Non-ironing fabric with high hang-dry appearance and manufacturing method thereof

Appearance and fabric technology, applied in the processing of textile materials, continuous processing of textile materials, textiles and papermaking, etc., can solve the problems that affect the appearance of fabrics, and the cotton fabric is easy to wrinkle, so as to improve the wrinkle recovery performance and improve the moisture content. Anti-wrinkle properties, reducing the effect of acid hydrolysis damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

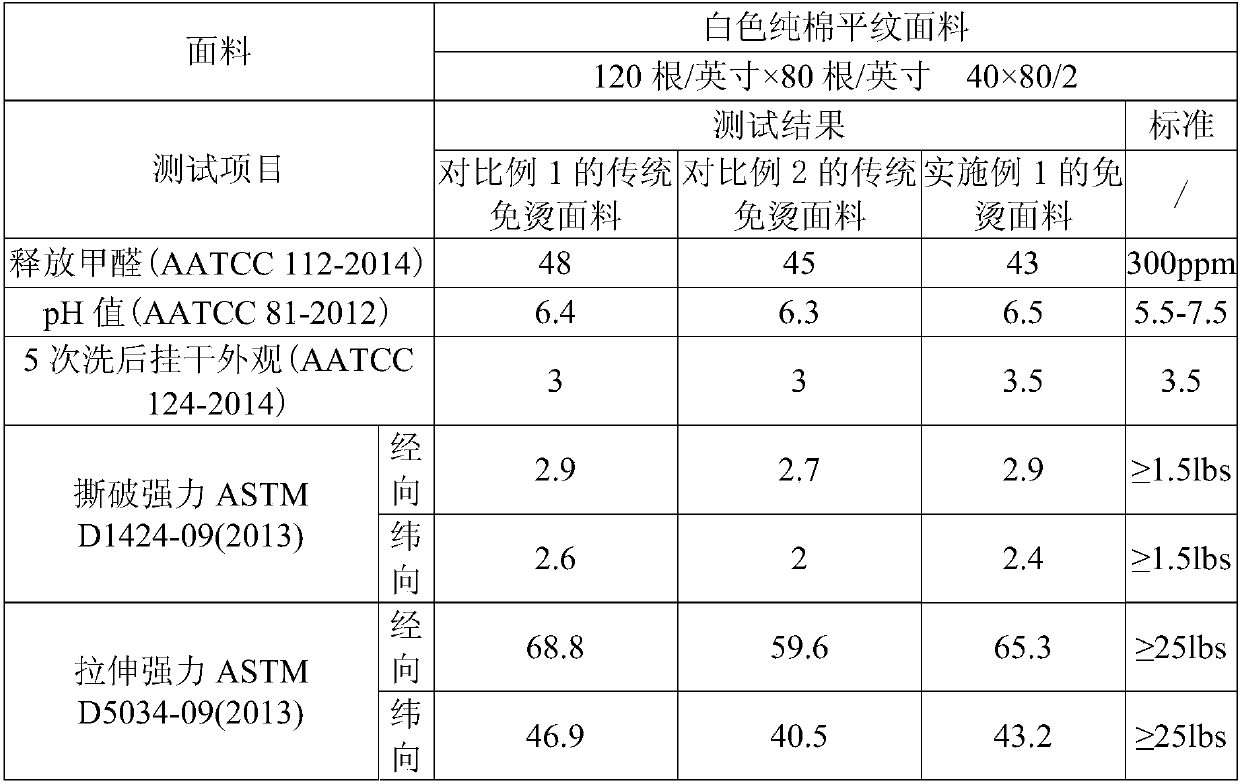

Embodiment 1

[0028] This embodiment 1 provides a preparation method of a pure cotton white plain weave high-hanging dry appearance non-ironing woven fabric, which specifically includes the following steps:

[0029] The plain weave cloth used has a specification of pure cotton 40s × pure cotton 80s / 2, and the warp density × weft density is 120 × 80 threads / inch.

[0030] Fabric padding is in the non-iron finishing liquid that pH is 1.8, and the total volume of non-ironing finishing liquid is 100% meter, and non-ironing finishing liquid contains 200g / L resin cross-linking agent ELF, 100g / L catalyst MC, 35g / L L powerful protective agent ECO, 40g / L softener RPU, 1g / L penetrating agent JFC-2, 5g / L acid-base buffer (HAC and NaAC). The fabric after the resin setting is stored in a constant temperature and humidity room with a humidity of 50% at 30°C for 10 hours, and then steamed on a steamer at a steaming temperature of 100°C and a steaming time of 5 minutes to finally obtain a high-hanging fabr...

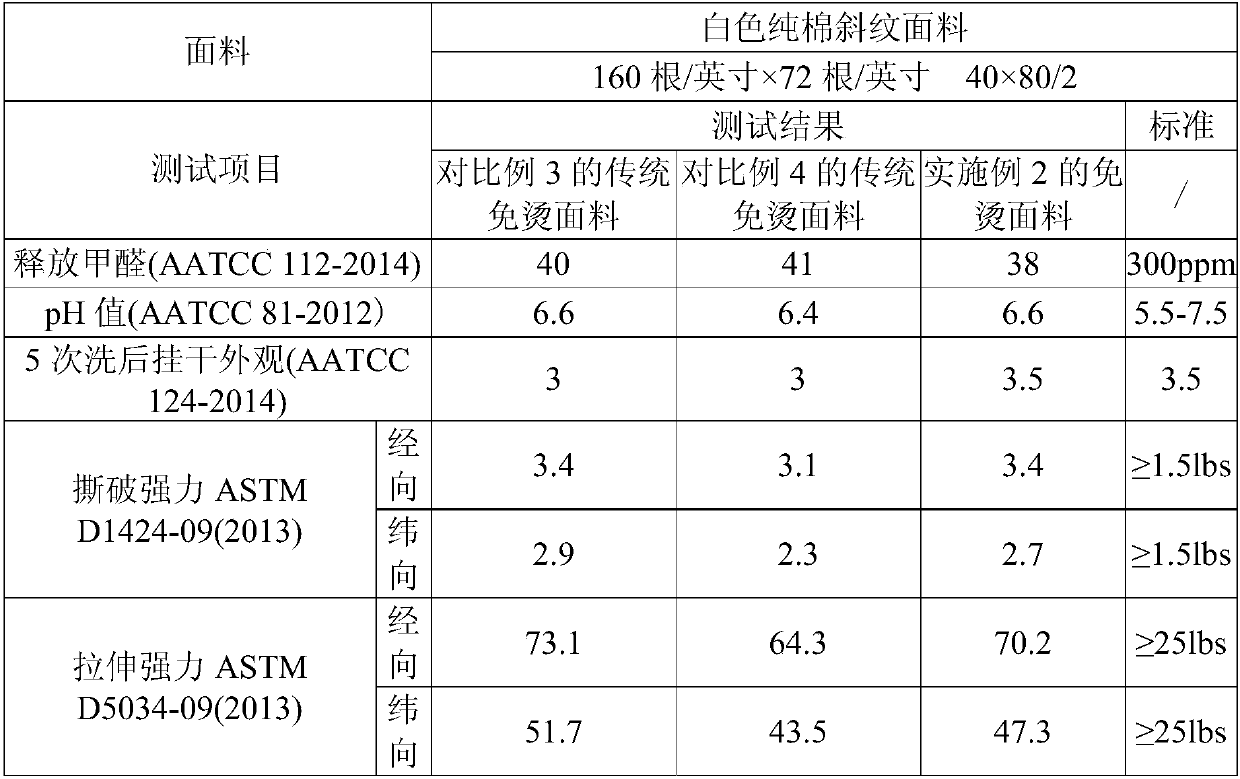

Embodiment 2

[0044] This embodiment provides a method for preparing a pure cotton white twill high-hanging dry appearance non-ironing woven fabric, which specifically includes the following steps:

[0045]It adopts twill fabric, and its specification is pure cotton 40s×pure cotton 80s / 2, and the warp density×weft density is 160×72 threads / inch.

[0046] The fabric is dipped in the non-iron finishing solution with a pH of 2, the total volume of the non-ironing finishing solution is 100%, and the non-ironing finishing solution contains 220g / L resin crosslinking agent ELF, 110g / L catalyst MC, 40g / L strong protective agent ECO, 35g / L softener RPU, 2g / L penetrating agent JFC-2, 10g / L acid-base buffer (H 2 CO 3 with NaHCO 3 ). h 2 CO 3 with NaHCO 3 The fabric after resin setting was stored in a constant temperature and humidity room at 35° C. and humidity 60% for 12 hours, and then steamed on a steamer at a steaming temperature of 110° C. and a steaming time of 4 minutes. Get a high-hang-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com