Preparation method of cellulose microsphere adsorbent

A technology of cellulose microspheres and adsorbents, applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal oxides/hydroxides, etc., can solve the problems of large discharge, deep color, treatment and recovery Difficulty and other problems, to achieve the effect of moderate particle size, good adsorption performance, and large total surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

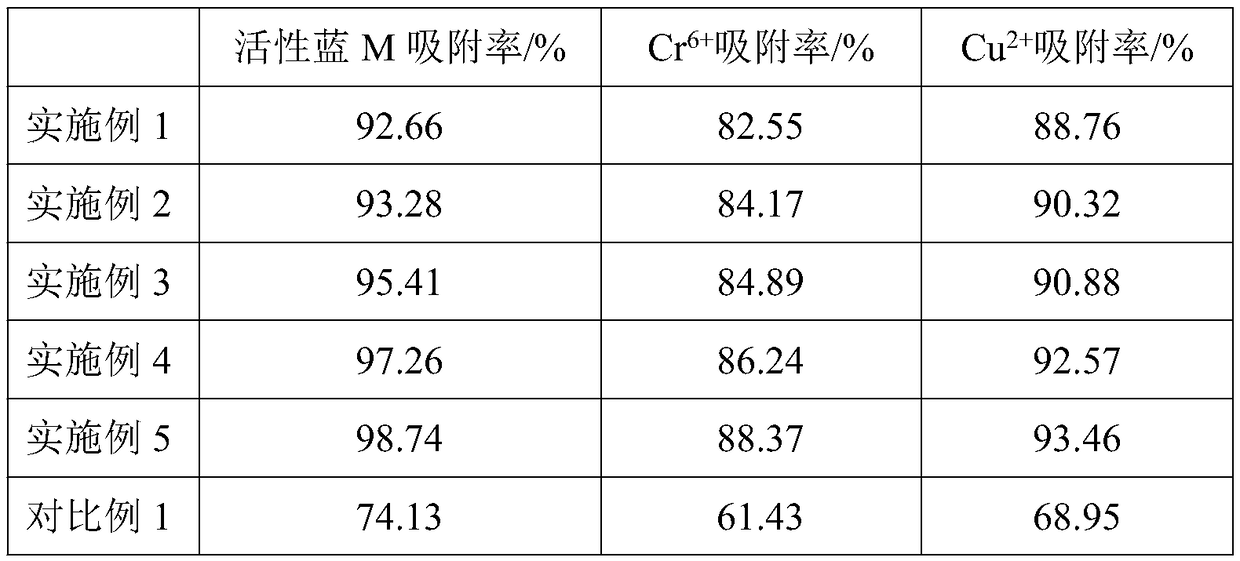

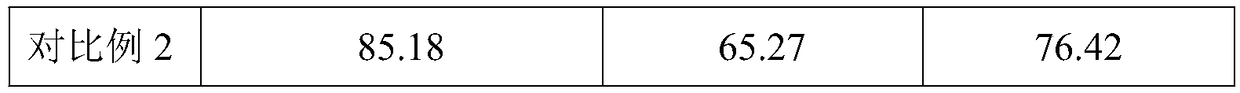

Examples

Embodiment 1

[0021] Step 1. Rinse the cotton stalks with distilled water, dry them and crush them mechanically to 50 mesh, add a mixture of xylene and ethanol to the cotton stalk powder, the ratio of solid to liquid is 1:10 (g / mL), wherein xylene The volume ratio with ethanol is 3:2, put it in a boiling water bath to react for 6h, take it out and wash it with ethanol three times, filter it with suction, add 0.1mol / L hydrochloric acid solution, the ratio of solid to liquid is 1:12 (g / mL), 90 ℃ water bath treatment for 1.5h, then add deionized water, the ratio of solid to liquid is 1:20 (g / mL), 85°C, 200r / min water bath reaction for 3h, suction filtration, dry at 60°C for later use;

[0022] Step 2. Add solution A to the pretreated cotton stalk powder in step 1, the ratio of solid to liquid is 1:20 (g / mL), solution A is 0.6mL hydrogen peroxide and 3g sodium hydroxide dissolved in 100mL deionized It is mixed with water, reacted at 90°C for 4 hours, filtered with suction, and dried at 60°C, th...

Embodiment 2

[0027] Step 1. Rinse the cotton stalks with distilled water, dry them and crush them mechanically to 50 mesh, add a mixture of xylene and ethanol to the cotton stalk powder, the ratio of solid to liquid is 1:10 (g / mL), wherein xylene The volume ratio with ethanol is 3:2, put it in a boiling water bath to react for 6h, take it out and wash it with ethanol three times, filter it with suction, add 0.1mol / L hydrochloric acid solution, the ratio of solid to liquid is 1:12 (g / mL), 90 ℃ water bath treatment for 1.5h, then add deionized water, the ratio of solid to liquid is 1:20 (g / mL), 85°C, 200r / min water bath reaction for 3h, suction filtration, dry at 60°C for later use;

[0028] Step 2. Add solution A to the pretreated cotton stalk powder in step 1, the ratio of solid to liquid is 1:20 (g / mL), solution A is 0.2mL hydrogen peroxide and 8g sodium hydroxide dissolved in 100mL deionized Mix in water, react at 60°C for 4 hours, filter with suction, dry at 60°C, add solution B to the ...

Embodiment 3

[0033] Step 1. Rinse the cotton stalks with distilled water, dry them and crush them mechanically to 50 mesh, add a mixture of xylene and ethanol to the cotton stalk powder, the ratio of solid to liquid is 1:10 (g / mL), wherein xylene The volume ratio with ethanol is 3:2, put it in a boiling water bath to react for 6h, take it out and wash it with ethanol three times, filter it with suction, add 0.1mol / L hydrochloric acid solution, the ratio of solid to liquid is 1:12 (g / mL), 90 ℃ water bath treatment for 1.5h, then add deionized water, the ratio of solid to liquid is 1:20 (g / mL), 85°C, 200r / min water bath reaction for 3h, suction filtration, dry at 60°C for later use;

[0034] Step 2: Add solution A to the pretreated cotton stalk powder in step 1, the ratio of solid to liquid is 1:20 (g / mL), solution A is 0.5mL hydrogen peroxide and 4g sodium hydroxide dissolved in 100mL deionized Mix in water, react at 80°C for 4 hours, filter with suction, dry at 60°C, add solution B to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com