Nylon 66 composite material for connecting rod sleeve and preparation method thereof

A composite material and connecting rod sleeve technology, applied in the preparation of the nylon 66 composite material, in the field of nylon 66 composite material, can solve the problems of material properties, insufficient product quality, etc., and achieve strong plasticity, easy processing and molding, and excellent quality and performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment relates to a nylon 66 composite material used for a connecting rod sleeve and a preparation method thereof.

Embodiment 11

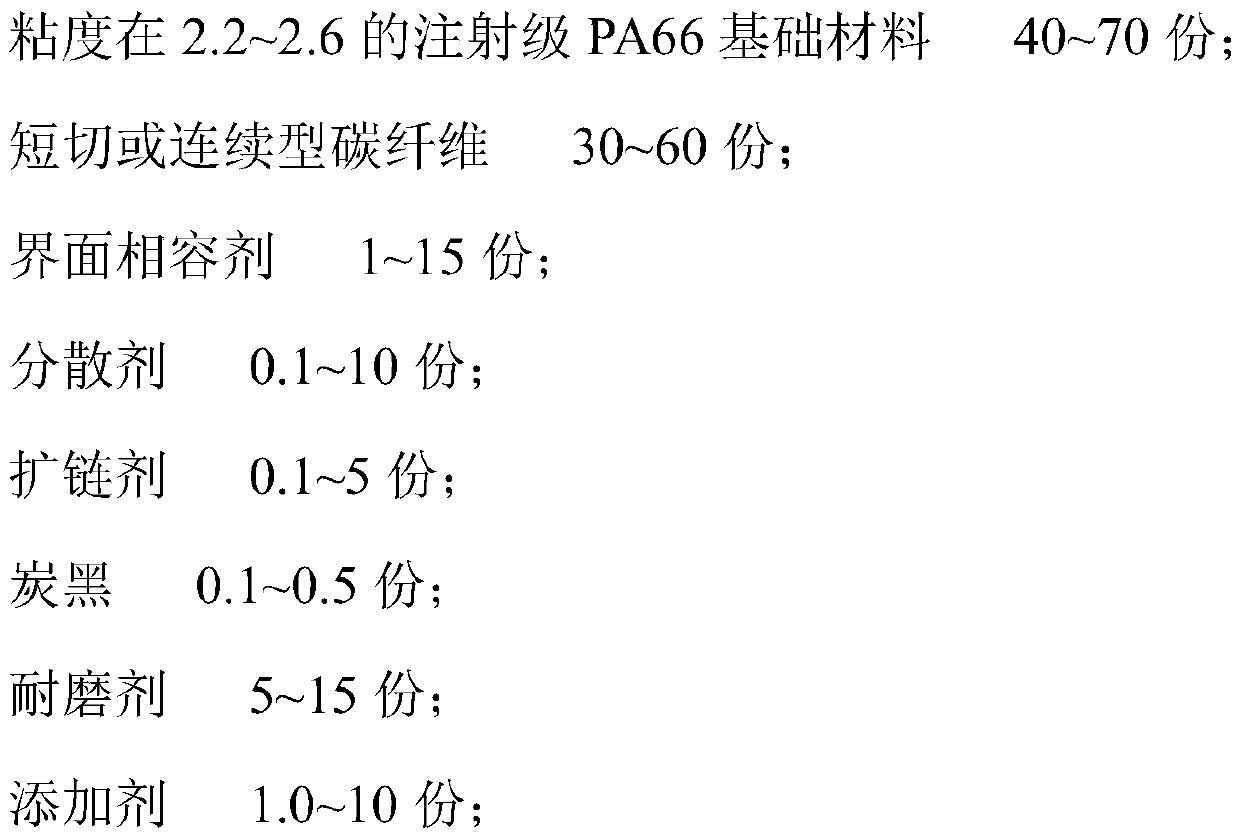

[0034] A nylon 66 composite material for connecting rod sleeves, comprising the following raw material components in parts by mass:

[0035]

[0036] The interfacial compatibilizer is prepared by melting and grafting 0.5g of isocene peroxide, 1.0g of acrylic acid monomer and 98.5g of polyethylene, and the MI value of polyethylene is 35g / 10min.

[0037] The preparation of the nylon 66 composite material for the connecting rod sleeve is carried out in the following steps:

[0038] a. Obtain interfacial compatibilizer: after carrying out dry material mixing (mixing speed is 300r / min, mixing time is 3min) of isocene peroxide, polyethylene and acrylic acid monomer, join twin-screw extruder, in reaction After reacting for 2.5 minutes at a temperature of 180-230°C and a screw speed of 500 rpm, the interfacial compatibilizer was obtained by melt extrusion;

[0039] b. Dry mix the PA66 base material, chain extender, carbon black, polytetrafluoroethylene, antioxidant and lubricant i...

Embodiment 12

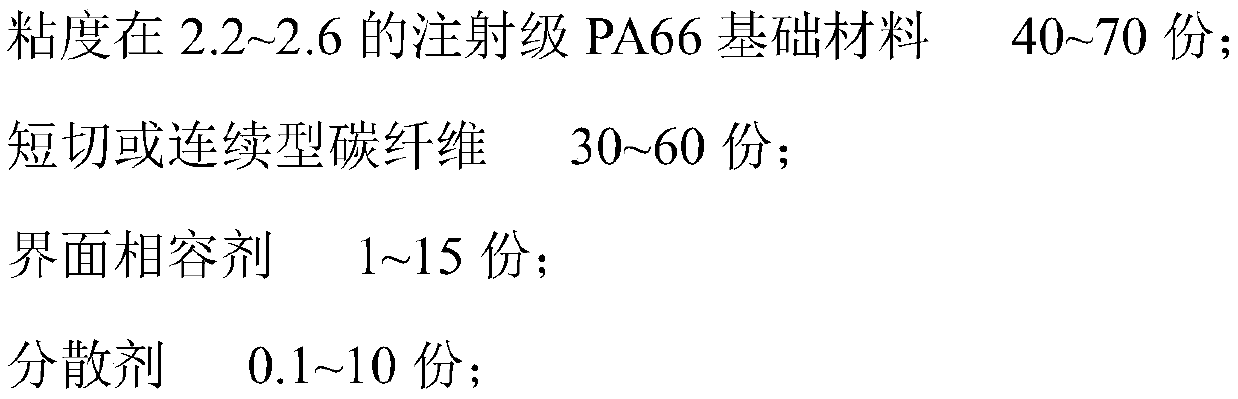

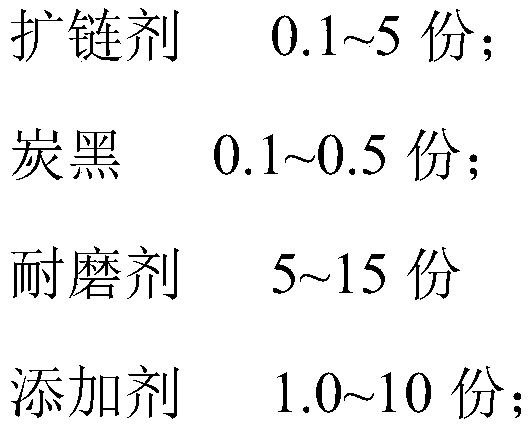

[0044]A nylon 66 composite material for connecting rod sleeves, comprising the following raw material components in parts by mass:

[0045]

[0046] The interfacial compatibilizer is prepared by melting and grafting 0.5g of isocene peroxide, 2.0g of acrylic acid derivative and 97.5g of polypropylene, and the MI value of polypropylene is 45g / 10min.

[0047] The preparation of the nylon 66 composite material for the connecting rod sleeve is carried out in the following steps:

[0048] a. Obtain interfacial compatibilizer: After mixing isocene peroxide, polypropylene and acrylic acid derivatives with dry materials (mixing speed is 800r / min, mixing time is 4min), add them to twin-screw extruder, After reacting for 2 minutes at a temperature of 180-230°C and a screw speed of 700rpm, the interfacial compatibilizer was obtained by melt extrusion;

[0049] b. Dry mix PA66 base material, chain extender, carbon black, molybdenum disulfide, antioxidant and lubricant in the raw materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com