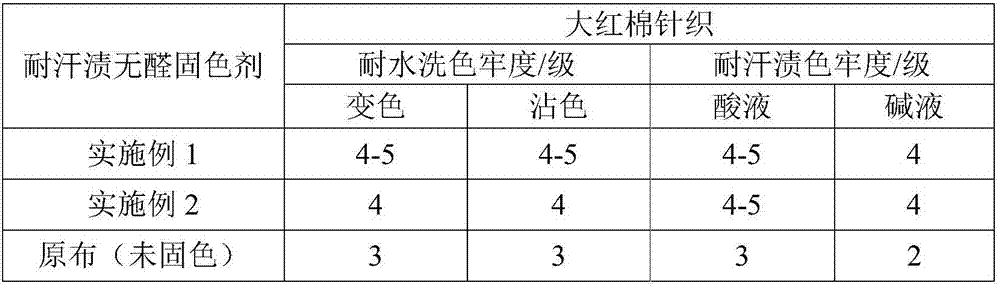

Cotton sweat-resistant formaldehyde-free color fixing agent and preparation method and application thereof

InactiveCN107216428AWashableGuaranteed color fastness to washingDyeing processFunctional monomerWater soluble

The invention discloses a cotton sweat-resistant formaldehyde-free color fixing agent. The cotton sweat-resistant formaldehyde-free color fixing agent is prepared from the following components in parts by weight: 50 to 100 parts of unsaturated quaternary ammonium salt olefin, 10 to 20 parts of functional monomer, 6 to 12 parts of water-soluble unsaturated polyoxy alkyl ether, 5 to 10 parts of crosslinking reaction monomer, 0.01 to 1 part of self-crosslinking accelerant, 0.005 to 0.02 part of metal ion chelating agent, 0.8 to 1.5 parts of initiator, and 20 to 50 parts of deionized water. The invention also discloses a preparation method and application of the cotton sweat-resistant formaldehyde-free color fixing agent.

Owner:苏州联胜化学有限公司

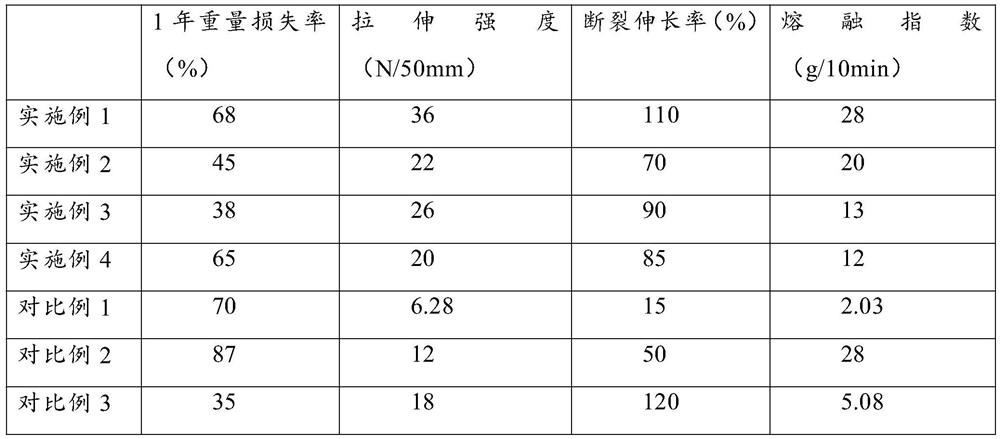

Preparation method of biodegradable cast film

The invention provides a preparation method of a biodegradable cast film, which comprises the following steps: carrying out melt blending on PLA, PBAT and a polyester chain extender in proportion to obtain a composite material, carrying out melt blending on the composite material and a dispersion lubricant to obtain a high-fluidity biodegradable material, and carrying out a cast film forming process on the high-fluidity biodegradable material to obtain the biodegradable cast film. By controlling the blending ratio of PLA and PBAT, the variety and the addition amount of the polyester chain extender and regulating and controlling the flowability of the mixed material, the compatibility of PLA and PBAT is improved, the material reaches the casting grade, and the process conditions of melt blending and casting film forming are further limited, so that the production cost is reduced, and the production efficiency is improved. The finally prepared biodegradable cast film not only has excellent biodegradability, but also has better heat resistance and impact property, good ductility and elongation at break, and soft hand feeling; the preparation method is simple and easy to implement, free of adding of redundant modifiers, low in cost and wide in application prospect.

Owner:湖北拓盈新材料有限公司

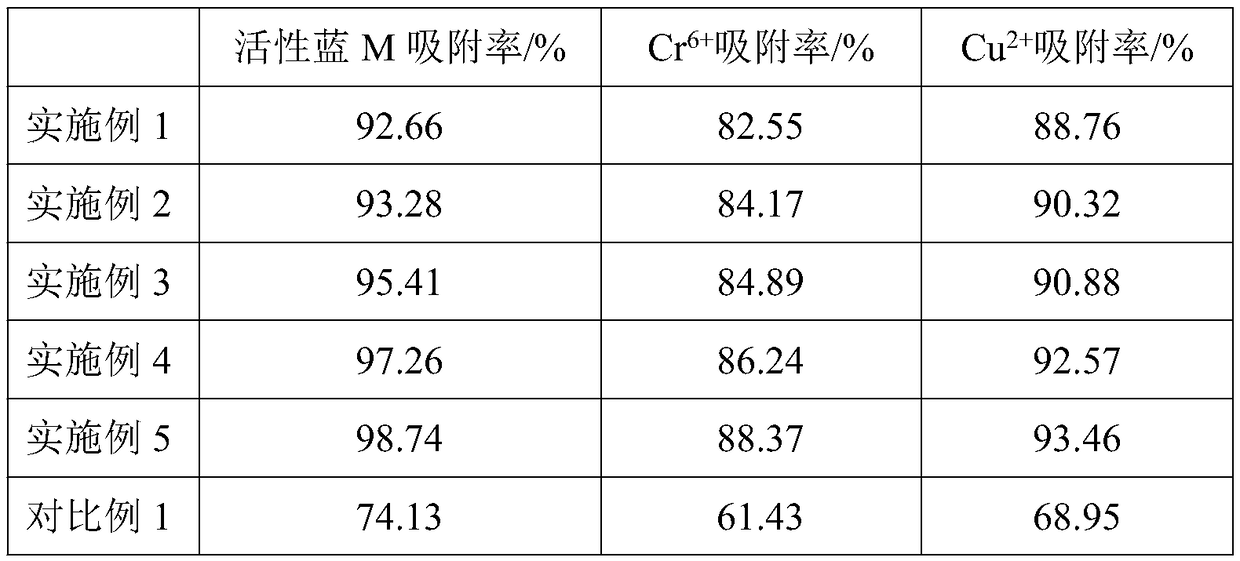

Preparation method of cellulose microsphere adsorbent

InactiveCN109201020AModerate size of microspheresLarge adsorption capacityOther chemical processesWater contaminantsWater bathsCellulose

The invention discloses a preparation method of a cellulose microsphere adsorbent, and relates to the field of chemical engineering and environmental protection. The preparation method of the cellulose microsphere adsorbent comprises the steps that cotton straw is cleaned, drying and smashing are performed and then mixed liquid of xylene and ethyl alcohol is added, the mixture reacts in a boiled water bath, and is subjected to washing and suction filtration, a hydrochloric acid solution is added to treat the product, deionized water is added to conduct a water bath reaction, suction filtrationis conducted, and the product is dried for stand-by application; a solution A is added into the pre-treated cotton straw powder to react mutually, after suction filtration and drying are conducted, asolution B is added to react with the product, the product is washed and dried to obtain cotton straw cellulose, the cotton straw cellulose is prepared to be a water solution for stand-by application; semen ricini oil and twain 80 are added into a beaker and stirred for 20 minutes, the cotton straw cellulose water solution is added into the beaker to react with the semen ricini oil and twain 80,and then epoxy chloropropane is added into the beaker to react with mixture; and the oil phase is removed from the reacted system, the product is washed and dried, and the cellulose microsphere adsorbent is obtained. The prepared cellulose microsphere adsorbent has the good adsorption effect on active blue M and metal ions Cr<6+> and Cu<2+> in the wastewater, and has the wide application prospect.

Owner:管敏富

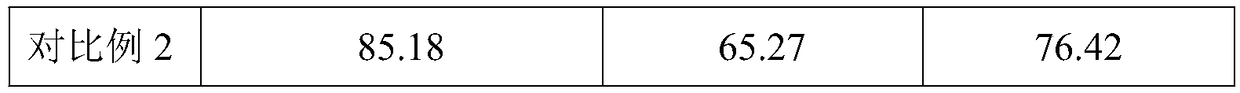

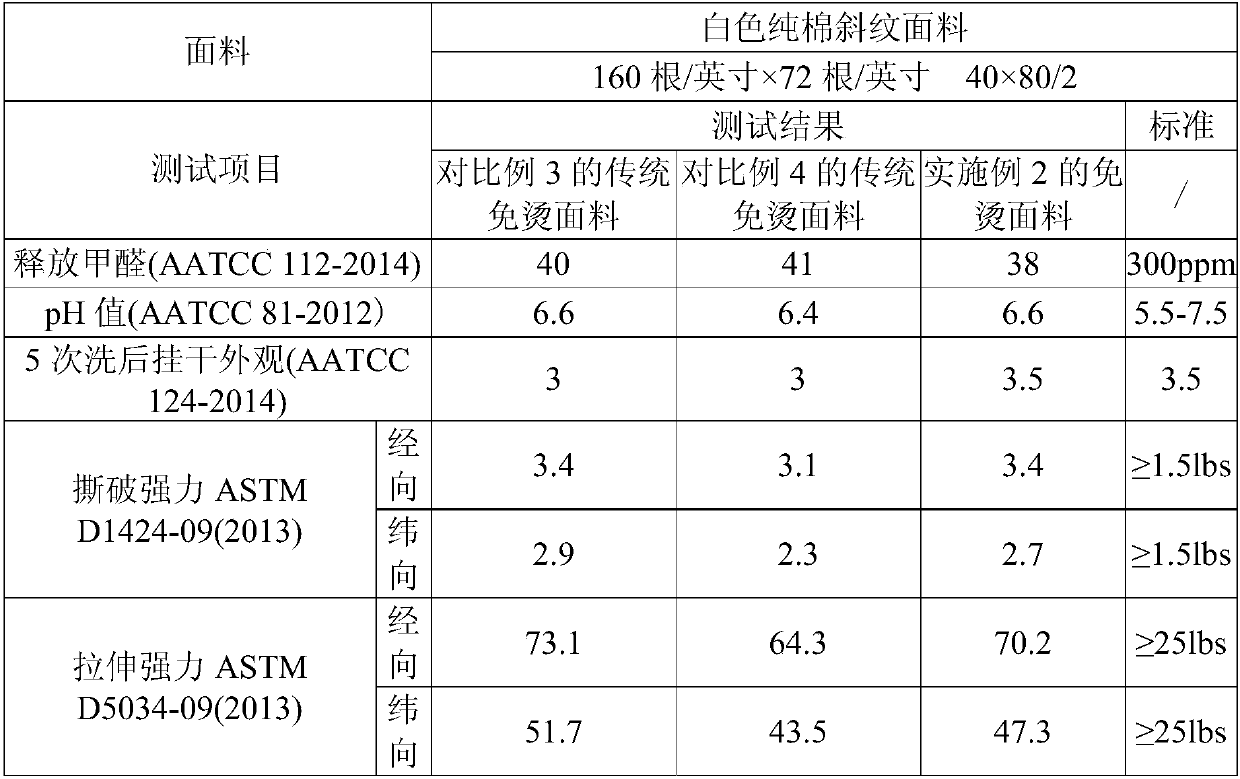

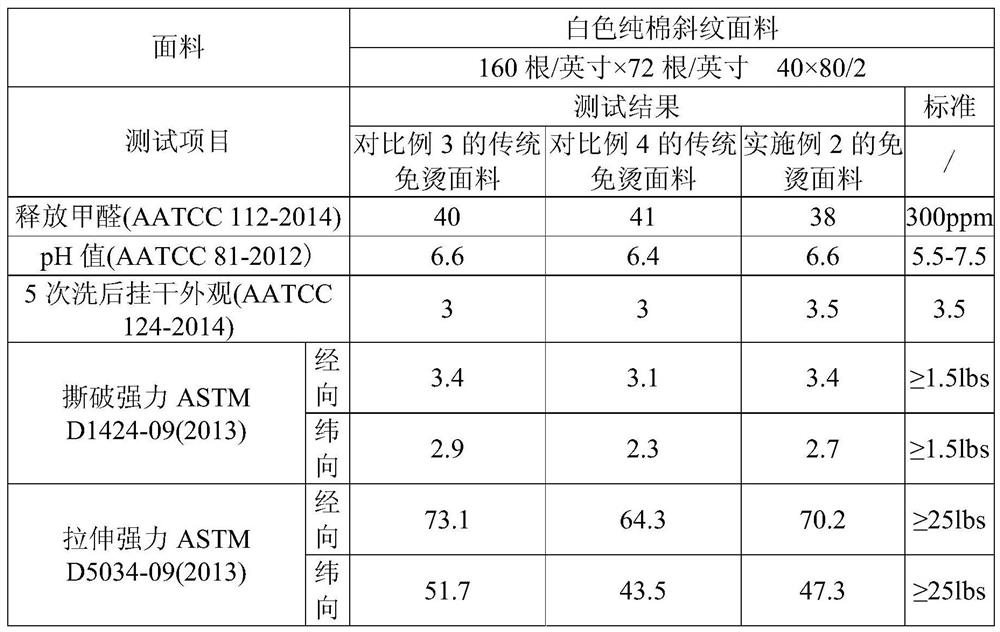

Non-ironing fabric with high hang-dry appearance and manufacturing method thereof

ActiveCN110219172AImprove moisture wrinkle resistanceImproves wrinkle recovery performanceSucessive textile treatmentsWrinkle resistant fibresBuffering agentEngineering

The invention provides non-ironing fabric with a high hang-dry appearance and a manufacturing method thereof. The manufacturing method includes padding the fabric in non-ironing finishing liquid, andstoring the padded fabric in an environment with the temperature of 28-40 DEG C and the humidity of 20-70% for 6-15 hours, wherein the non-ironing finishing liquid comprises a resin crosslinking agentand an acid-base buffering agent; performing steaming treatment at 80-150 DEG C for 2-8 minutes to obtain the non-ironing fabric with the high hang-dry appearance. The non-ironing fabric produced bythe manufacturing method has the high hang-dry appearance under the condition of enough power.

Owner:GUANGDONG ESQUEL TEXTILES

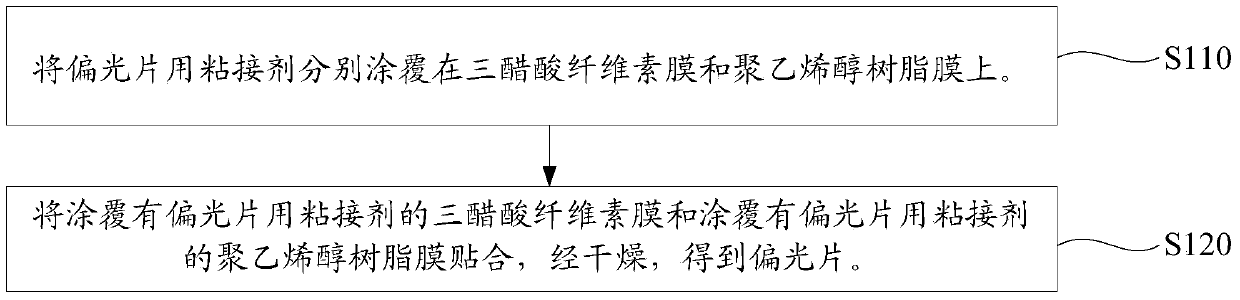

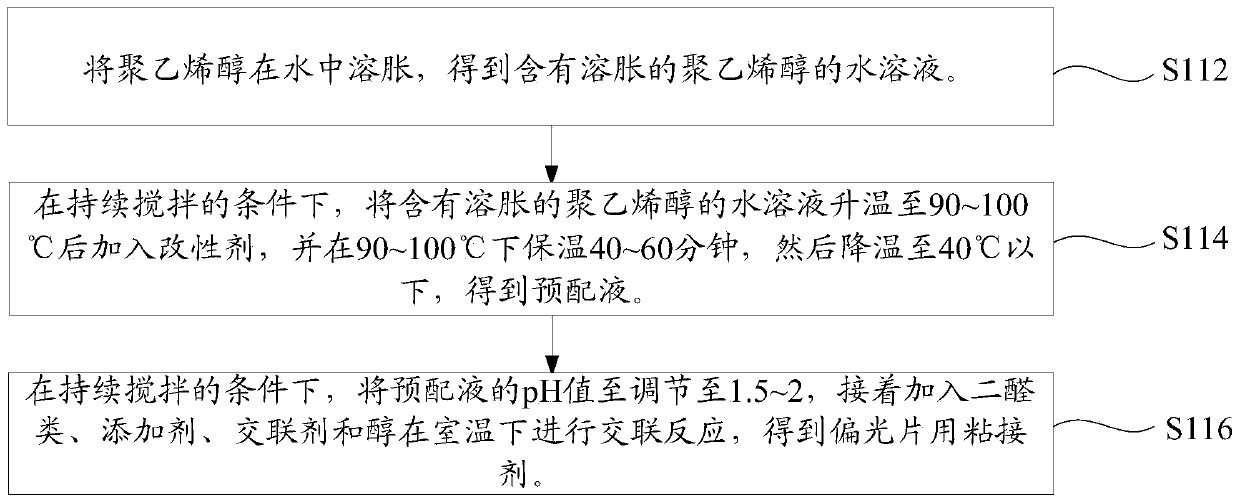

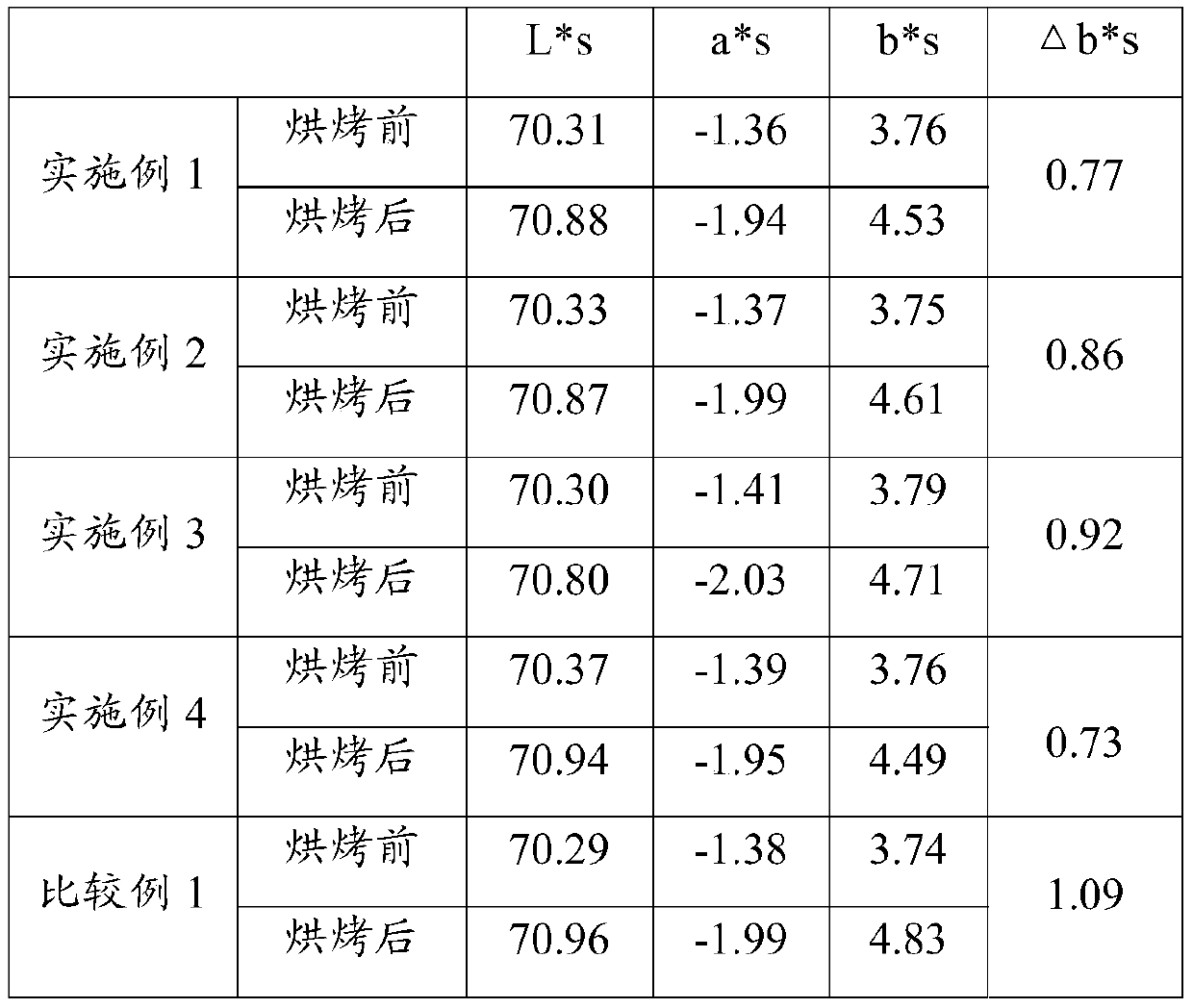

Preparation method of adhesive for polarizer and preparation method of polarizer

ActiveCN107586521BGood adhesionImprove heat resistanceNon-macromolecular adhesive additivesPolarising elementsCross-linkAlcohol

The invention relates to a preparation method of a polaroid adhesive and a preparation method of a polaroid. The preparation method of the polaroid adhesive comprises swelling polyvinyl alcohol in water to obtain an aqueous solution containing swollen polyvinyl alcohol, heating the aqueous solution containing the swollen polyvinyl alcohol to 90-100 DEG C under stirring, then adding a modifier intothe mixed solution, keeping the temperature of 90-100 DEG C for 40 to 60 minutes, cooling the mixture to 40 DEG C or less to obtain a pre-mixed solution, adjusting pH of the pre-mixed solution to 1.5-2 under continuous stirring, and adding dialdehydes, additives, a cross-linking agent and alcohol into the pre-mixed solution for a cross-linking reaction at the room temperature so that an adhesiveis obtained. The polaroid adhesive obtained by the preparation method has good adhesive properties and improves high temperature and yellowing resistance of a polaroid.

Owner:SHENZHEN SAPO PHOTOELECTRIC

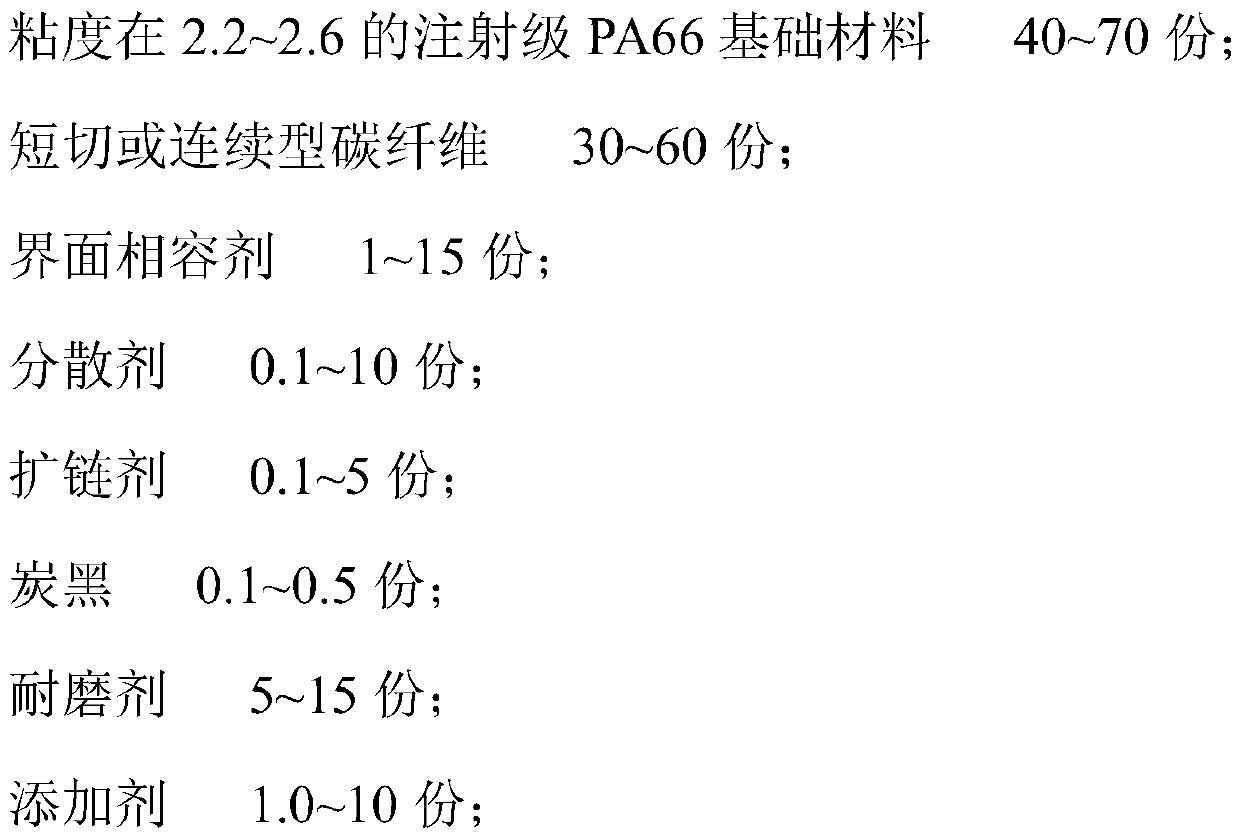

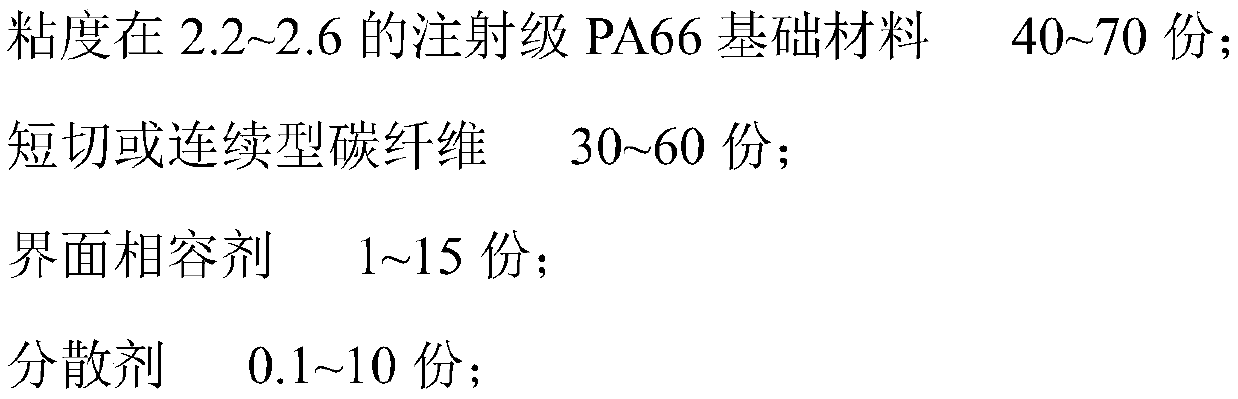

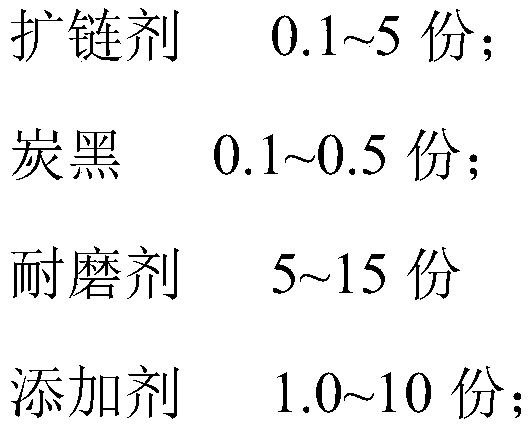

Nylon 66 composite material for connecting rod sleeve and preparation method thereof

The invention discloses a nylon 66 composite material for a connecting rod sleeve. The nylon 66 composite material is prepared from raw material components such as a PA66 base material, carbon fiber,an interfacial compatibilizer, a dispersant, a chain extender, carbon black, an anti-wear agent and an additive; the obtained nylon 66 composite material is light in specific weight, has very strong designability, not only is easy to mould, but also is uniform in material after moulding, and has various significantly improved properties in lubricity, wear resistance, impact resistance, high temperature resistance, corrosion resistance, ageing resistance and the like. In addition, by a preparation method of the nylon 66 composite material, provided by the invention, the raw material mixing sequence is clarified, and especially after the carbon fiber is mixed with the specific interfacial compatibilizer and the matching dispersant in a dry state, melt extrusion is performed through a single-screw extruder and then feeding is performed through a side feed port, so that processing damage such as surface burring and easy tearing and layering due to addition of the carbon fiber is solved, performance advantages of the carbon fiber are fully played, the preparation limitation is broken through, and thus the high strength and the high performance of the nylon 66 composite material are guaranteed.

Owner:烟台恒大聚合体有限公司

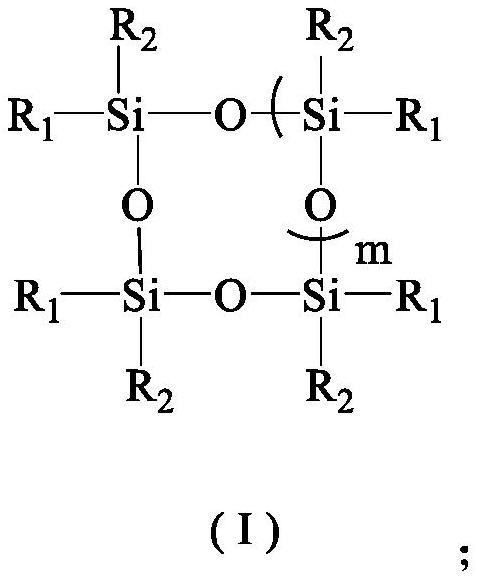

Resin composition, prepreg, circuit board and printed circuit board

PendingCN113801462AImprove heat resistanceNot volatileCircuit susbtrate materialsPolymer scienceCarbon chain

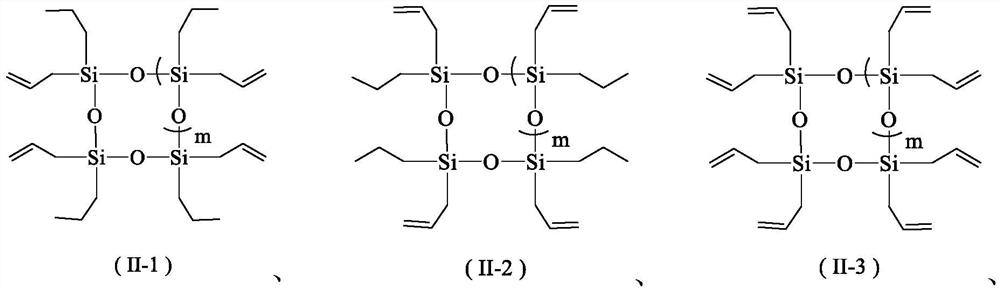

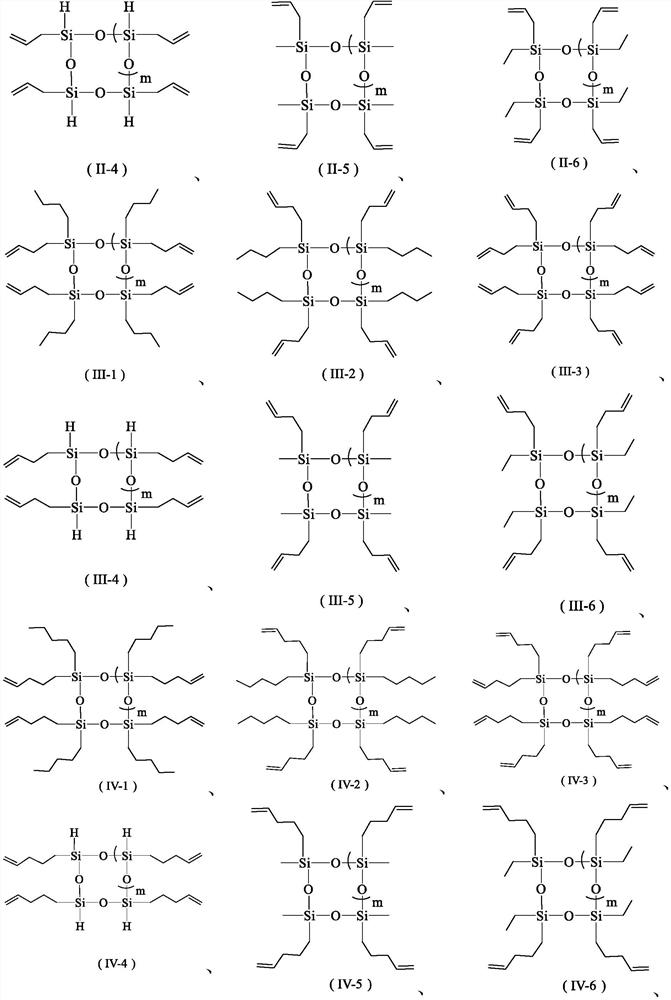

The invention relates to a resin composition, a prepreg, a circuit board and a printed circuit board. The resin composition comprises carbon-carbon conjugated group-terminated polyphenyl ether resin, carbon-carbon double bond-containing hydrocarbon resin, a polysiloxane curing agent and a solvent, wherein the structure of the polysiloxane curing agent is shown as a formula (I), in the formula (I), m is an integer of 1-20, R1 is a first alkyl group with a carbon chain length of 1-12, R2 is hydrogen or a second alkyl group with a carbon chain length of 1-12, and at least one of R1 or R2 contains an alkenyl active functional group. The polysiloxane curing agent in the resin composition is not easy to volatilize, so that the stable performance of circuit substrates prepared in different batches can be ensured; moreover, the polysiloxane curing agent does not contain hydrophilic groups and cannot be hydrolyzed, so that in the use process of the circuit substrate, the hygroscopicity of the circuit substrate can be effectively reduced, and the dielectric property of the circuit substrate can be prevented from being degraded due to moisture absorption.

Owner:ZHEJIANG WAZAM NEW MATERIAL CO LTD +2

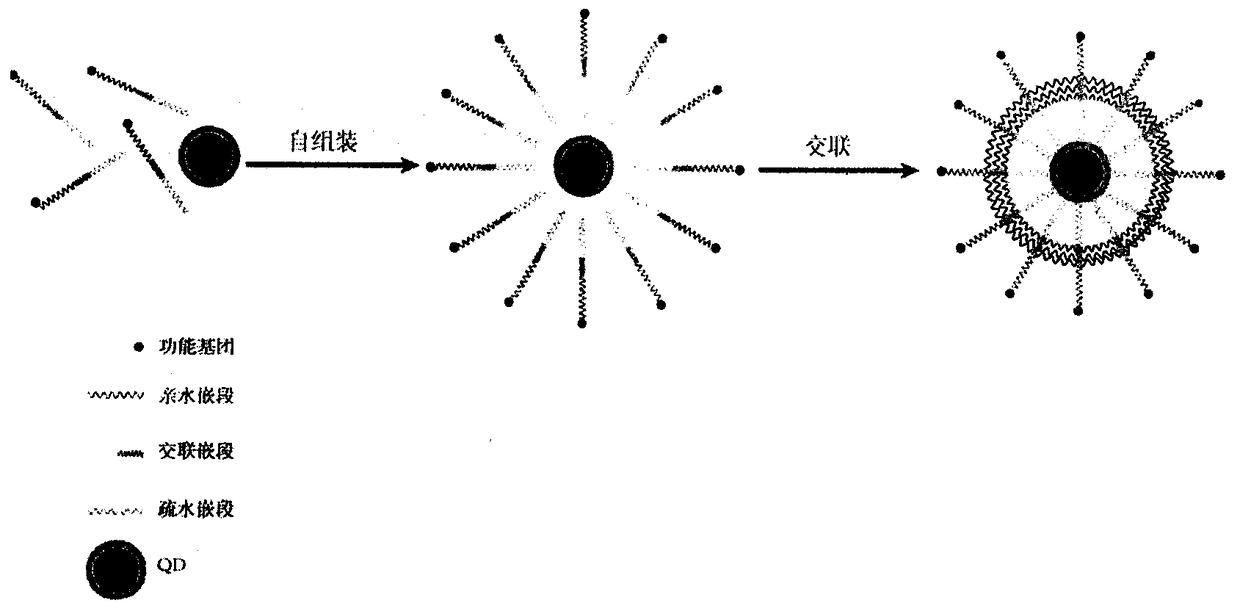

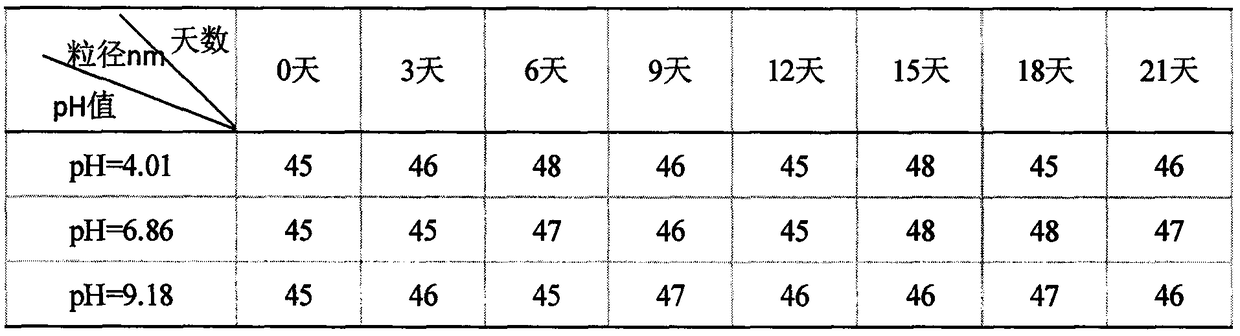

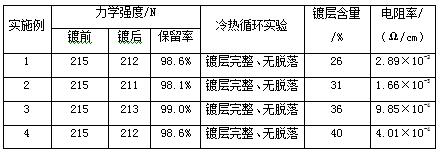

High-stability micelle type water-soluble quantum dot for coupling of macromolecular proteins

InactiveCN108329905ATaking into account the quantum yieldTaking into account stabilityImmunoglobulins against animals/humansNanoopticsCouplingQuantum dot

The invention relates to a high-stability micelle type water-soluble quantum dot for coupling of macromolecular proteins. The high-stability micelle type water-soluble quantum dot has a typical core-shell structure, a hydrophobic inner core of the high-stability micelle type water-soluble quantum dot is composed of an oil-soluble quantum dot and a hydrophobic block of a tri-block amphiphilic polymer, and a crosslinking layer and a hydrophilic layer of the tri-block amphiphilic polymer are respectively composed of a crosslinking block and a hydrophilic block of the tri-block amphiphilic polymer. Since the crosslinking block contains a hydroxyl group and has hydrophily before crosslinking, crosslinking reaction can be generated in a water-phase environment after micelle formation, and a covalent bond network surrounding the hydrophobic inner core is formed, so that the stability of the high-stability micelle type water-soluble quantum dot is comprehensively increased; meanwhile, the tailend of a hydrophilic segment of the tri-block amphiphilic polymer is terminated by functional groups except the hydroxyl group, and the high-stability micelle type water-soluble quantum dot can be used for coupling of various macromolecular proteins. Since the high-stability micelle type water-soluble quantum dot has extremely high stability, the high-stability micelle type water-soluble quantumdot is particularly suitable for coupling and fluorescent labeling of the macromolecular proteins.

Owner:刘宏飞

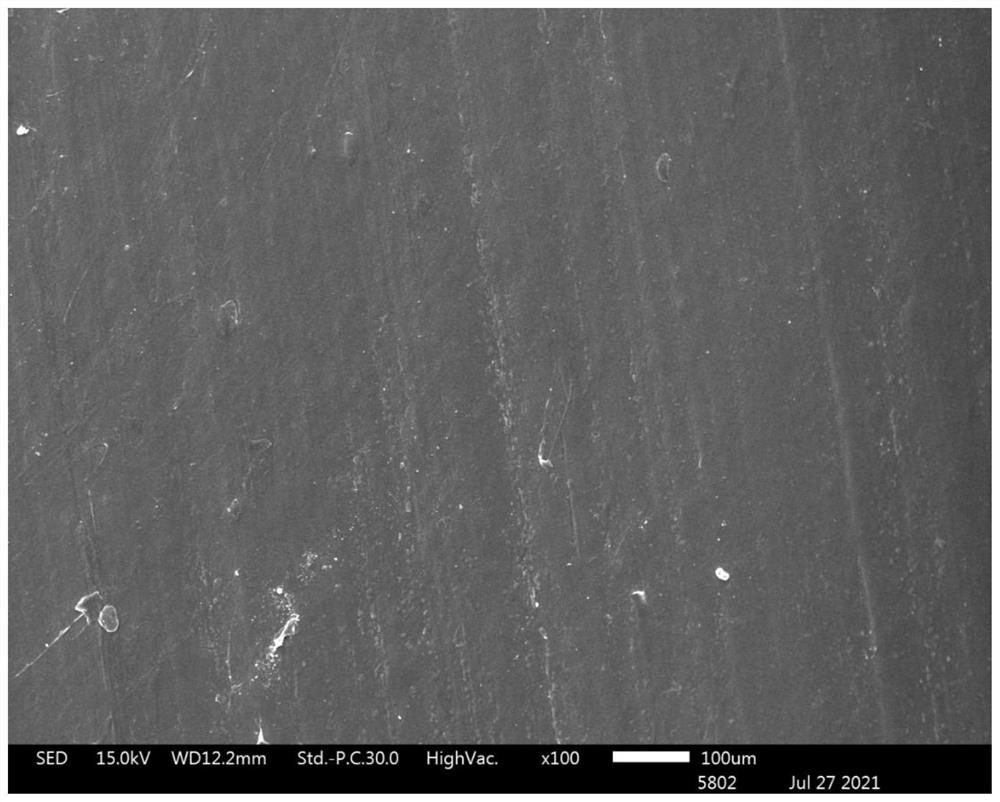

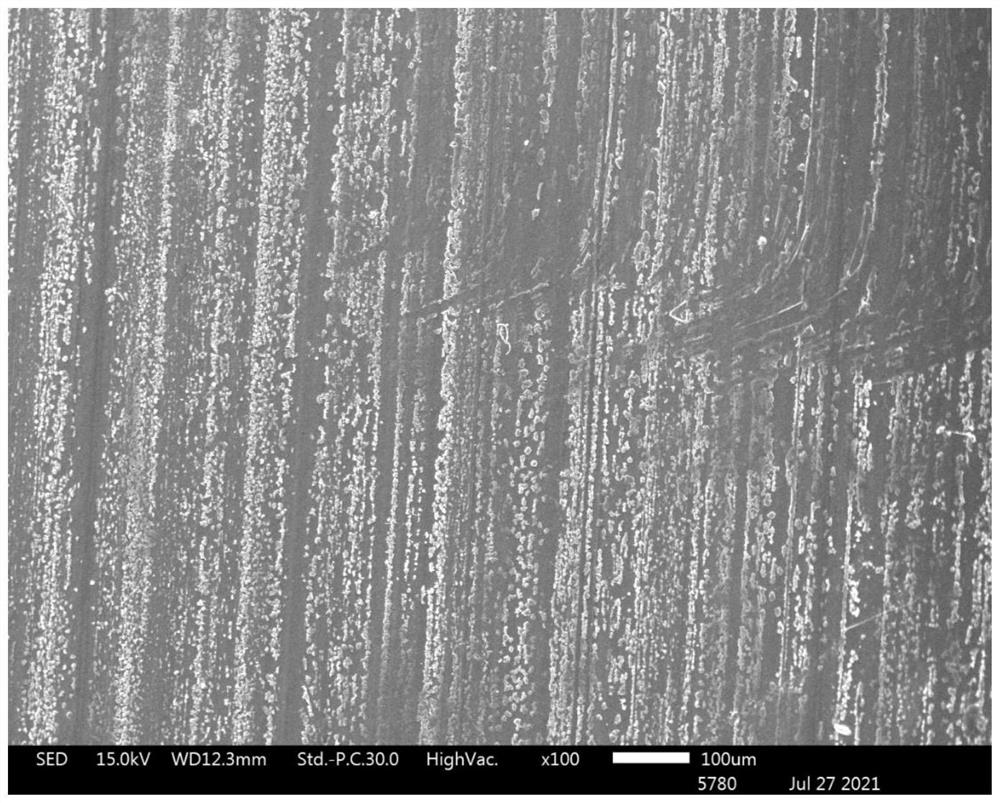

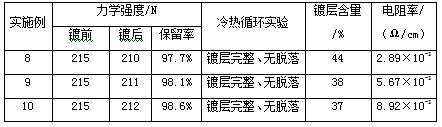

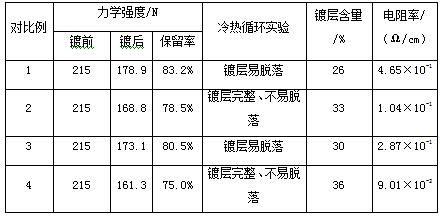

A kind of preparation method of surface metallized aramid fiber

ActiveCN109554916BAvoid structural damageImprove mechanical propertiesFibre typesLiquid/solution decomposition chemical coatingChemical platingMelamine formaldehyde resin

The invention provides a method for preparing surface metallization aramid fibers. The method includes steps of 1, carrying out aramid surface treatment, to be more specific, removing oil from aramidfibers, cleaning the aramid fibers, then placing the aramid fibers in melamine formaldehyde resin prepolymer solution, treating the aramid fibers at the temperatures of 20-80 DEG C for 5-60 s, then taking out the aramid fibers, mangling moisture on the surfaces of the aramid fibers and drying the aramid fibers; 2, carrying out activation, to be more specific, immersing the aramid fibers, which aretreated at the step 1, in activation solution, carrying out surface activation treatment on the aramid fibers and then removing residual solution on the surfaces of the aramid fibers by water; 3, carrying out reduction, to be more specific, placing the aramid fibers in reducing agents capable of reducing metal ions in the activation solution after the activation treatment is carried out on the aramid fibers, carrying out room-temperature reaction for 1-5 min, then rinsing the aramid fibers by water and drying the aramid fibers; 4, carrying out chemical plating, to be more specific, placing the reduced aramid fibers in plating solution, carrying out chemical plating on the aramid fibers, taking out the aramid fibers after the chemical plating is completely carried out on the aramid fibersand washing and drying the aramid fibers. The method has the advantages that the method is simple, feasible, safe, reliable, ecological and environmentally friendly and is convenient to operate, and large-scale production can be facilitated; the surface metallization aramid fibers prepared by the aid of the method are small in density, high in strength and good in electric conductivity, and the like.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

Zinc oxide resistor disc end surface welding agent

ActiveCN112743258AEasy to processImprove electrical performance parametersResistor manufactureWelding/cutting media/materialsElectrical resistance and conductanceOrganic solvent

The invention relates to the field of welding auxiliaries, in particular to a zinc oxide resistor disc end surface welding agent which comprises the following components in parts by weight: 20-30 parts of polyaniline nanofibers, 100-180 parts of an organic solvent, 20-25 parts of conductive inorganic nonmetal filler, 20-25 parts of conductive metal filler, 100-150 parts of thermosetting resin, 10-60 parts of a curing agent and 5-30 parts of an accelerant. By utilizing the synergistic effect between the polyaniline nanofibers and the graphene, the graphene can provide a conductive skeleton for the polyaniline nanofibers, and the polyaniline can improve the stability of the graphene; the thermosetting resin has good processability and is easily mixed with the curing agent, the conductive filler and the like, so that the conductive filler is uniformly distributed in the welding agent and is tightly attached to the surface of an aluminum layer of a resistor disc after being cured, and thus, the aluminum layer of a resistor surface is protected; and the welding agent has the advantages of good conductivity, strong adhesiveness, good chemical stability and better mechanical properties.

Owner:NANYANG JINNIU ELECTRIC

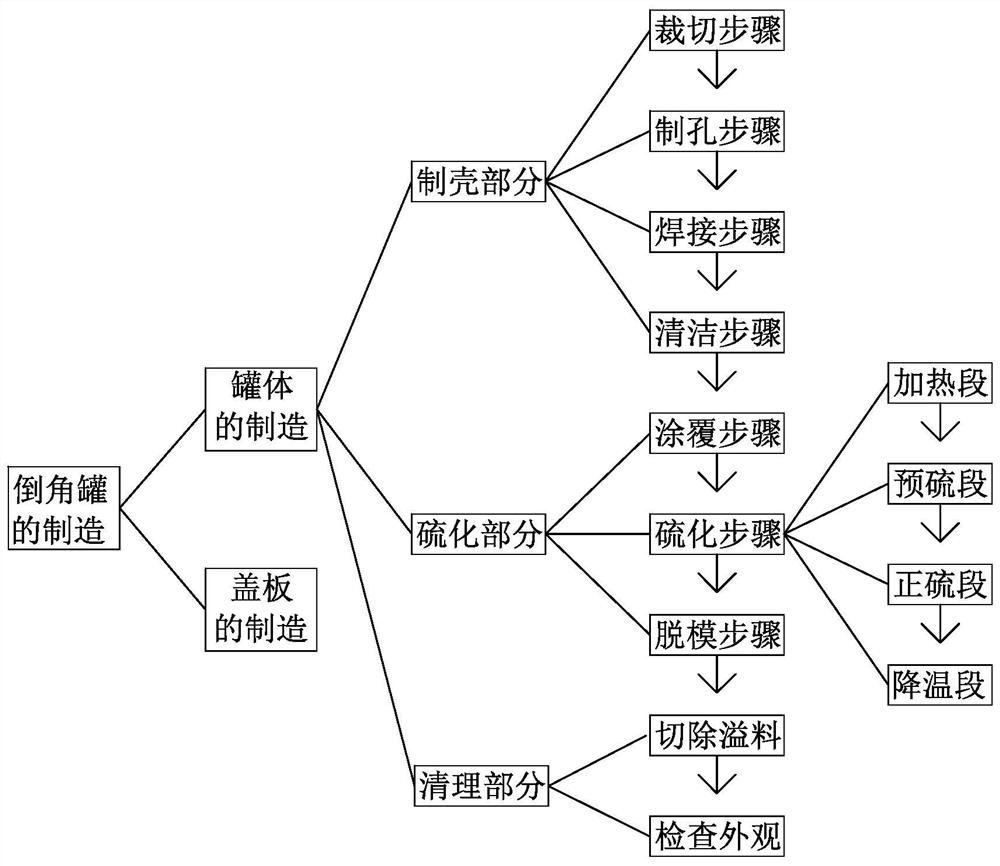

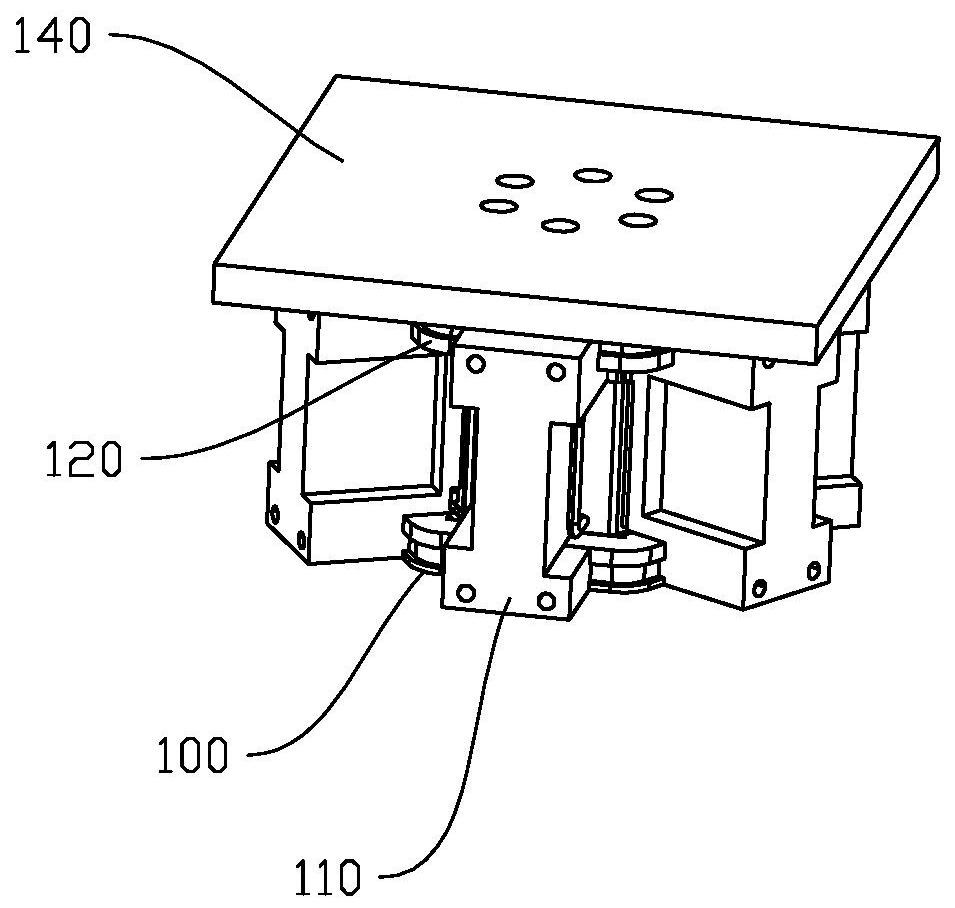

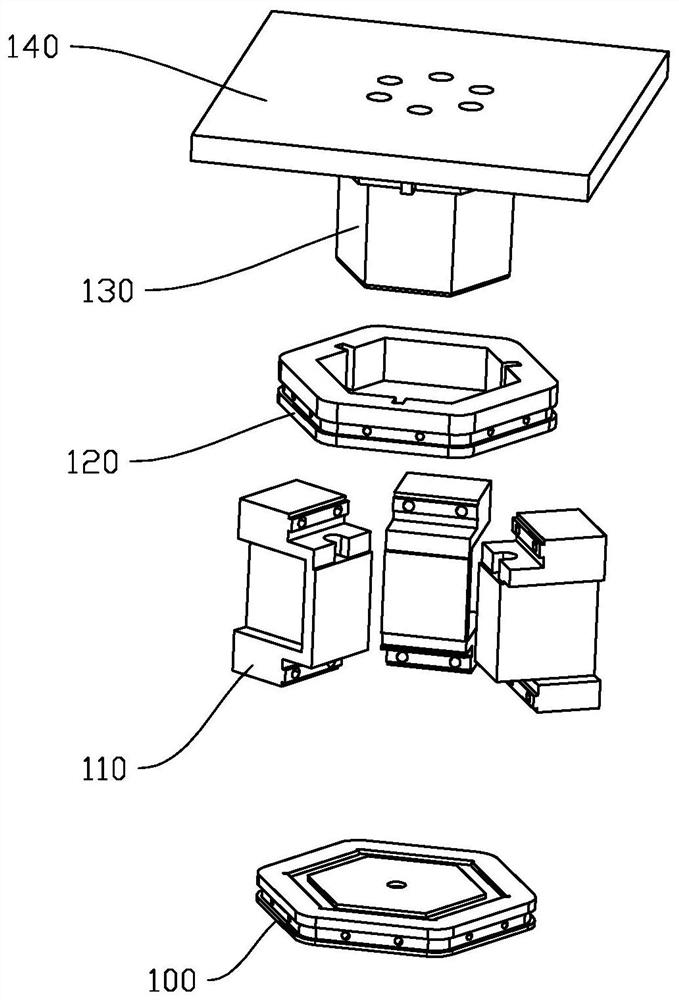

A kind of manufacturing method of chamfered can

The invention discloses a manufacturing method of a chamfered tank, comprising: a shell-making part of the tank body: manufacturing a metal shell of the tank body, and the surface of the metal shell is clean; the vulcanization part of the tank body: filling the metal shell with glue Vulcanization, including a coating step, a vulcanization step, and a mold release step, wherein the coating step coats the inner surface of the metal shell with an adhesive, the vulcanization step uses a vulcanizer and a vulcanization mold, and the vulcanization step The metal shell is filled with rubber and vulcanized. The vulcanization step includes a preheating section, a pre-vulcanizing section, a positive sulfur section, a cooling section and a demoulding section; the cleaning part of the tank body: remove the vulcanization flash to obtain the tank body. The manufacturing method of the chamfered can of the present invention can reduce or even prevent the occurrence of pits in the rubber layer of the can body, avoid poor chamfering, and save the cost of picking and rework.

Owner:广东昊达智能装备科技有限公司

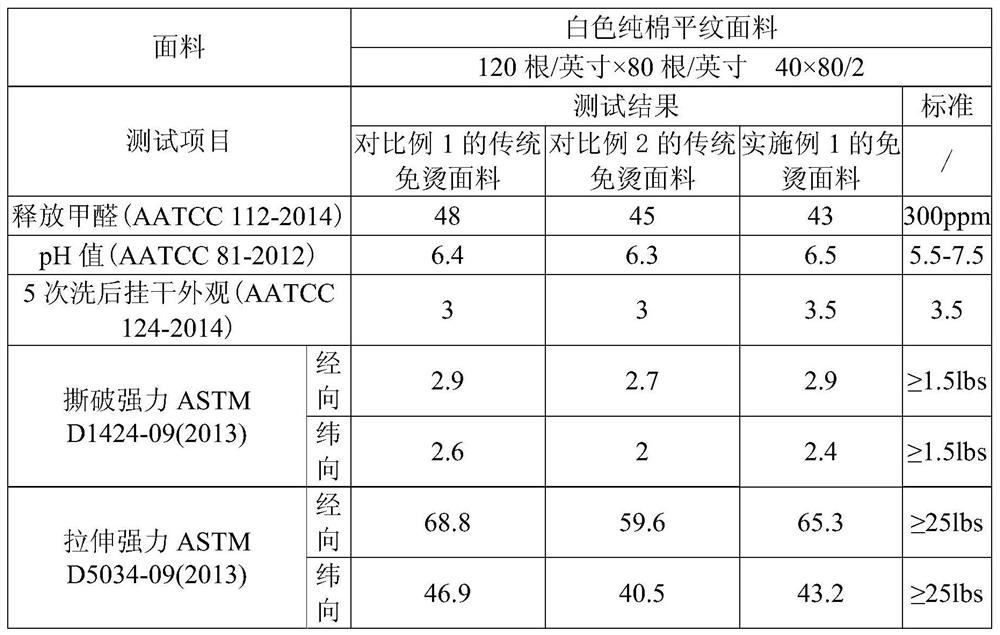

A kind of non-ironing fabric with high-hanging dry appearance and preparation method thereof

ActiveCN110219172BImproves wrinkle recoveryCross-linking reaction is sufficientSucessive textile treatmentsWrinkle resistant fibresProcess engineeringCross linker

The invention provides a non-ironing fabric with a high-hanging dry appearance and a preparation method thereof. The preparation method comprises padding the fabric in the non-ironing finishing liquid, and storing the padded fabric for 6h-15h in an environment of 28°C-40°C and a humidity of 20%-70%; wherein, the non-ironing finishing liquid contains Resin cross-linking agent and acid-base buffering agent; steaming treatment, the temperature of steaming treatment is 80°C-150°C, and the time of steaming treatment is 2min-8min, so as to obtain a non-ironing fabric with a high-hanging dry appearance. The non-ironing fabric prepared by the above-mentioned preparation method of the present invention has a high hang-dry appearance under the condition of sufficient strength.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

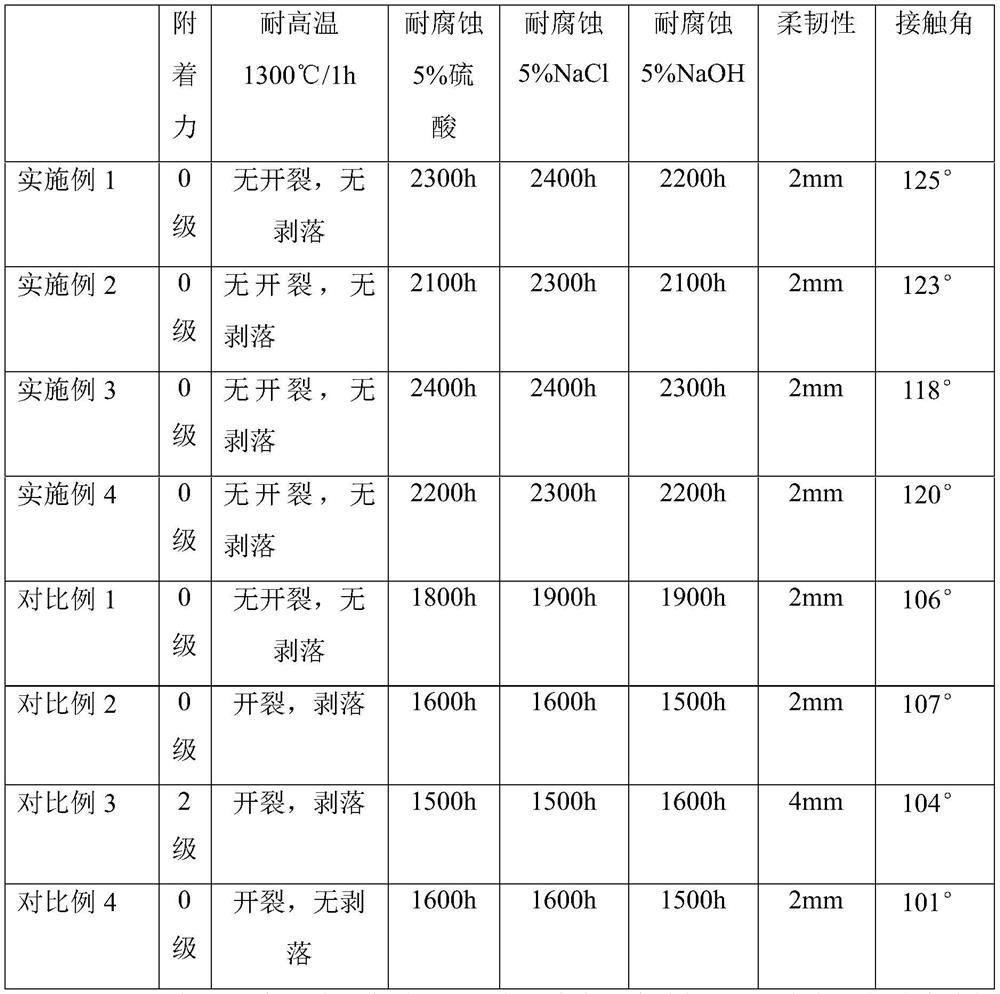

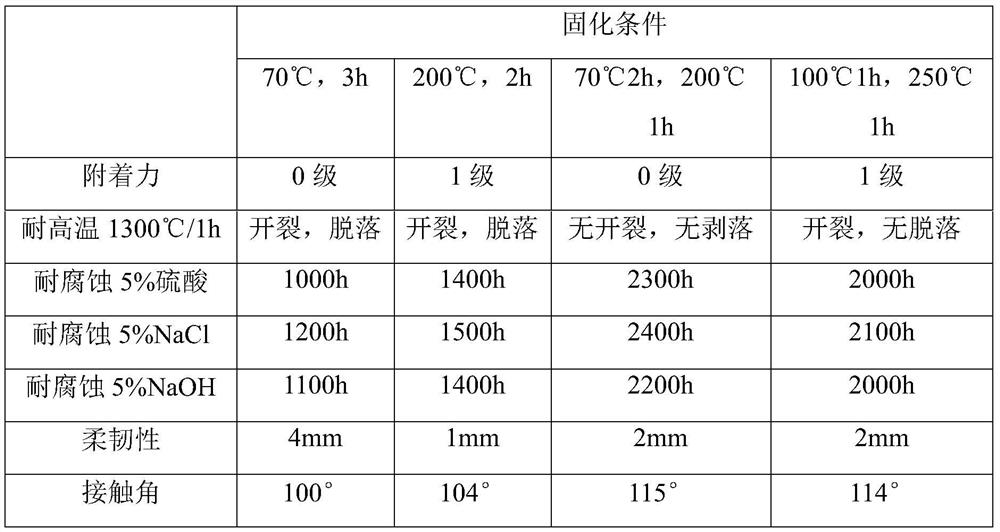

Anti-corrosion and anti-sticking coating for fire grate segment of garbage incinerator as well as preparation method and application of anti-corrosion and anti-sticking coating

ActiveCN114644843ASimple construction methodDry fastFireproof paintsPretreated surfacesDoped grapheneNanoceramic

The invention relates to an anti-corrosion and anti-sticking coating for a fire grate segment of a garbage incinerator as well as a preparation method and application of the anti-corrosion and anti-sticking coating. The paint of the anti-corrosion and anti-sticking coating is prepared from the following components: 40 to 60 parts of metal oxide sol, 2 to 4 parts of fluorine-doped graphene, 8 to 12 parts of nano ceramic powder, 6 to 8 parts of anti-corrosion filler, 3 to 6 parts of compatilizer, 1 to 3 parts of silane coupling agent, 4 to 7 parts of auxiliary agent and 40 to 60 parts of solvent, and the sum of all the components is 100 parts.

Owner:深圳优易材料科技有限公司

A kind of anti-radiation antibacterial fabric

ActiveCN110820128BImprove radiation protection performanceImprove the interface binding forceWoven fabricsYarnPolyesterFiber

Owner:安徽深呼吸纺织科技有限公司

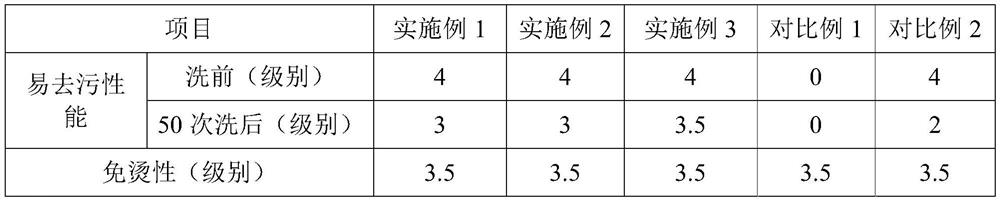

Environment-friendly processing technology for improving soil release performance of resin finishing

ActiveCN114808450AReasonable configurationImprove permeabilityVegetal fibresFiberAgricultural engineering

The invention relates to an environment-friendly processing technology for improving the soil release performance of resin finishing, and belongs to the technical field of textile finishing and processing. The method comprises the following steps: performing singeing, desizing, bleaching, mercerizing and whitening or dyeing treatment on a pure cotton fabric to obtain a semi-finished fabric; padding the semi-finished fabric in the finishing liquid, and then drying, rolling and sealing, reacting and post-processing to obtain the environment-friendly easy-to-clean fabric. The finishing liquid is prepared from the following raw materials in mass volume concentration: 180 to 240g / L of moist cross-linked resin, 90 to 120g / L of resin catalyst, 30 to 40g / L of fiber protective agent, 30 to 40g / L of softening agent, 40 to 90g / L of fluoride-free soil-release auxiliary agent and the balance of water. The method is scientific and reasonable in design, energy-saving and environment-friendly, and the product has good soil release performance and washing resistance and has remarkable economic benefits.

Owner:鲁丰织染有限公司

Processing method for improving abrasion resistance of ironing-free shirt ready-made clothes

ActiveCN101818426BAvoid blowing hot air directlyEasy to operateHeating/cooling textile fabricsFiberCross-link

The invention discloses a processing method for improving abrasion resistance of ironing-free shirt ready-made clothes, which is characterized in that a heat insulation protective cover is sleeved on a particularly easily-abraded part of a shirt such as a collar and a cuff before high-temperature baking to reduce cross-linking reaction between the fabric of the collar and cuff parts and ironing-free resin, and the heat insulation protective cover is taken down after the high-temperature baking. The method has the advantages that: by using good heat insulation effect of the heat insulation protective cover, the temperature rise rate and the heated baking time of the shirt collar and cuff parts are reduced to a certain degree, the reaction degree of the resin on the collar and cuff parts and the fiber is reduced, and the strength and abrasion-resistant durability of the fabric on the parts are improved; and the resin and the fiber on the other parts of the shirt without sleeving the heat insulation protective cover still can produce complete cross-linking reaction; therefore, the shirt realizes the durable ironing-free function.

Owner:YOUNGOR GRP CO LTD +1

Radiation-proof antibacterial fabric

ActiveCN110820128AImprove radiation protection performanceAvoid timeWoven fabricsYarnMethacrylatePolyester

The invention discloses a radiation-proof antibacterial fabric, and particularly relates to the technical field of textiles. According to the prepared radiation-proof antibacterial fabric, due to addition of radiation-proof antibacterial fibers, the radiation-proof property of the fabric is greatly improved, the antibacterial property is excellent, and the bacteriostasis rate on escherichia coli and staphylococcus aureus can reach 99% or above; and a carboxyl-rich lead tungstate-samarium methacrylate complex is obtained by polymerization addition reaction of methacrylic acid monomer and samarium methacrylate on the surface of lead tungstate under the action of an initiator to form a film structure, so that the interface binding force of the lead tungstate and a polyester substrate is greatly promoted.

Owner:安徽深呼吸纺织科技有限公司

Polymers containing blocked isocyanate groups, compositions containing the same and uses thereof

ActiveCN105008411BFull solvent resistanceGood solvent resistanceOptical filtersPolyurea/polyurethane coatingsPolystyreneAcid value

Provided is a curable polymer that contains an acid group, a polymerizable unsaturated group and a blocked <span lang=EN style='font-family:"Courier New"'>isocyanato group. The curable polymer<span lang=EN style='font-family:"Courier New"'> has a weight average molecular weight of 1,000 to 50,000 in terms of polystyrene, and preferably has an acid value of 20 to 300 mg KOH / g, an unsaturated group equivalent of 100 to 4,000 g / mol, and a blocked isocyanato group equivalent of 400 to 6,000 g / mol. After mixing the curable polymer with a solvent, blending in a reactive diluent, a photopolymerization initiator and a colorant to prepare a photosensitive material for a color filter, and using said photosensitive material to form a pattern, a color filter is obtained by preferably baking said pattern at 210°C or less.

Owner:RESONAC CORP

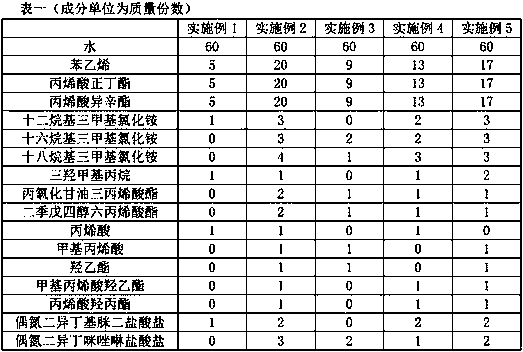

A kind of cationic styrene-acrylic primer emulsion and preparation method thereof

A cationic styrene-acrylic primer emulsion, which includes water, styrene, n-butyl acrylate, isooctyl acrylate, cationic emulsifier, high-density crosslinking monomer, hydrophilic monomer, azo initiator, the above components In terms of parts by mass, they are: 60 parts of water, 5-20 parts of styrene, 5-20 parts of n-butyl acrylate, 5-20 parts of isooctyl acrylate, 1-10 parts of cationic emulsifier, high-density cross-linking unit 1-5 parts of monomer, 1-5 parts of hydrophilic monomer, 1-5 parts of azo initiator. The cationic styrene-acrylic primer emulsion of the present invention has excellent sealing performance on the wall.

Owner:上海巴德富实业有限公司

Processing method for interface of molded joint of high-voltage cable

PendingCN114347453ALarge specific surface areaIncrease contact areaApparatus for joining/termination cablesChemistryPlasma treatment

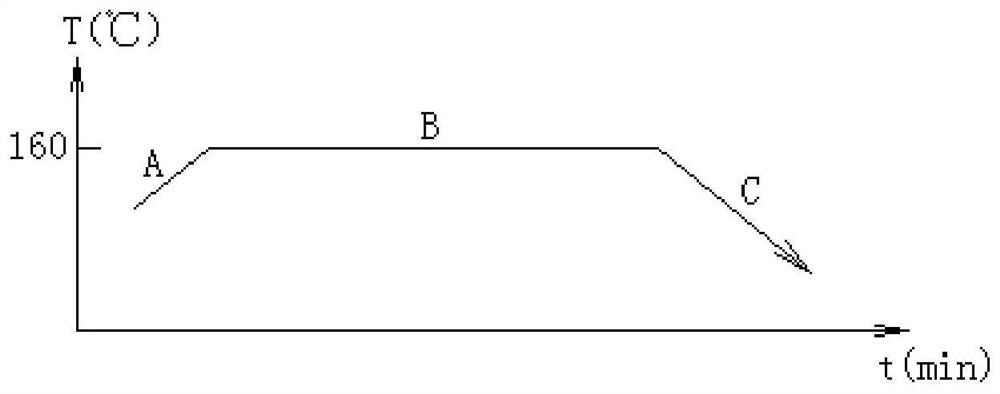

The invention discloses a high-voltage cable molded joint interface treatment method, which comprises the following specific operations: (1) treating a crosslinked cable insulation body by using plasma, and immediately performing insulation material extrusion molding after treatment; (2) after full filling, a vulcanization process is carried out, a cross-linking reaction is carried out, and the vulcanization process comprises three heating and heat preservation stage processes; and (3) after the reaction is finished, cooling and preserving heat to eliminate internal stress. According to the method, the cable insulation surface is treated through plasma, so that a cross-linked network structure on the surface is cracked, steric hindrance is reduced, meanwhile, a large number of free radicals are generated, firm binding force between the cable insulation surface and a newly injected insulation material is promoted, and the performance of a body cannot be affected by over-crosslinking; and the electrical and mechanical properties of the molded joint under high-pressure work are improved.

Owner:HENGTONG SUBMARINE POWER CABLE CO LTD

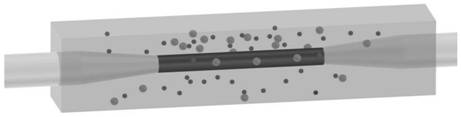

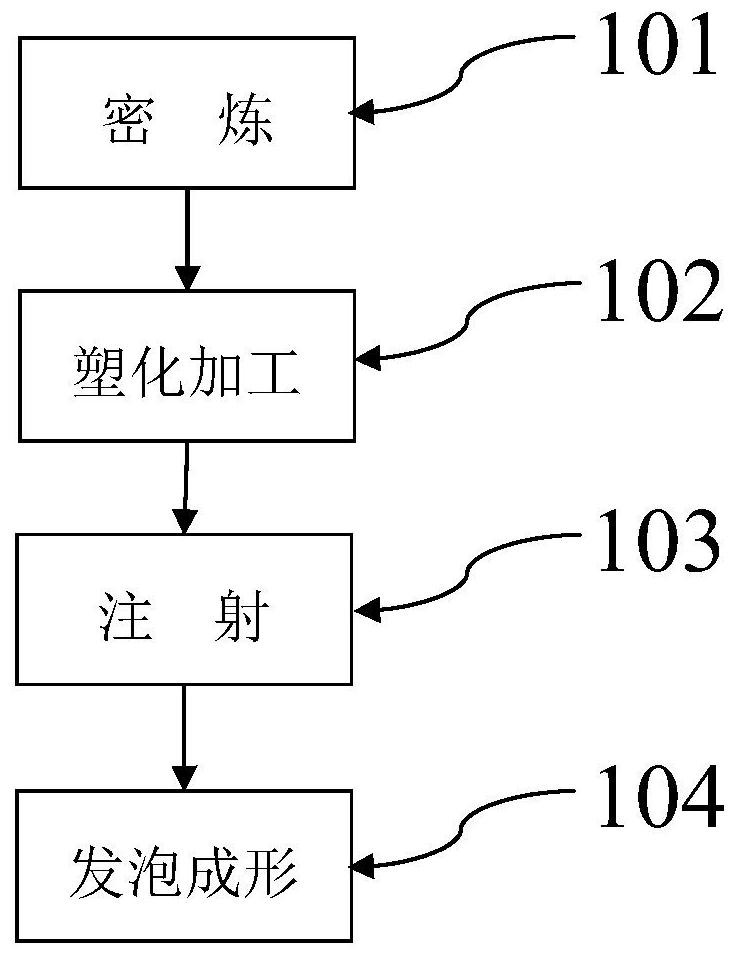

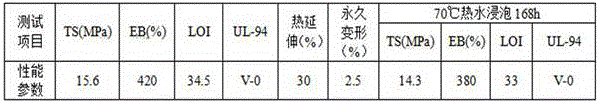

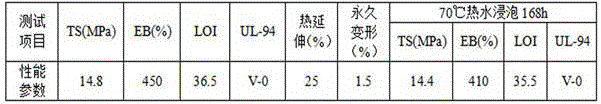

A production formula and preparation method of an elastic rotating body

The invention discloses a production formula and a preparation method of an elastic rotating body, belonging to the technical field of road traffic equipment. Its formula includes the following specific components: ethylene-octene copolymer (POE) 10-20%, EVA 40-60%, EPDM rubber 10-20%, anti-shrinkage agent 5-10%, filler 1- Weight Total is 100%. Mix and refine POE, EPDM materials and EVA materials, and add a variety of additives, so that the three materials can maintain their own properties and complement each other. It is dense and light in weight, which ensures good anti-aging performance of the elastic rotating body, and is not easy to crack when subjected to impact force, effectively prolonging the service life of the elastic rotating body.

Owner:江苏恪铭智慧交通科技有限公司

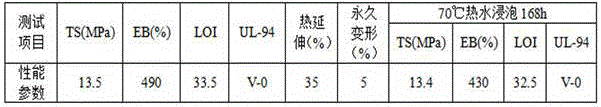

Silane crosslinked halogen-free flame-retardant polyolefin composite material and preparation method thereof

The invention relates to a silane crosslinking halogen-free flame retardant polyolefin composite material. The composite material is prepared by uniformly mixing a base stock, a flame-retardant master batch and a catalyzing master batch according to a weight ratio of 50:45:5, extruding the materials through a screw extruder, and conducting a cross-linking reaction through a warm water bath or a steam bath to prepare the product. A phosphorus-nitrogen compound flame retardant system is prepared by compounding a microencapsulated flame retardant and a macromolecular hyperbranched triazine char forming agent; the flame-retardant master batch, the catalyzing master batch and the base stock are separately prepared and then mixed to prepare the silane crosslinking halogen-free flame retardant polyolefin composite material. Compared to the prior art, the flame retardant efficiency, the water resisting property and the durability of the material are obviously increased; furthermore, the good surface properties and the excellent mechanical properties of the material are kept.

Owner:ANHUI HUGEE NEW FLAME RETARDANT MATERIAL

A kind of high temperature resistant pressure sensitive coating material, preparation method and protective film

ActiveCN112251171BFully contactedImprove moisture resistanceNon-macromolecular adhesive additivesEster polymer adhesivesPolymer scienceMeth-

The invention discloses a high-temperature-resistant pressure-sensitive coating material, a preparation method and a protective film. The raw materials of the pressure-sensitive coating material include: polyacrylate pressure-sensitive adhesive: 50% to 65%; cross-linked Agent: 0.5% to 6%; solvent: 10% to 30%; auxiliary agent: 5% to 20%; the crosslinking agent uses a liquid mixture of hexamethylene diisocyanate and dicyclohexylmethane diisocyanate and diphenyl Methane diisocyanate hollow particles; the outer diameter of the hollow particles is 1 mm to 80 mm; the auxiliary agent is ethanol. In the present invention, by improving the type, proportion and adding state of the isocyanate crosslinking agent, adding additives, and adjusting the overall proportioning relationship of the pressure-sensitive coating material raw materials, the polyacrylate pressure-sensitive adhesive and the isocyanate crosslinking agent are fully Contact and sufficient cross-linking reaction to obtain a protective film with good resistance to high temperature, heat and humidity, and acid and alkali.

Owner:SICHUAN YUXI ELECTRONICS TECH CO LTD

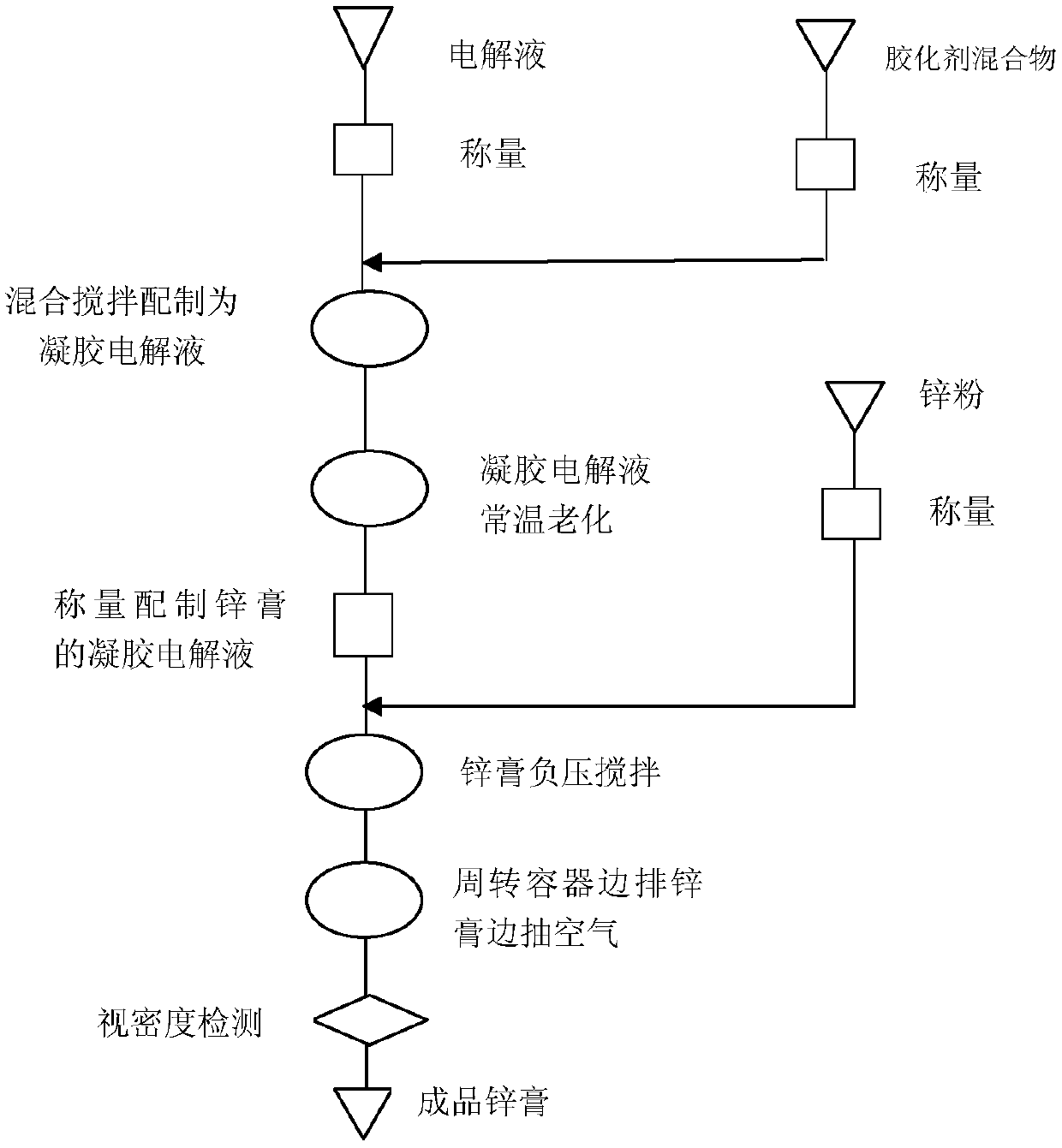

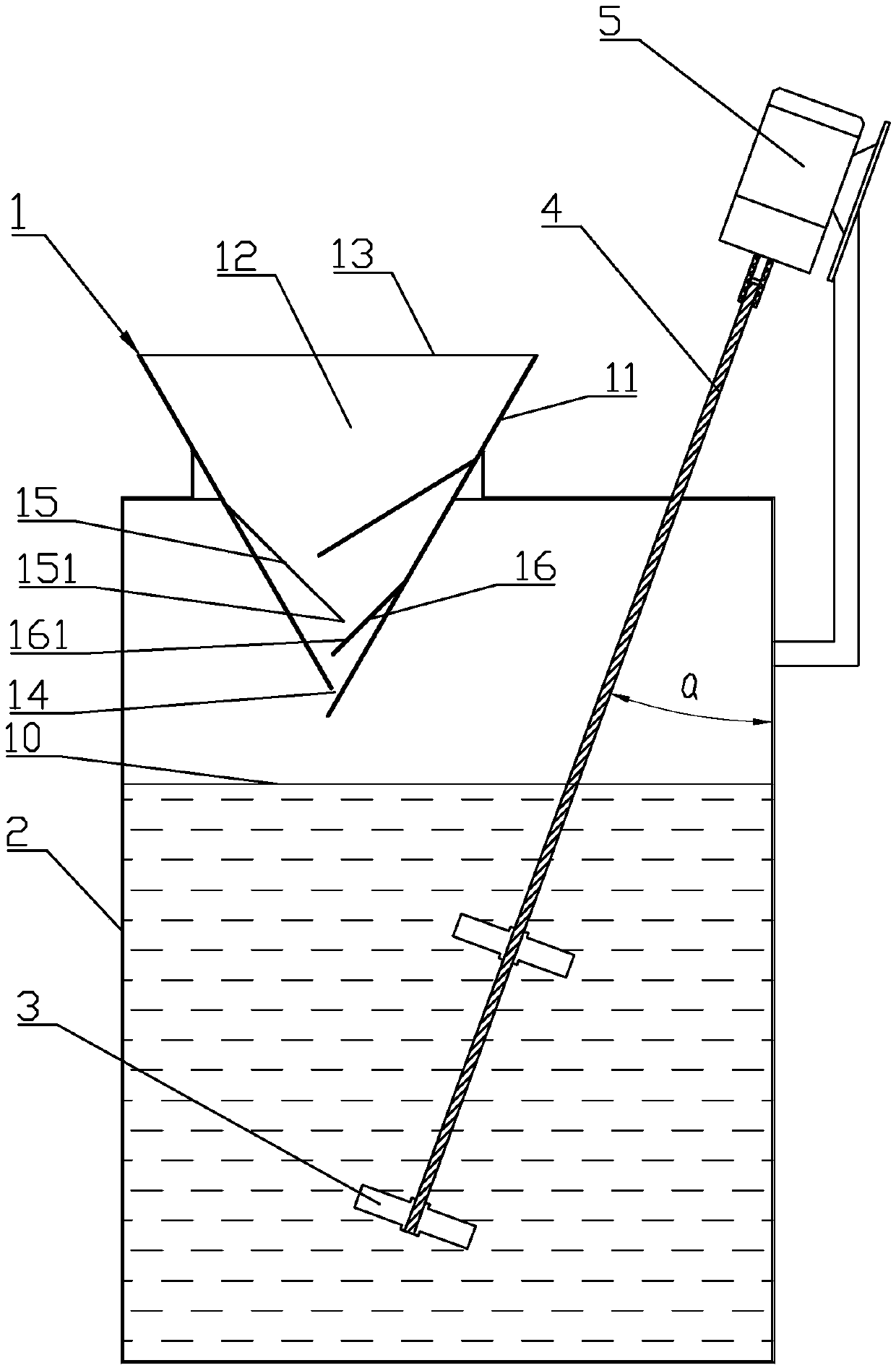

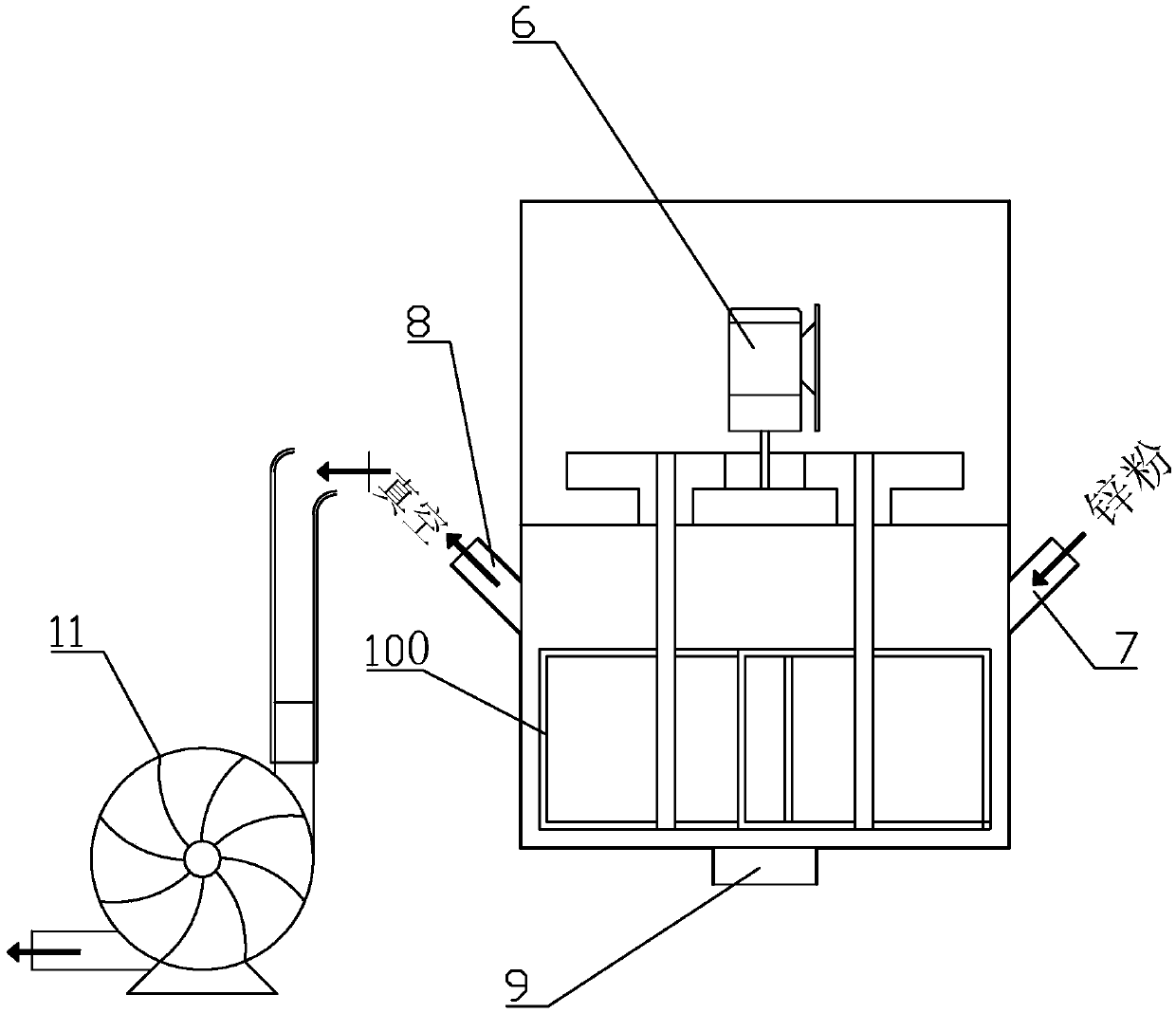

A kind of alkaline battery negative electrode preparation method

ActiveCN106684318BGood dispersionHigh viscosityPrimary cell electrodesDry cellsDispersityPolymer science

The invention discloses an alkaline battery cathode preparation method, and aims to improve the uniform dispersity of a gelatinizing agent for preparing gel electrolyte. The alkaline battery cathode preparation method comprises the following steps: (1) metering and feeding an electrolyte into a stirring tank of a gel electrolyte stirring device, and starting a stirring motor of the gel electrolyte stirring device to enable the gel electrolyte stirring device to firstly stir the electrolyte for time A; (2) after the electrolyte is stirred for the time A, metering the gelatinizing agent, then dispersively feeding the gelatinizing agent into the stirring tank of the gel electrolyte stirring device, completing the feeding of the gelatinizing agent within time B, and keeping the stirring motor of the gel electrolyte stirring device working during the feeding of the gelatinizing agent; (3) continuously enabling the stirring motor of the gel electrolyte stirring device to work for time C; (4) aging a product obtained in the step (3) for time D to swell the gelatinizing agent; (5) metering the gel electrolyte obtained in the step (4), then feeding the gel electrolyte into a stirring container of zinc paste stirring equipment, adding metered zinc powder, and uniformly mixing the zinc powder and the gel electrolyte through the zinc paste stirring equipment; (6) feeding zinc paste obtained in the step (5) into a zinc paste transfer container.

Owner:浙江长虹飞狮电器工业有限公司

A kind of sealing primer emulsion for fresh cement and preparation method thereof

A sealing primer emulsion for fresh cement comprises the following components in parts by mass: 50 parts of water, 5-20 parts of styrene, 5-20 parts of n-butyl acrylate, 5-20 parts of 2-ethylhexyl acrylate, 1-5 parts of an emulsifier, 1-5 parts of a high-density crosslinking monomer, 1-5 parts of a hydrophilic monomer and 1-5 parts of an initiator. The sealing primer emulsion for the fresh cement has excellent air permeability and closure.

Owner:上海巴德富实业有限公司

A kind of preparation technology of anode gasket for ion-exchange membrane electrolyzer

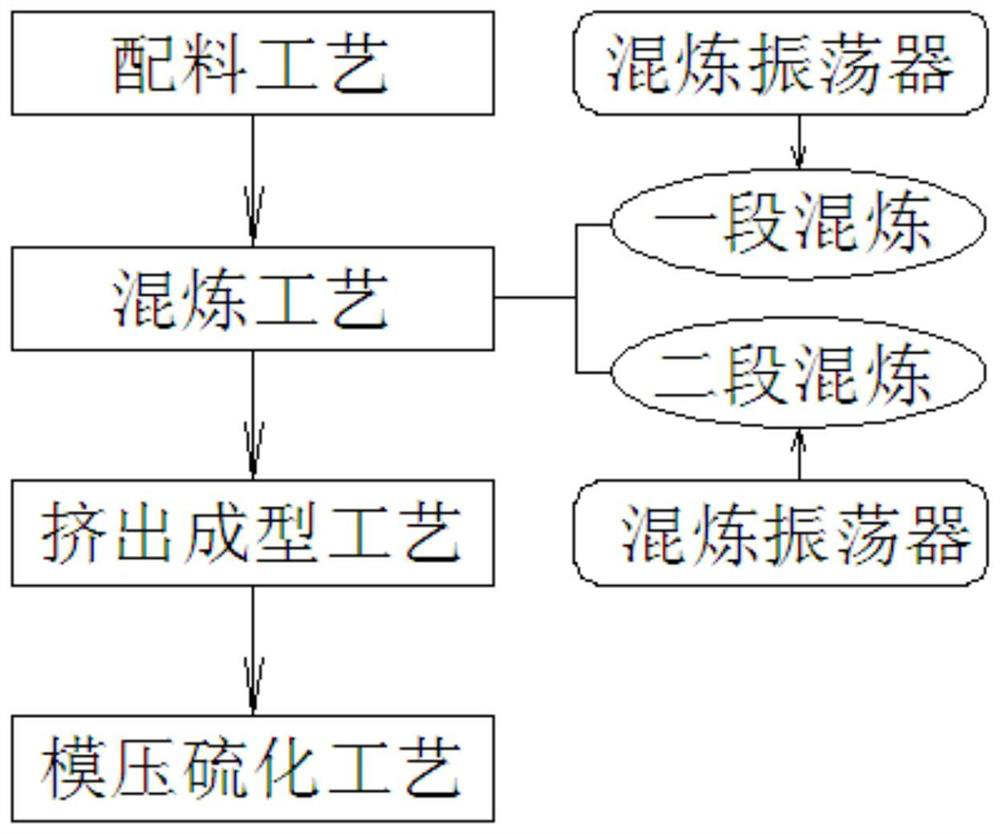

ActiveCN109721859BIncrease elasticityImproves sealing reliabilityElectrodesVulcanizationButadiene Dioxide

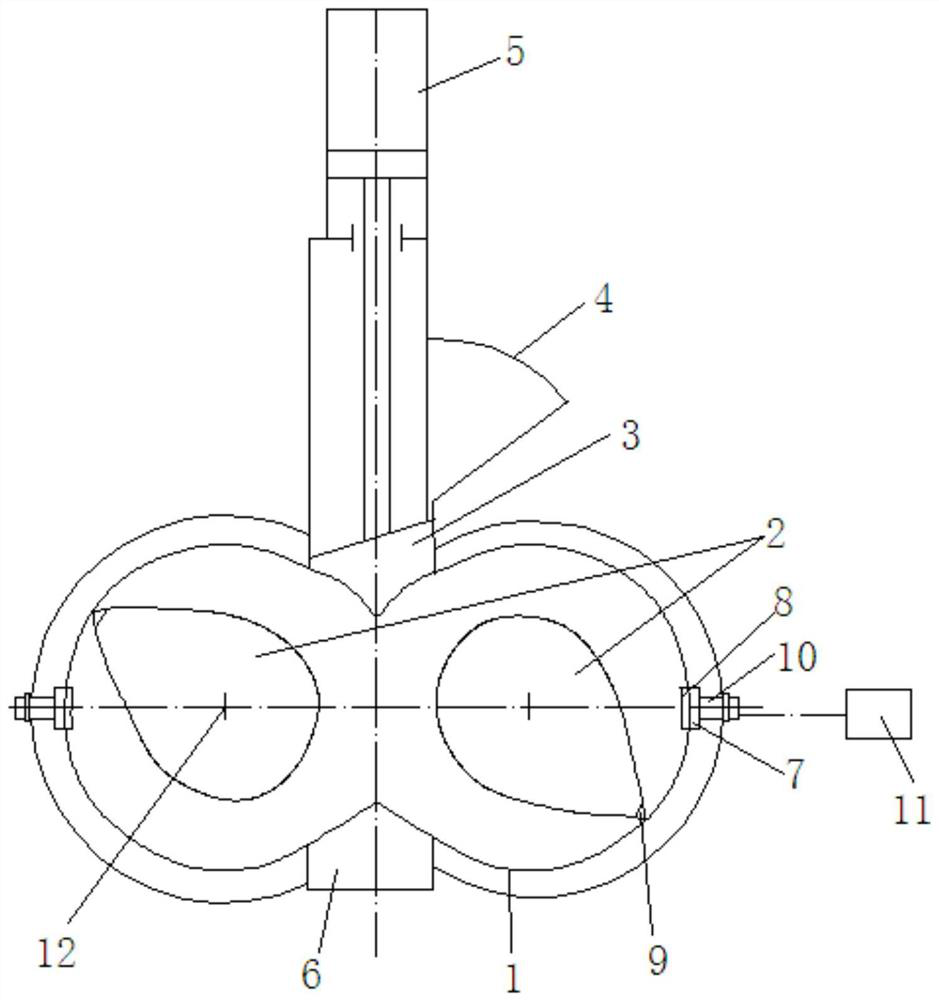

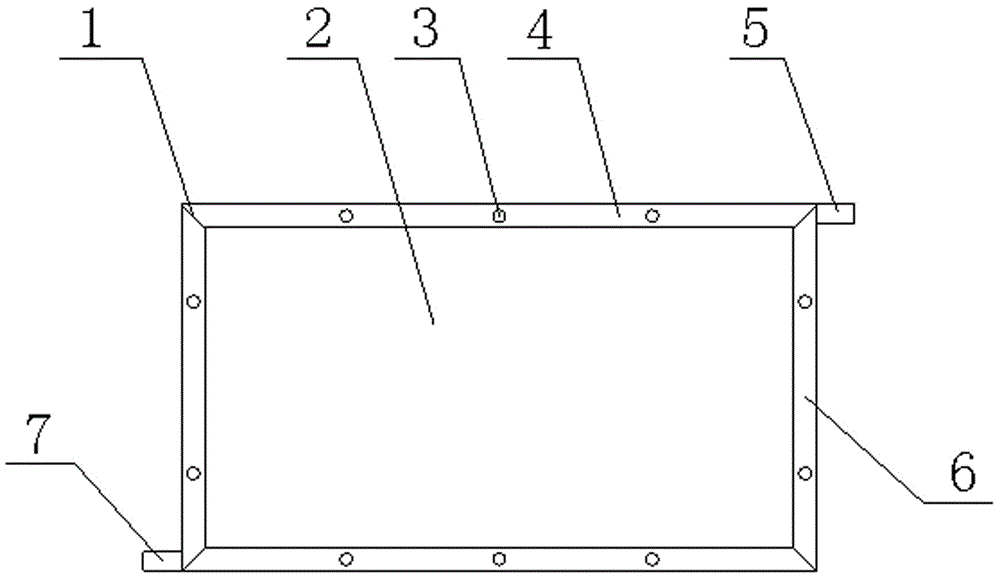

The invention relates to the technical field of electrolytic cells, which discloses a preparation process for an anode gasket for an ion-exchange membrane electrolytic cell, which sequentially includes a batching process, a mixing process, an extrusion molding process and a molding vulcanization process, and the batching process is as follows: Proportionate ingredients: 100 parts of binary ethylene propylene rubber raw material, 85-90 parts of natural gas semi-reinforced carbon black raw material, 2.5-3.0 parts of molded flow aid, 2-5 parts of anti-aging agent, 2-5 parts of peroxide crosslinking agent parts, 3 to 5 parts of crosslinking aids, and 0.5 to 1.0 parts of liquid polybutadiene; the mixing process includes using an internal mixer to carry out one-stage mixing and two-stage mixing successively; the extrusion molding process includes using The extruder extrudes the compounded compound into shape; the molding vulcanization process includes adding the extruded compound into a mold for molding, heating and vulcanization to make the anode gasket. The invention can improve the corrosion resistance of the anode gasket, prolong the overall service life of the electrolytic cell, and reduce the maintenance cost of the electrolytic cell.

Owner:JIANGYIN ANCAN ELECTROCHEM EQUIP

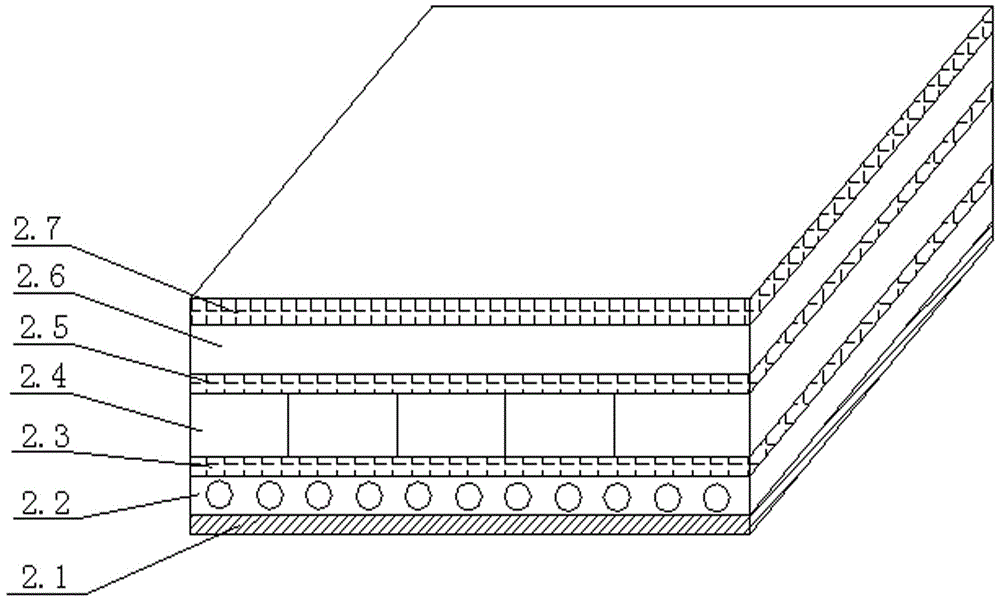

A high-performance solar module in a reliable and durable eva package

ActiveCN105449021BHigh light transmittanceImprove heat resistancePhotovoltaicsPhotovoltaic energy generationEngineeringSolar module

The invention relates to a high-performance solar module packaged through reliable durable EVA, and belongs to the technical field of solar devices. The module comprises a frame and a cell unit in the frame, and two opposite side edges of the frame are respectively provided with a water inlet and a water outlet. The cell unit comprises a substrate, and the substrate is sequentially provided with a heat-dissipation layer, a first film layer, a solar cell layer, a second film layer, a transparent cover plate, and a third film layer. The interior of the heat-dissipation layer is uniformly provided with column tubes at intervals, and two ends of each column are respectively communicated with the water inlet and the water outlet. The first, second and third films are all EVA films. The module is sealed through three EVA films, thereby guaranteeing the sealingness of a solar cell and the working stability.

Owner:RENESOLA JIANGSU LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com