A kind of preparation technology of anode gasket for ion-exchange membrane electrolyzer

An ion-exchange membrane electrolyzer and its preparation technology are applied in the field of preparation of anode gaskets for ion-exchange membrane electrolyzers, which can solve problems such as reducing the overall service life of the electrolyzer, damaging the sealing effect of the rubber gasket, and increasing the maintenance cost of the electrolyzer. , to achieve the effect of enhancing elasticity, improving performance and optimizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

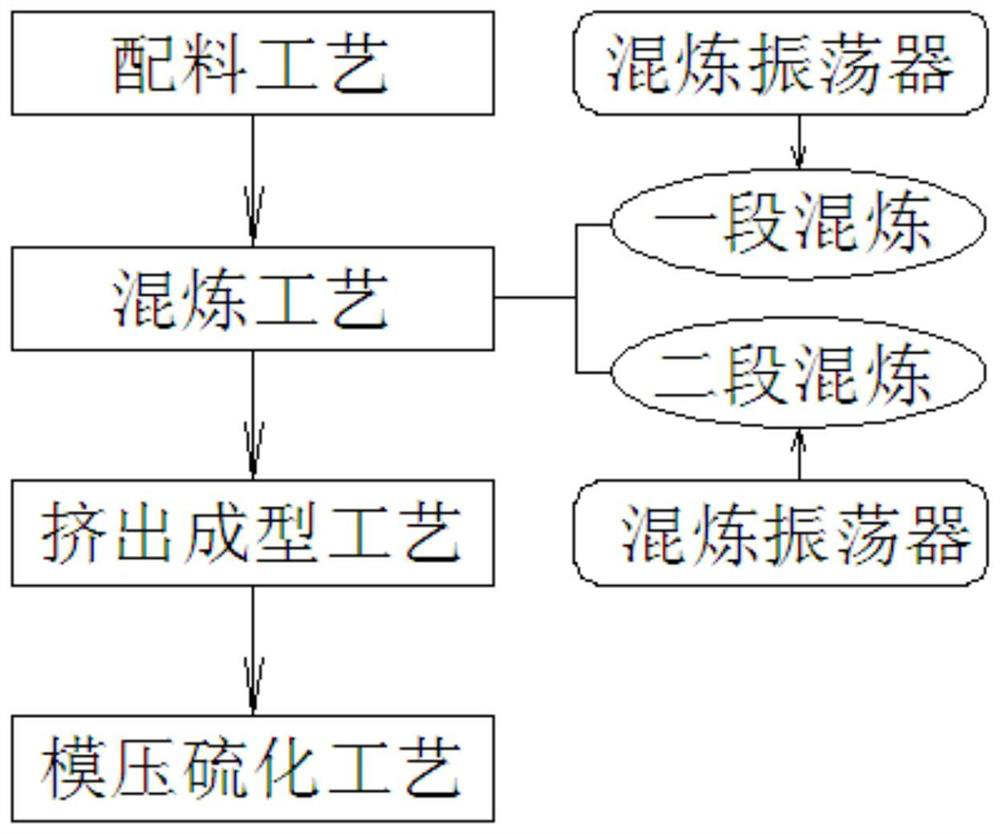

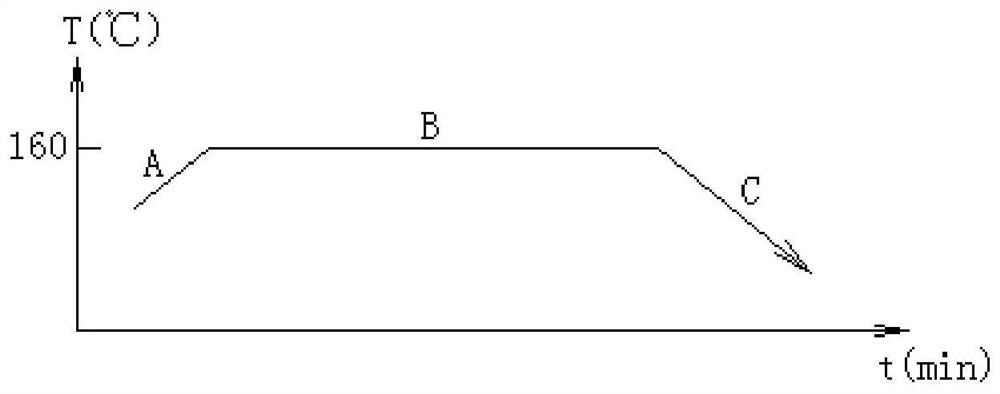

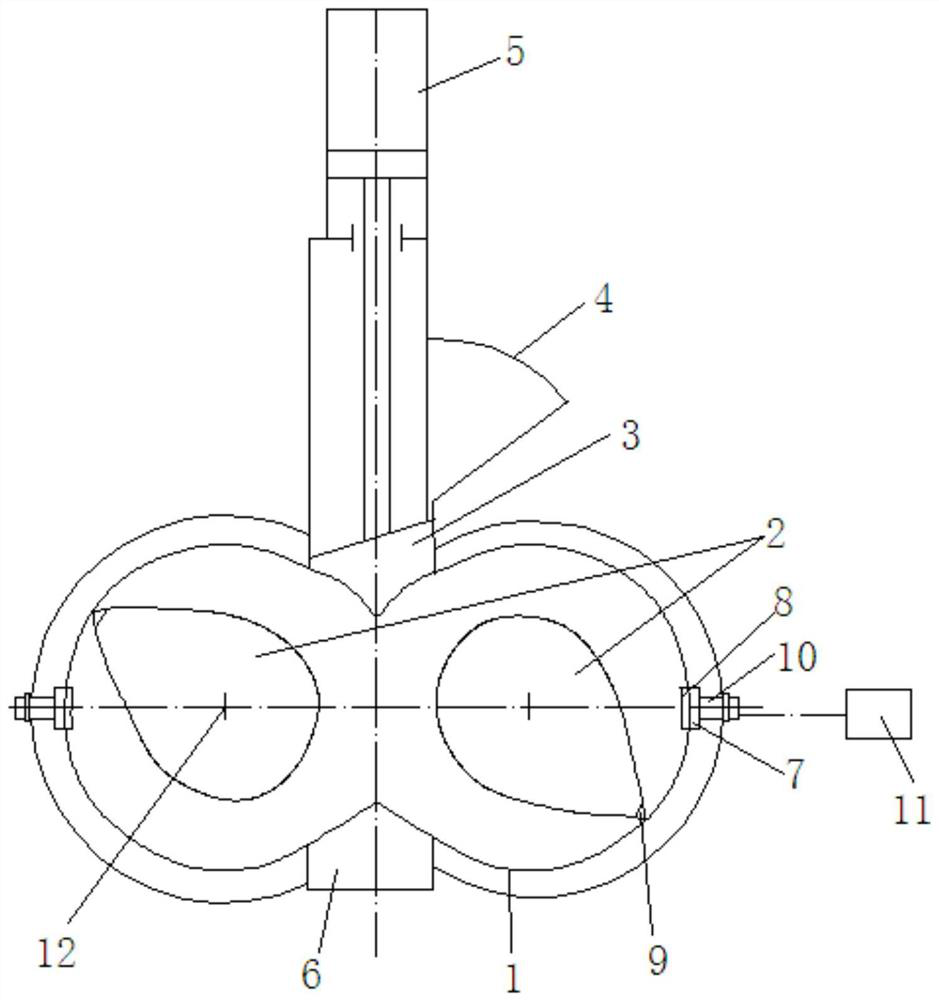

[0043] Such as Figures 1 to 4 Shown is an embodiment of the preparation process of an anode gasket for an ion-exchange membrane electrolyzer of the present invention, which successively includes a batching process, a mixing process, an extrusion molding process and a molding vulcanization process, wherein the batching process includes raw material mixing Ratio process steps, the raw material proportioning is carried out according to the following weight ratio: 100 parts of binary ethylene propylene rubber raw material, 85-90 parts of natural gas semi-reinforced carbon black raw material, 2.5-3.0 parts of molded flow aid, 2 parts of anti-aging agent ~5 parts, 2~5 parts of peroxide crosslinking agent, 3~5 parts of crosslinking auxiliary agent, 0.5~1.0 part of liquid polybutadiene; The mixing process includes using an internal mixer to carry out one stage of mixing, The process step of two-stage mixing; the extrusion molding process includes the process step of extruding the mixed...

Embodiment 2

[0068] Adopt some quantity of anode gaskets that are made by embodiment 1, carry out tensile strength, elongation at break and accelerated corrosion test respectively, and compare with the anode gaskets manufactured by conventional process, the results are as follows:

[0069] (1) Test results of tensile strength and elongation at break

[0070] Conventional Anode Gasket Anode gasket of the present invention Tensile strength MPa 9~12 10~14 Elongation at break% 270~300 280~320

[0071] (2) Accelerated corrosion test

[0072] 1. Test method: A number of anode gaskets prepared in Example 1 were used, soaked in the anode solution and cathode solution for a long time respectively, and the corrosion situation was observed regularly, and compared with the anode gaskets manufactured by conventional processes.

[0073] Wherein, the anode solution of the accelerated corrosion test is 5.2% NaClO solution, and the test temperature is normal temperature.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com