Automatic cable wiring detection system

An automatic detection and wiring technology, applied in the direction of measuring electricity, measuring devices, short-circuit testing, etc., can solve the problems of wrong wiring, time-consuming and laborious testing efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable those skilled in the art to better understand the solutions of the present application, the technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the drawings in the embodiments of the present application.

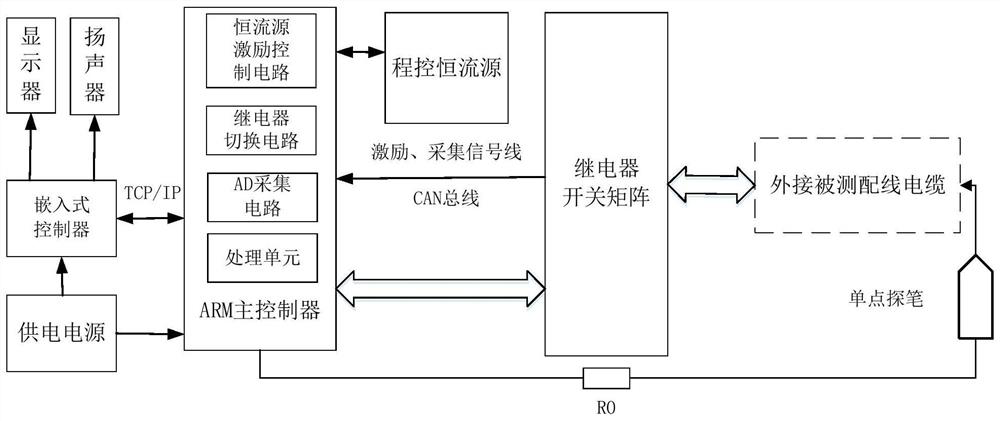

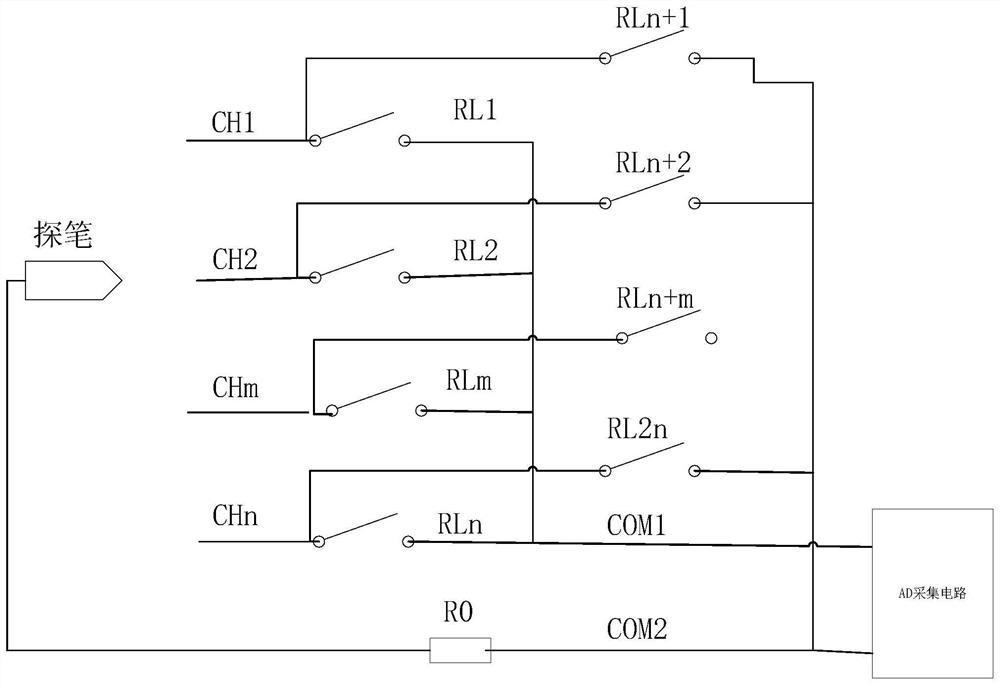

[0021] The basic measurement principle of the present invention is: adopt the design idea of automatic control of the embedded controller, use the relay switch matrix to connect one end of the cable under test, adopt the principle of traversal scanning and constant current excitation measurement principle, and use the AD acquisition circuit to collect the measured data in real time The conduction resistance measurement information of the circuit where the core is located, the automatic detection and configuration of the cable wiring number, automatically finds the connection point line number at the other end of the tested cable, and displays the conduction and connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com