Preparation method of adhesive for polarizer and preparation method of polarizer

A technology of polarizers and adhesives, applied in the direction of adhesive types, polymer adhesive additives, unsaturated alcohol copolymer adhesives, etc., can solve the problem of poor high temperature resistance, high humidity and high temperature resistance, and cannot meet the requirements Product use requirements, the effect of bonding and other problems, to achieve good high temperature yellowing performance, good bonding performance, improve the effect of bonding performance and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

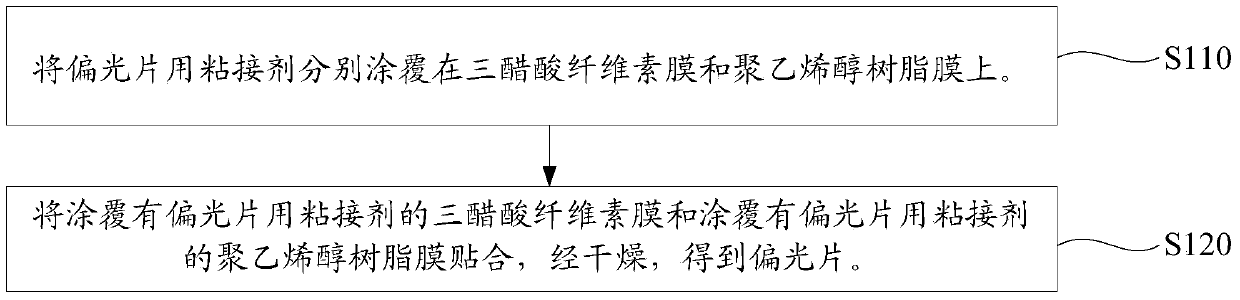

[0025] Such as figure 1 As shown, the preparation method of a polarizer in one embodiment includes the following preparation steps:

[0026] Step S110: Coating the adhesive for the polarizer on the cellulose triacetate film and the polyvinyl alcohol resin film respectively.

[0027] Specifically, the method of coating the adhesive agent for the polarizer on the cellulose triacetate film and the polyvinyl alcohol resin film is drop coating by rolling and spreading.

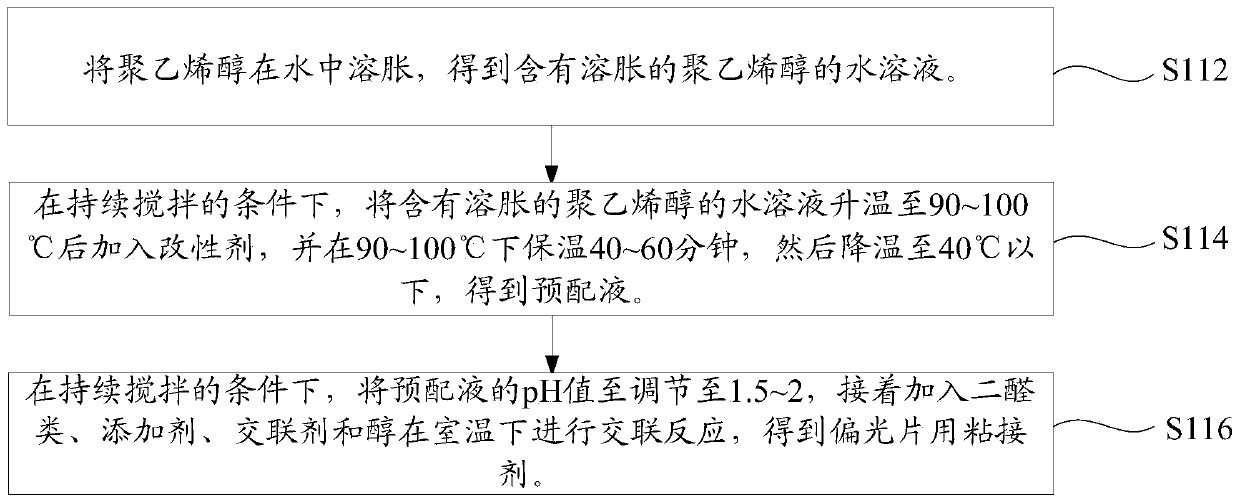

[0028] see figure 2 , wherein the adhesive for polarizers in step S110 is prepared by the following method:

[0029] Step S112: Swell the polyvinyl alcohol in water to obtain an aqueous solution containing swollen polyvinyl alcohol.

[0030] Among them, the degree of polymerization of polyvinyl alcohol is 1700-2500, so as to ensure the solid content and viscosity of the binder and ensure the bonding effect.

[0031] Among them, the degree of alcoholysis of polyvinyl alcohol is 85-99%.

[0032] Wherein, the st...

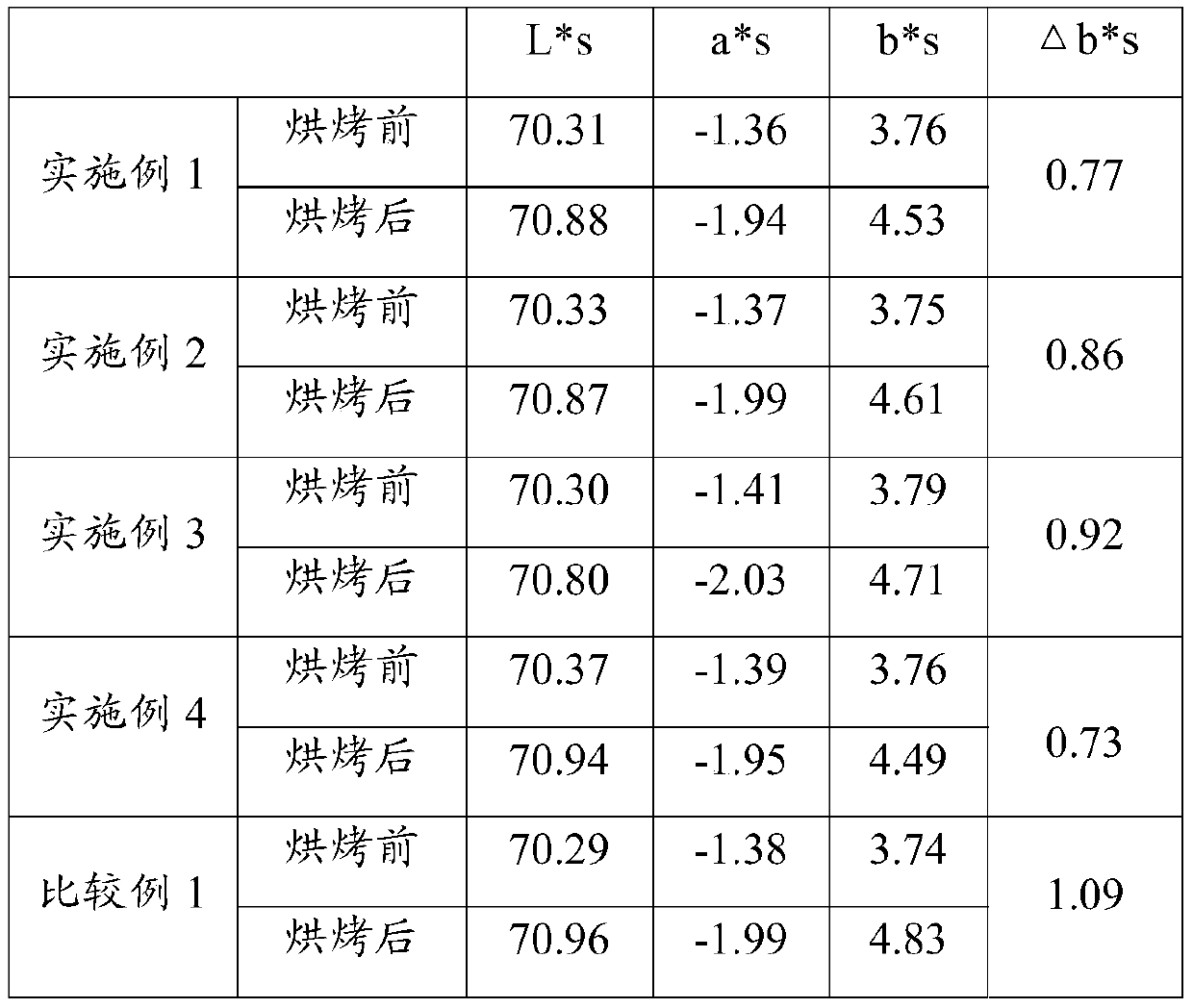

Embodiment 1

[0055] The preparation process of the polarizer of the present embodiment is as follows:

[0056] (1) Add polyvinyl alcohol powder into water, and soak at room temperature for 5 hours to obtain a soaking solution containing polyvinyl alcohol. Wherein, the degree of polymerization of the polyvinyl alcohol powder is 1700, and the alcoholysis degree of the polyvinyl alcohol is 88%. In the soaking solution containing the polyvinyl alcohol, the mass percentage of the polyvinyl alcohol is 10%.

[0057] (2) Under the condition of continuous stirring, the soaking solution containing polyvinyl alcohol was heated from room temperature for 35 minutes to 60°C, and kept at 60°C for 30 minutes to obtain an aqueous solution containing swollen polyvinyl alcohol. The aqueous solution of polyvinyl alcohol is heated from 60°C to 95°C for 35 minutes, then polyethylene glycol is added, kept at 95°C for 60 minutes, and then cooled down to 40°C for 45 minutes to obtain a pre-mixed solution. Wherein...

Embodiment 2

[0064] The preparation process of the polarizer of the present embodiment is as follows:

[0065] (1) Add polyvinyl alcohol powder into water, and soak at room temperature for 3 hours to obtain a soaking solution containing polyvinyl alcohol. Wherein, the degree of polymerization of polyvinyl alcohol is 2000, and the degree of alcoholysis of polyvinyl alcohol is 99%. In the soaking solution containing polyvinyl alcohol, the mass percentage of polyvinyl alcohol is 5%.

[0066] (2) Under the condition of continuous stirring, the soaking solution containing polyvinyl alcohol was heated from room temperature for 30 minutes to 50°C, and kept at 50°C for 20 minutes to obtain an aqueous solution containing swollen polyvinyl alcohol, and the immersion solution containing swollen The aqueous solution of polyvinyl alcohol is heated from 50°C to 90°C for 30 minutes, then polyethylene glycol is added, kept at 90°C for 60 minutes, and then cooled for 60 minutes to 30°C to obtain a pre-mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com