Metering shell press sealing system of diaphragm gas meter

A membrane gas meter and clamping cylinder technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as prone to failure, affecting production efficiency, and inconvenient riveting of metering shells, so as to reduce production failures and improve efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below with reference to the accompanying drawings.

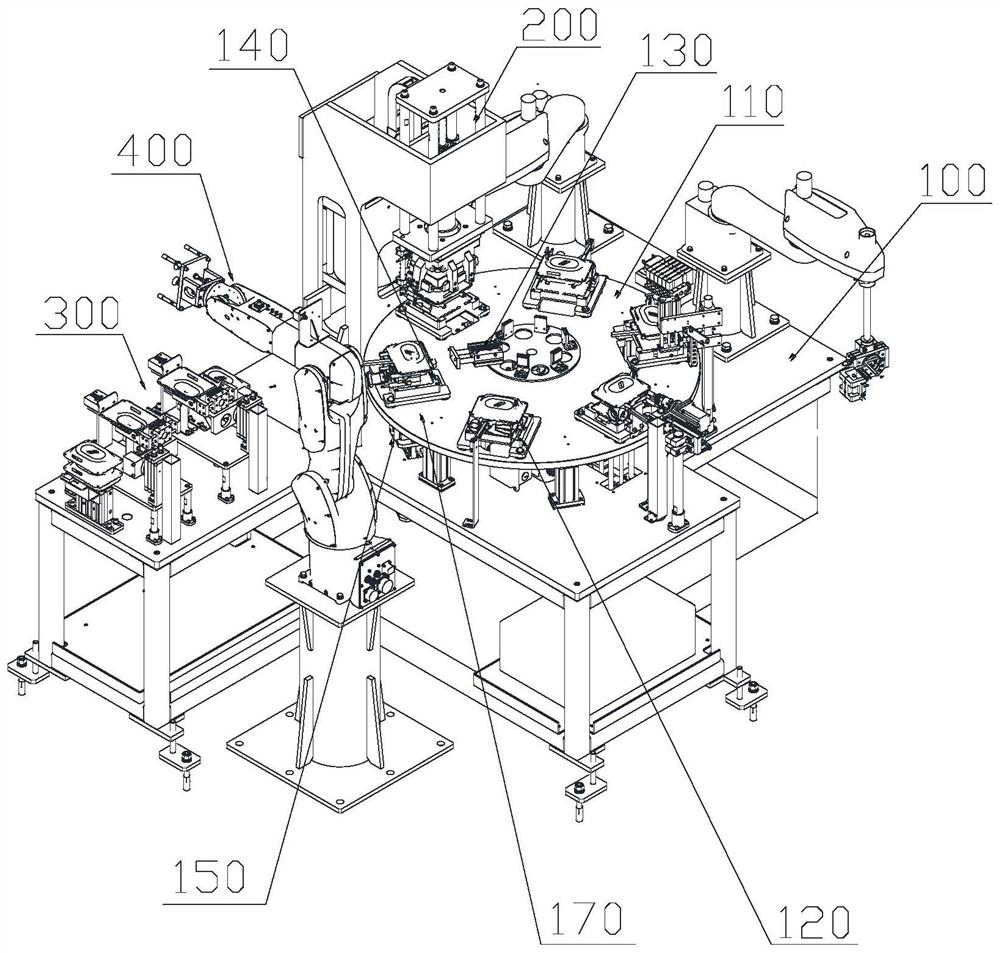

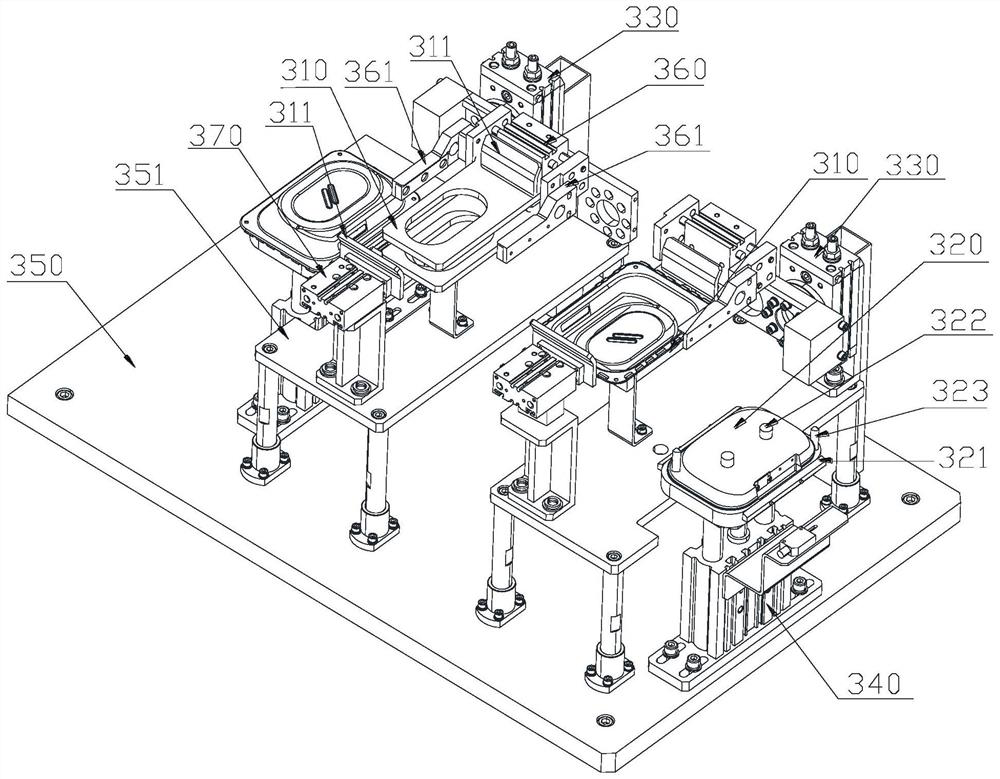

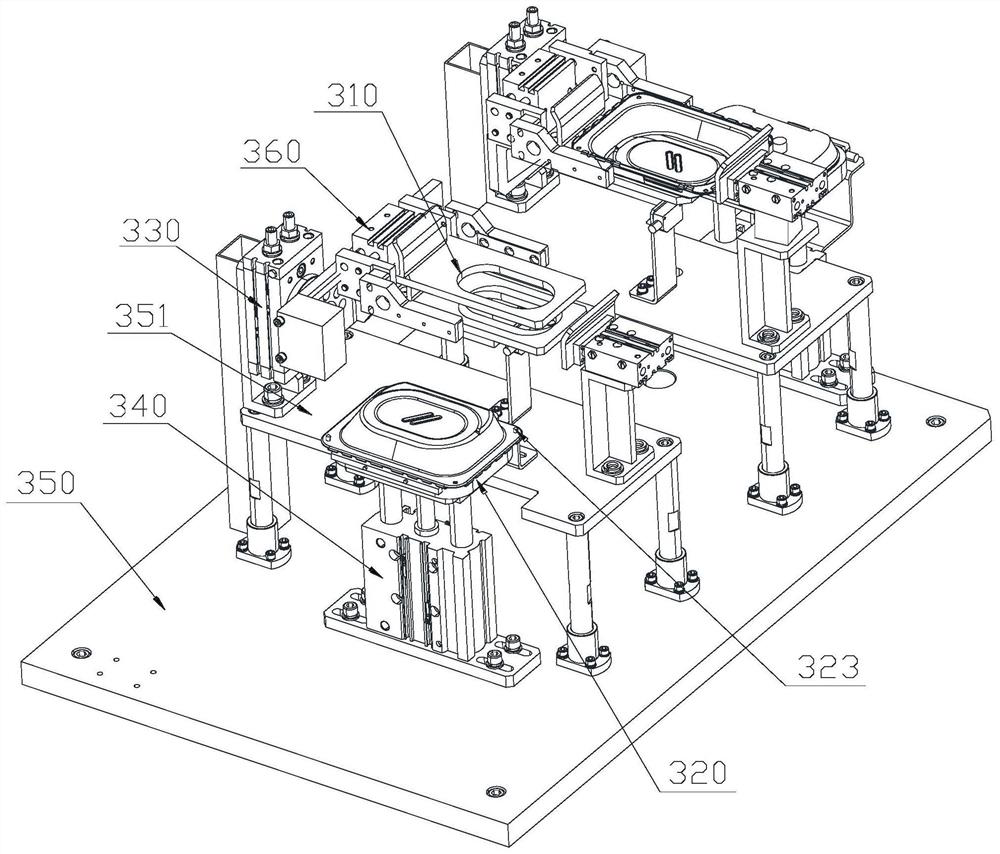

[0032] refer to Figure 1 to 9 Gas pressure diaphragm metering housing seal system shown includes a frame 100, and 110 and 200, the rotary indexing of the rotary indexing table 100 on the rotating gantry to be press packer indexing plate 110 is provided disposed in the on the disc 110 having a circumferential direction thereof, the movement positioning seat body 120 uniformly distributed, in the present application the rotary indexing table 110 is a conventional six-station indexing plate, each station has positioning seat movement body 120, machine the core 120 has a positioning seat body shape with the movement positioning structure adapted, capable of movement in a relatively stable posture is placed on the seat positioning movement body 120, particularly six-station rotary indexing table 110 is divided as follows, wherein a first station for the movement member is located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com