Patents

Literature

44results about How to "Dense metallographic structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

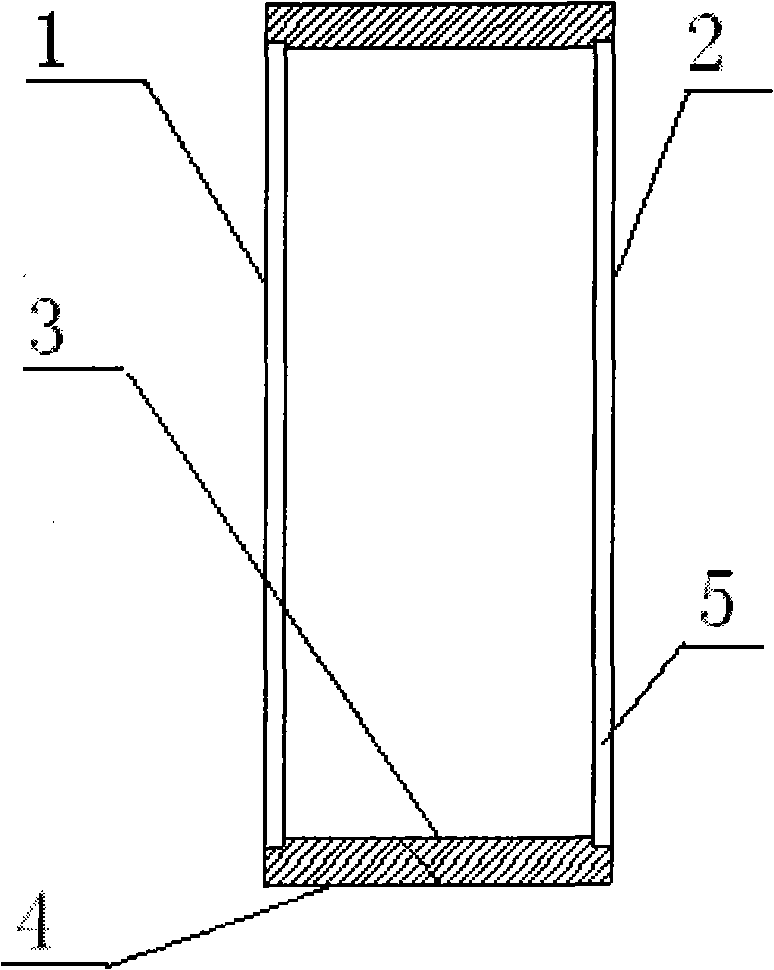

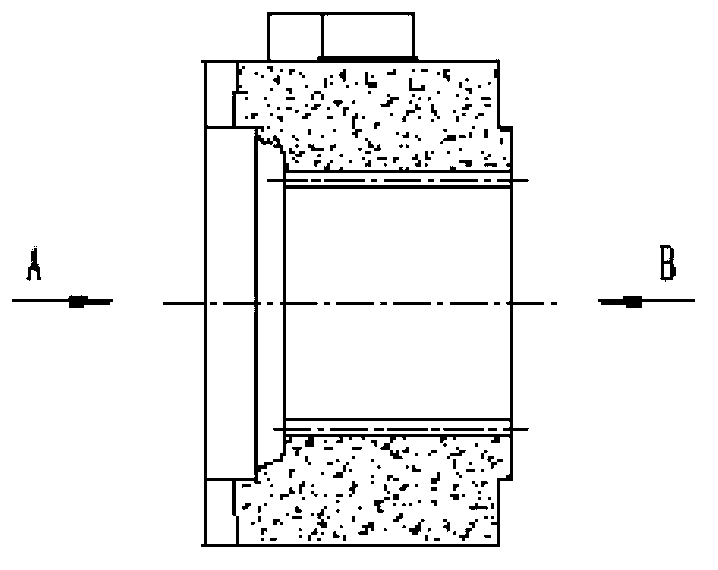

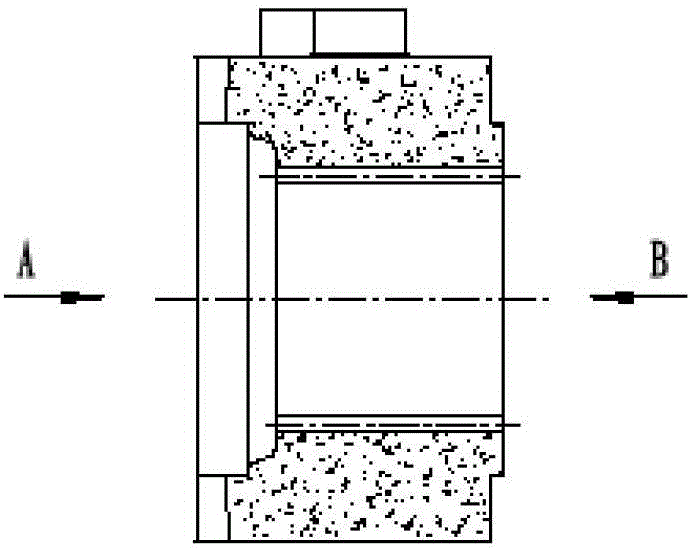

Manufacturing process of high-power low-speed diesel shaft bushing

InactiveCN101275606AReduced edge defectsHigh bonding strengthBearing componentsManufacturing technologyLow speed

Owner:CHONGQING YUEJIN MACHINERY

Preparation method of magnesium-aluminum layered composite plate

InactiveCN102166846AStable mechanical propertiesImprove corrosion resistanceLaminationLamination apparatusAlloyComposite plate

The invention relates to a preparation method of a magnesium-aluminum layered composite plate, aiming at solving the problems that the magnesium-aluminum alloy plate is light in weight, low in strength and poor in corrosion resistance. The method comprises the steps of: pressing and labeling a layer of aluminum plate on the magnesium-aluminum alloy plate; taking magnesium-aluminum eutectic alloy powder as a pressing and labeling material; pressing and labeling the magnesium-aluminum alloy plate+the magnesium-aluminum eutectic alloy powder+the aluminum plate into a magnesium-aluminum layered composite plate in an open-close through groove mould on a press machine under the temperature of 480 DEG C and the pressure of 30M Pa for 60s; and performing the low-temperature thermal treatment, so that an internal metallographic phase tissue of the magnesium-aluminum layered composite plate is more compact and stable. The method is advanced and reasonable, small in use equipment, short in technological process, and fast in speed. The mechanical property tensile strength of the magnesium-aluminum layered composite plate can reach 24MPa. Compared with the prior art, the mechanical property tensile strength can be improved by 95%, and the corrosion resistant performance can be improved by 94%, therefore, the preparation method of the magnesium-aluminum layered composite plate is very ideal.

Owner:TAIYUAN UNIV OF TECH

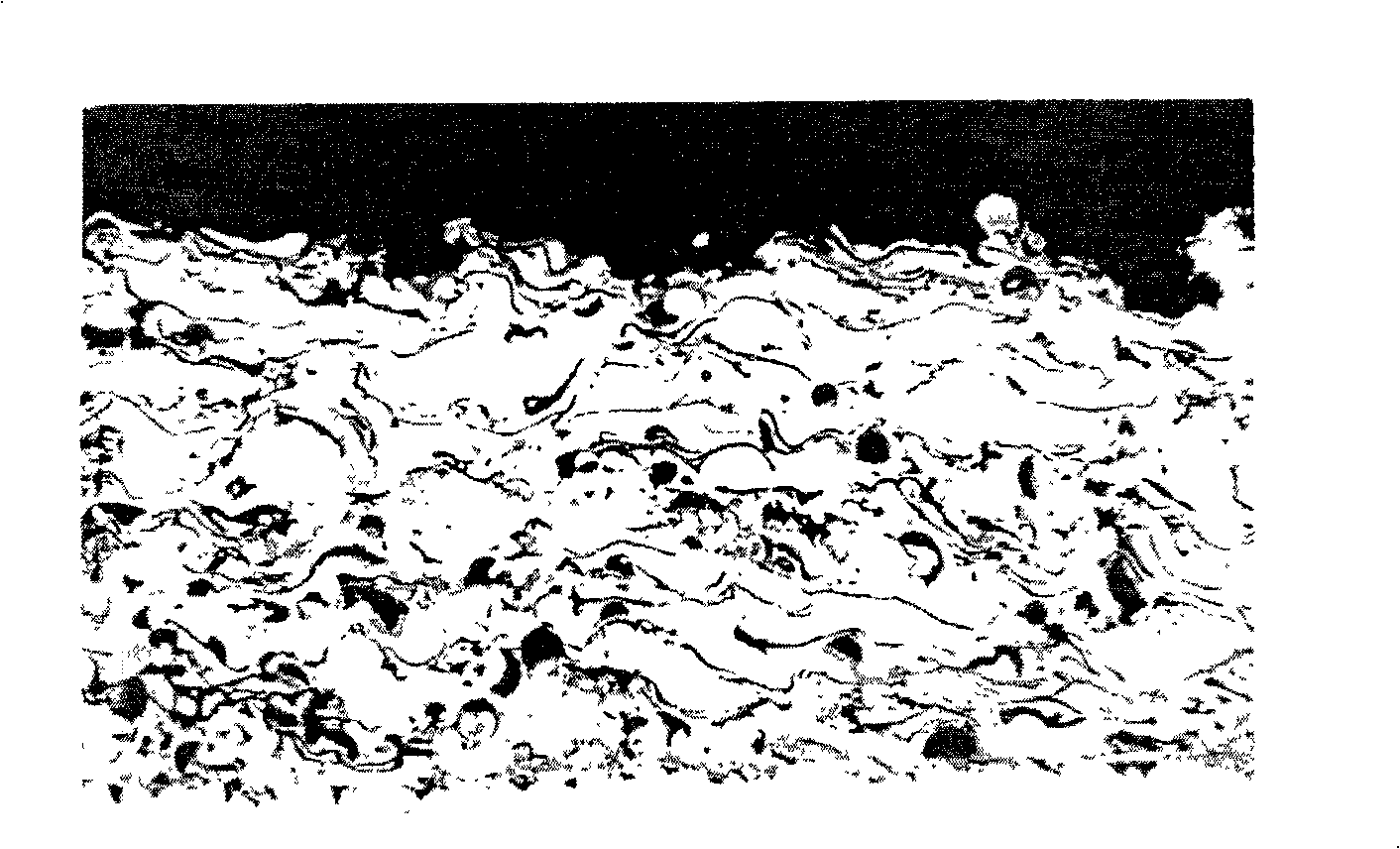

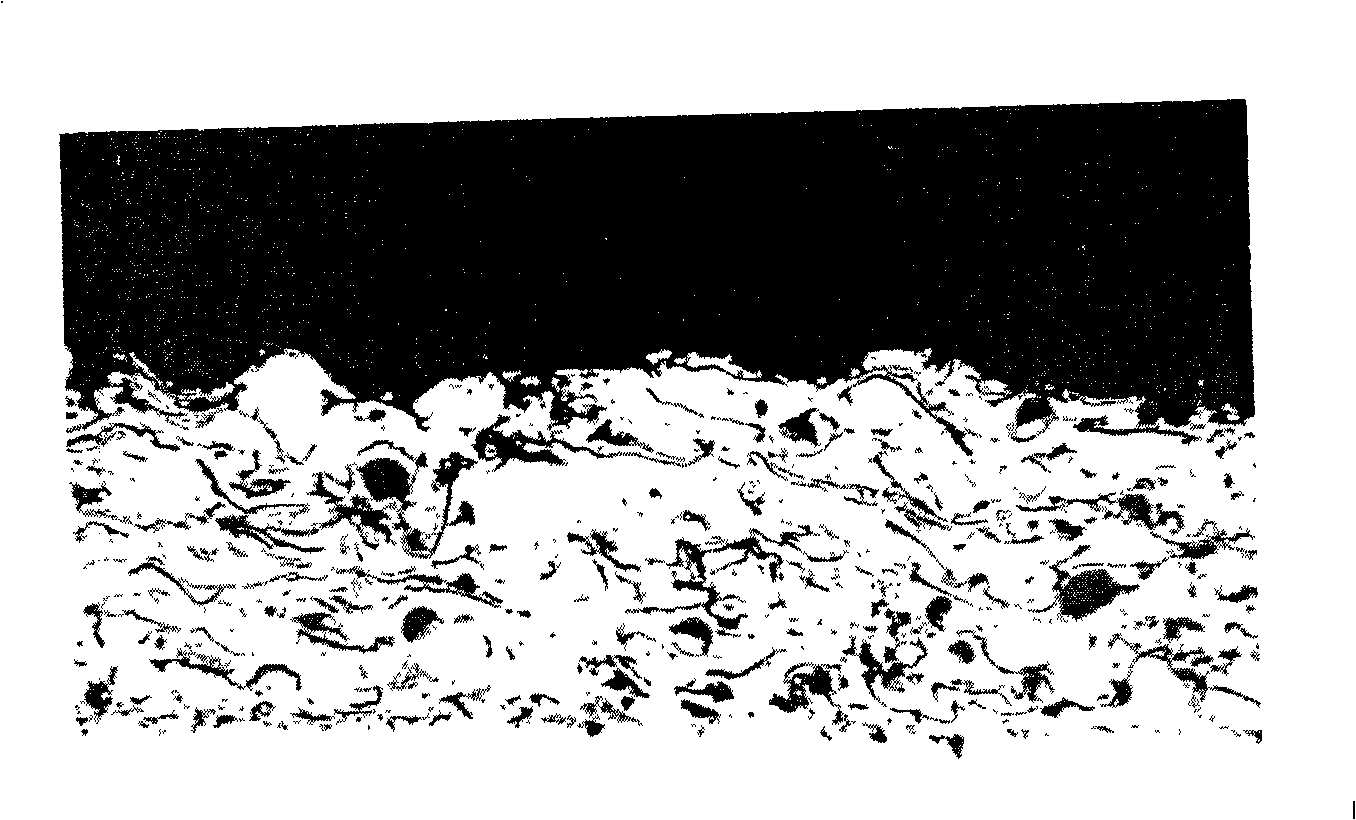

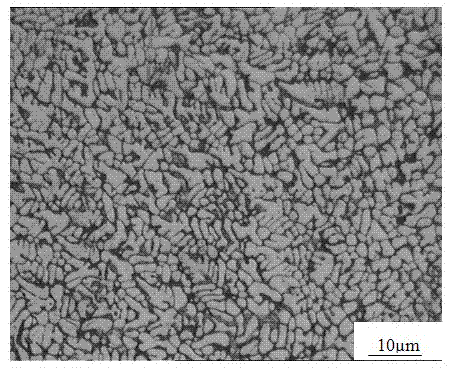

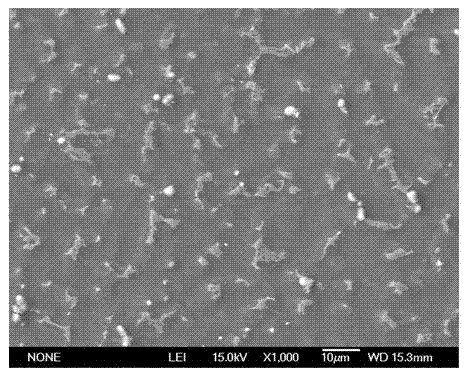

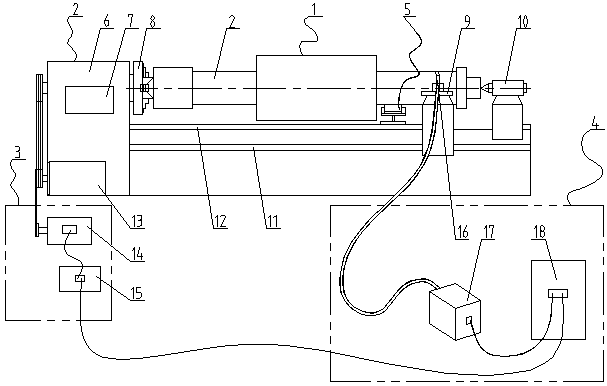

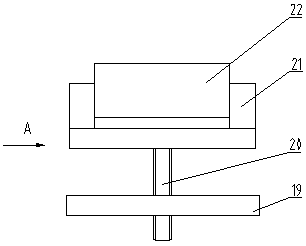

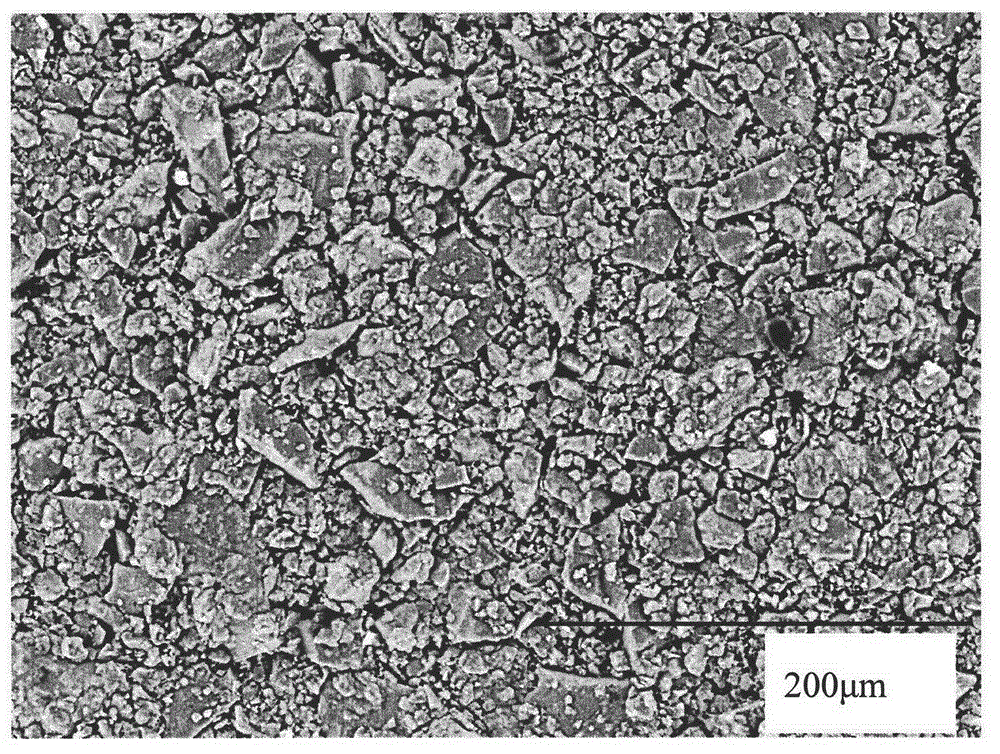

Method for renovating lubricant pump casing bush with plasma spraying Cu-Al coating

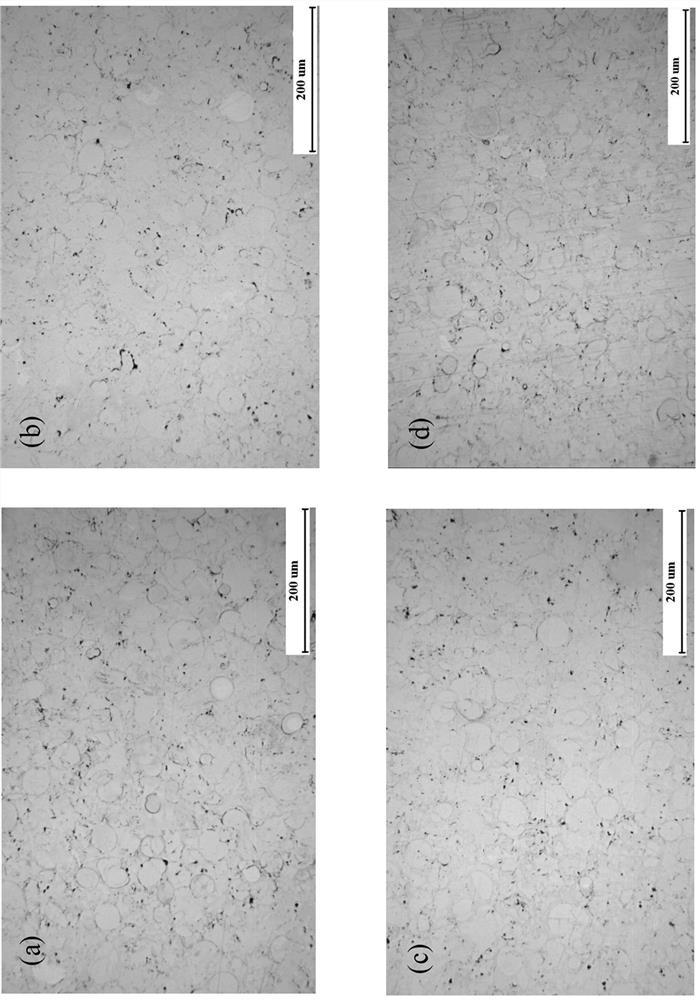

InactiveCN101403086ADense metallographic structureLess porosity and oxidesMolten spray coatingGrit blastingEngineering

A method for repairing a lubricant pump shell bushing by plasma sprayed Cu-Al coating belongs to the technical field of aviation. The repairing of a narrow-arc convex end face of the lubricant pump shell bushing by a plasma spraying method comprises the steps of washing, grit blasting, protection, spraying the spray material on the narrow-arc convex end face of the lubricant pump shell bushing by plasma spraying equipment. By adopting the method for repairing the lubricant pump shell bushing by plasma sprayed Cu-Al coating, the sprayed coating has as high as 41.07MPa of bonding strength and relatively stable hardness value. Bending test result shows that the coating bond is relatively good, and coating microscopic test shows that the metallurgical structure is relatively compact. The method has the advantages of reasonable process and correct preferences, which achieves the effect of repairing the lubricant pump shell bushing and has significance in prolonging the service life of the lubricant pump shell bushing and reducing economic loss.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

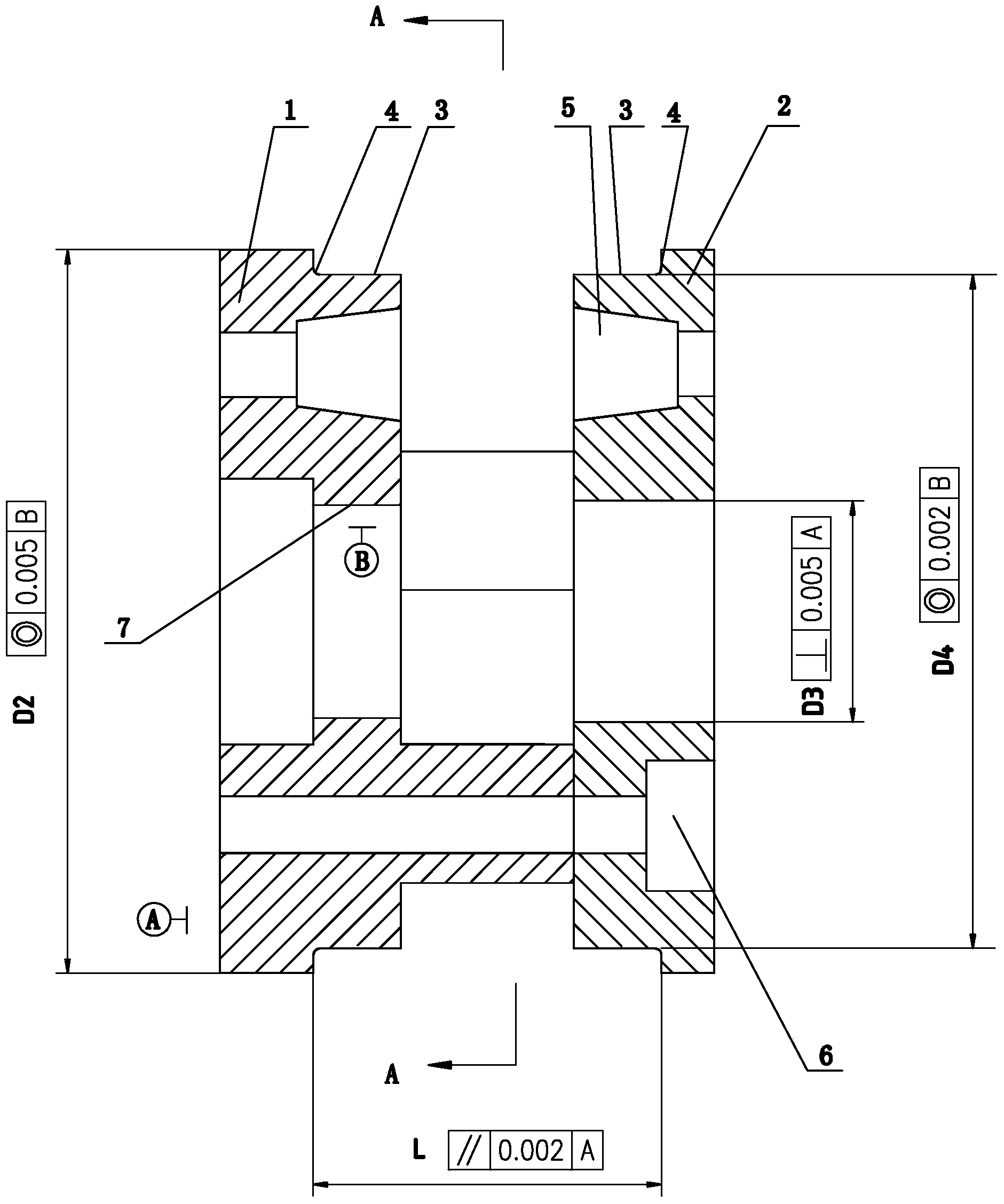

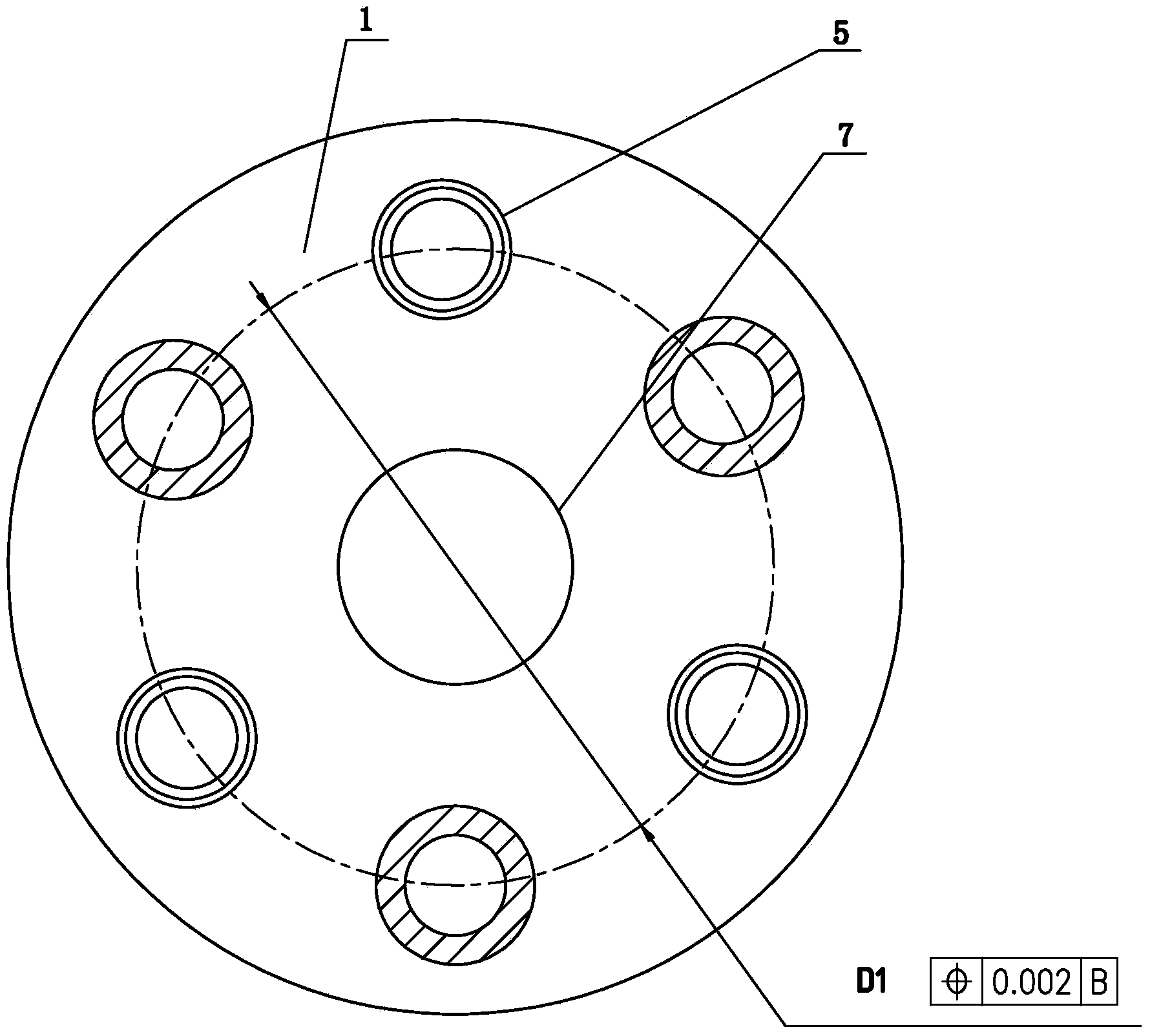

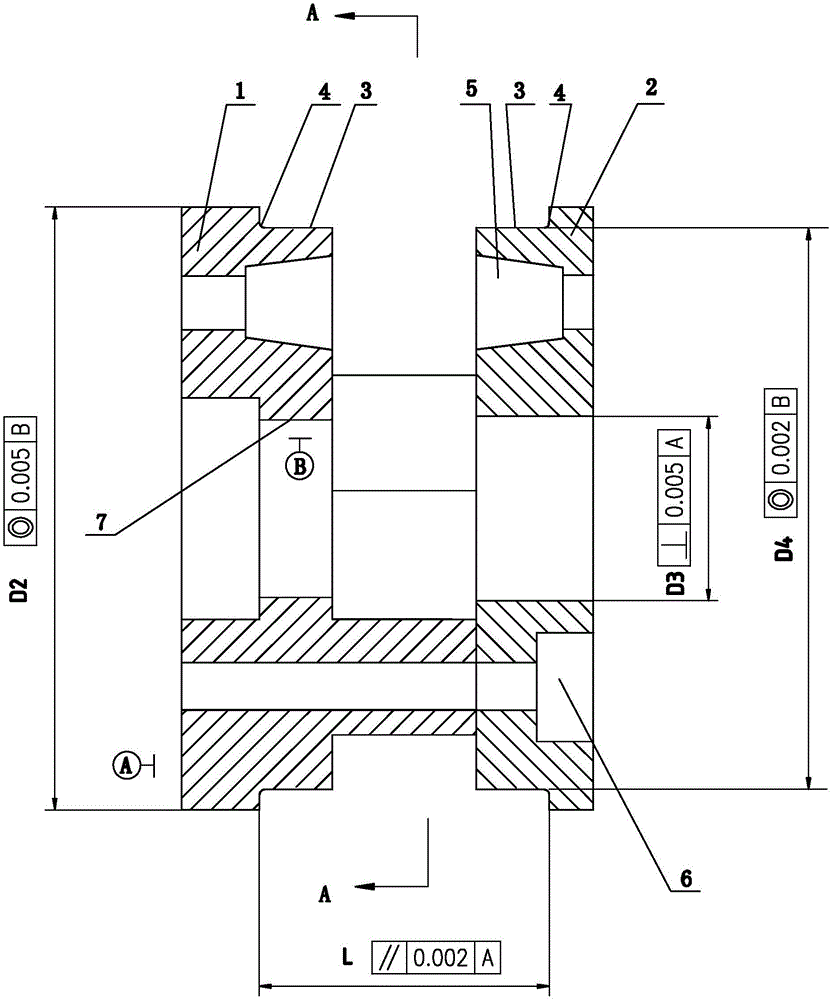

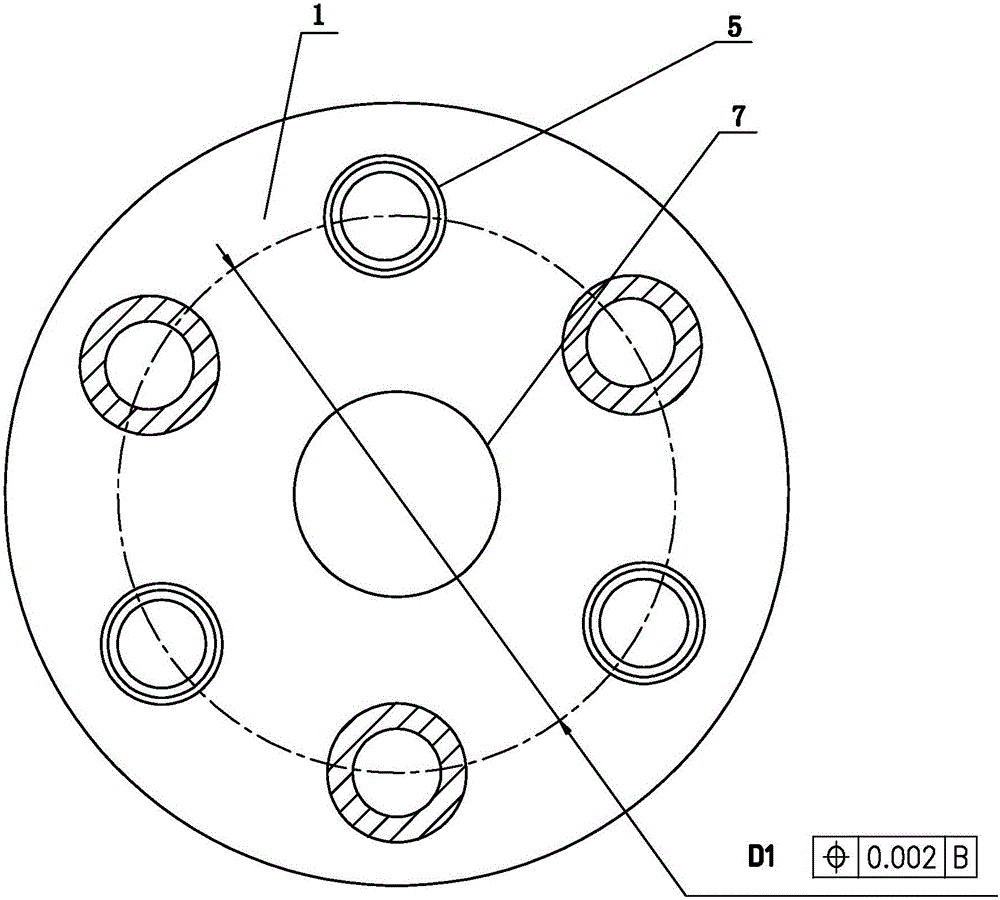

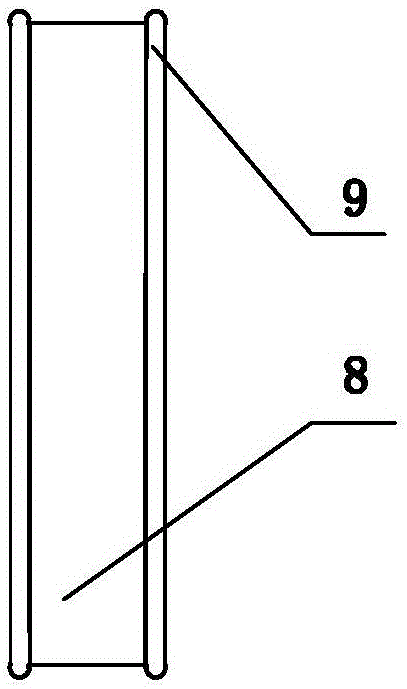

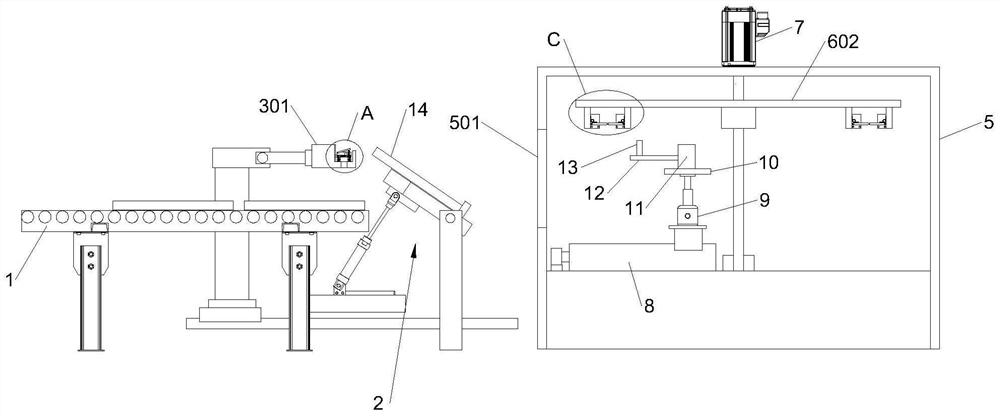

Integrated machining method of planet carrier of robot RV reducer

The invention discloses an integrated machining method of a planet carrier of a robot RV reducer, and belongs to the technical field of robot RV reducer machining. The method comprises the steps as follows: forging a first casing and a second casing, and performing hot extrusion on the first casing and the second casing respectively; performing thermal refining; performing tempering; performing finish machining on end surfaces respectively; connecting the first casing with the second casing to be clamped to a clamp, and performing finish machining on inner holes formed in the first casing and the second casing with a center of gyration serving as a locating basis; performing finish machining on outer surface with the locating basis; directly machining inner rings of rolling bearings on the first casing and the second casing; accurately grinding an outer track on each inner ring simultaneously; and performing finish machining bearing positions of three tapered roller bearings on the first casing and the second casing with the location reference, and directly machining outer rings of the tapered roller bearings. With the adoption of the method, the mounting accuracy, the manufacturing accuracy and the transmission accuracy are ensured, the requirement for high accuracy is met, the service life is prolonged, machining and assembling errors and accumulative errors are reduced, the output torque is increased, and the machining cost is effectively reduced.

Owner:SHANDONG SHKE MACHINERY MFG

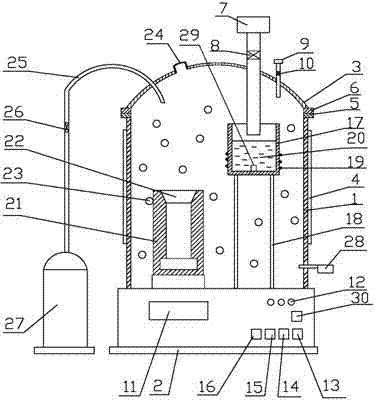

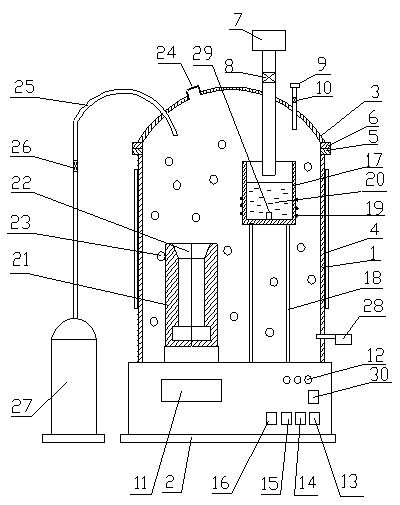

Smelting degassing method of aluminum-silicon alloy liquid

InactiveCN102041401ADense metallographic structureNo shrinkage cavityElectric fieldShrinkage porosity

The invention relates to a smelting degassing method of aluminum-silicon alloy liquid. Aiming at the actual condition that gas and impurities exist in the aluminum-silicon alloy liquid in the smelting course, a method of smelting direct-current electric field purification and circulation degassing outside a furnace is adopted to remove 99.5% of main gas, i.e. hydrogen, from the aluminum-silicon alloy liquid, so that an aluminum-silicon alloy having a compact metallographic structure can be obtained, and the aluminum-silicon alloy has no bubble or shrinkage cavity and is not subject to shrinkage porosity. The method has the advantages of advanced and reasonable process, continuous step, environment protection and energy conversation, the properties of aluminum-silicon products are greatly enhanced, the tensile strength can be enhanced by 91%, and the method is an ideal degassing method of aluminum-silicon alloy liquid.

Owner:ZHONGBEI UNIV

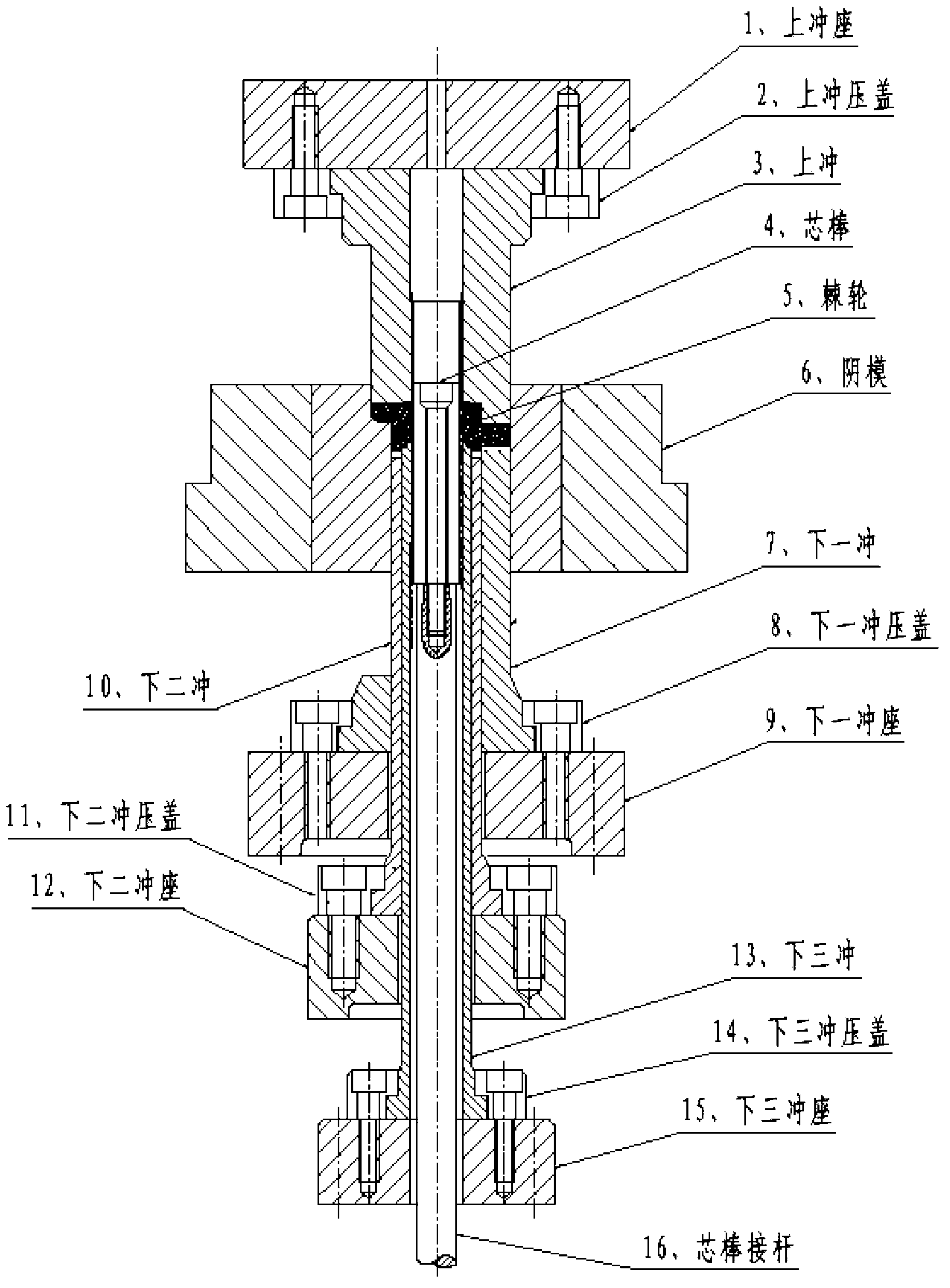

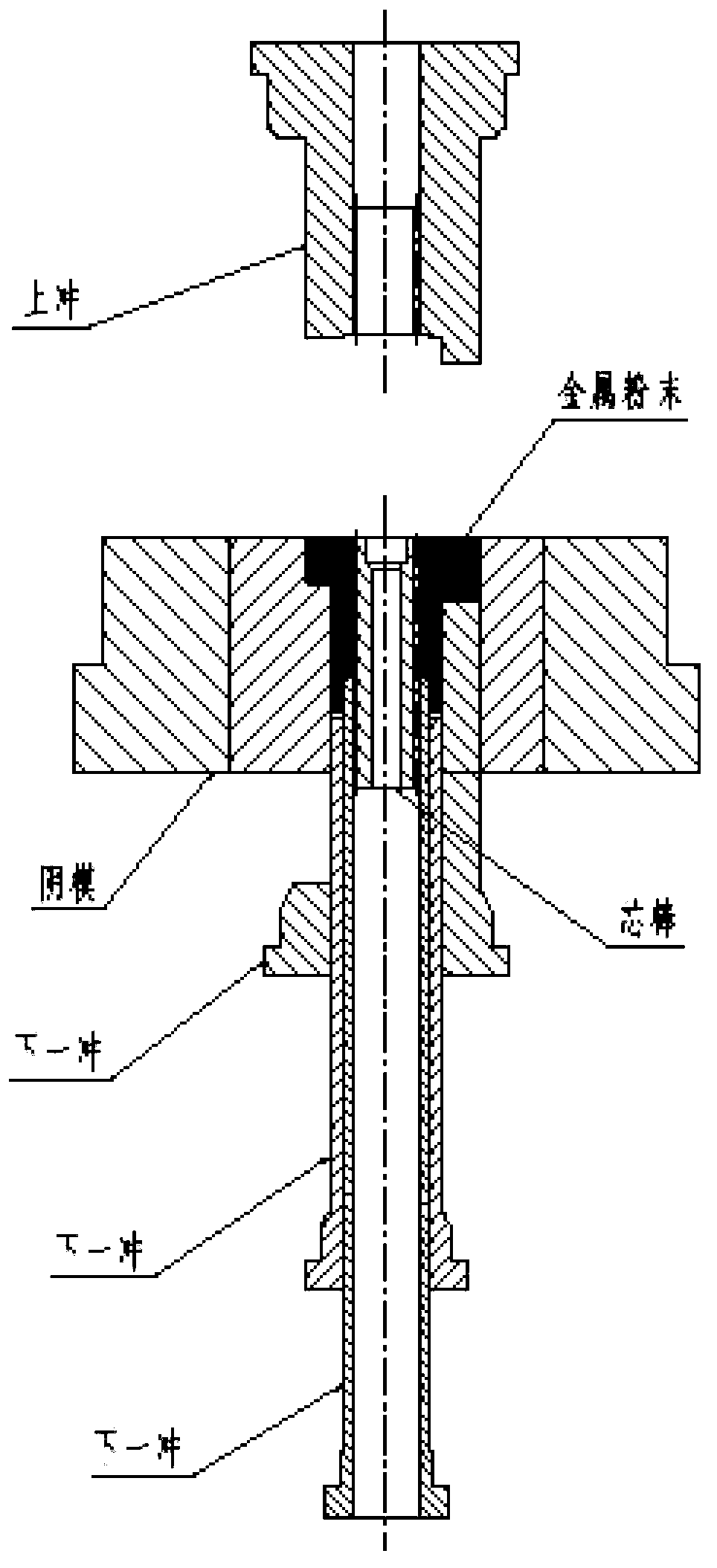

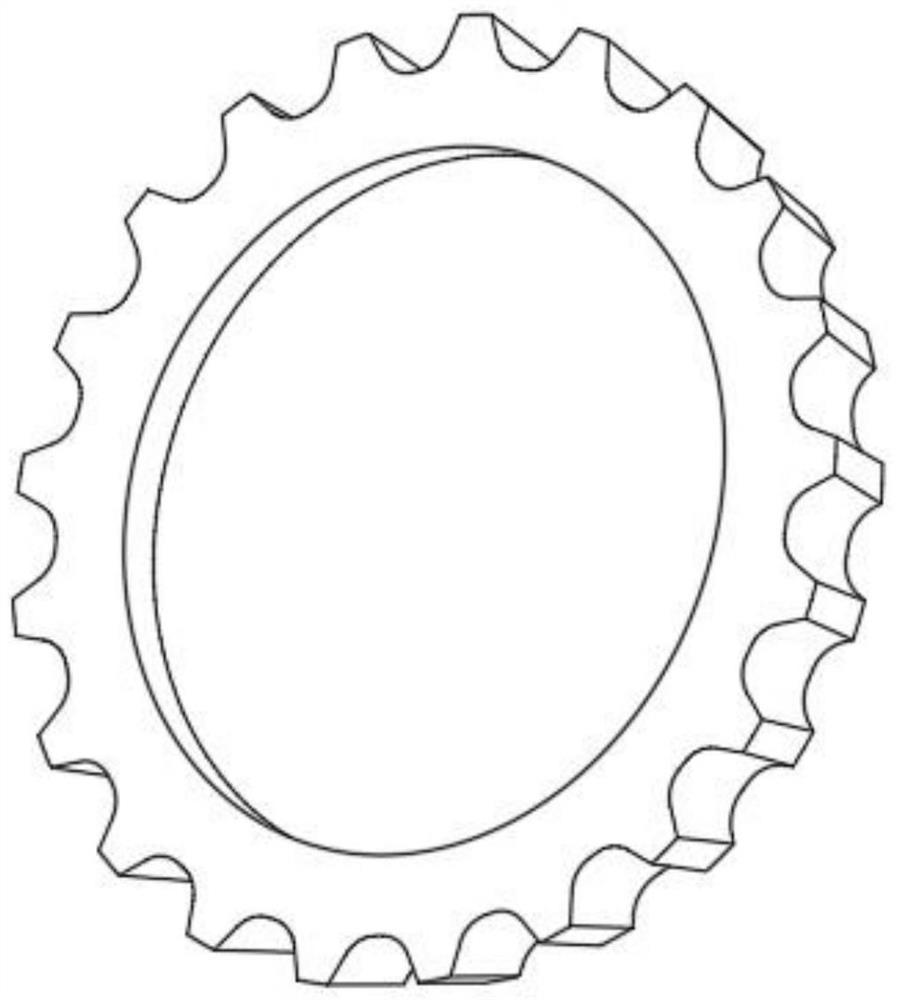

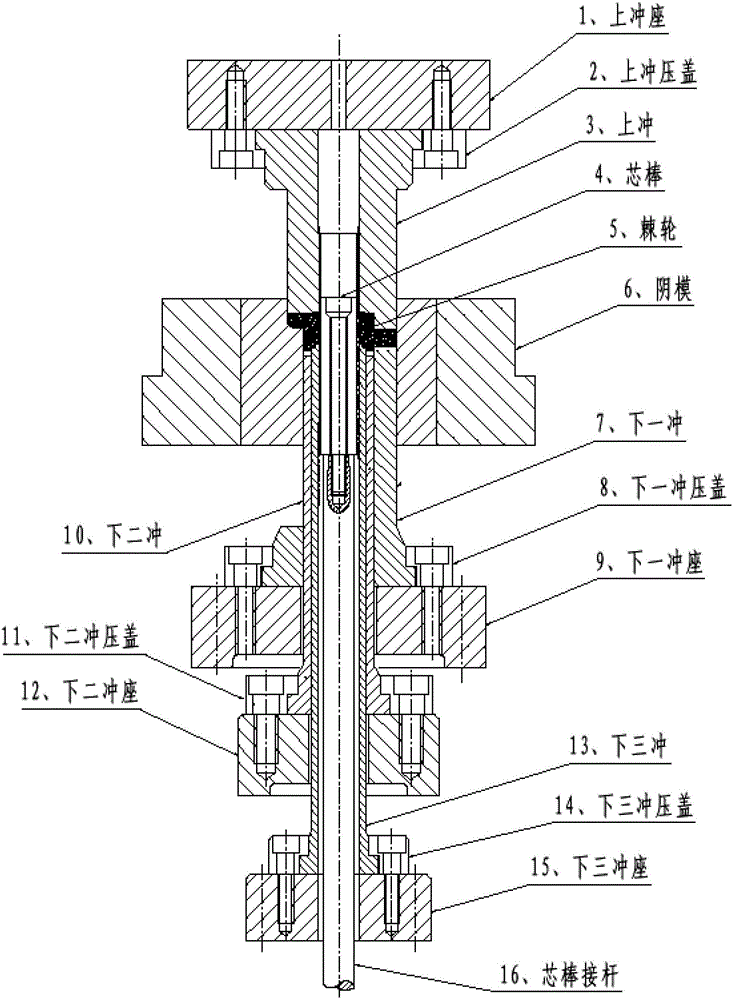

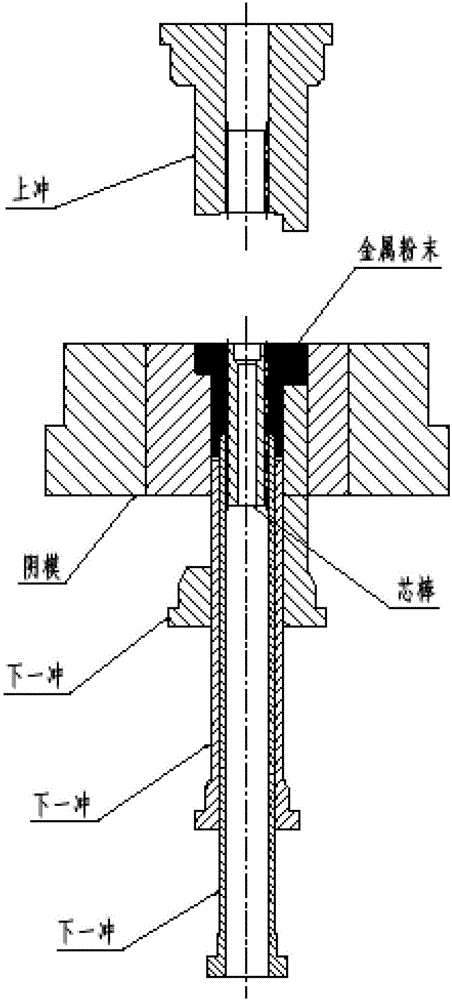

Method for manufacturing starting ratchet wheel of motorcycle

Provided is a method for manufacturing a starting ratchet wheel of a motorcycle. Metal powder serves as a raw material and is sintered after compression forming in a mould. The method is characterized in that pressure for compression is 80-115 tons, and dwell pressure for demoulding is 9-15 tons. The metal powder serves as the raw material, is alloyed into alloy steel by compressing and sintering, and is completely free of mechanical cutting, and accordingly waste of steel materials is avoided, steel resource is greatly saved, and the produced starting ratchet wheel of the motorcycle has mechanical performance of the alloy steel, the mechanical performance and overall quality of the starting ratchet wheel are further improved, and production efficiency is also greatly increased. The method is simple in production process, the starting ratchet wheel is high in precision and fine in consistency, and stability of quality of products in mass production is guaranteed.

Owner:重庆聚能粉末冶金股份有限公司

Preparation method of Ca (Calcium) and Ho (Holmium)-doped Mg (Magnesium) alloy

The invention relates to a preparation method of a Ca and Ho-doped Mg alloy. The preparation method comprises the following steps of: using Mg and Al (Aluminum) as raw materials, adding an Mg-Ca intermediate alloy and an Mg-Ho intermediate alloy, melting in a vacuum melting furnace, casting under the protection of argon to form ingots, and preparing Ca and Ho-doped Mg alloy ingots by cutting and low-temperature tempering. The preparation method of the Ca and Ho-doped Mg alloy is advanced in process, reasonable in proportion, detailed and accurate in data, environment-friendly, safe, stable and reliable; the prepared Ca and Ho-doped Mg alloy is compact in metallographic structure, and has a tensile strength up to 278MPa, a yield strength up to 167MPa and an elongation of 5.5% at a room temperature of 25 DEG C, so that the preparation method of a Ca and Ho-doped Mg alloy is ideal.

Owner:TAIYUAN UNIV OF TECH

Zinc-aluminum-nickel alloy co-penetrated protective layer preparation method

ActiveCN105951037AUniform thicknessDense metallographic structureSolid state diffusion coatingHydrogenRare earth

The invention discloses a zinc-aluminum-nickel alloy co-penetrated protective layer preparation method, which comprises the following steps of weighing co-penetrated agent raw materials: zinc powder, aluminum powder, alumina powder, nickel powder, rare-earth metal oxide powder and catalyst; uniformly mixing the weighed powder, heating the mixture to be 150 to 200 DEG C, insulating for 30 min to 50 min, cooling to be room temperature, and then uniformly mixing with the catalyst to prepare a co-penetrated agent; stacking bridge embedded parts plates with smooth and clean surfaces to form a stack with approximate height and width, paving a layer of co-penetrated agent between each two adjacent bridge embedded part plates, then packaging to form bundles, placing the bundles into a co-penetrated furnace, adding the co-penetrated agent, heating to be 400 to 500 DEG C, and carrying out co-penetrated treatment for 2 h to 3 h under the pressure of 0.10 to 0.20 MPa. According to the zinc-aluminum-nickel alloy co-penetrated protective layer preparation method provided by the invention, the space of the co-penetrated furnace can be efficiently utilized; a zinc-aluminum-nickel alloy co-penetrated protective layer is uniform in thickness and compact in metallographic structure, and has excellent resistance to corrosion on high-temperature salt mist gas; and the phenomenon of hydrogen brittleness does not exist.

Owner:FUJIAN HONGGUAN ROADS & BRIDGE ANTI CORROSIVE TECH

Zinc-aluminum-nickel alloy co-diffusion agent for bridge embedded part

InactiveCN105861982AUniform thicknessDense metallographic structureSolid state diffusion coatingOxideMetal

The invention discloses a zinc-aluminum-nickel alloy co-penetration agent for bridge embedded parts. The raw materials include the following components in parts by mass: 100 parts of zinc powder, 10-20 parts of aluminum powder, 80-100 parts of aluminum oxide powder, and nickel powder 10 to 30 parts, 2 to 10 parts of rare earth metal oxide powder, 0.1 to 2.0 parts of catalyst, the particle size of the above raw materials is 300 mesh; the zinc powder, aluminum powder, alumina powder, nickel powder and rare earth powder in the above raw materials The metal oxide powder is mixed evenly, heated to 150-200°C, kept for 30-50 minutes, cooled to room temperature, and then mixed with the catalyst to prepare the zinc-aluminum-nickel alloy co-penetrating agent. The zinc-aluminum-nickel alloy co-infiltration anti-corrosion protection layer obtained by applying the invention has the advantages of uniform thickness and compact metallographic structure, excellent corrosion resistance to high-temperature salt spray gas, and no hydrogen embrittlement phenomenon.

Owner:WUHU ZHONGYUAN COMPOSITE NEW MATERIALS CO LTD

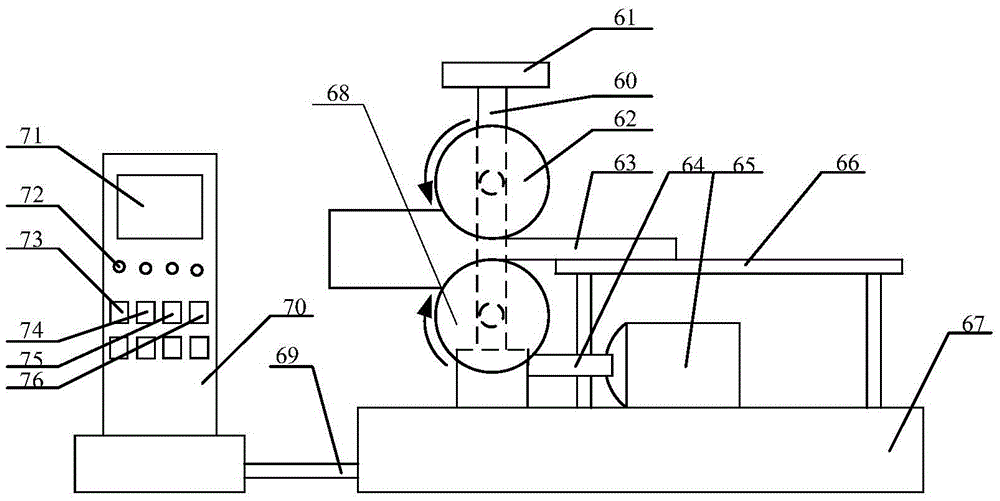

Hardware ball-head forming technique

InactiveCN101337312AReduce processing timeReduce mechanical dispersionMetal rollingMan-hourEngineering

The invention discloses a process for forming a hardware ball end. A hardware ball end cross wedge rolling forming process is added between the step of blanking round steel and cutting the length of a deviatoric plane, and the step of drilling a center hole. By using the cross wedge rolling forming process, a major diameter of a bar workpiece is heated instantaneously, entering a rolling mill in the axial direction, and is rolled and formed quickly for one step in two rolling dies. The process of the invention has the advantages of high production efficiency, high forming precision of rolled workpiece, thereby greatly saving hardware processing man-hours and raw materials.

Owner:RUGAO DASHENG LINE EQUIP

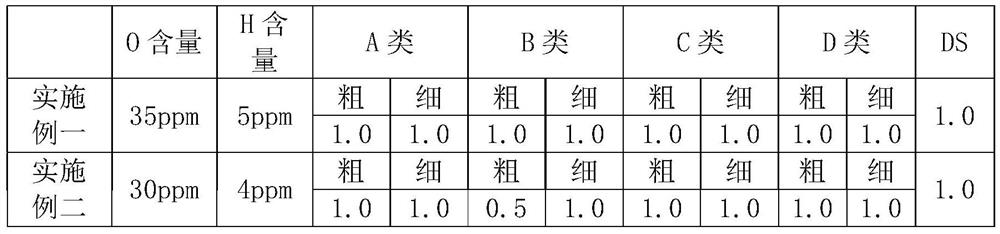

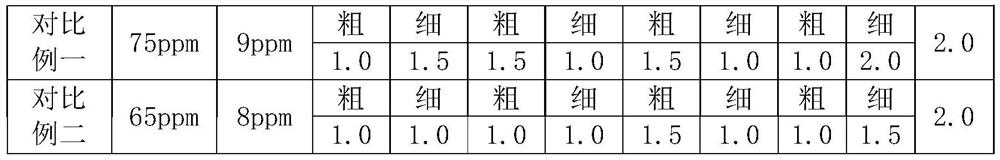

Production method for smelting F55 dual-phase steel in intermediate frequency furnace

The invention provides a production method for smelting F55 dual-phase steel in an intermediate frequency furnace. The production method comprises the following steps that S1, molten steel is prepared in the intermediate frequency furnace according to the following ingredients in percentage by mass: less than or equal to 0.03% of C, less than or equal to 1.00% of Si, less than or equal to 1.00% of Mn, less than or equal to 0.02% of P, less than or equal to 0.015% of S, 24.0%-26.0% of Cr, 6.0%-8.0% of Ni, 3.0%-4.0% of Mo, 0.2%-0.3% of N and the balance of Fe; S2, abottom slag accounting for 2% of the weight of the molten steel is added into the intermediate frequency furnace, and melting is conducted; S3, after melting down, a Si-Ca wire is added for deoxidation; S4, slagging off is conducted after adding Si-Ca wires for 10 minutes, and high-aluminum refractory brick fragments and CaF2 are added to make new slag; S5, a deoxidizing agent is added into the slag layer in batches for first diffusion deoxidation; S6, components in front of the furnace are sampled and analyzed, FeCrNi alloy and alloy elements of Si, Mn, Mo and N are supplemented, and then diffusion deoxidation for the second time is conducted; and S7, the slag amount is adjusted, and tapping is conducted after white slag is kept for 15 minutes. Compared with the prior art, the oxygen content and the inclusion content in the intermediat requency smelting duplex stainless steel are reduced through reasonable intermediate frequency smelting burdening, deoxidation and slagging processes.

Owner:JIANGXI BAOSHUNCHANG SPECIAL ALLOY CO LTD

Sugarcane squeezing roller shaft restoration process

The invention relates to the technical field of machining of sugar factory machines, in particular to a sugarcane squeezing roller shaft restoration process for a sugar factory. The sugarcane squeezing roller shaft restoration process for the sugar factory includes the following process steps of pre-heating treatment, surface removing, turning removing, measuring, welding repairing, annealing treatment, ageing treatment, rough turning machining, finish turning machining, surface hardening pretreatment, journal hardening treatment, grinding and warehousing. The squeezing roller shaft restoration process has the characteristics that the process is simple, convenient and easy to implement, and low in restoration cost; a restored sugarcane squeezing roller shaft is stable in quality, high in strength and hardness, and good in durability; and the structure is reasonable, and the using adaptability is wide.

Owner:广西隆盛双金属铜合金制造有限公司

Multicomponent alloy infiltration anticorrosion method

InactiveCN108930013AHigh tensile strengthHigh yield strengthMolten spray coatingSolid state diffusion coatingCapacitanceWear resistance

The invention belongs to the technical field of metal surface anticorrosion, and more specifically relates to a zincizing enclosing anticorrosion method. The zincizing enclosing anticorrosion method is simple in technology, excellent in corrosion resistance and wear resistance, and high in toughness, tensile strength, and yield strength, and is friendly to the environment. The zincizing enclosinganticorrosion method comprises following steps: surface treatment shot blasting, high temperature heating, double zinc aluminum wire capacitance spraying onto steel surface, secondary heating penetration, and forming of surface zinc aluminium ferroalloy layers. The best collision resistance and corrosion resistance are achieved, and zincizing waste heat is adopted for another time of spraying of sealing layer alloy powder. The zincizing enclosing anticorrosion method is widely adopted in the field of steel structure member anticorrosion processing.

Owner:山西军昊实业有限公司

Method for smelting ultra-low carbon stainless steel through intermediate frequency furnace

ActiveCN105463156AFast melting speedImprove battery saving performanceProcess efficiency improvementElectric furnaceElectricityIntermediate frequency

The invention discloses a method for smelting ultra-low carbon stainless steel through an intermediate frequency furnace. The method comprises the specific steps of firstly, molten iron pretreatment; secondly, intermediate frequency smelting; thirdly, oxygen blowing and carbon reducing; fourthly, microelement adding; fifthly, deoxidation treatment; sixthly, casting shaping; and seventhly, electroslag remelting. An intermediate frequency furnace smelting manner and an electroslag remelting refining manner are adopted to produce the ultra-low carbon stainless steel, the production manner is flexible, and the material supply manner of small batches, multiple specifications and urgent demands of a customer can be met; the intermediate frequency furnace is high in smelting speed, good in power-saving effect, few in burning loss and low in energy consumption; the smelting efficiency is improved; and electroslag remelting refining is adopted to enable the inner structure of a steel ingot to be more compact, and the ultra-low carbon stainless steel is high in purity, low in sulfur containing, less in nonmetallic inclusion, smooth in surface, clean, even and compact and even in gold phase structure and chemical component.

Owner:四川民盛特钢锻造有限公司

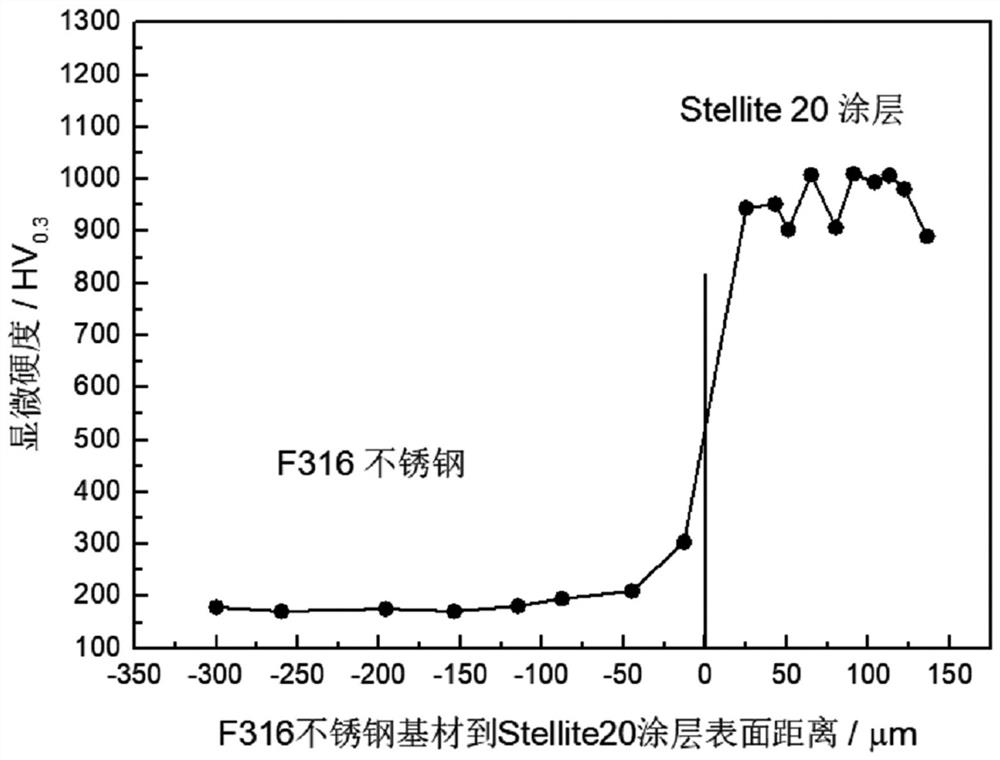

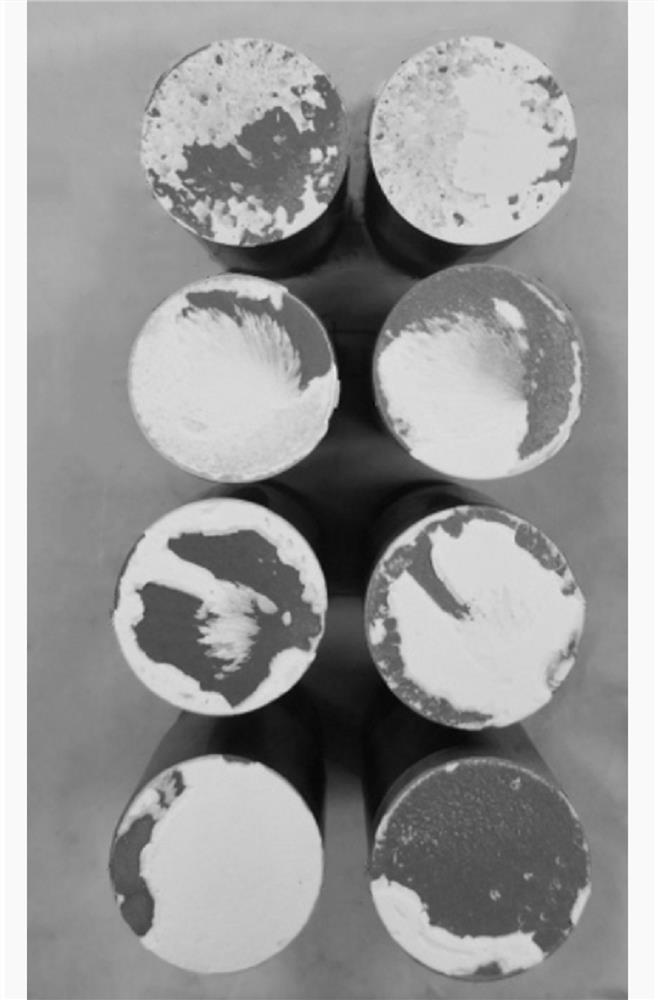

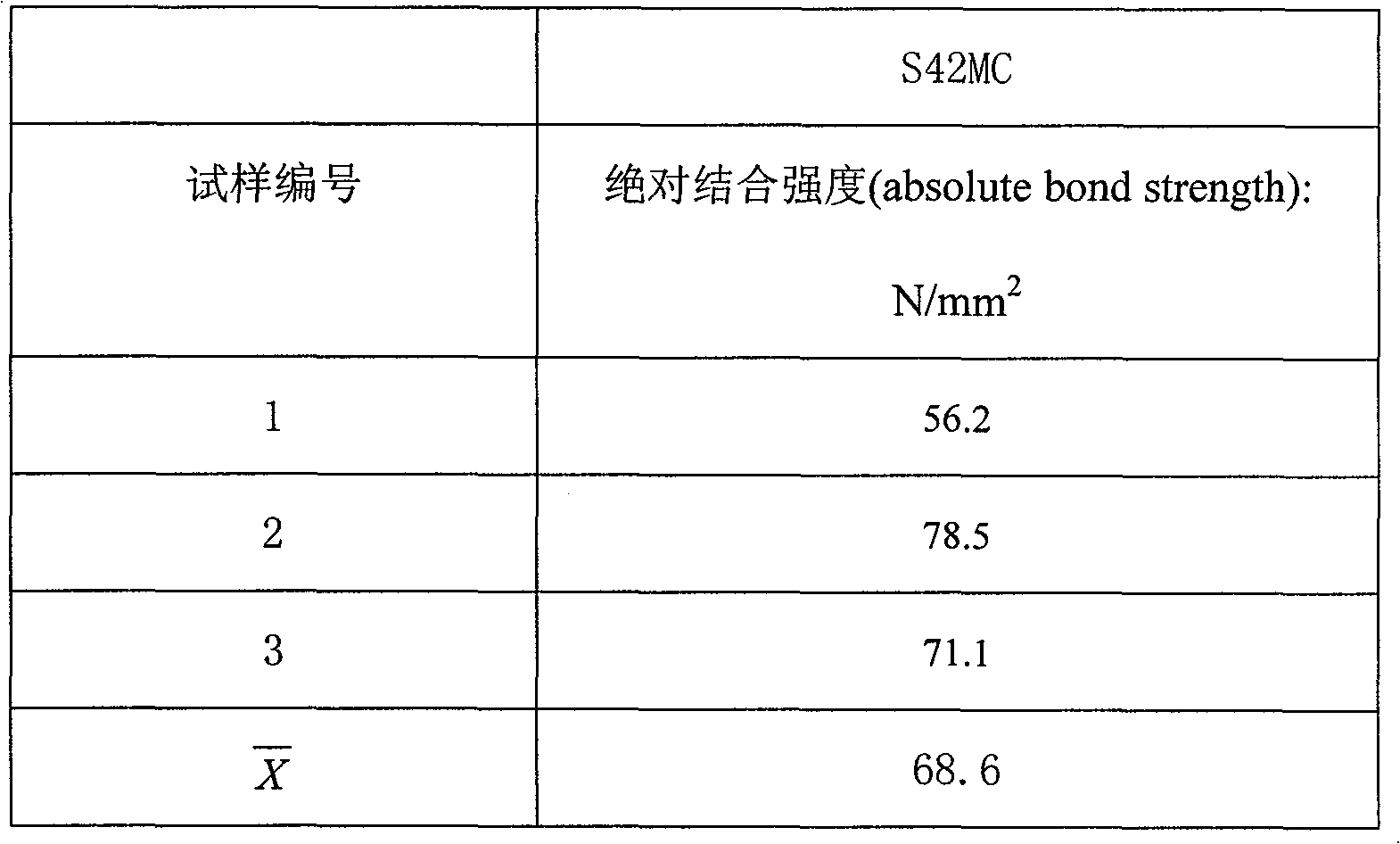

Method for spraying Stellite 20 alloy on surface of workpiece

The invention relates to a method for spraying a Stellite 20 alloy on the surface of a workpiece. The method comprises the following steps that (1), surface treatment is conducted, specifically, the size of a machined workpiece is detected, cleaning is conducted, and sand blasting and roughening are conducted on the surface of the workpiece, so that the roughness Ra of the surface of the workpiece is 10 microns-13 microns; and (2), the surface of the sprayed workpiece is preheated to 70 DEG C-90 DEG C, spraying equipment is adopted for spraying Stellite 20 alloy powder to the surface of the workpiece, and a coating is deposited for multiple times to make the thickness of the coating be 0.25 nm-0.35 mm. By the adoption of the method, the thickness of the coating on the surface of the workpiece is uniform, the binding force between the coating and a base body is good, the porosity of the coating is low, oxide inclusions are few, the abrasion resistance and corrosion resistance of the coating are good, and the technical indexes required by the valve application field can be met, wherein the hardness is larger than or equal to 750 HV0.3, the porosity is smaller than or equal to 1%, the binding force is larger than or equal to 70 MPa, and the oxide content is smaller than or equal to 2%.

Owner:CHONGQING CHUANYI CONTROL VALVE

Preparation method of magnesium-aluminum layered composite plate

InactiveCN102166846BStable mechanical propertiesImprove corrosion resistanceLaminationLamination apparatusAlloyComposite plate

The invention relates to a preparation method of a magnesium-aluminum layered composite plate, aiming at solving the problems that the magnesium-aluminum alloy plate is light in weight, low in strength and poor in corrosion resistance. The method comprises the steps of: pressing and labeling a layer of aluminum plate on the magnesium-aluminum alloy plate; taking magnesium-aluminum eutectic alloy powder as a pressing and labeling material; pressing and labeling the magnesium-aluminum alloy plate+the magnesium-aluminum eutectic alloy powder+the aluminum plate into a magnesium-aluminum layered composite plate in an open-close through groove mould on a press machine under the temperature of 480 DEG C and the pressure of 30M Pa for 60s; and performing the low-temperature thermal treatment, so that an internal metallographic phase tissue of the magnesium-aluminum layered composite plate is more compact and stable. The method is advanced and reasonable, small in use equipment, short in technological process, and fast in speed. The mechanical property tensile strength of the magnesium-aluminum layered composite plate can reach 24MPa. Compared with the prior art, the mechanical property tensile strength can be improved by 95%, and the corrosion resistant performance can be improved by 94%, therefore, the preparation method of the magnesium-aluminum layered composite plate is very ideal.

Owner:TAIYUAN UNIV OF TECH

Preparation method of alloy co-penetration Dacromet and closing layer composite coating

ActiveCN106046867AUniform thicknessDense metallographic structureSolid state diffusion coatingAnti-corrosive paintsRoom temperatureMetal sheet

The invention discloses a preparation method of an alloy co-penetration Dacromet and closing layer composite coating. The method includes the following steps of weighing a co-penetration agent raw material to be evenly mixed to prepare a co-penetration agent, stacking platy metal sheets with cleaned surfaces to form a stack with high and width approximately the same, laying a layer of co-penetration agent between every two adjacent platy metal sheets, packing the metal sheets into bundles, putting the bundles in a co-penetration furnace, weighing a Dacromet anticorrosion raw material to be evenly mixed and stirred, adjusting pH, putting the platy metal sheets in a coating solution soaking cage, making the platy metal sheets soaked in a Dacromet anticorrosion coating solution, conducting rotary draining, sending the platy metal sheets into an online drying device to be baked, cooling the platy metal sheets to the room temperature, preparing a normal temperature curing agent from tetraethylenepentamine and cashew phenol glycidyl ether, preparing a front pre-mix component and a curing reaction component to be evenly mixed to prepare a closing solution, spraying the closing solution onto the rotating platy metal sheets, making the platy metal sheets enter a tunnel oven to be dried, and then putting the platy metal sheets in the normal temperature for 2-4 h.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

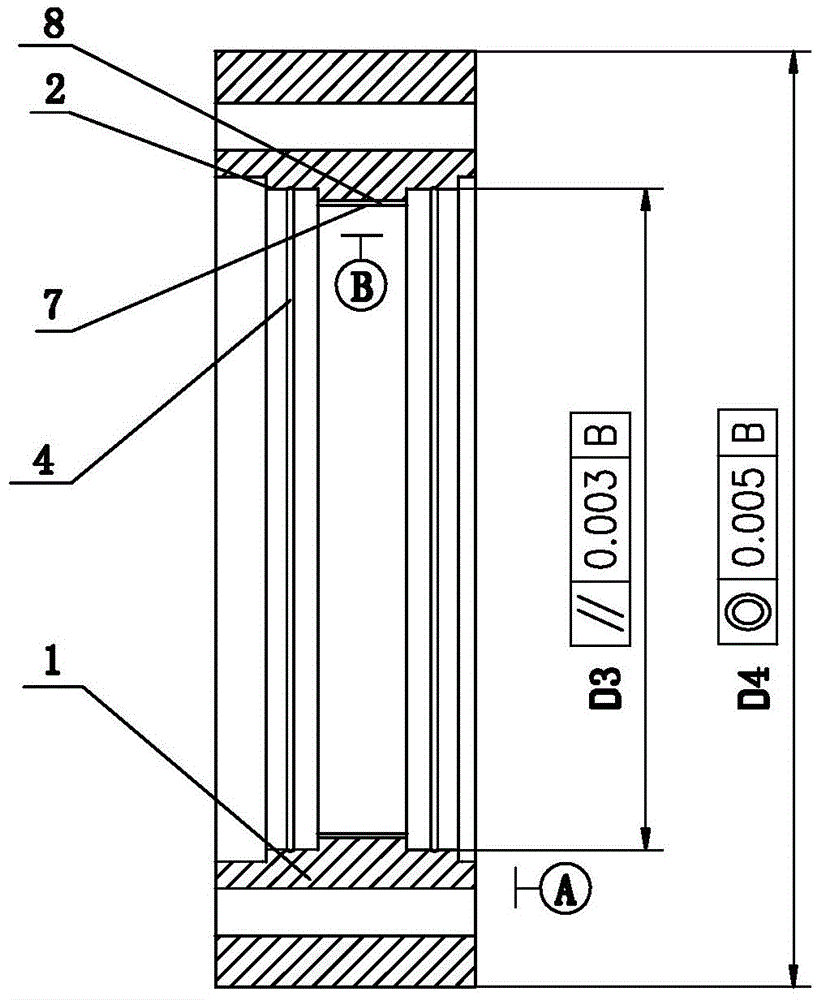

The processing method of the integrated planet carrier of the rv reducer of the robot

The invention discloses an integrated machining method of a planet carrier of a robot RV reducer, and belongs to the technical field of robot RV reducer machining. The method comprises the steps as follows: forging a first casing and a second casing, and performing hot extrusion on the first casing and the second casing respectively; performing thermal refining; performing tempering; performing finish machining on end surfaces respectively; connecting the first casing with the second casing to be clamped to a clamp, and performing finish machining on inner holes formed in the first casing and the second casing with a center of gyration serving as a locating basis; performing finish machining on outer surface with the locating basis; directly machining inner rings of rolling bearings on the first casing and the second casing; accurately grinding an outer track on each inner ring simultaneously; and performing finish machining bearing positions of three tapered roller bearings on the first casing and the second casing with the location reference, and directly machining outer rings of the tapered roller bearings. With the adoption of the method, the mounting accuracy, the manufacturing accuracy and the transmission accuracy are ensured, the requirement for high accuracy is met, the service life is prolonged, machining and assembling errors and accumulative errors are reduced, the output torque is increased, and the machining cost is effectively reduced.

Owner:SHANDONG SHKE MACHINERY MFG

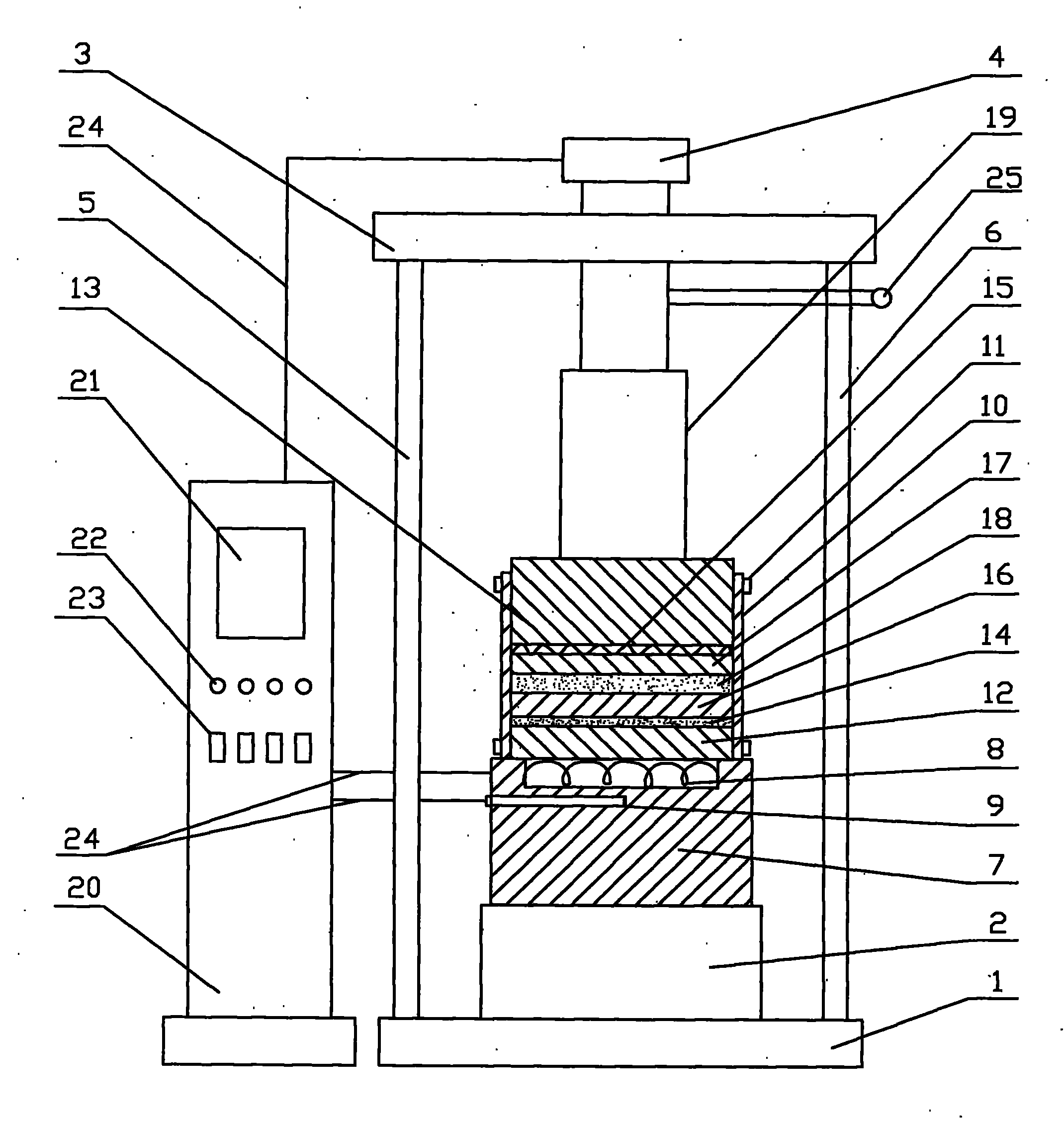

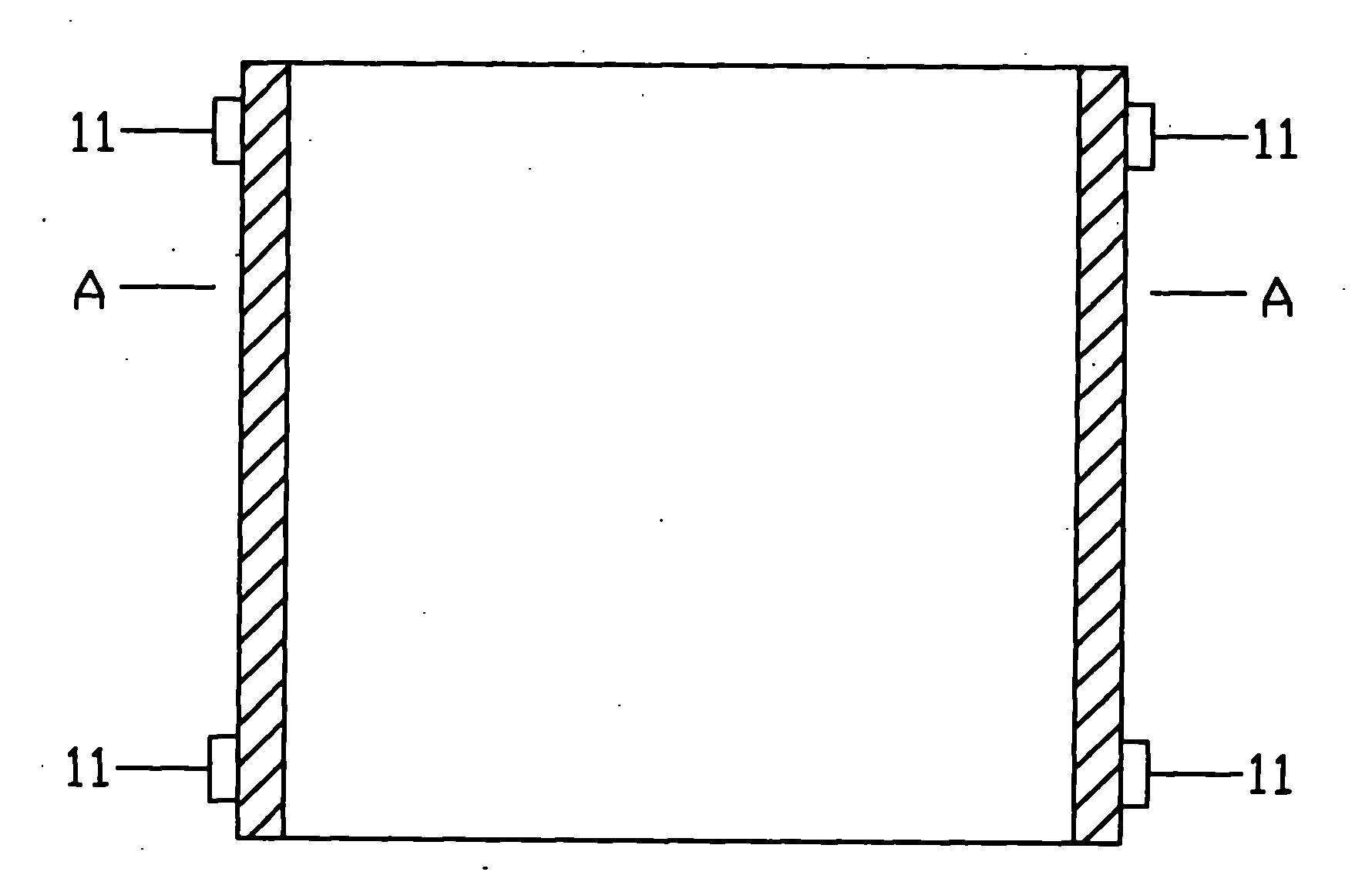

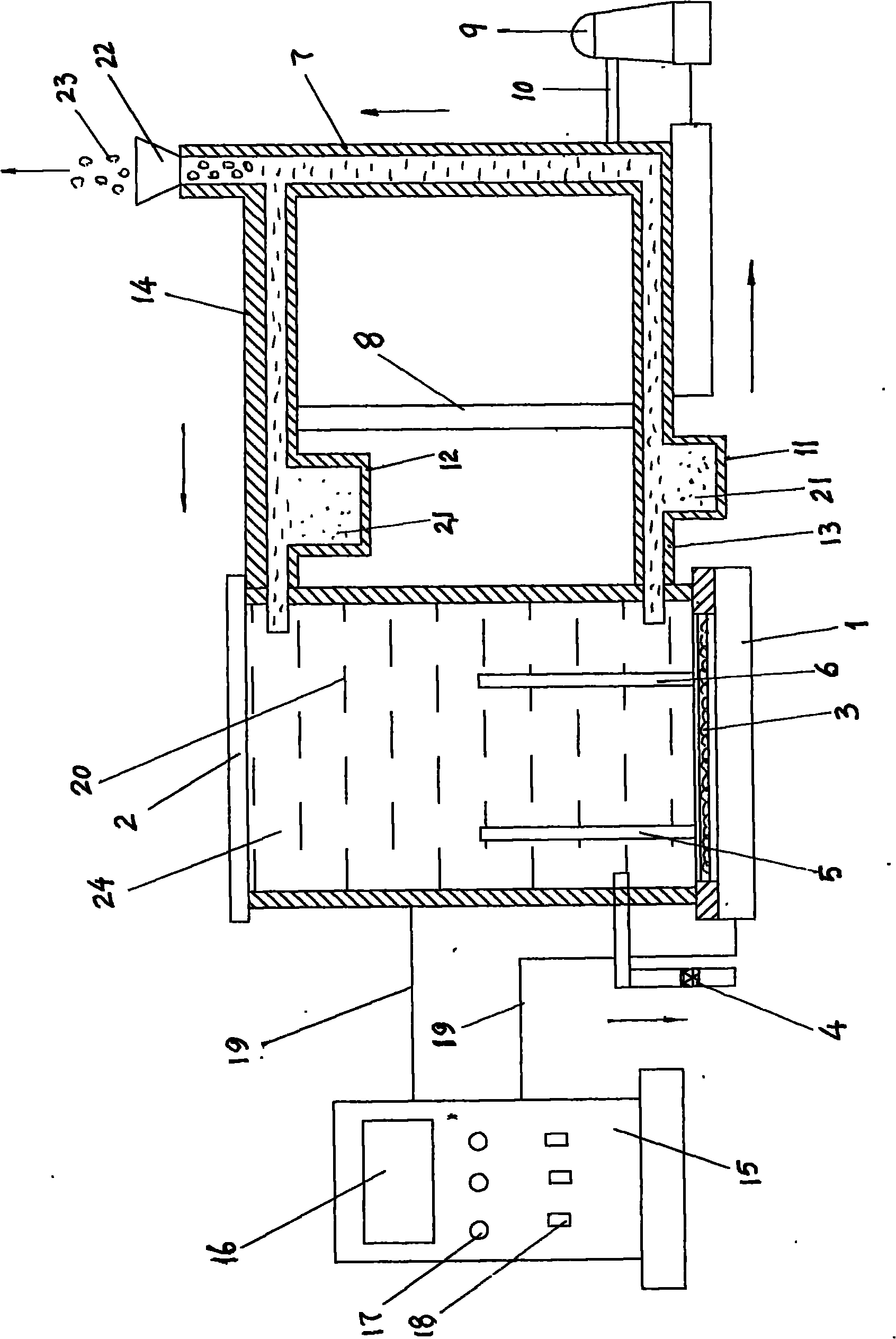

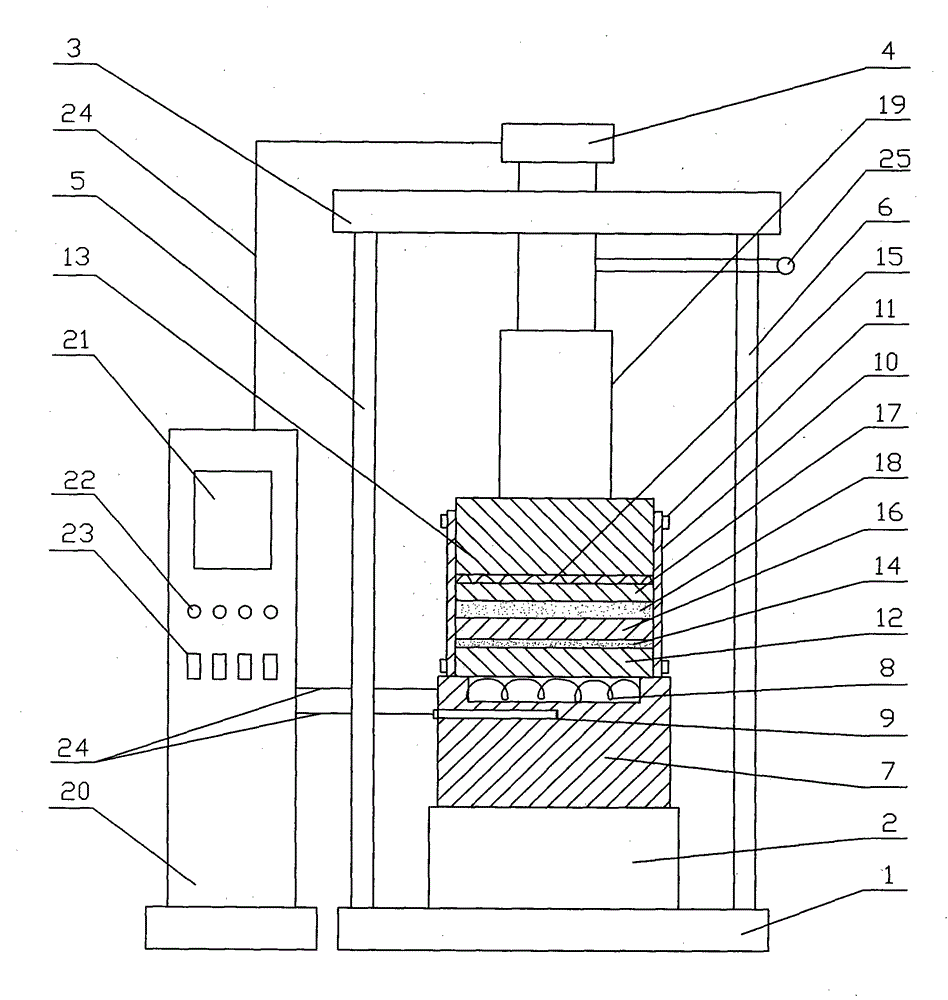

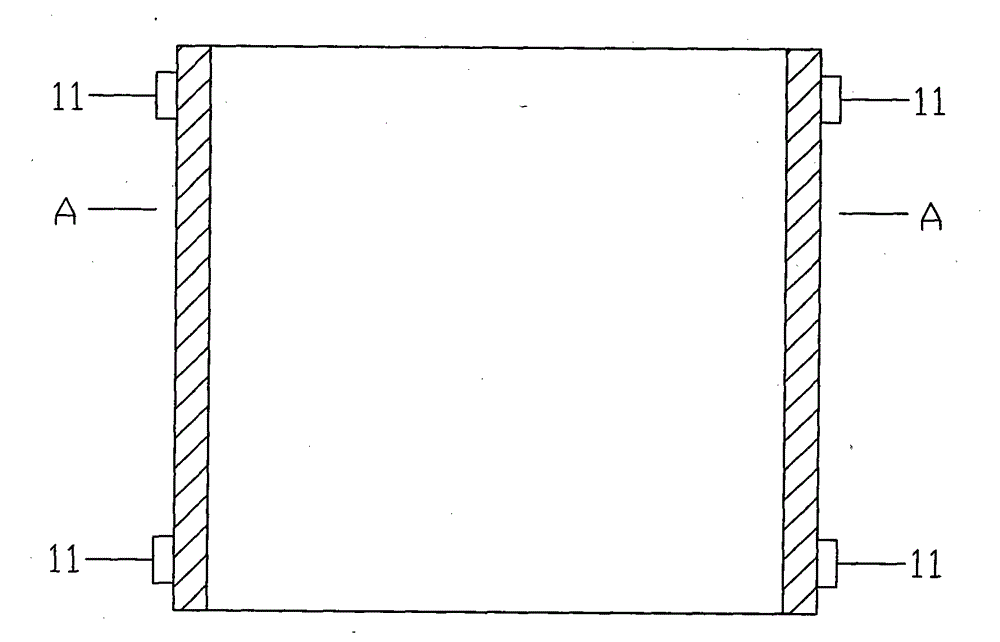

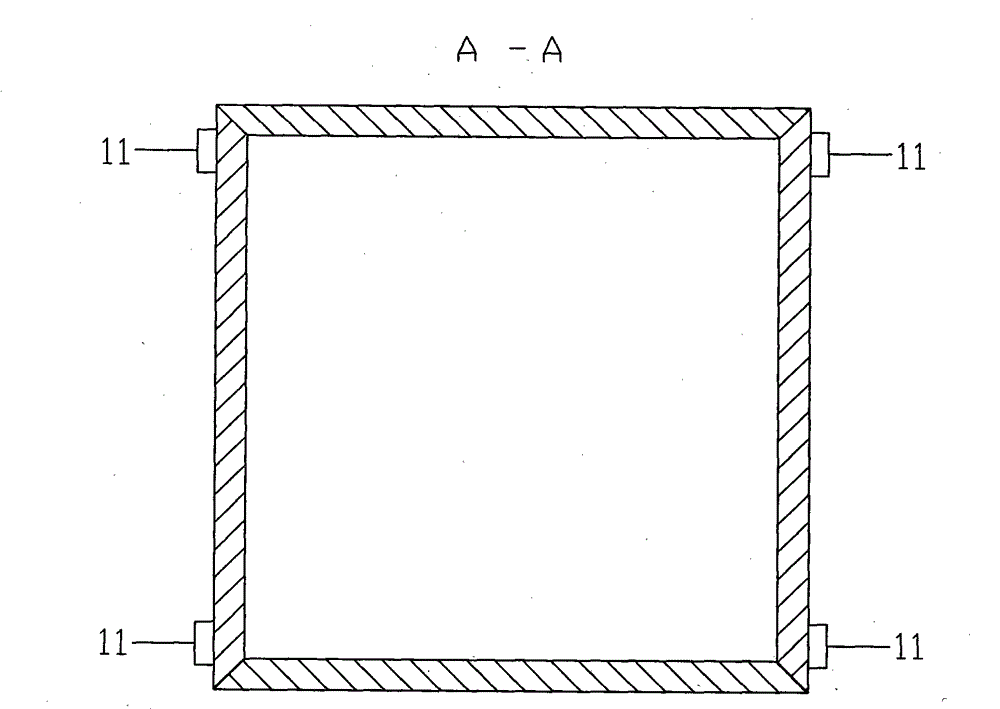

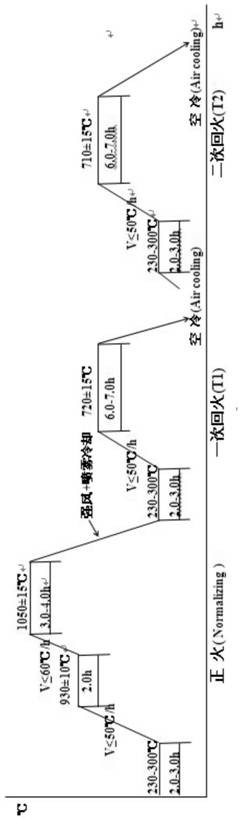

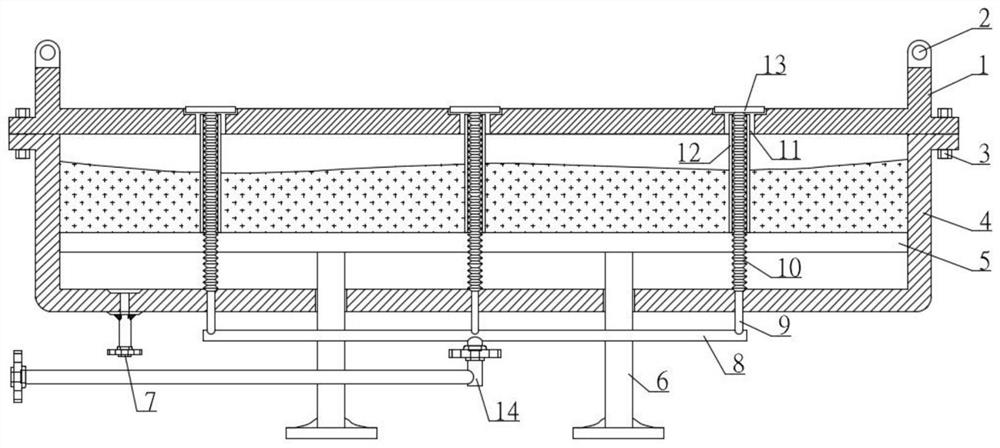

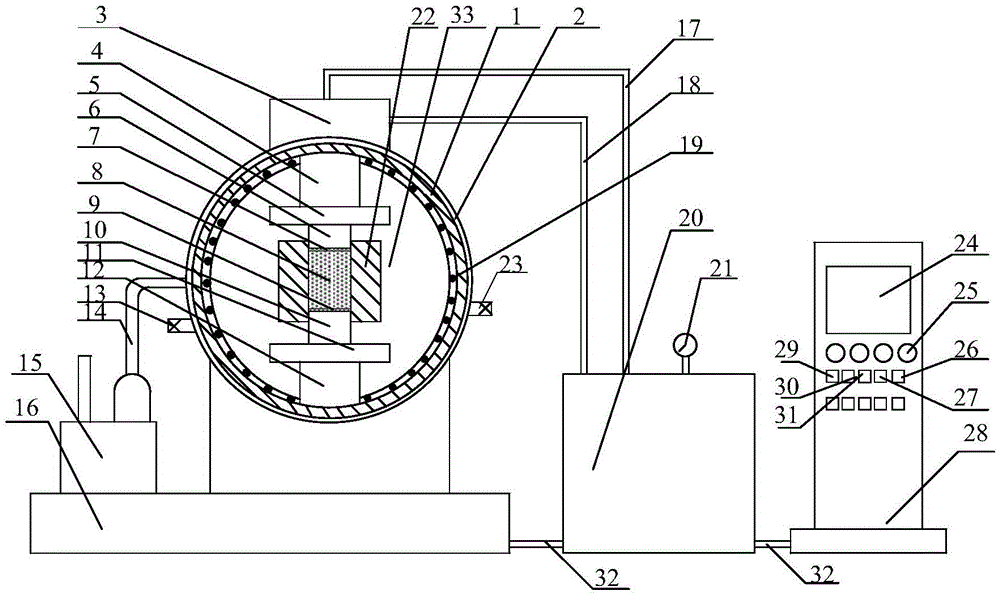

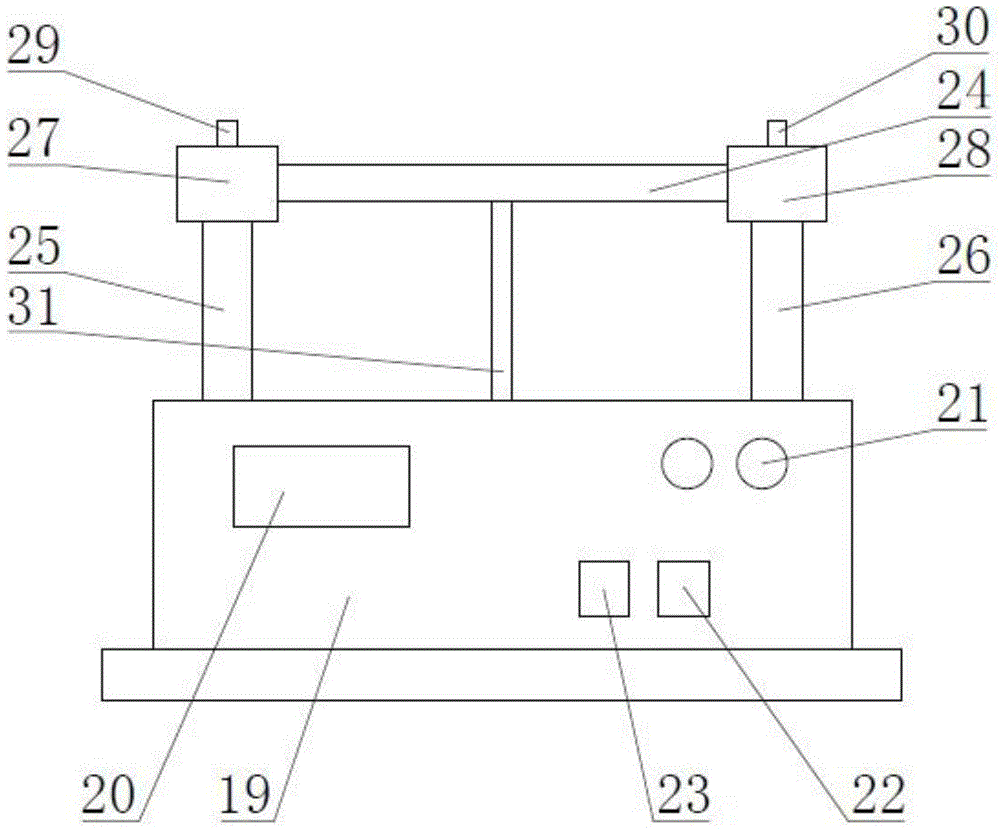

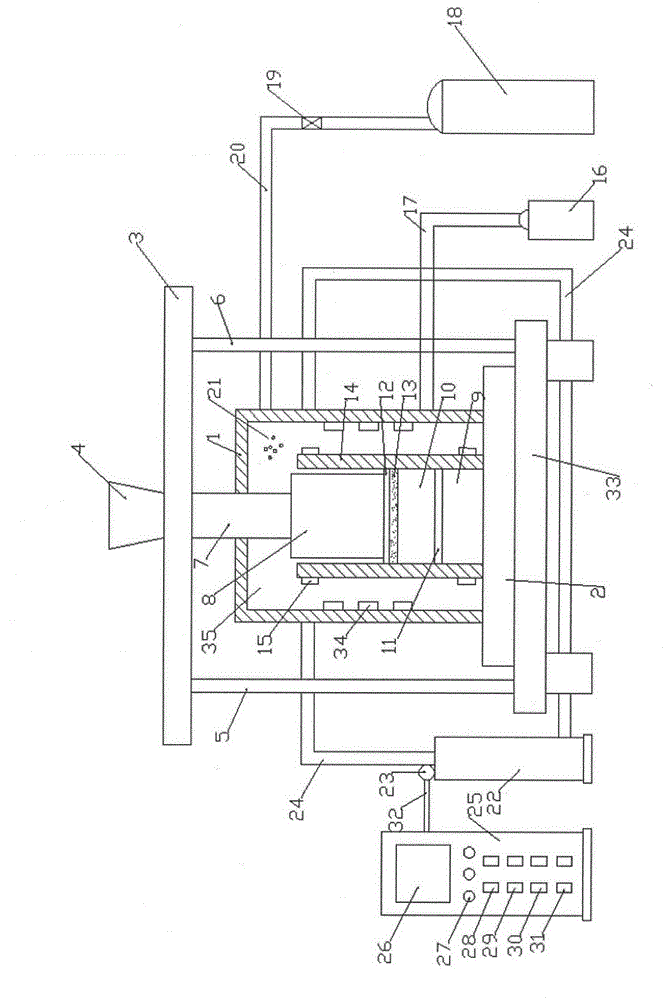

High alloy steel heat-resistant martensitic stainless steel heat treatment device

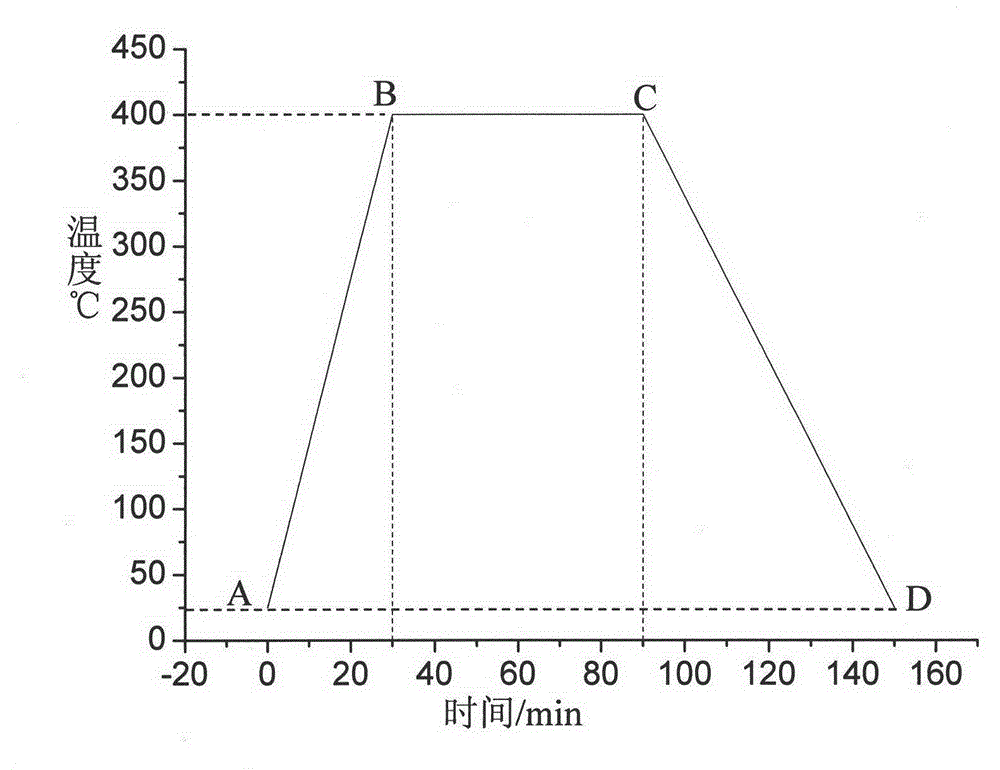

PendingCN113403454ADense metallographic structureElimination of retained austeniteFurnace typesHeat treatment furnacesMartensitic stainless steelAlloy steel

The invention discloses a high alloy steel heat-resistant martensitic stainless steel heat treatment device, and relates to the technical field of stainless steel heat treatment. The high alloy steel heat-resistant martensitic stainless steel heat treatment device comprises a box-type gas furnace and a tray, the upper end of the tray is provided with a plurality of lifting lugs, the tray is provided with at least one slot, and the lower end of the tray is connected with a chassis through bolts; a partition plate is arranged in the chassis, and a sand layer is arranged at the upper end of the partition plate; and at least one supporting leg is arranged at the bottom end of the partition plate, penetrates through the chassis in a clearance manner and extends to the outer side of the chassis. The extension type cooling design in the tray is adopted, the device is adopted, uniform cooling is matched with two times of tempering, so that the metallographic structure of martensitic stainless steel is compact, retained austenite is eliminated, stress is further eliminated, the strength of the martensitic stainless steel is not changed, the toughness is improved, meanwhile, the effects of stabilizing and refining grains and homogenizing the structure can be completely achieved, and the obtained mechanical property result and the high-temperature lasting tensile property completely meet the standard requirements.

Owner:HUSN CASTING ANHUI YINGLIU GROUP

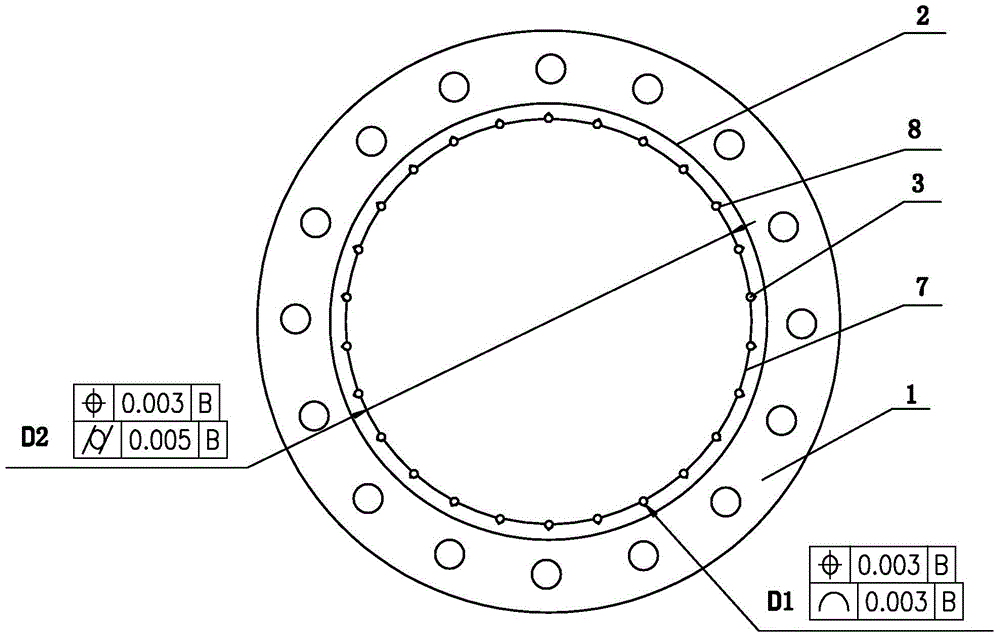

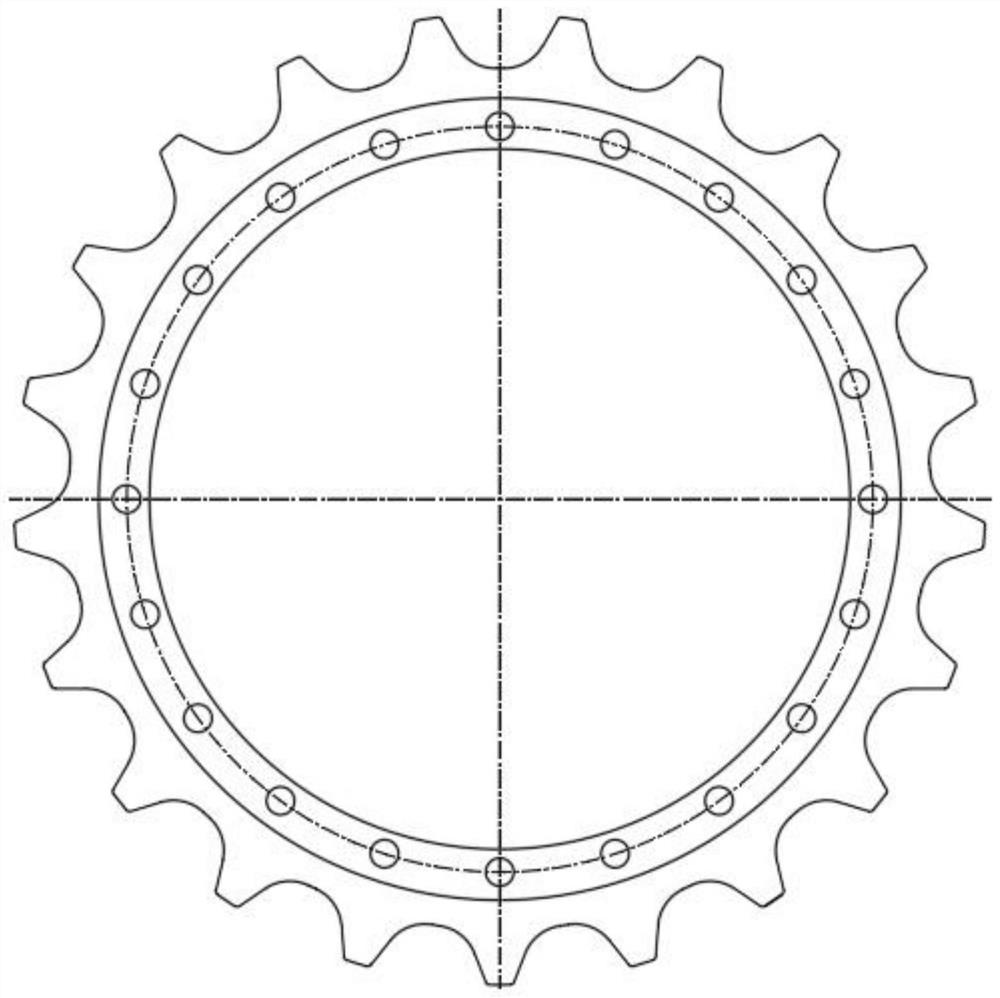

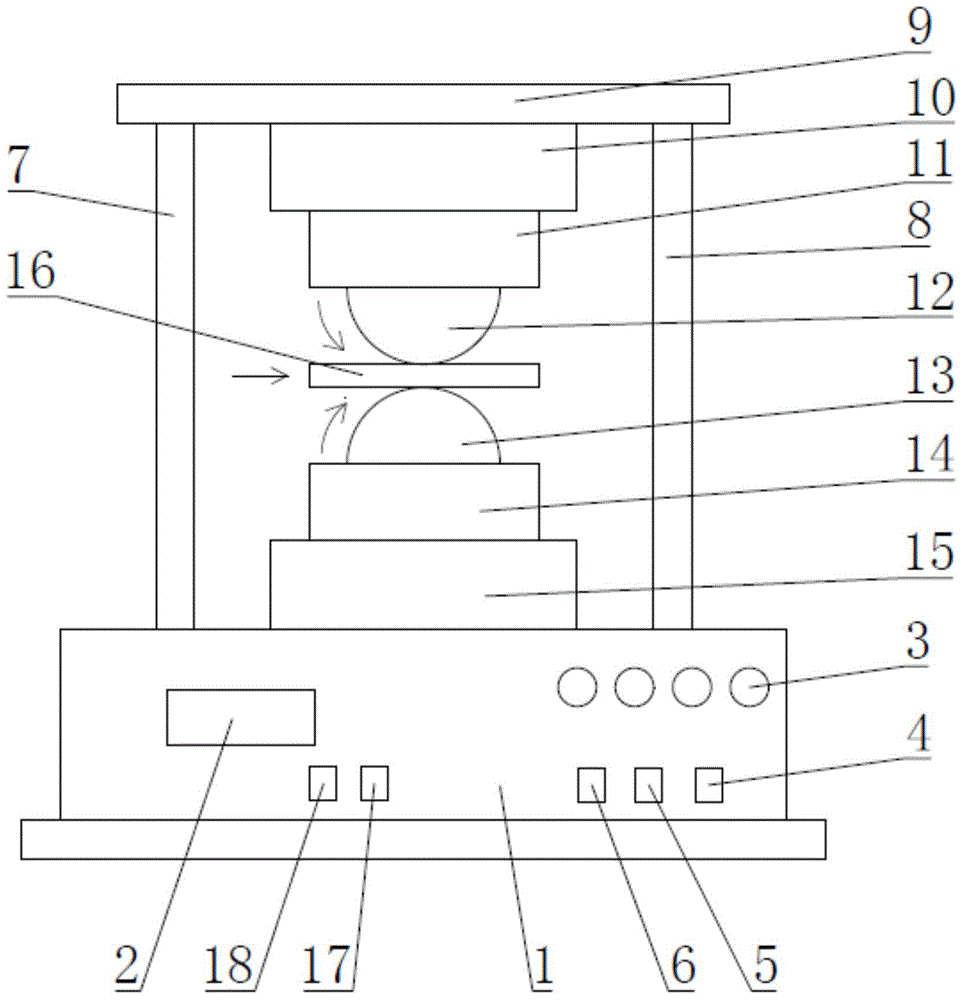

The processing technology of the pin gear housing of robot rv reducer

InactiveCN103433705BSmooth runningGuaranteed coaxiality accuracyNeedle roller bearingReduction drive

The invention discloses a processing technology of a robot RV speed reducer needle gear shell, and belongs to the technical field of robot RV speed reducer processing. The processing technology includes the steps that precise casting or forging is carried out on a needle gear shell blank; the needle gear shell blank is clamped after the surface of the needle gear shell blank is machined, and the rotation center of the needle gear shell blank is taken as a positioning reference; the end face of the needle gear shell blank, a bearing position of a roller pin bearing and bearing positions of two main bearings are machined; finish machining is carried out on the inner surface of the roller pin bearing according to the positioning reference; finish machining is carried out on a roller pin groove in line contact with a roller pin of the roller pin bearing according to the positioning reference; inner grooves are simultaneously machined in the bearing positions of the two main bearings in a finish machining mode according to the positioning reference; finish machining is carried out on the outer surface of the needle gear blank. The needle gear shell machined according to the steps improves machining precision and the parallelism degree of the bearing positions of the main bearings, guarantees coaxiality, the position degree and cylindricity of the main bearings after installation, achieves one-time clamping, can meet requirements of multiple process parameters, improves machining precision and installation precision of the needle gear shell, reduces accumulated errors, meets the high-precision requirements, and prolongs service life.

Owner:SHANDONG SHKE MACHINERY MFG

Alloy co-infiltration dacromet and sealing layer composite coating preparation method

ActiveCN106046867BUniform thicknessDense metallographic structureSolid state diffusion coatingAnti-corrosive paintsFirming agentAlloy

The invention discloses a method for preparing a composite coating of alloy co-infiltration, dacromet and sealing layer, which comprises the following steps: weighing the co-infiltration agent raw materials, mixing them uniformly to prepare the co-infiltration agent; treating the clean plate metal The pieces are stacked into stacks with similar height and width, and a layer of co-infiltration agent is laid between adjacent plate-shaped metal parts, and then packed into bundles and put into the co-infiltration furnace; Dacromet anti-corrosion raw materials are weighed, mixed and After stirring evenly, adjust the pH; place the plate-shaped metal parts in the coating liquid dipping cage, then impregnate the Dacromet anti-corrosion coating liquid, rotate and drain, send it to the online drying equipment for baking, and cool to room temperature; Cardanol glycidyl ether is used to prepare a curing agent at room temperature; the pre-preparation component and the curing reaction component are prepared, and the pre-preparation component and the curing reaction component are mixed uniformly to obtain a sealing liquid, and the rotating plate metal parts are subjected to Spraying; drying in a tunnel oven and then placed at room temperature for 24 hours.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Gear ring forming process

PendingCN113981205ADense metallographic structureFine grainFoundry mouldsFurnace typesTemperingAutonomation

The invention discloses a gear ring forming process, and relates to the technical field of gear ring forming processes. The gear ring forming process comprises the following steps that S1 blank forming is conducted, specifically, manganese steel alloy is smelted in a medium open furnace to be in a molten state, the manganese steel alloy in the molten state is cast into a gear ring mold, and a gear ring blank ring is formed; S2 quenching and tempering treatment are conducted, specifically, the gear ring blank ring is taken out and conveyed into a heat preservation box through an automatic conveying device for quenching and tempering treatment; and S3 forming is conducted, specifically, the quenched and tempered gear ring blank ring is taken out, and a gear ring body is formed through machining. The gear ring blank ring is cast, then the blank material is transferred into the heat preservation box through the automatic device for heat quenching and tempering, the internal quality of the gear ring blank ring is improved, manual operation is not needed in the transferring process, and the manual labor intensity is reduced.

Owner:福建省四轮工程机械有限公司

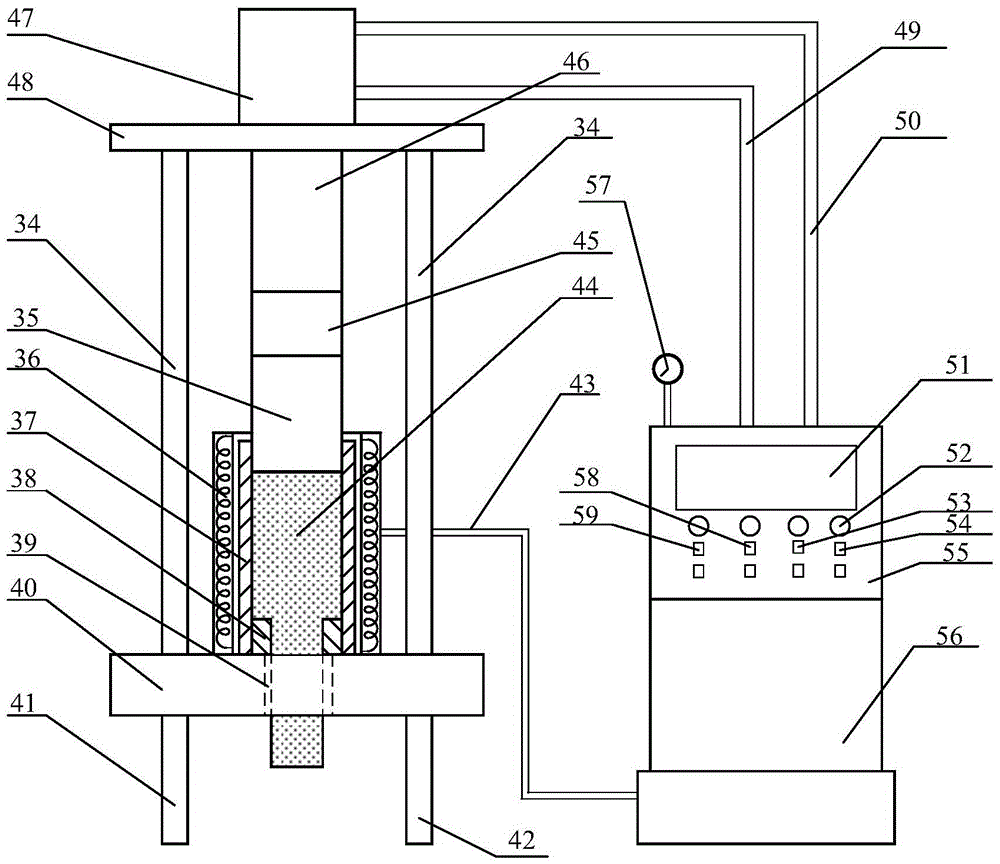

A kind of preparation method of reinforced magnesium alloy base neutron absorbing plate

The invention relates to a preparation method of an enhanced magnesium alloy-based neutron absorption plate. The method comprises the following steps: aiming at the actual condition of nuclear radiation protection, with boron carbide powder, boron powder, magnesium powder and aluminum alloy powder as raw materials, adopting a vacuum hot-pressing technique under the assisted action of an electric field, and preparing a magnesium alloy-based neutron absorption plate blank under electric field heating, resistance heating, pressurizing and vacuum conditions, so that B4C particles and B particles are evenly distributed in a matrix; oxidation of the material is effectively prevented by the vacuum environment; the interface bonding intensity is improved by the electric field action; the blank is molded in a hot extrusion manner; the particle distribution uniformity is improved; the plastic deformation property of the material is improved; the extruded blank is subjected to hot rolling to obtain the plate; the internal metallographic structure of the material is relatively dense; the preparation method is advanced in process, and accurate, detailed and accurate in data; the neutron absorption property of the magnesium alloy-based neutron absorption plate reaches 98%; the material density reaches 99%; the material hardness reaches HV0.1=186.7; the particle distribution is uniform; and the enhanced magnesium alloy-based neutron absorption plate is a lightweight and high-strength composite plate with good neutron absorption property.

Owner:TAIYUAN UNIV OF TECH +1

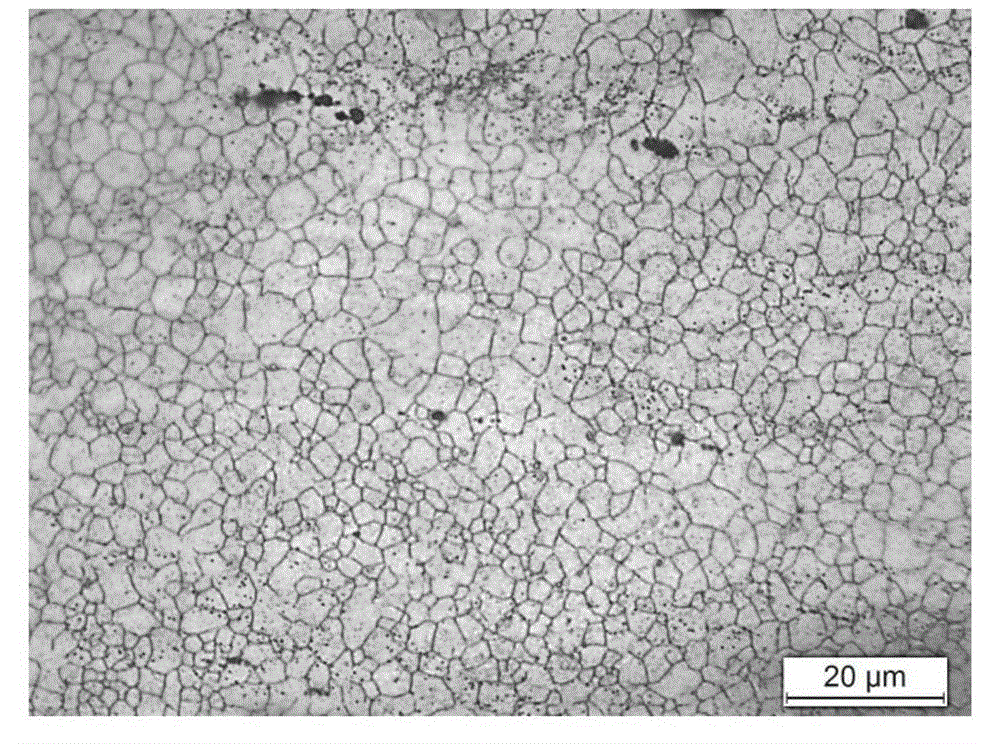

A kind of preparation method of fine-grained magnesium alloy plate

The invention relates to a preparation method of a fine-grained magnesium alloy plate. Aiming at the low strength and plasticity of the magnesium alloy plate, the magnesium alloy plate is rolled and deformed, and the static recrystallization of the deformed structure induced by an electric pulse current is adopted. The plate is processed to make the metallographic structure of the magnesium alloy plate dense and the grains refined, which greatly improves the strength and plasticity of the magnesium alloy plate. This preparation method has advanced technology, accurate and detailed data, and the grain size of the metallographic structure is ≤5μm. The uniformity is good, the tensile strength reaches 295MPa, and the elongation reaches 22%, which is a very ideal method for preparing fine-grained magnesium alloy plates.

Owner:TAIYUAN UNIV OF TECH

A kind of manufacturing method of motorcycle starting ratchet

Provided is a method for manufacturing a starting ratchet wheel of a motorcycle. Metal powder serves as a raw material and is sintered after compression forming in a mould. The method is characterized in that pressure for compression is 80-115 tons, and dwell pressure for demoulding is 9-15 tons. The metal powder serves as the raw material, is alloyed into alloy steel by compressing and sintering, and is completely free of mechanical cutting, and accordingly waste of steel materials is avoided, steel resource is greatly saved, and the produced starting ratchet wheel of the motorcycle has mechanical performance of the alloy steel, the mechanical performance and overall quality of the starting ratchet wheel are further improved, and production efficiency is also greatly increased. The method is simple in production process, the starting ratchet wheel is high in precision and fine in consistency, and stability of quality of products in mass production is guaranteed.

Owner:重庆聚能粉末冶金股份有限公司

A method for smelting ultra-low carbon stainless steel in an intermediate frequency furnace

ActiveCN105463156BFast melting speedImprove battery saving performanceElectric furnaceProcess efficiency improvementElectricityIntermediate frequency

The invention discloses a method for smelting ultra-low carbon stainless steel through an intermediate frequency furnace. The method comprises the specific steps of firstly, molten iron pretreatment; secondly, intermediate frequency smelting; thirdly, oxygen blowing and carbon reducing; fourthly, microelement adding; fifthly, deoxidation treatment; sixthly, casting shaping; and seventhly, electroslag remelting. An intermediate frequency furnace smelting manner and an electroslag remelting refining manner are adopted to produce the ultra-low carbon stainless steel, the production manner is flexible, and the material supply manner of small batches, multiple specifications and urgent demands of a customer can be met; the intermediate frequency furnace is high in smelting speed, good in power-saving effect, few in burning loss and low in energy consumption; the smelting efficiency is improved; and electroslag remelting refining is adopted to enable the inner structure of a steel ingot to be more compact, and the ultra-low carbon stainless steel is high in purity, low in sulfur containing, less in nonmetallic inclusion, smooth in surface, clean, even and compact and even in gold phase structure and chemical component.

Owner:四川民盛特钢锻造有限公司

Preparation method for alkaline earth heatproof magnesium alloy

The invention relates to a preparation method for alkaline earth heatproof magnesium alloy. According to the invention, magnesium and aluminum are used raw materials, and magnesium-strontium intermediate alloy, magnesium-calcium intermediate alloy, magnesium-yttrium intermediate alloy, magnesium-lanthanum intermediate alloy and alkaline earth magnesium-strontium intermediate alloy and magnesium-calcium intermediate alloy are added as a main addition chain; and then melting at a vacuum melting furnace under the protection of argon, casting for formation of an ingot, cutting and low temperature tempering are carried out so as to prepare an alkaline earth heatproof magnesium alloy ingot. The preparation method provided by the invention has the advantages of an advanced process, reasonable proportioning, detailed and accurate data, no pollution to the environment, safety, stability and reliability; the prepared alkaline earth heatproof magnesium alloy ingot has a compact metallographic structure and high strength and has a tensile strength of 190 MPa, a yield strength of 140 MPa and elongation of 4.0% after insulation at a temperature of 200 DEG C for 20 min; and the preparation method is an ideal preparation method for the alkaline earth heatproof magnesium alloy.

Owner:TAIYUAN UNIV OF TECH

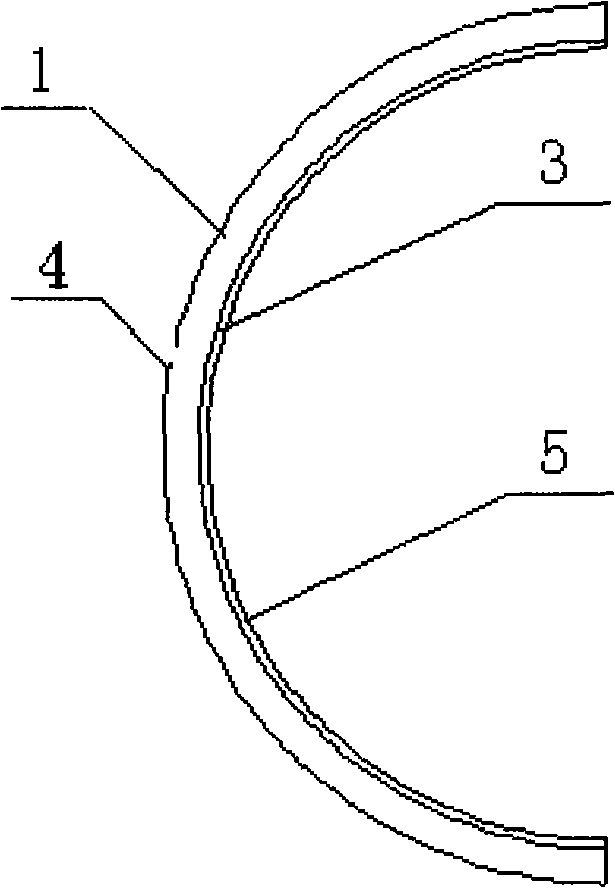

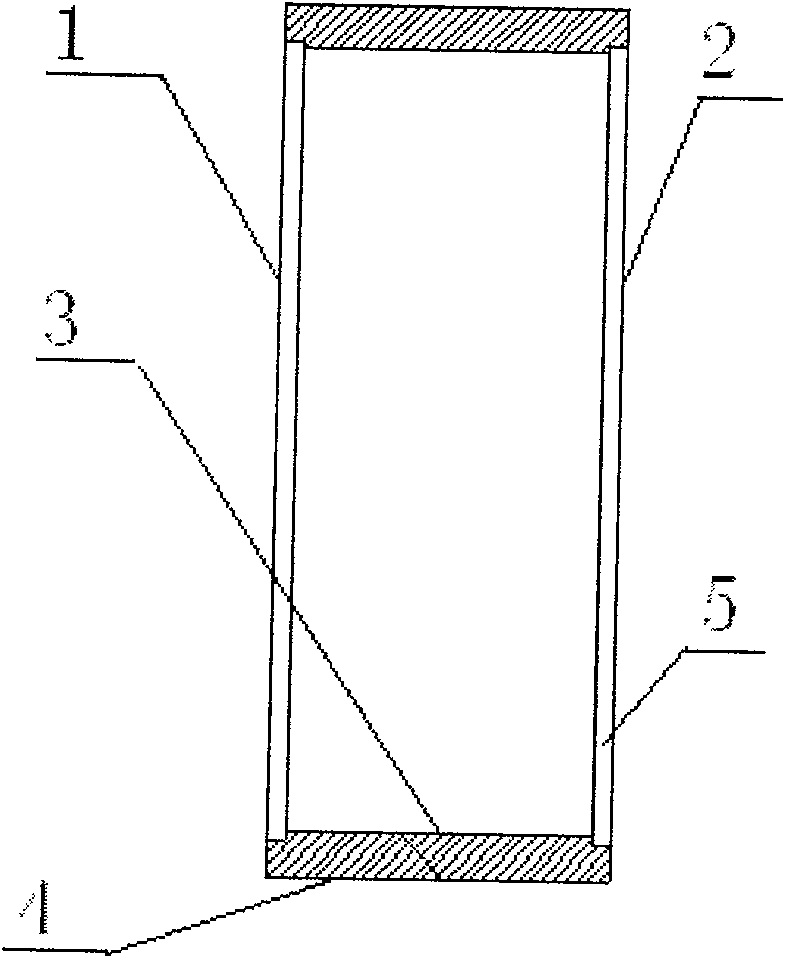

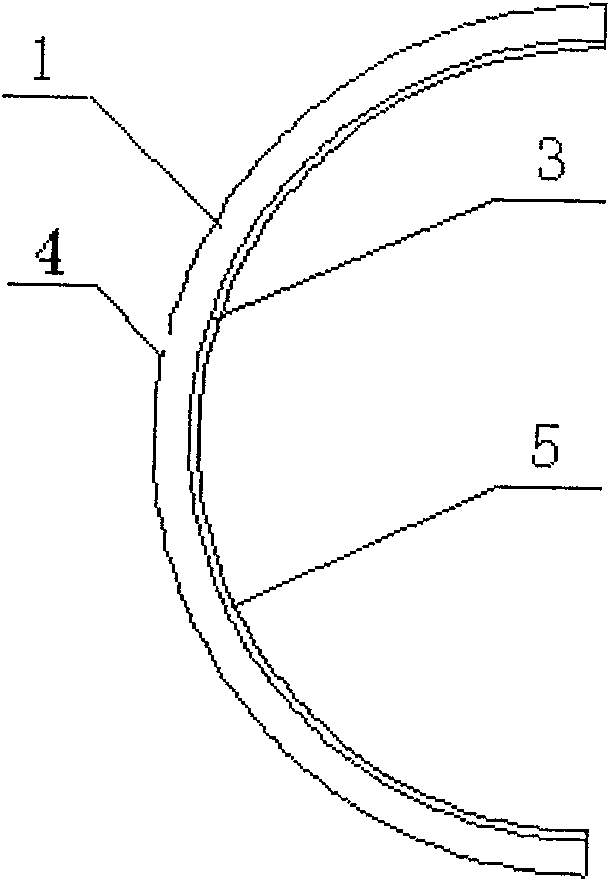

Manufacturing process of high-power low-speed diesel shaft bushing

InactiveCN100552248CReduced edge defectsHigh bonding strengthBearing componentsLow speedManufacturing technology

The invention relates to a manufacturing process of a bearing bush of a high-power low-speed diesel engine, which belongs to the technical field of manufacturing bearing bushes of large mechanical equipment. In the invention, the bearing bush is manufactured according to the technological sequence of: rough blank manufacturing → blank pouring surface treatment (shot blasting treatment and cleaning) → tin enamel → casting babbitt alloy → finishing machining and final inspection. Because the method of the present invention has the characteristics of simple manufacture, high product strength, good quality, high reliability, and low production cost, the product manufactured by the process of the present invention has a uniform metallographic structure, high bonding strength of the alloy layer, and can meet large Therefore, the bearing bush manufactured by the present invention can be widely used in large-scale heavy-duty mechanical equipment, and is especially suitable for marine high-power low-speed diesel engines.

Owner:CHONGQING YUEJIN MACHINERY

Coating hot-pressing reinforcement method of magnesium-aluminum alloy plate

The invention relates to a coating hot-pressing reinforcement method of a magnesium-aluminum alloy plate. According to the coating hot-pressing reinforcement method, aiming at the situations of soft texture, low hardness and strength and poor corrosion resistance of the magnesium-aluminum alloy plate, a layer of magnesium-aluminum-erbium alloy coating is formed on the magnesium-aluminum alloy plate through hot-pressing sintering by taking rare earth erbium as a reinforcing agent and using the steps of casting of magnesium-aluminum-erbium alloy, powder forming through ball milling, hot-pressing sintering and low-temperature tempering, wherein firm bonding between the coating and the alloy plate is achieved, therefore strength, hardness and corrosion resistance of the magnesium-aluminum alloy plate are greatly increased, coating hardness reaches 270HV which is increased by 3.55 times, and corrosion resistance of the magnesium-aluminum alloy plate with the magnesium-aluminum-erbium alloy coating is increased by 519 percent compared with that of the magnesium-aluminum alloy plate without the magnesium-aluminum-erbium alloy coating. The preparation method disclosed by the invention has the advantages of advanced process, detailed and accurate magnitude, good coating bonding force, compact metallographical tissues and capability of being applied in multiple industrial fields and is the very ideal coating hot-pressing sintering reinforcement of the magnesium-aluminum alloy plate.

Owner:TAIYUAN UNIV OF TECH

Technique for manufacturing high-carbon steel thrust sliding bearing of high-power low speed diesel engine

InactiveCN101225856BHigh bonding strengthIncrease decarburization processBearing componentsLow speedHigh carbon

The invention relates to a manufacturing craft of high carbon steel thrust sliding bearing for high power low speed diesel engines, belonging to a field of thrust sliding bearing manufacturing craft for large mechanical equipment. The process steps are as follows: roughcast manufacturing: roughcast pouring surface processing (decarburization processing, shot peening and rinsing): hot dip coating tin; pouring babbit alloy; machining and censoring. The manufacturing craft of high carbon steel thrust sliding bearing for high power low speed diesel engines has the advantages of simple technique, convenient operation, low production cost, good production safety, high degree of bonding for alloy layer of the finished products, less babbit alloy consumption, satisfied working requirement of the high carbon steel thrust sliding bearing for high power low speed diesel engine, wide application range in large mechanical equipment, in particular to oil tanker, large freighter and other high powerlow speed diesel engines with high load.

Owner:CHONGQING YUEJIN MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com