Environment-friendly processing technology for improving soil release performance of resin finishing

A technology of resin finishing and processing technology, which is applied in fiber treatment, plant fiber, textiles and papermaking, etc. It can solve the problems of unsatisfactory decontamination effect, low energy consumption and durability, poor washing resistance, etc., and achieve good promotion Foreground, good penetration performance, reasonable configuration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

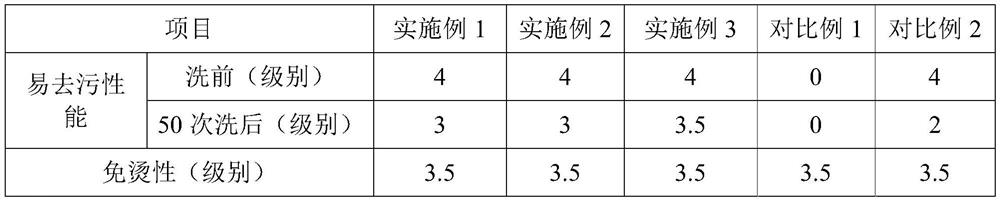

Examples

Embodiment 1

[0031] An environmentally friendly processing technology for improving the easy decontamination performance of resin finishing, the pure cotton fabric is processed by singeing → de-cooking → bleaching → mercerizing → whitening or dyeing to obtain semi-finished products;

[0032] Pure cotton semi-products padding resin and fluorine-free environment-friendly and easy-to-decontaminate finishing liquid. The finishing liquid is composed of the following raw materials with the following mass and volume concentrations:

[0033] Moisture cross-linking resin AMC: 180g / L, resin catalyst LRMC: 90g / L, fiber protection agent ACN: 35g / L, softener LA: 40g / L, fluorine-free decontamination additive TF-9901B: 40g / L , and the rest is water. The nip rate of the fabric is 70%, and the moisture content of the fabric after drying is 7%.

[0034] The fabric with a moisture content of 7% was rolled and sealed, and was stacked in an environment of 40 ° C for 24 hours for reaction. After the reaction, ...

Embodiment 2

[0037] An environmentally friendly processing technology for improving the easy decontamination performance of resin finishing, the pure cotton fabric is processed by singeing → de-cooking → bleaching → mercerizing → whitening or dyeing to obtain semi-finished products;

[0038] Padding resin for cotton semi-products and fluorine-free, environmentally friendly and easy-to-decontaminate finishing fluid, finishing fluid prescription: Moisture cross-linked resin AMC: 210g / L, resin catalyst LRMC: 110g / L, fiber protectant ACN: 30g / L, soft Agent LA: 40g / L, fluorine-free decontamination additive TF-9901B: 90g / L, the rest is water. The nip rate of the fabric is 65%, and the moisture content of the fabric after drying is 8%.

[0039] The fabric with a moisture content of 8% was rolled and sealed, and was stacked in an environment of 39 ° C for 22 hours for reaction. After the reaction, it was washed with a solution of soda ash concentration of 4 g / L, and then fully washed and dried at ...

Embodiment 3

[0042] An environmentally friendly processing technology for improving the easy decontamination performance of resin finishing, the pure cotton fabric is processed by singeing → de-cooking → bleaching → mercerizing → whitening or dyeing to obtain semi-finished products;

[0043] Padding resin for cotton semi-products and fluorine-free, environmentally friendly and easy-to-decontaminate finishing liquid, finishing liquid prescription: Moisture cross-linked resin AMC: 240g / L, resin catalyst LRMC: 120g / L, fiber protectant ACN: 40g / L, soft Agent LA: 35g / L, fluorine-free decontamination additive TF-9901B: 60g / L, the rest is water. The fabric nip rate is 60%, and the moisture content of the fabric after drying is 7.5%.

[0044]The fabric with a moisture content of 7.5% was rolled and sealed, and was stacked in an environment of 38 ° C for 20 hours for reaction. After the reaction, it was washed with a solution of soda ash concentration of 5 g / L, and then fully washed and dried at 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com