Preparation method of magnesium-aluminum layered composite plate

A clad plate, magnesium-aluminum alloy technology, applied in metal layered products, chemical instruments and methods, lamination, etc., can solve the problems of poor corrosion resistance, low strength, low melting point, etc., and achieve improved corrosion resistance and mechanical properties. Stable and dense metallographic structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

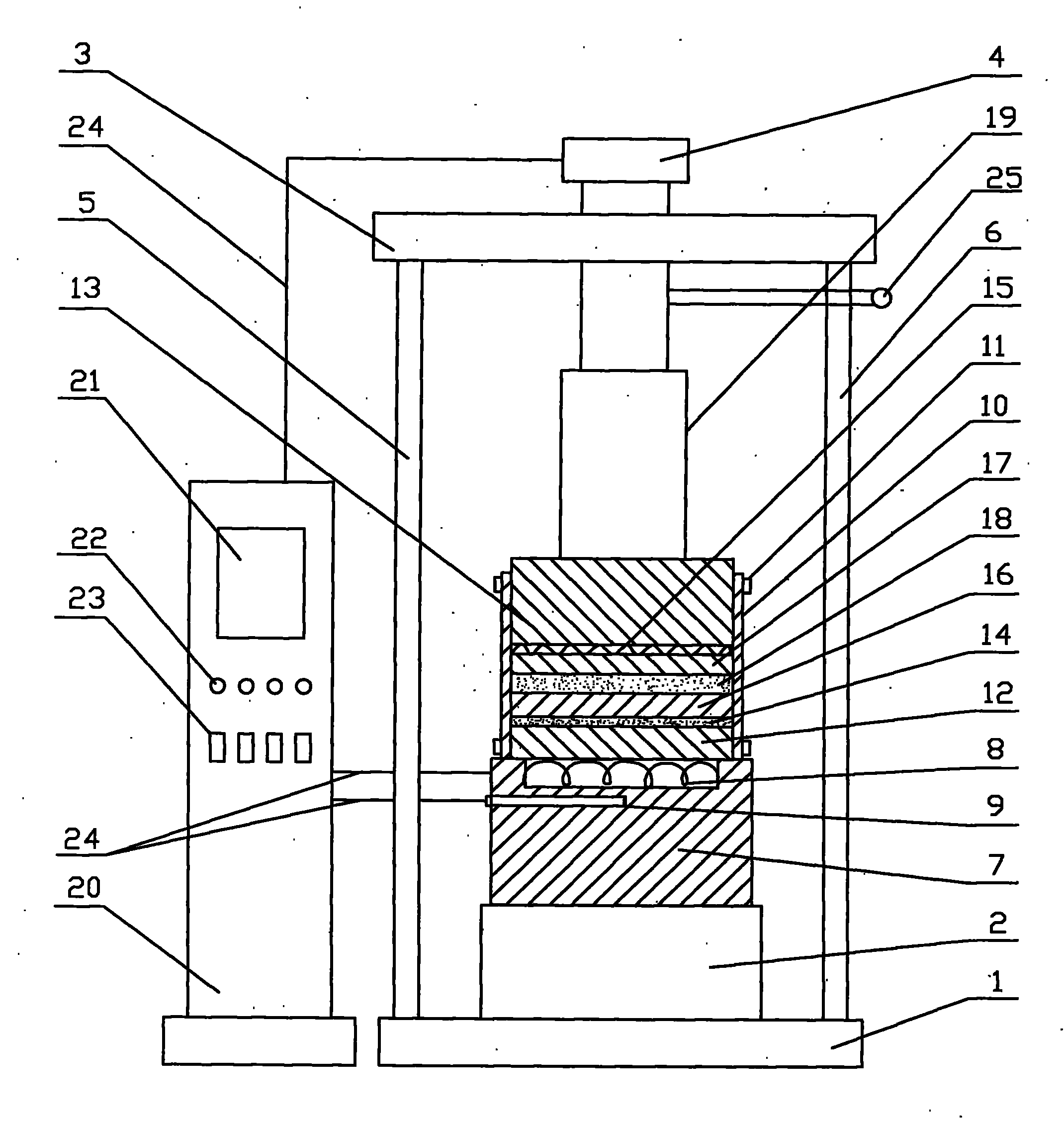

[0086] The method of preparing the magnesium-aluminum laminated composite board by heating the upper part of the press is as follows:

[0087] ①. Fix the preheated through-slot stainless steel mold on the stainless steel workbench of the press;

[0088] ②. Place the preheated stainless steel backing plate in the lower part of the through-groove mold;

[0089] ③. Repeatedly smear the lower surface of the upper workbench with a graphite block to form a film layer on the lower surface of the upper workbench. The thickness of the graphite film layer is 0.01mm;

[0090] ④. Turn on the resistance heater to raise the temperature of the upper workbench to 480°C±2°C;

[0091] ⑤. Put the magnesium-aluminum eutectic alloy powder in the powder sprayer, and the powder sprayer is aimed at the surface of the magnesium-aluminum alloy plate and sprayed repeatedly evenly, forming a magnesium-aluminum eutectic alloy powder layer on the magnesium-aluminum alloy plate, and the thickness of the po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com