A kind of preparation method of surface metallized aramid fiber

A kind of aramid fiber and surface metal technology, applied in the direction of fiber treatment, fiber type, metal material coating process, etc., can solve the problems of low utilization rate of palladium chloride, reduced fiber mechanical properties, low density, etc. performance, reduced operating steps, low density effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

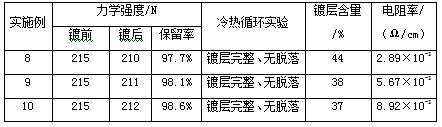

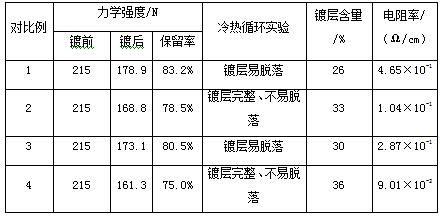

Examples

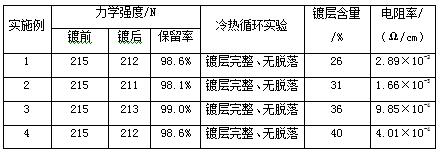

Embodiment 1

[0031] A preparation method for surface metallized aramid fibers, comprising the steps of:

[0032] ① Put the aramid fiber in the MF resin prepolymer with a solid content of 1% at 80°C for 10s. Dry the treated aramid fibers at 80°C after drying the surface moisture;

[0033] ② Put the aramid fiber treated in step ① in 20mg / L palladium chloride solution, activate it at 80°C for 1min, take it out, wash and dry;

[0034] ③Place the aramid fibers treated in step ② in a 10g / L sodium hypophosphite solution for 5 minutes, take it out, wash and dry;

[0035] ④Place the aramid fibers treated in step ③ in the silver plating solution at 40°C for 30 minutes, and the silver plating solution is composed of 30g / L silver nitrate, 30ml / L ammonia water, and 32ml / L formaldehyde solution (the formaldehyde content is 37%), then rinsed with water until neutral, and dried to obtain the surface silver-plated aramid fiber, and its properties are shown in Table 1.

Embodiment 2

[0037] A preparation method for surface metallized aramid fibers, comprising the steps of:

[0038] ① Place the aramid fiber in MF resin prepolymer with a solid content of 3% at 60°C for 30s. Dry the treated aramid fibers at 120°C after drying the surface moisture;

[0039] ②Place the aramid fiber treated in step ① in 100mg / L palladium chloride solution, activate it at 40°C for 5min, take it out, wash and dry;

[0040] ③Place the aramid fibers treated in step ② in 10g / L potassium hypophosphite solution for 5 minutes, take it out, wash and dry;

[0041] ④Place the aramid fiber treated in step ③ in the silver plating solution at 40°C for 30 minutes. The composition of the plating solution is the same as in Example 1, then rinse with water until neutral, and dry to obtain the surface silver-plated aramid fiber. Its properties are shown in the table 1.

Embodiment 3

[0043] A preparation method for surface metallized aramid fibers, comprising the steps of:

[0044] ① Place the aramid fiber in MF resin prepolymer with a solid content of 5% at 40°C for 30s. Dry the treated aramid fibers at 140°C after drying the surface moisture;

[0045] ② Put the aramid fiber treated in step ① in 60mg / L palladium chloride solution, activate it at 60°C for 2min, take it out, wash and dry;

[0046] ③Place the aramid fibers treated in step ② in a 60g / L sodium hypophosphite solution for 5 minutes, take it out, wash and dry;

[0047] ④Place the aramid fiber treated in step ③ in the silver plating solution at 40°C for 30 minutes. The composition of the plating solution is the same as in Example 1, then rinse with water until neutral, and dry to obtain the surface silver-plated aramid fiber. Its properties are shown in the table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com