Heat insulated anticorrosive coating for coiled material

A technology of anti-corrosion coils and heat-insulating fillers, applied in anti-corrosion coatings, polyester coatings, coatings, etc., can solve the problems of no heat-insulation and anti-corrosion coil coatings, and achieve significant heat insulation and energy saving effects, enhanced weather resistance, and excellent The effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

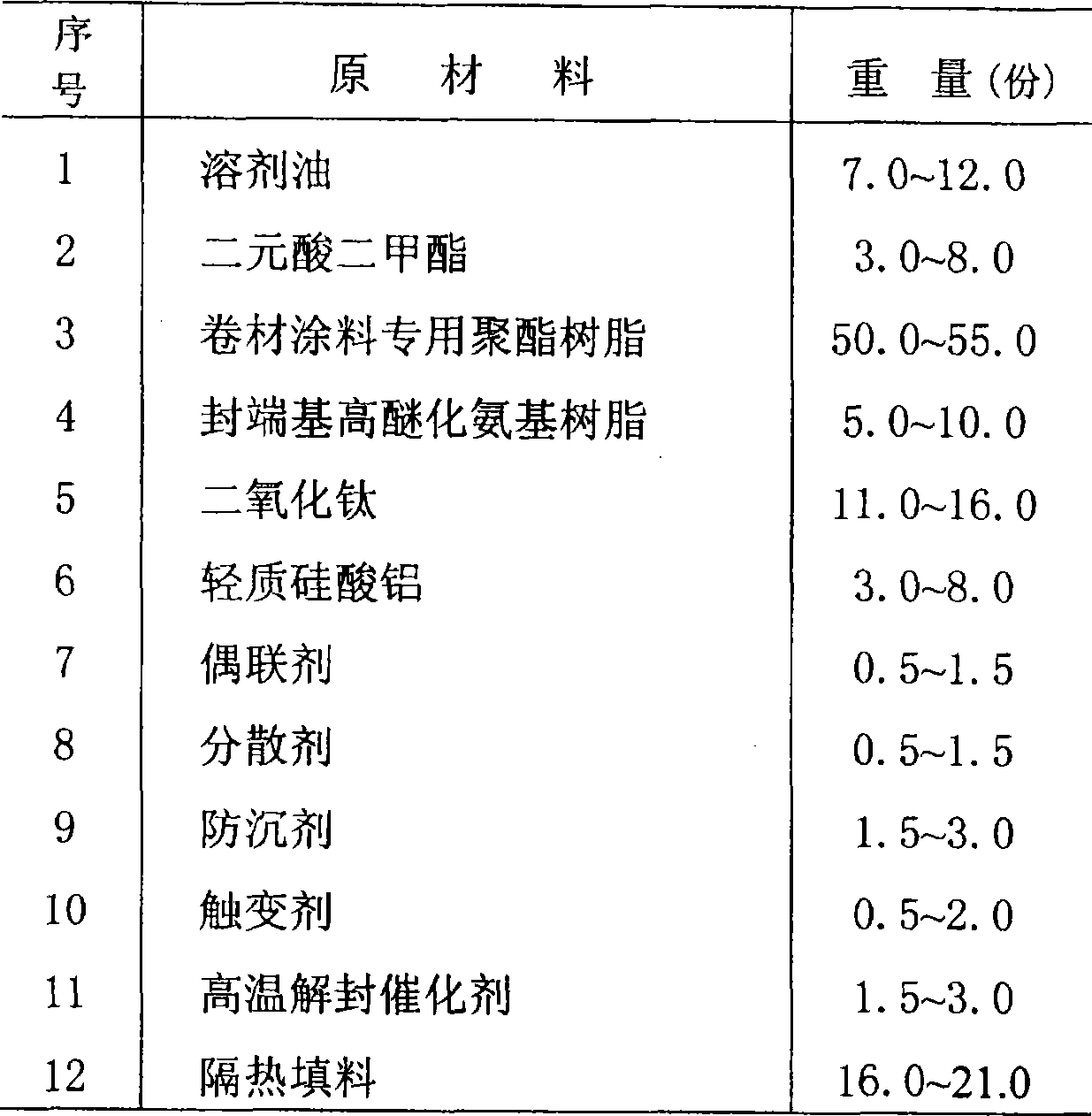

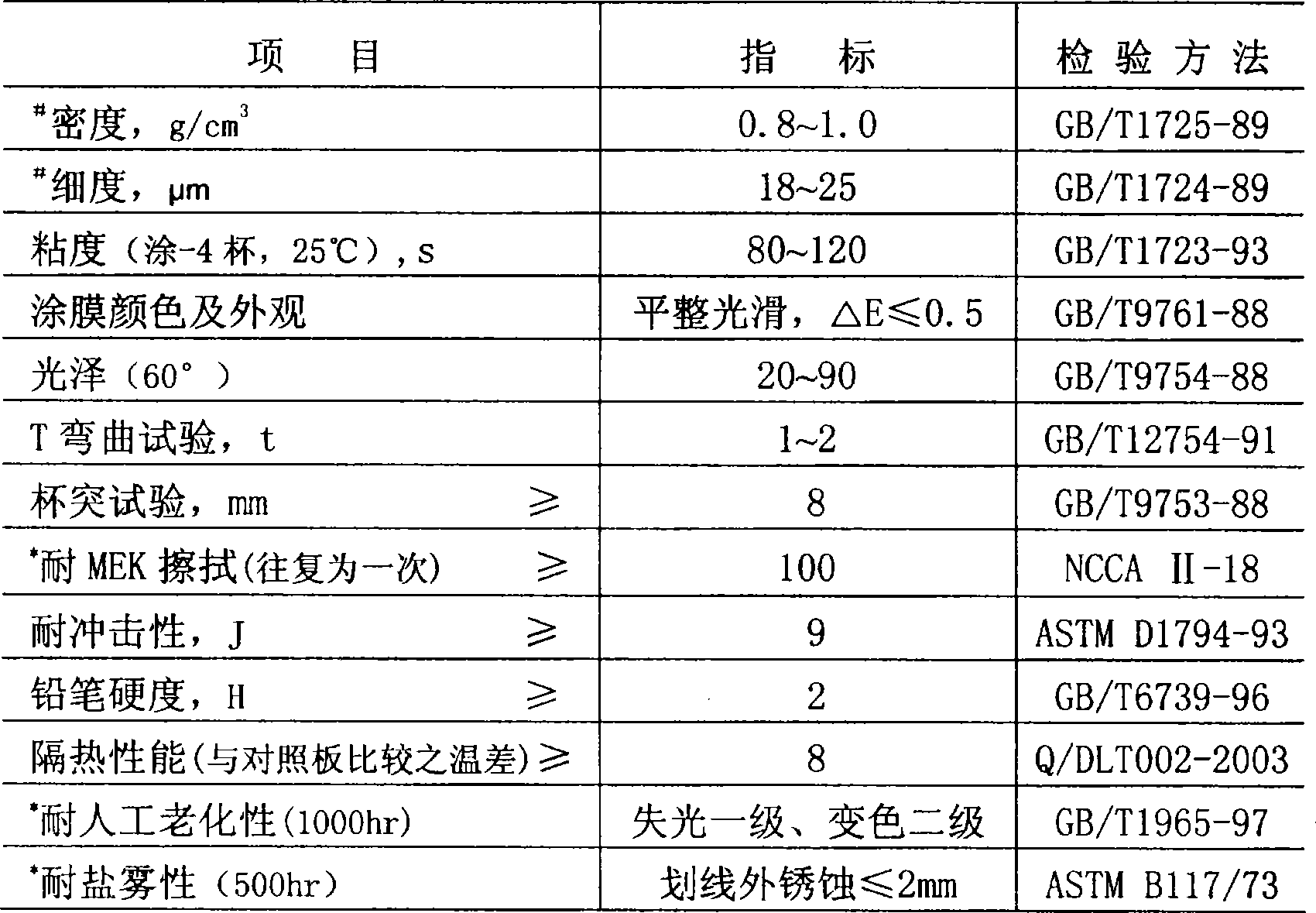

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with specific examples.

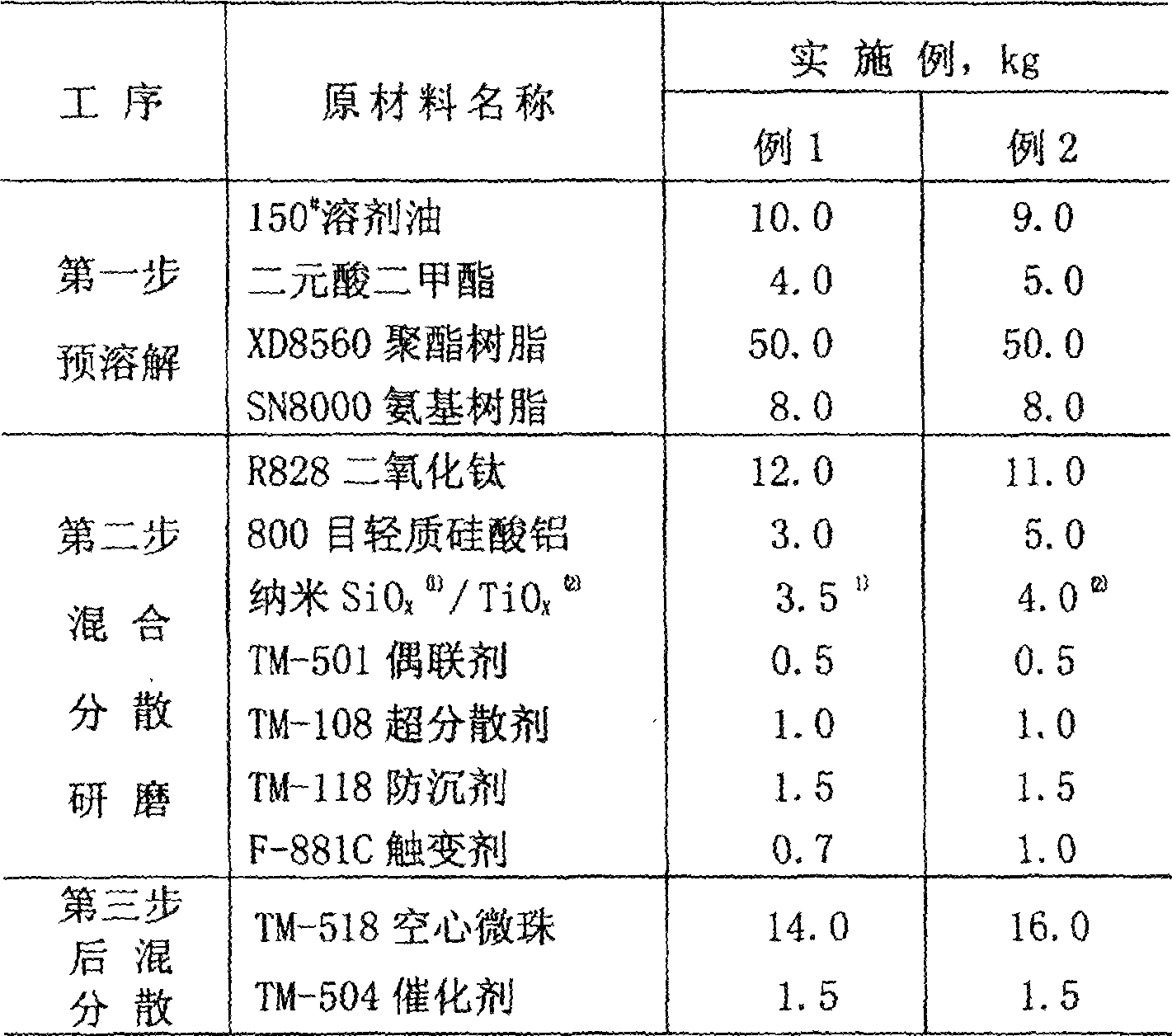

[0025] As shown in Table-2, the ratio of raw materials for two kinds of heat-insulating and anti-corrosion coil coatings:

[0026] Table-2 Raw material ratio of two kinds of thermal insulation and anticorrosion coil coatings

[0027]

[0028] The base material resin mentioned in the table is the saturated polyester of model XD8560 specially used for coil coatings; the amino cross-linking resin is melamine urea-formaldehyde resin with end-blocking group and high etherification degree and model SN8000.

[0029] The thermal insulation filler described in the table includes two types of materials, one is the hollow microsphere material, the other is the thermal insulation nano-oxide, and the hollow microsphere material is TM-518 vacuum glass microsphere or TM-519 hollow ceramic Microbeads or TM-520 fly ash bleached enamel hollow microspheres, accounting for 80% of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com