Rapid cross-linking method of cellulosic fiber and preparation method of antigen fibrillated cellulosic fiber

A technology of cellulose fiber and cross-linking method, which is applied in the field of functional cellulose fiber, can solve the problems of long time for fiber heat preservation in the production line, high industrial production cost, and large energy consumption, and achieve stable and controllable temperature, heating Good uniformity and prevent gelatinization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

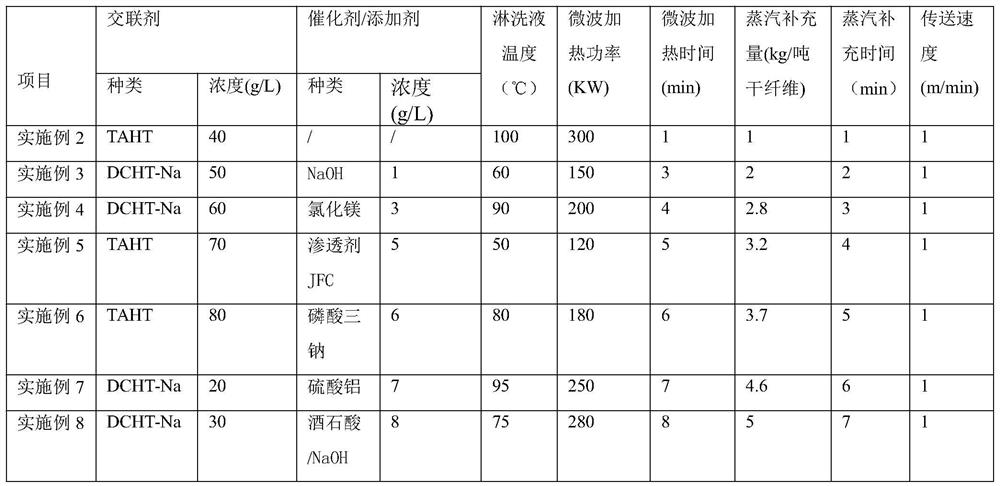

[0040] (1) The Lyocell staple fibers laid into blanket after cutting are carried out cross-linking agent treatment, and the cross-linking agent is 2,4-dichloro-6-hydroxyl-1,3,5-s-triazine sodium (DCHT-Na), NaOH is mixed with water to prepare eluent, the concentration of cross-linking agent in eluent is 20g / L, the concentration of NaOH in eluent is 2g / L, and the temperature of eluent is 70°C. Place the Lyocell staple fiber laid into a blanket on the conveyor belt, and spray the washing liquid on the cellulose fiber through the spray device to treat the fiber with a crosslinking agent.

[0041] (2) Send the fiber treated with the crosslinking agent into the microwave heating device, the microwave heating power is 100KW, the microwave heating time is 2min, the inlet temperature is 30°C, the transmission speed is 1m / min, and the fiber passes through the microwave heating device at a speed of 1m / min, when the cellulose fiber runs to the middle of the microwave heating device, the ...

Embodiment 9

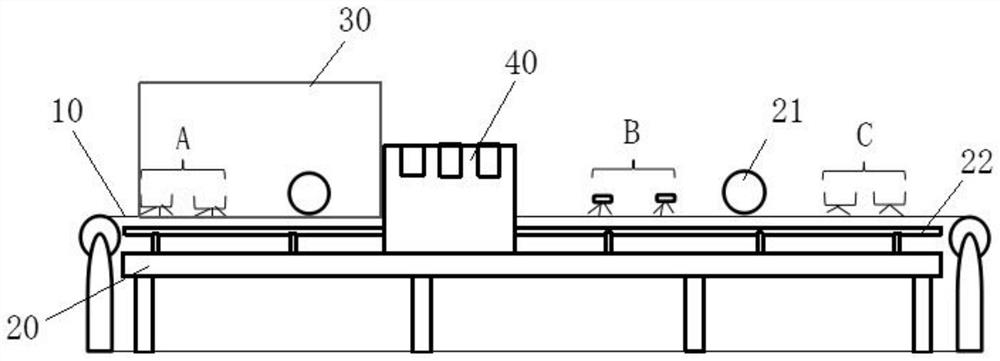

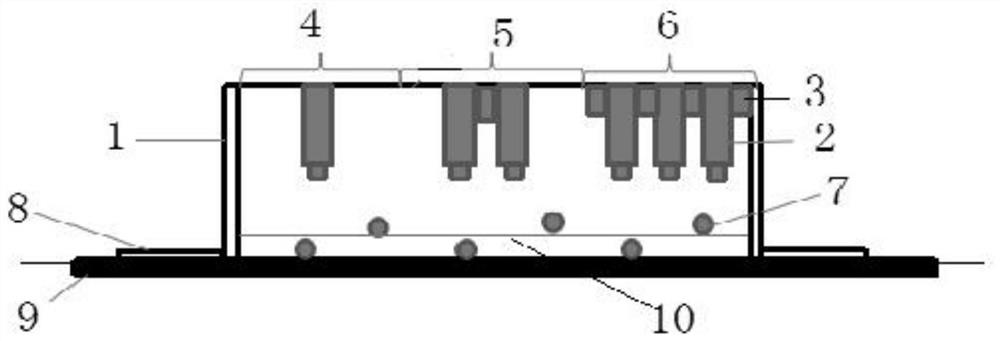

[0048] This example is a detailed description of the equipment used in the process of preparing fibrillated cellulose fibers in Examples 1-8. Such as figure 1 Shown, is the equipment figure of the whole continuous production line of Lyocell short fiber, comprises frame 20, and described frame 20 is provided with driving device and transmission device 22, and described transmission device 22 is the conveyer belt that is arranged along frame 20 length direction, A number of pressing rollers 21 are arranged on the conveyor belt, and the Lyocell short fibers paved into a blanket are flatly spread on the conveyor belt, and the conveyor belt moves under the drive of the driving device and drives the fiber layer 10 to move. Along the length direction of the frame 20, a thermal insulation device 30 and a microwave heating device 40 are also arranged in sequence. Spraying equipment is set in the thermal insulation device 30, and the spraying equipment is set figure 1 In the position s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com