Preparation method of Ca (Calcium) and Ho (Holmium)-doped Mg (Magnesium) alloy

A magnesium alloy and master alloy technology, which is applied in the preparation and application of non-ferrous metal alloys, and can solve problems such as low strength and poor high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] Quantities of chemicals used in preparation are determined in pre-set ranges in grams, milliliters, millimeters, centimeters 3 is the unit of measurement.

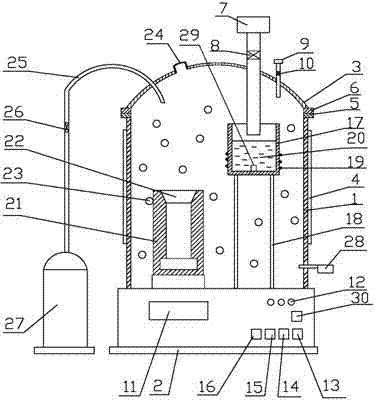

[0080] The preparation of Ca and Ho-doped magnesium alloy ingots is carried out in a vacuum melting furnace, which is completed under heating, vacuuming, argon protection, adding calcium, holmium intermediate alloy, and external water circulation cooling; the vacuum melting furnace is a vertical The lower part of the vacuum melting furnace 1 is the furnace seat 2, and the upper part is the furnace cover 3. A sealing ring 5 and an opening and closing frame 6 are arranged between the vacuum melting furnace 1 and the furnace cover 3; the outside of the vacuum melting furnace 1 is cooled by external water circulation. 4 Surrounding; a split mold 21 is set at the left bottom of the vacuum melting furnace 1, and the upper part of the split mold 21 is a sprue 22, and a crucible support 18 is arranged at the bottom right si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com