Cotton sweat-resistant formaldehyde-free color fixing agent and preparation method and application thereof

A formaldehyde-free color-fixing agent and perspiration-resistant technology, which is applied in the field of textile and chemical printing and dyeing auxiliaries, can solve the problems of uneven quality, formaldehyde content, and non-environmental protection, so as to improve quality, improve color fastness to perspiration, Improvement of color fastness to washing and color fastness to perspiration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

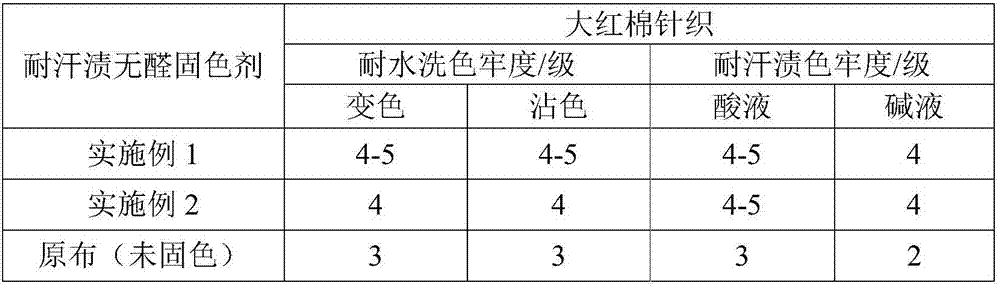

Examples

Embodiment 1

[0022] The following raw materials are obtained in parts by weight: 60 parts of unsaturated quaternary ammonium salt olefin (dimethyl diallyl ammonium chloride), 12 parts of functional monomer (1-vinylimidazole), 8 parts of water-soluble unsaturated Polyoxyalkyl ether (allyl alcohol polyoxyalkyl ether), 5 parts of crosslinking reactive monomer (diacetone acrylamide), 0.05 part of self-crosslinking accelerator (adipic hydrazide), metal ion chelating agent 0.01 Parts, 30 parts of deionized water, 1.0 parts of initiator (ammonium persulfate-sodium bisulfite).

[0023] The specific preparation process of the perspiration-resistant and formaldehyde-free color-fixing agent for cotton involved in the present invention is as follows.

[0024] The metal ion chelating agent is formulated into an aqueous solution of the metal ion chelating agent through deionized water, and the initiator is formulated into an aqueous solution of the initiator through deionized water. The metal ion chela...

Embodiment 2

[0032]The following raw materials are obtained in parts by weight: 80 parts of unsaturated quaternary ammonium salt olefin (methacryloyloxyethylene trimethylammonium chloride), 10 parts of functional monomer (1-vinylimidazole), 10 parts of water-soluble Unsaturated polyoxyalkyl ether (allyl alcohol polyoxyalkyl ether), 6 parts of crosslinking reactive monomer (diacetone acrylamide), 0.08 part of self-crosslinking accelerator (adipic hydrazide), metal ion chelate 0.008 parts of mixture, 40 parts of deionized water, 1.2 parts of initiator (ammonium persulfate-sodium bisulfite).

[0033] The specific preparation process of the perspiration-resistant and formaldehyde-free color-fixing agent for cotton involved in the present invention is as follows.

[0034] The metal ion chelating agent is formulated into an aqueous solution of the metal ion chelating agent through deionized water, and the initiator is formulated into an aqueous solution of the initiator through deionized water. ...

Embodiment 3

[0042] The following raw materials are obtained in parts by weight: 100 parts of unsaturated quaternary ammonium salt olefin (diethyl diallyl ammonium chloride), 8 parts of functional monomer (1-vinylimidazole), 11 parts of water-soluble unsaturated Polyoxyalkyl ether (allyl alcohol polyoxyalkyl ether), 8 parts of crosslinking reactive monomer (diacetone acrylamide), 0.07 part of self-crosslinking accelerator (adipic hydrazide), metal ion chelating agent 0.008 Parts, 40 parts of deionized water, 1.2 parts of initiator (ammonium persulfate-sodium bisulfite).

[0043] The specific preparation process of the perspiration-resistant and formaldehyde-free color-fixing agent for cotton involved in the present invention is as follows.

[0044] The metal ion chelating agent is formulated into an aqueous solution of the metal ion chelating agent through deionized water, and the initiator is formulated into an aqueous solution of the initiator through deionized water. The metal ion chel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com