Safety valve applicable to controlling high temperature flue gas

A safety valve and valve plate technology, applied in the field of safety valves, can solve problems such as high temperature deformation of the valve body, and achieve the effects of fewer production failures, low equipment cost, and strong structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below through embodiment and accompanying drawing.

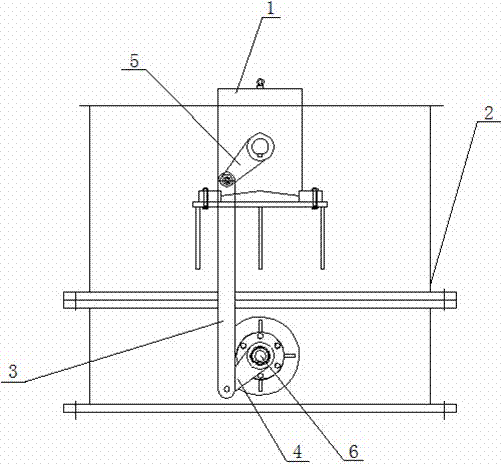

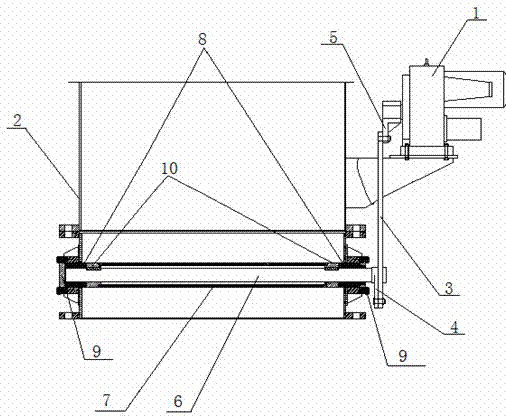

[0021] Such as figure 2 , 3 , 4, 5, the safety valve suitable for controlling high-temperature flue gas includes an actuator 1 and a flap valve body 2, the actuator 1 is arranged outside the flap valve body 2, and the flap valve body 2 includes a flap swivel body Protective cover 7, flap swivel body and sealing ring 13 that are arranged on the inner wall of flap valve body 2, described flap swivel body includes rotating shaft 6 and valve plate 12 welded on both sides of rotating shaft 6, valve plate 12 is provided with There are several reinforcing ribs 11, the rotating shaft 6 is fixed on the flap valve body 2 through the cast iron sleeve 8 and the end cover 9, and the rotating shaft 6 is connected with the actuator 1 through the connecting rod mechanism, which includes the first connecting rod 3 , the second connecting rod 4 and the third connecting rod 5, the execu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com