A kind of preparation method of silver oxide/silver/copper three-layer composite strip

A silver oxide, composite strip technology, applied in contact materials, electrical components, electrical switches, etc., can solve the problems of difficult to achieve atmosphere protection, lack of versatility, difficult to achieve, etc., to solve the problem of reducing atmosphere Protects difficult problems, avoids oxide-poor areas, and solves the effect of rapid heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

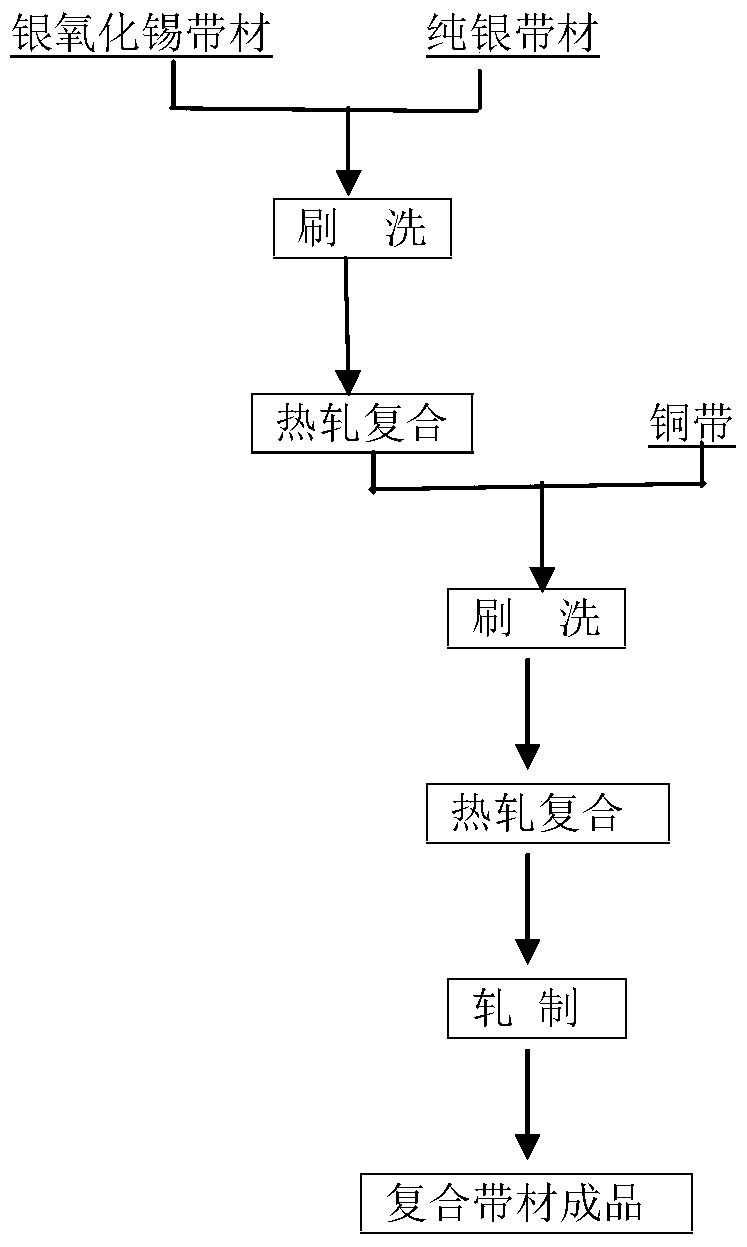

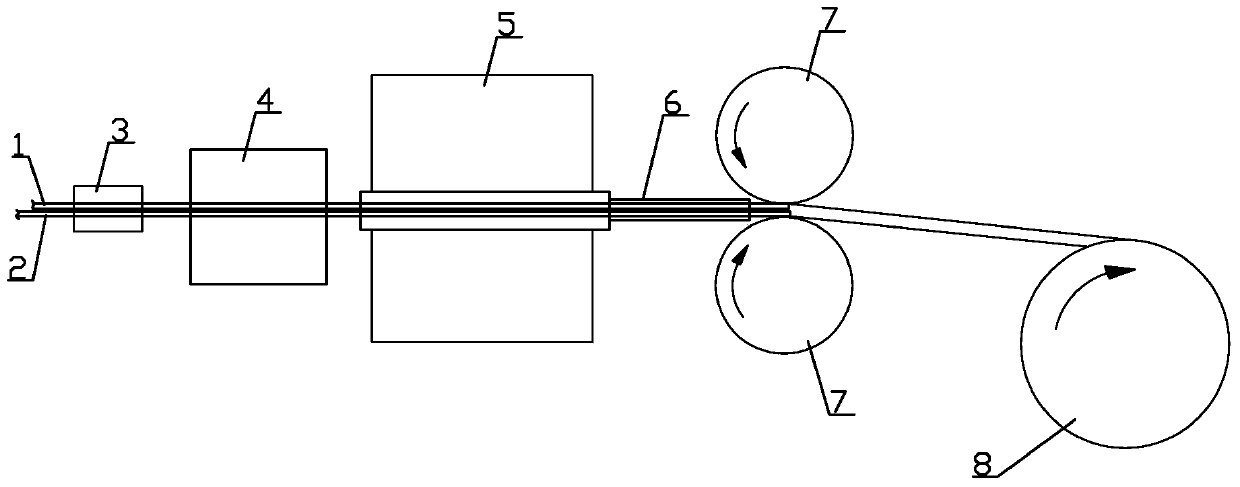

[0031] Embodiment 1: adopt figure 2 The shown device (wherein the length of the heating zone in the tubular resistance furnace is 1.2m, and the number of turns of the high-frequency induction coil of the high-frequency induction furnace is 9 turns) makes silver oxide / silver / copper composite strip

[0032] 1) Take the extruded silver tin oxide strip with a width of 6±0.2mm and a thickness of 3±0.10mm, and clean it by brushing;

[0033] 2) Take the extruded silver strip, roll it to a width of 6±0.2mm and a thickness of 0.5±0.05mm, and clean it by brushing;

[0034] 3) The two strips are used figure 2 The thermal bonding is carried out in the device shown, and no protective atmosphere is required during the entire heating process. Specifically, the two kinds of strips are stacked and sent to the high-frequency induction furnace for heating through the positioning device. The material enters the tubular resistance furnace for heating, and the temperature in the heating zone i...

Embodiment 2

[0045] Embodiment 2: the silver oxide / silver / copper composite strip that embodiment 1 makes is made sheet contact product

[0046] 1) Install the silver oxide / silver / copper composite strip obtained in Example 1 on the discharge device of the automatic punching machine, send it into the stamping die, and punch out square, circular or other shaped sheets as required Shaped contact products, stamped into square sheet-shaped contact products in this embodiment;

[0047] 2) After the square sheet contact product obtained in step 1) is subjected to conventional pickling, polishing, etc., the final sheet contact product is obtained, such as image 3 shown.

[0048] Metallographic structure analysis is carried out to the contact product that present embodiment makes, and its metallographic structure picture is as follows Figure 4 shown.

Embodiment 3

[0050] Repeat Example 1, the difference is:

[0051] In step 6), the temperature in the high-frequency induction furnace is controlled to be 700° C., and the tape running speed is 3 m / min. The strip coming out of the high-frequency induction furnace enters the tubular resistance furnace for heating, and the temperature of the heating zone in the tubular resistance furnace is controlled. is 850°C;

[0052] In step 7)), when the strip heated by the tubular resistance furnace is sent into the roll through the feeding fixture for hot rolling and compounding, the rolling deformation is controlled to be 45%, and the rolling speed is 3m / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com