Light-moisture dual-curing polyurethane hot melt adhesive

A polyurethane hot-melt adhesive, dual-curing technology, used in the field of light-moisture curing polyurethane hot-melt adhesive and reactive polyurethane hot-melt adhesive, can solve the problems of poor thermal stability of adhesives, curing rate colloid bubbles, long pressure holding time, etc. , to achieve the effect of fast fixing, improving initial adhesion and avoiding air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

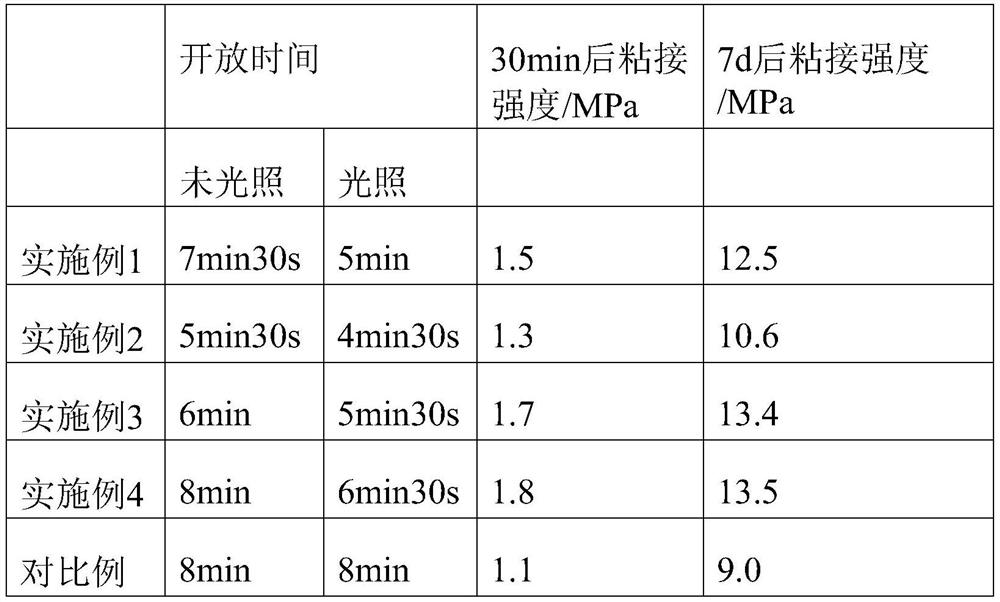

Examples

Embodiment 1

[0026] In parts by weight, 30 parts of polybutylene adipate polyol with a molecular weight of 2000, 24 parts of polyoxypropylene diol with a molecular weight of 1000, and 8 parts of polyhexamethylene phthalate diol with a molecular weight of 1000 12.5 parts of polyacrylic acid resin BR103 were added to the reaction flask, heated to 130-140°C, and vacuum dehydrated for 2 hours under the stirring condition of 350r / min; then, the temperature was lowered to 100°C, and 24 parts of 4,4'-diphenyl Methyl methane diisocyanate (MDI), after reacting at a stirring speed of 450r / min for 1h under vacuum conditions, add 1 part of photobase generator (WPG174), 0.3 part of photosensitizer (4-isopropylthioxanthone ), 0.2 parts of catalyst (DMDEE) and continue to stir for 30 minutes before discharging, and store in a vacuum-sealed dark place.

Embodiment 2

[0028] In parts by weight, 22 parts of polyhexamethylene adipate polyol with a molecular weight of 2000, 28 parts of polytetrahydrofuran with a molecular weight of 2000, 10 parts of polyneopentyl adipate diol with a molecular weight of 1000, 18 parts Add polyacrylic resin (BR116) into the reaction flask, heat to 120-140°C, and vacuum dehydrate for 2h under the stirring condition of 350r / min; then, cool down to 100°C, add 26 parts of 4,4-diisocyanate bicyclic Hexylmethane (HMDI), after reacting at a stirring speed of 450r / min for 1h under vacuum, add 3 parts of photobase generator (WPG174), 0.9 part of photosensitizer (2,4-diethylthioxanthene- 9-ketone), 0.1 part of catalyst (DMDEE) and continue to stir for 30 minutes before discharging, and store in a vacuum-sealed dark place.

Embodiment 3

[0030] In parts by weight, 18 parts of polyhexamethylene adipate diol with a molecular weight of 3500, 24 parts of polycaprolactone diol with a molecular weight of 2000, 17 parts of polycarbonate diol with a molecular weight of 1000, 17 parts of Add polyacrylic acid resin (ELVACITE4197) into the reaction flask, heat to 120-140°C, vacuum dehydrate for 2h under stirring condition of 350r / min; then, cool down to 100°C, add 18 parts of 4,4'-diphenylmethane Diisocyanate (MDI), after reacting at a stirring speed of 450r / min for 1h under vacuum conditions, add 4.46 parts of photobase generator (WPG174), 1.46 parts of photosensitizer (2-isopropylthioxanthone), 0.08 part of catalyst (DMDEE) was discharged after continuing to stir for 30 minutes, and stored in a vacuum seal and protected from light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com