Method for spraying Stellite 20 alloy on surface of workpiece

A workpiece surface and alloy technology, applied in the field of spraying Stellite20 alloy on the workpiece surface, can solve the problems of reducing the bonding strength of the coating and the substrate, reducing the wear resistance and corrosion resistance, and stress concentration inside the coating, so as to eliminate oxides. Inclusions, improved corrosion resistance, and uniform metallographic structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] 1. Stellite 20 alloy powder (purchased from Kennametal Stellite Metal (Shanghai) Co., Ltd.):

[0032] The composition of the alloy powder: 2.3≤C≤2.5 wt%, 31≤Cr≤34 wt%, 0≤Fe≤3 wt%, 0≤Mn≤0.5 wt%, 0≤Mo≤1 wt%, 0≤Ni≤ 3 wt%, 0≤P≤0.03 wt%, 0≤S≤0.03 wt%, 0≤Si≤1 wt%, 16≤W≤18 wt%, the balance is Co; the average particle size of powder particles is 25~40um.

[0033] 2. Workpiece pre-processing size inspection:

[0034] Take the workpiece, measure and record the pre-processing size of the workpiece with a micrometer, the dimensional tolerance and shape tolerance must meet the technical requirements of the process, so as to ensure the uniformity of the coating thickness in all directions of the workpiece;

[0035] 3. Sand blasting roughening:

[0036] Sandblasting is performed using a sandblasting machine. The compressed air is required to be clean, dry and oil-free during sandblasting, and the sandblasting machine must be discharged every 60 minutes; the abrasive of the sandblas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

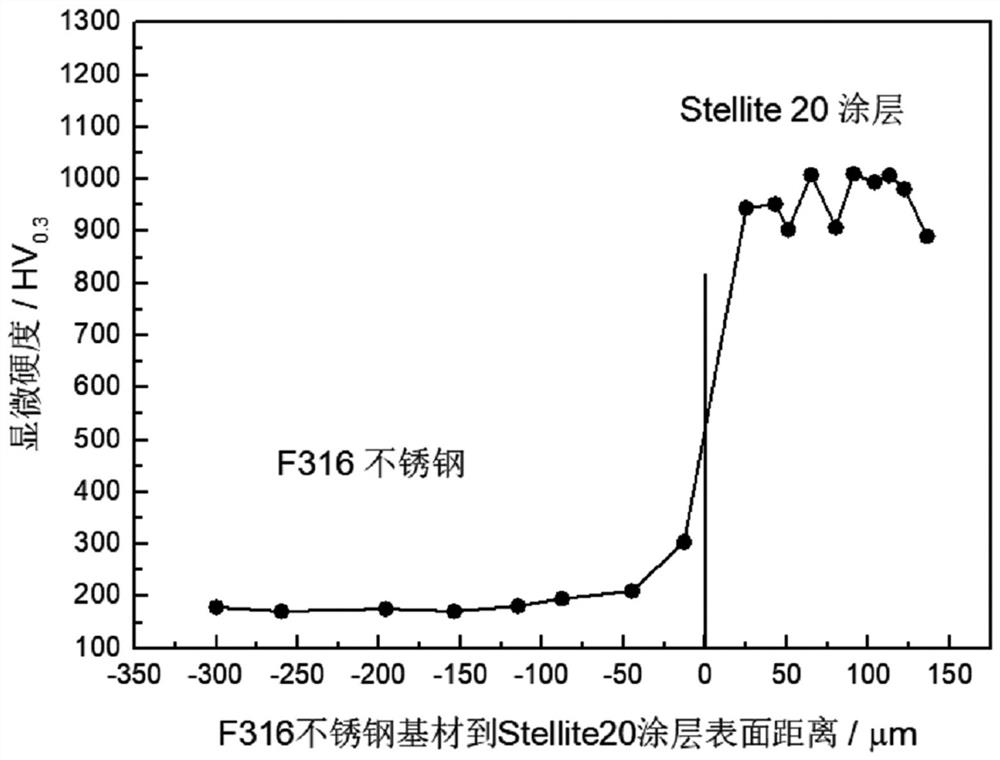

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com