Preparation method of biodegradable cast film

A casting film, biological technology, applied in the field of biodegradable casting film preparation, can solve the problems of uneven film thickness, difficult to control transparency, poor hand feeling, etc., achieve good heat resistance and impact performance, excellent The effect of biodegradability and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

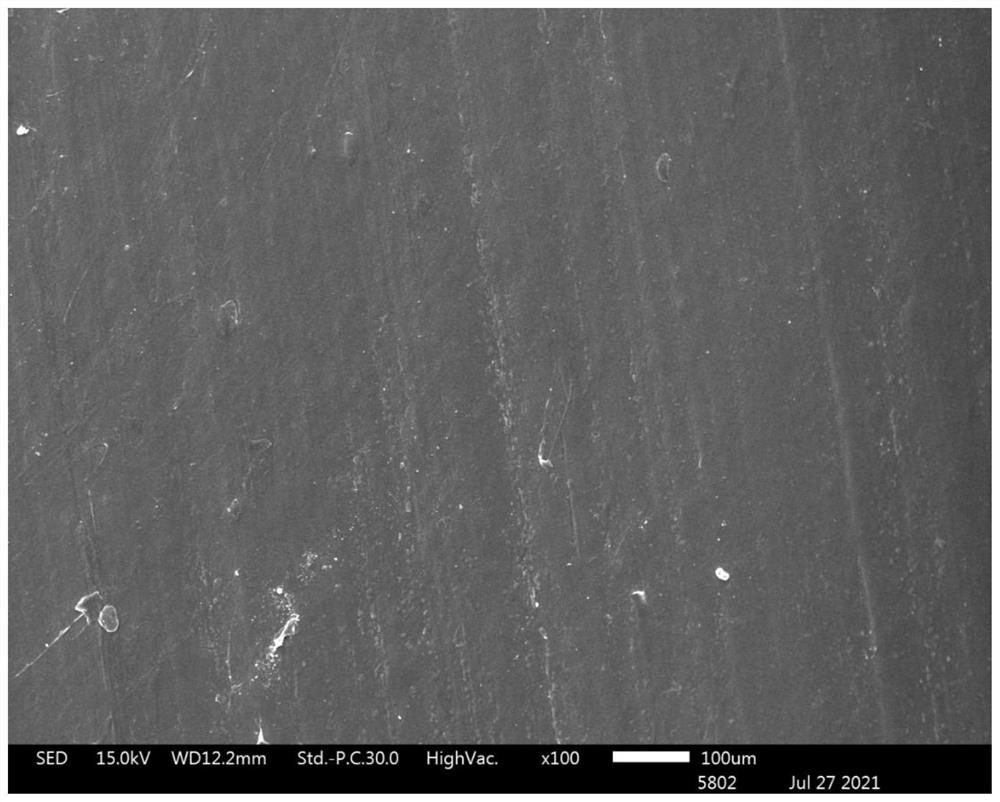

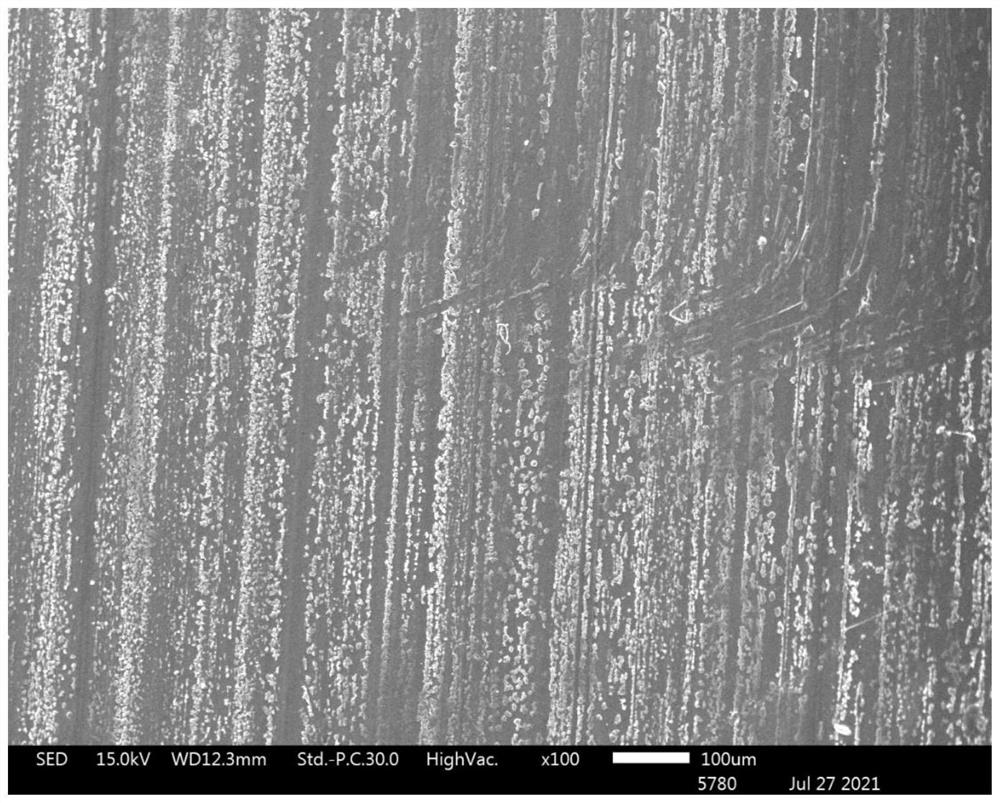

Image

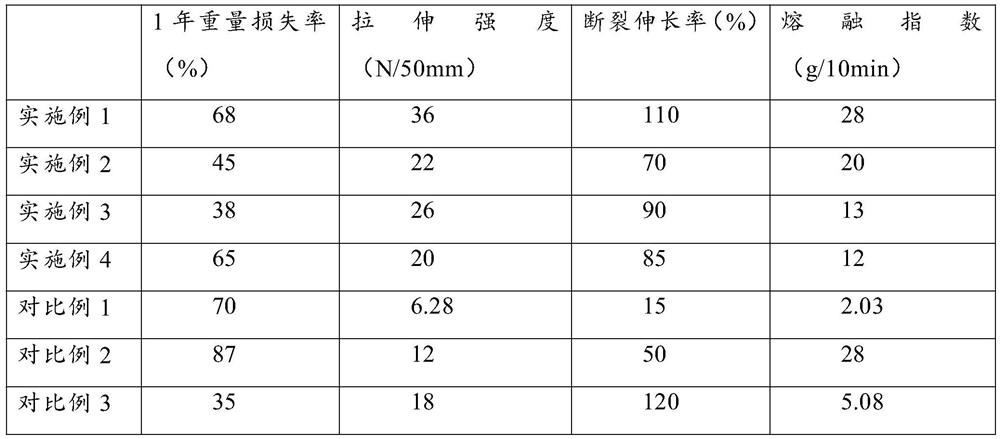

Examples

preparation example Construction

[0034] A preparation method of a biodegradable casting film, comprising the following steps:

[0035] S1. Composite material preparation

[0036]PLA (polylactic acid), PBAT (polyadipate / butylene terephthalate) and polyester chain extender are melt-blended to obtain a composite material; wherein, PLA and PBAT are based on (15%-85 %): (85% to 15%) for blending, and the chain extender accounts for 1% to 15% of the total mass of PLA and PBAT. The polyester chain extender is one of polyol, polyamine or multiple epoxy molecule chain extenders, and the range of functionality n of the chain extender is 2≤n≤4; the preferred functionality is 3 multiple epoxy molecules Compounds used as chain extenders include triglycidyl isocyanurate, glycerol triglycidyl ether, or trimethylolpropane triglycidyl ether. Polyol chain extenders include 1,4-butanediol, 1,6-hexanediol, trimethylolpropane, diethylene glycol, triethylene glycol, neopentyl glycol and diethylaminoethanol; Chaining agents incl...

Embodiment 1

[0049] This embodiment provides a method for preparing a biodegradable cast film, comprising the following steps:

[0050] S1. Composite material preparation

[0051] PLA, PBAT and triglycidyl isocyanurate chain extender are carried out melt blending processing, obtain composite material; Wherein the ratio of PLA, PBAT is 70%: 30%, triglycidyl isocyanurate The ester chain extender accounts for 5% of the total mass of PLA and PBAT; during the melt blending process, the vacuum degree of the melt is kept less than -0.1MPa, the temperature is 200°C, and the time is 40min;

[0052] S2. Preparation of high fluidity biodegradable materials

[0053] Melt blend the composite material obtained in step S1 with the epoxy soybean oil dispersion lubricant at 160°C for 40 minutes to obtain a high fluidity biodegradable material; the epoxy soybean oil dispersion lubricant accounts for 1% of the composite material 2%;

[0054] S3. Preparation of biodegradable cast film

[0055] S31. Pour t...

Embodiment 2

[0062] This embodiment provides a method for preparing a biodegradable cast film. Compared with Example 1, the difference is that in step S1, the ratio of PLA and PBAT is 50%:50%, and the rest are roughly the same as those in the implementation. Example 1 is the same and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com