Patents

Literature

82results about How to "Remove inclusions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal Nitrides and Process for Production Thereof

InactiveUS20080193363A1High yieldAvoid residuePolycrystalline material growthFrom normal temperature solutionsGallium nitrideProduct gas

To provide a method for efficiently producing a high quality metal nitride containing a small amount of impurities, particularly gallium nitride.A method for producing a metal nitride characterized by employing a container made of a nonoxide material. By using a nonoxide for a material of a container to be in contact with a raw metal or a metal nitride to be formed, reaction or adhesion of the raw metal or the metal nitride to be formed to the container can be avoided, and inclusion of oxygen derived from the material of the container can be prevented, whereby a high quality metal nitride having high crystallinity will be obtained. By securing a certain or larger supply amount and a certain or higher flow rate of the nitrogen source gas, the raw metal can be converted into a nitride with an extremely high conversion, and a metal nitride having a small amount of an unreacted raw metal remaining and containing a metal and nitrogen in a stoichiometric constant can be obtained with a high yield. The obtained metal nitride having a small amount of oxygen included and containing a metal and nitrogen in a stoichiometric constant, is very useful as a raw material for bulk crystal growth.

Owner:MITSUBISHI CHEM CORP

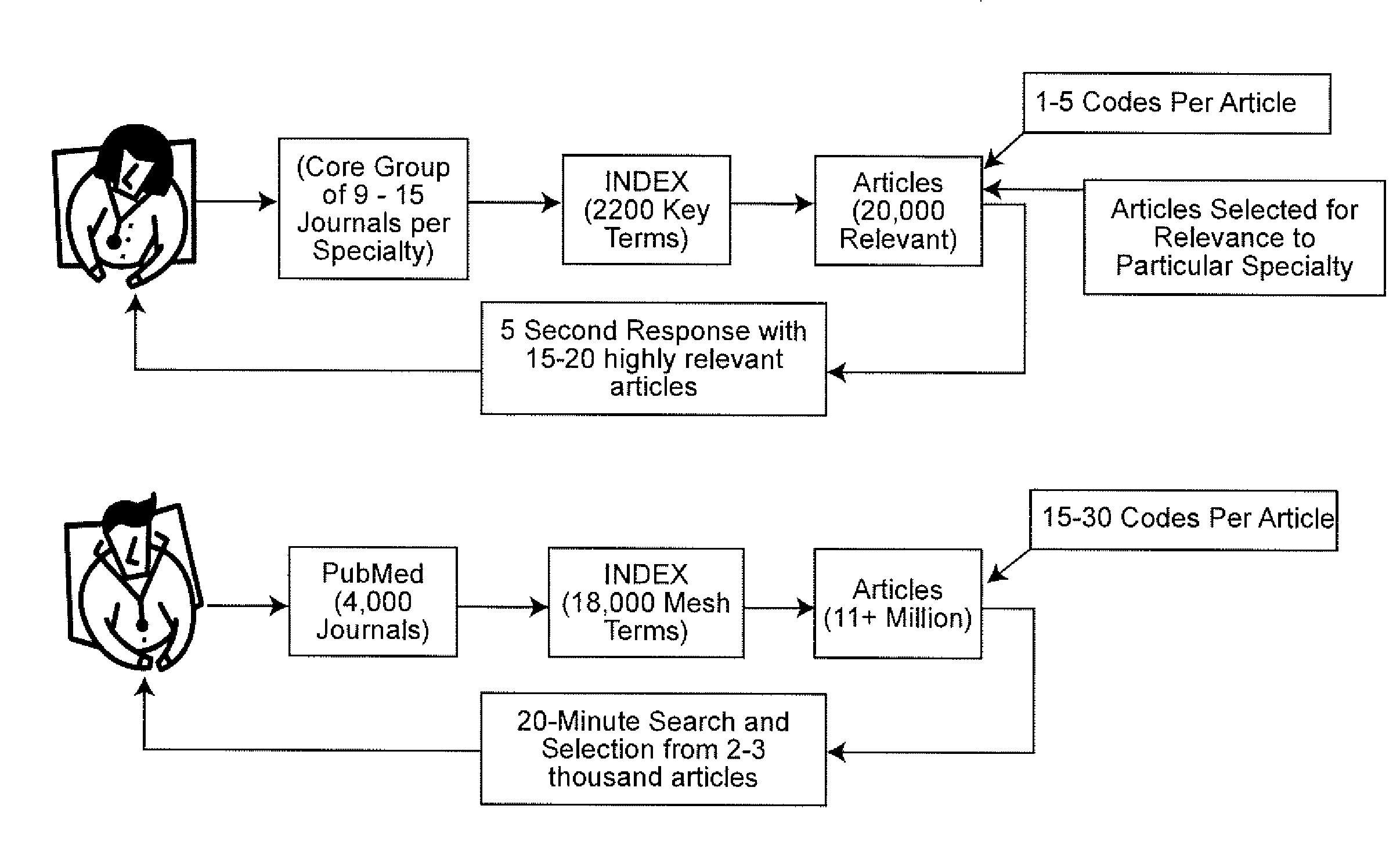

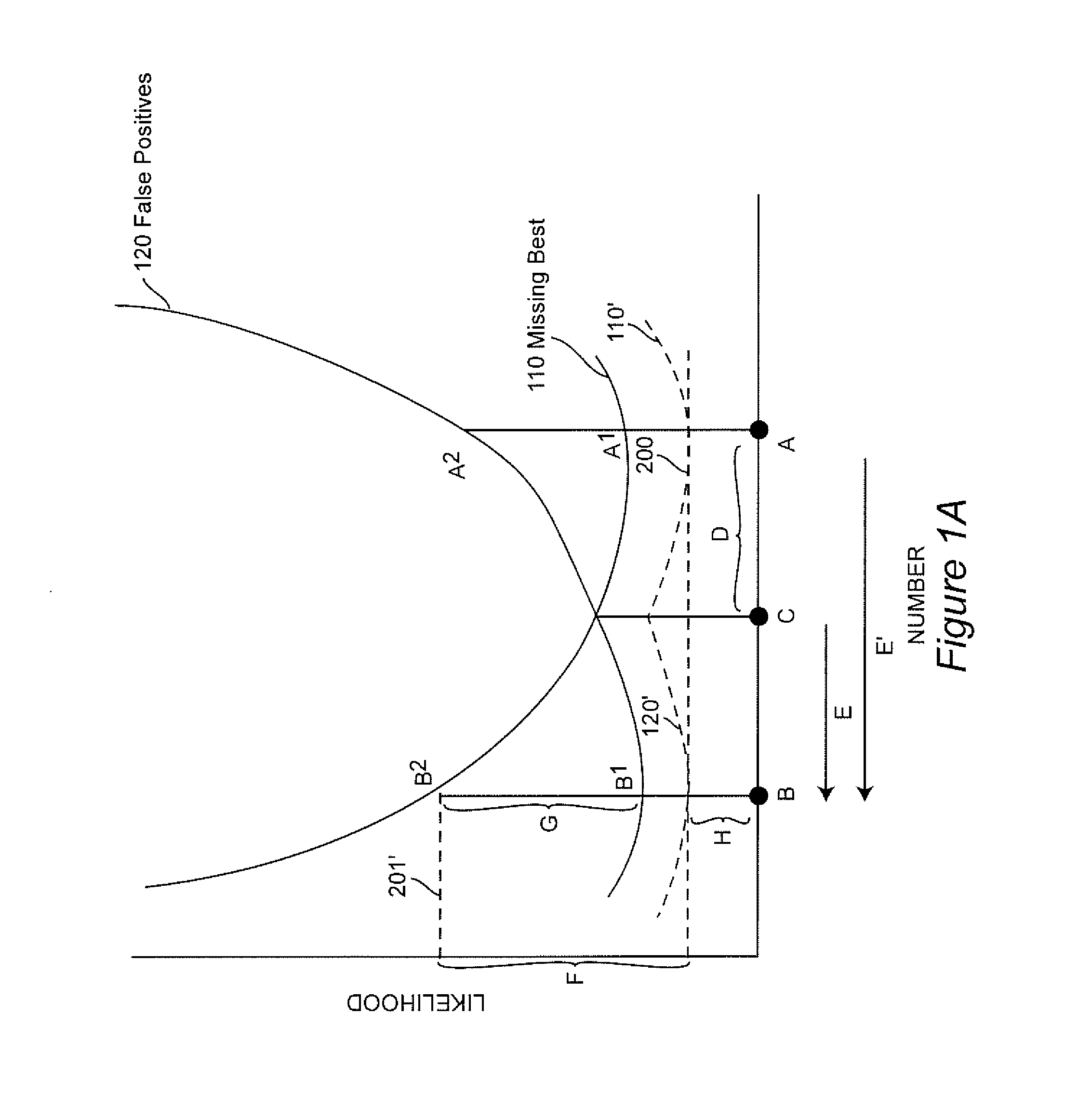

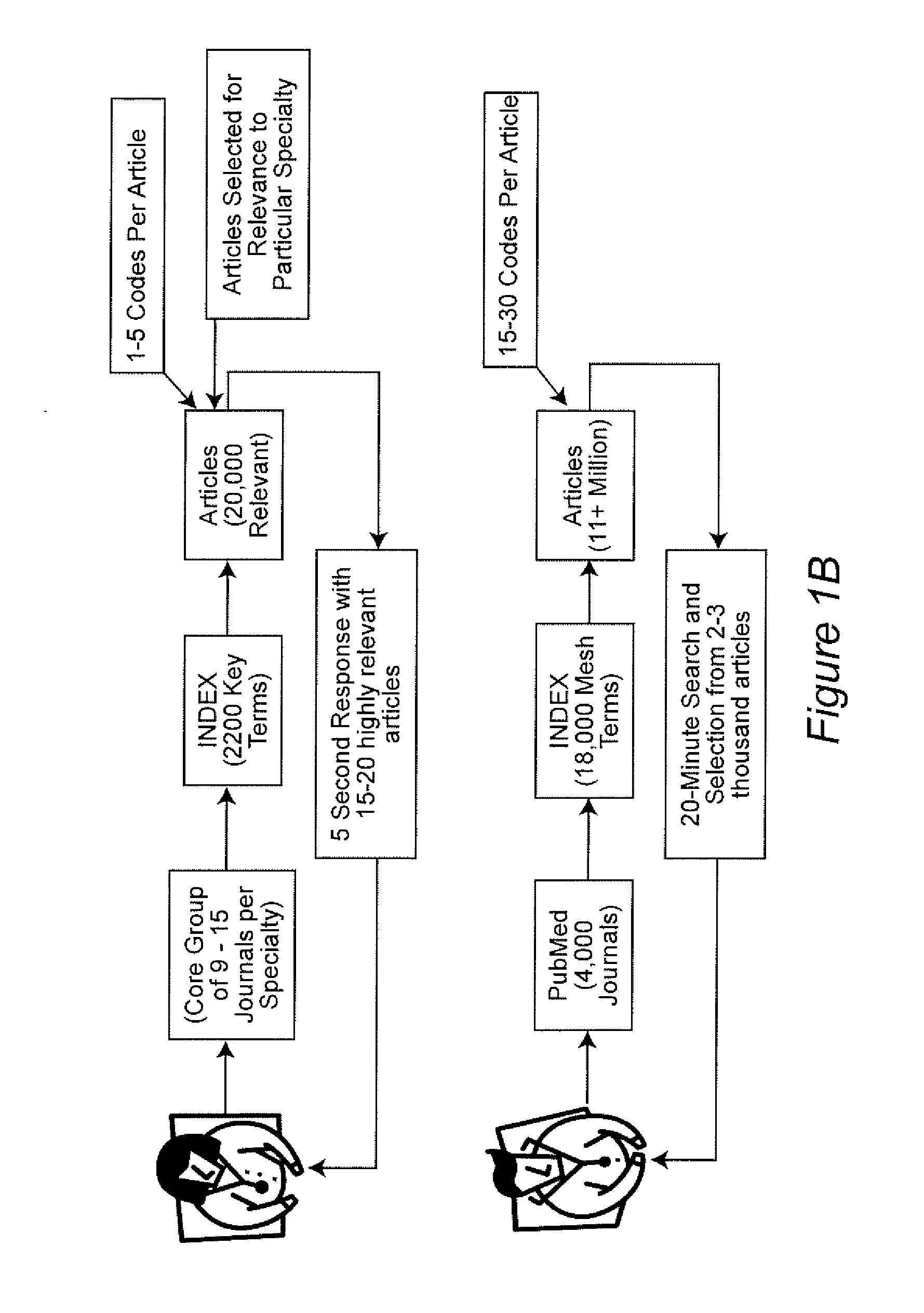

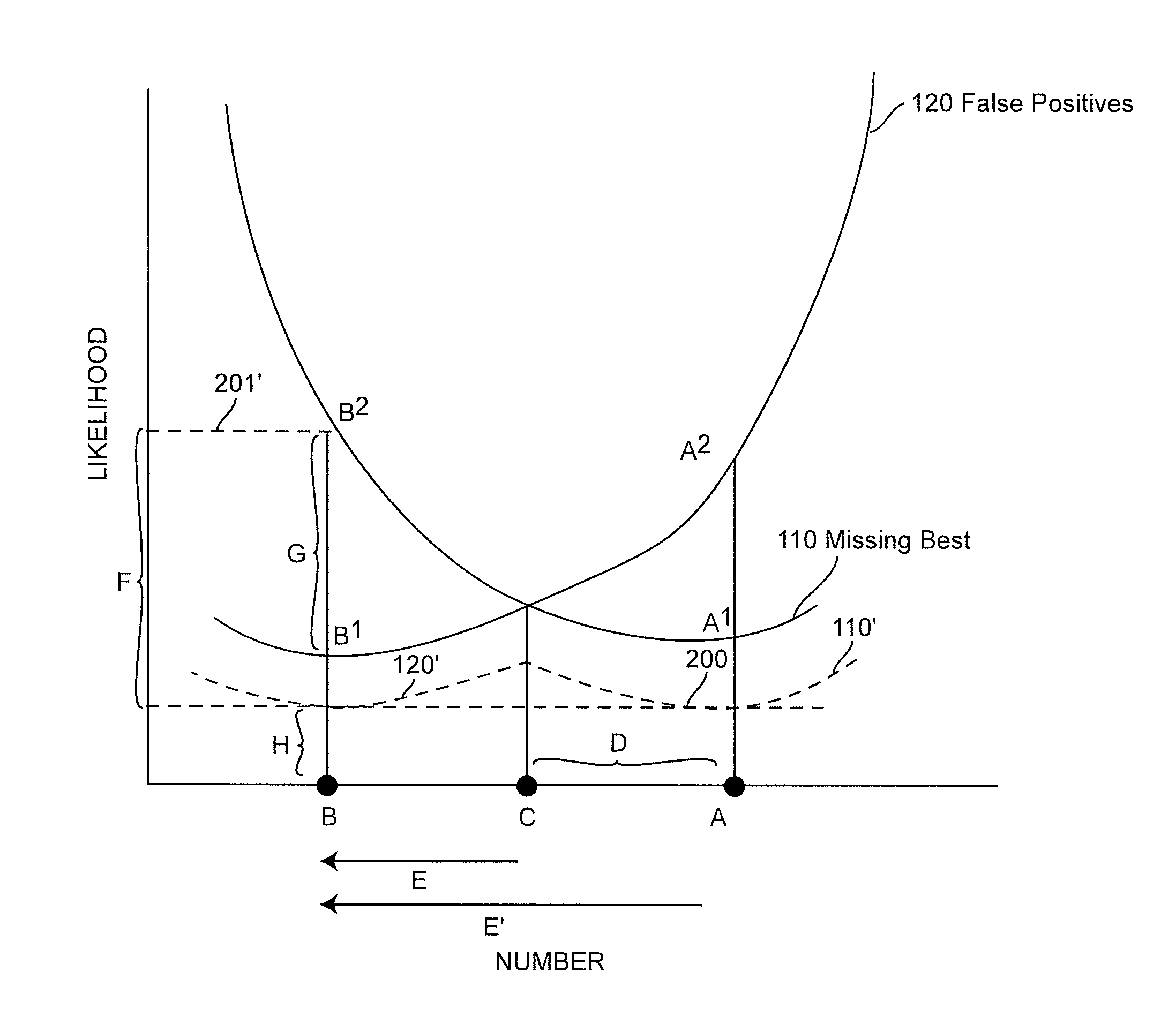

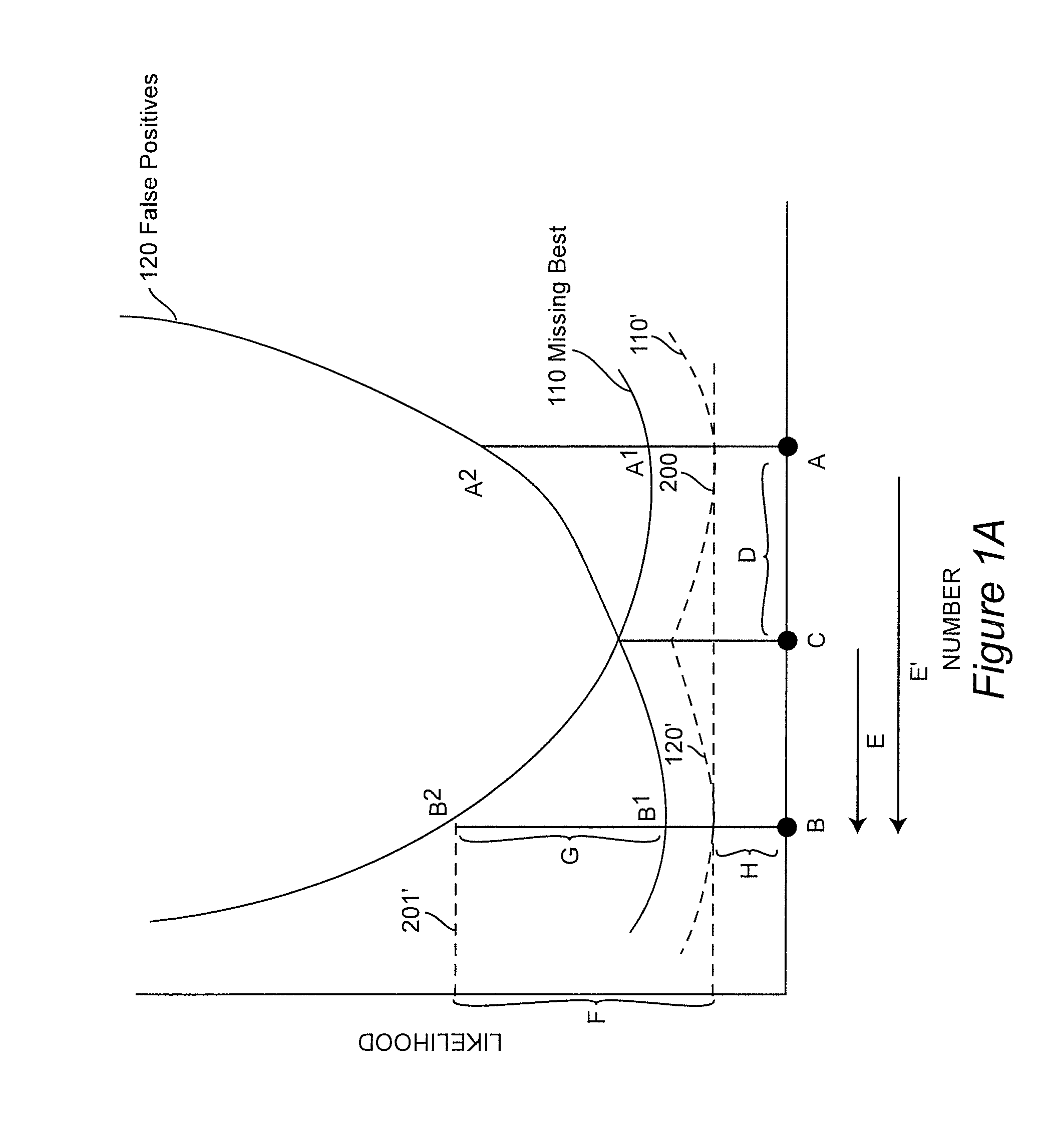

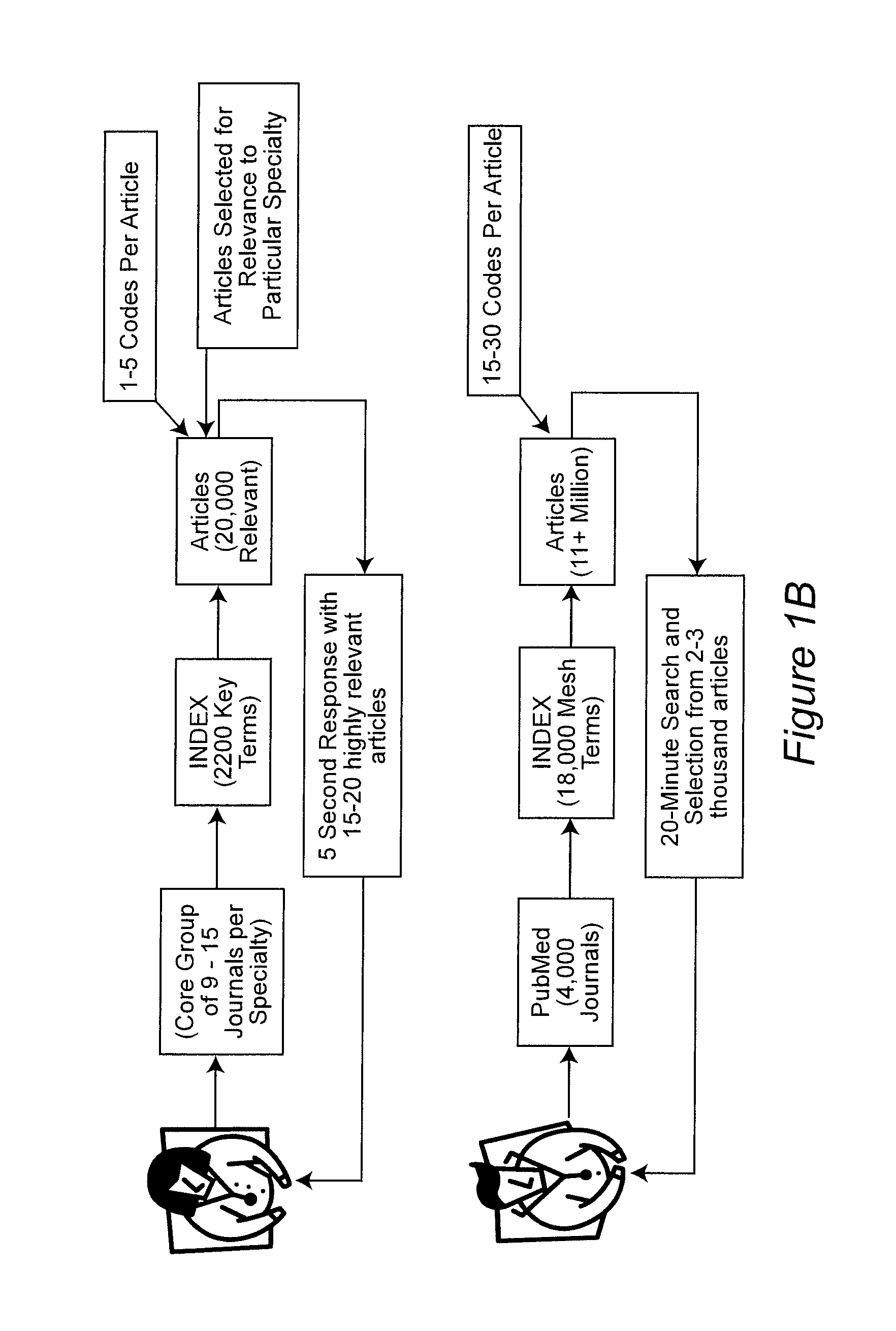

Database and index organization for enhanced document retrieval

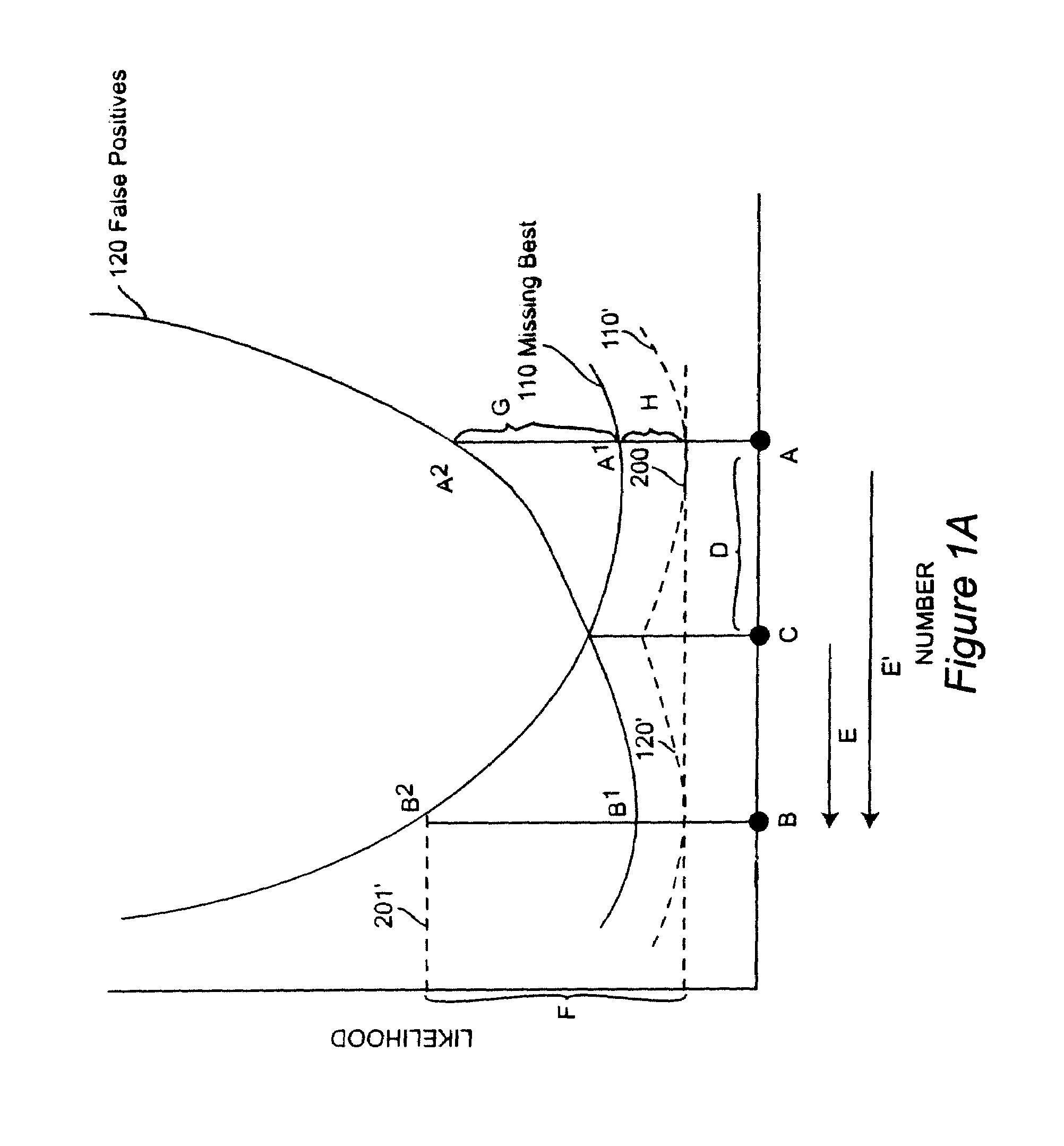

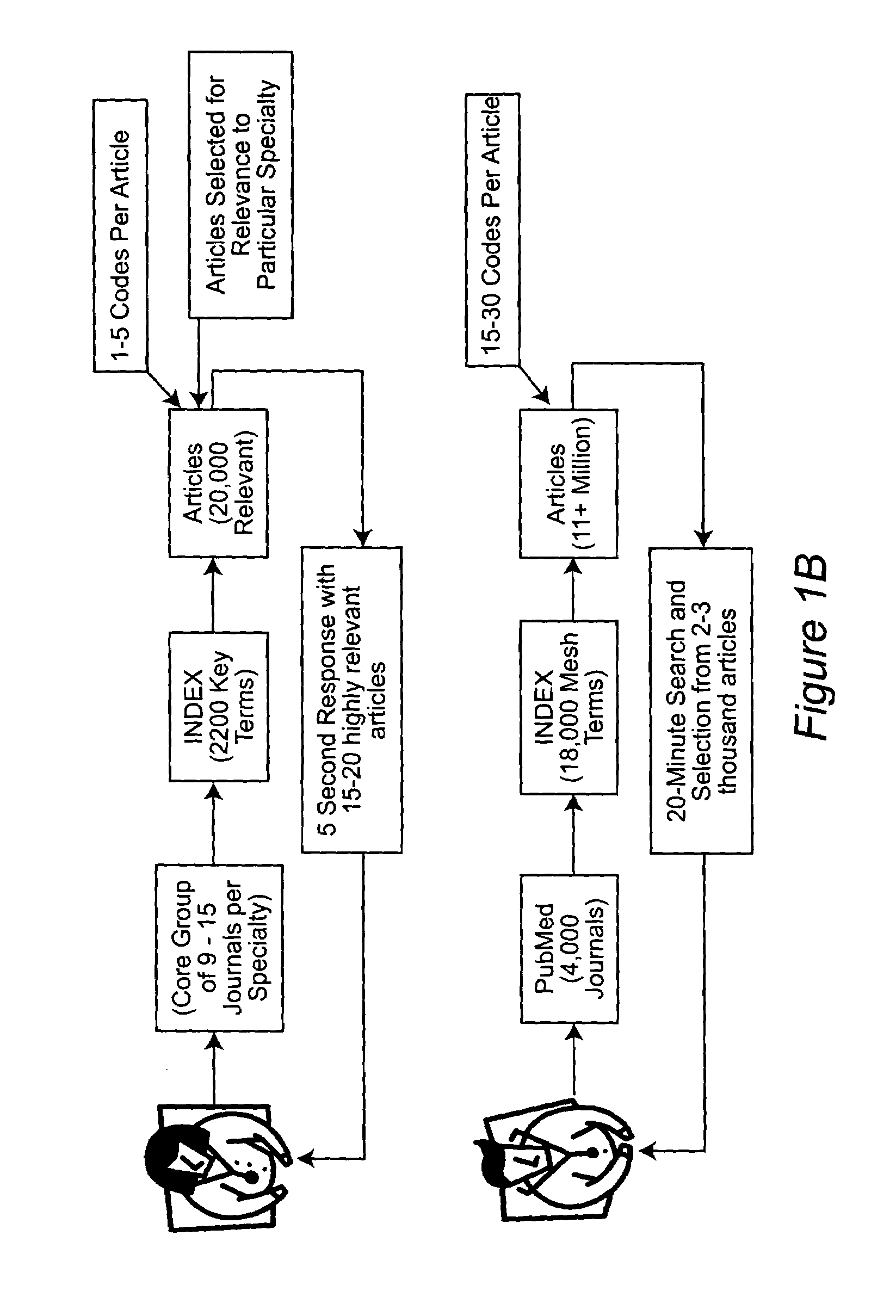

ActiveUS20060253441A1Quick searchRemove inclusionsMetadata text retrievalData processing applicationsDocumentation procedureKey articles

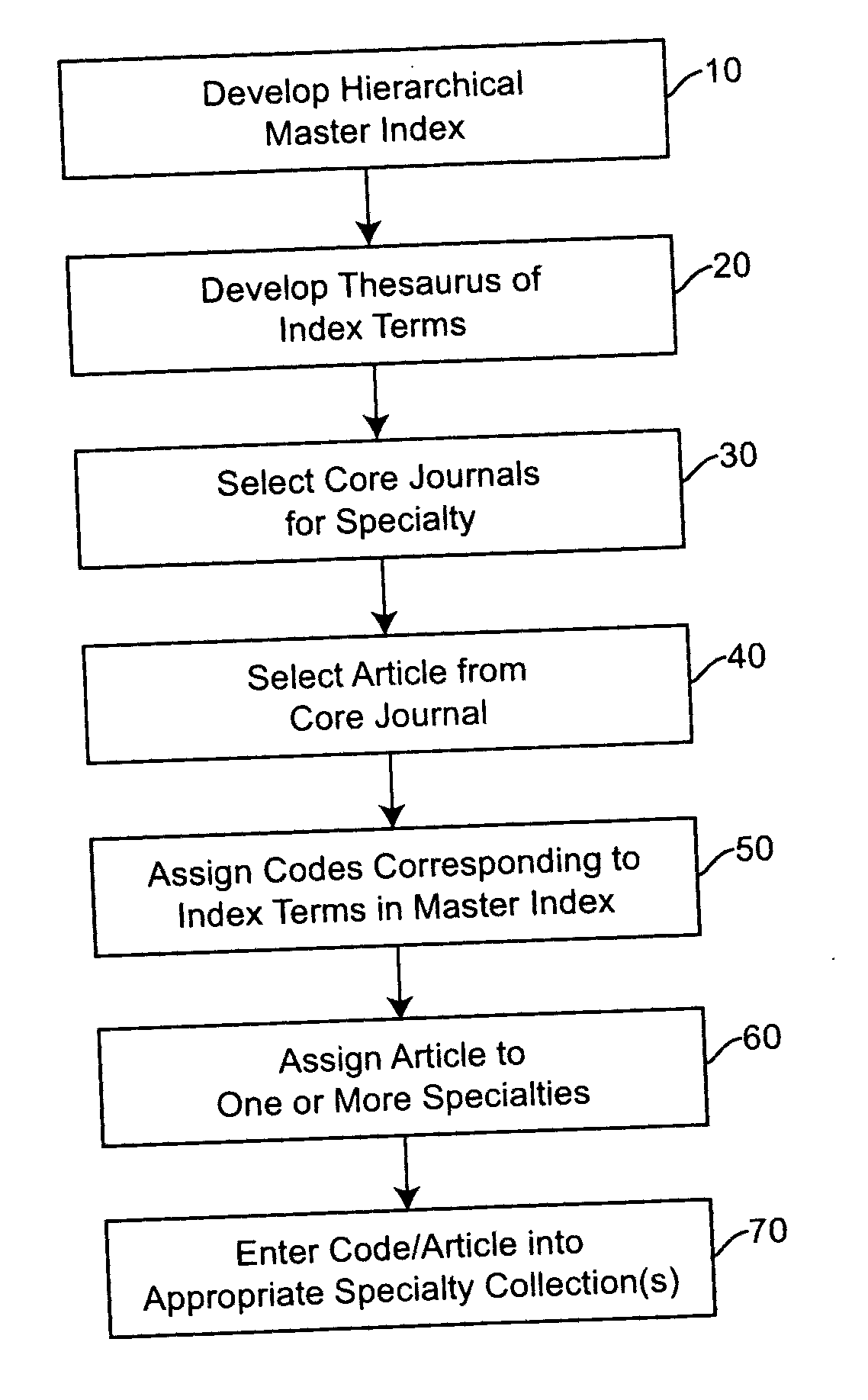

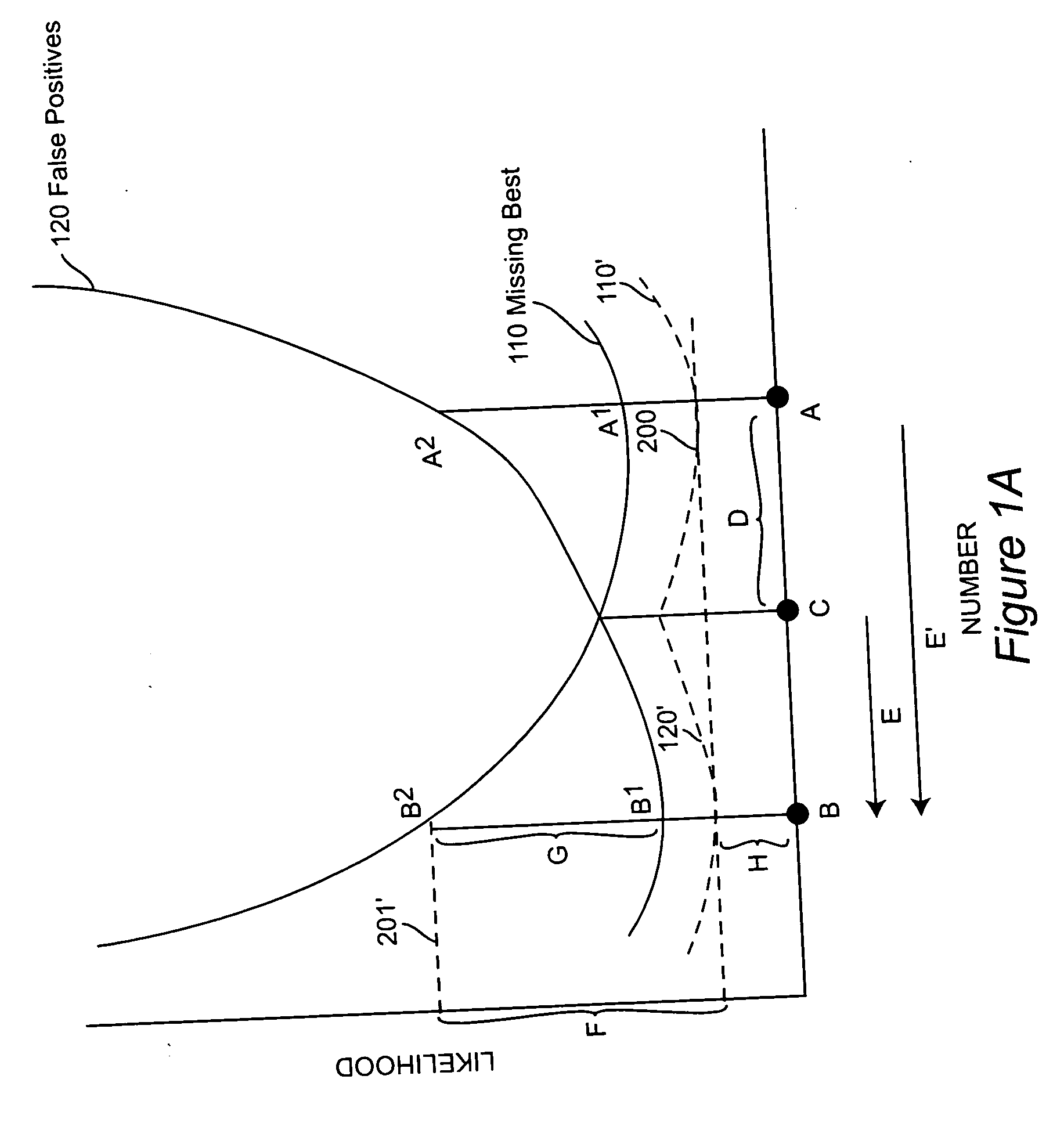

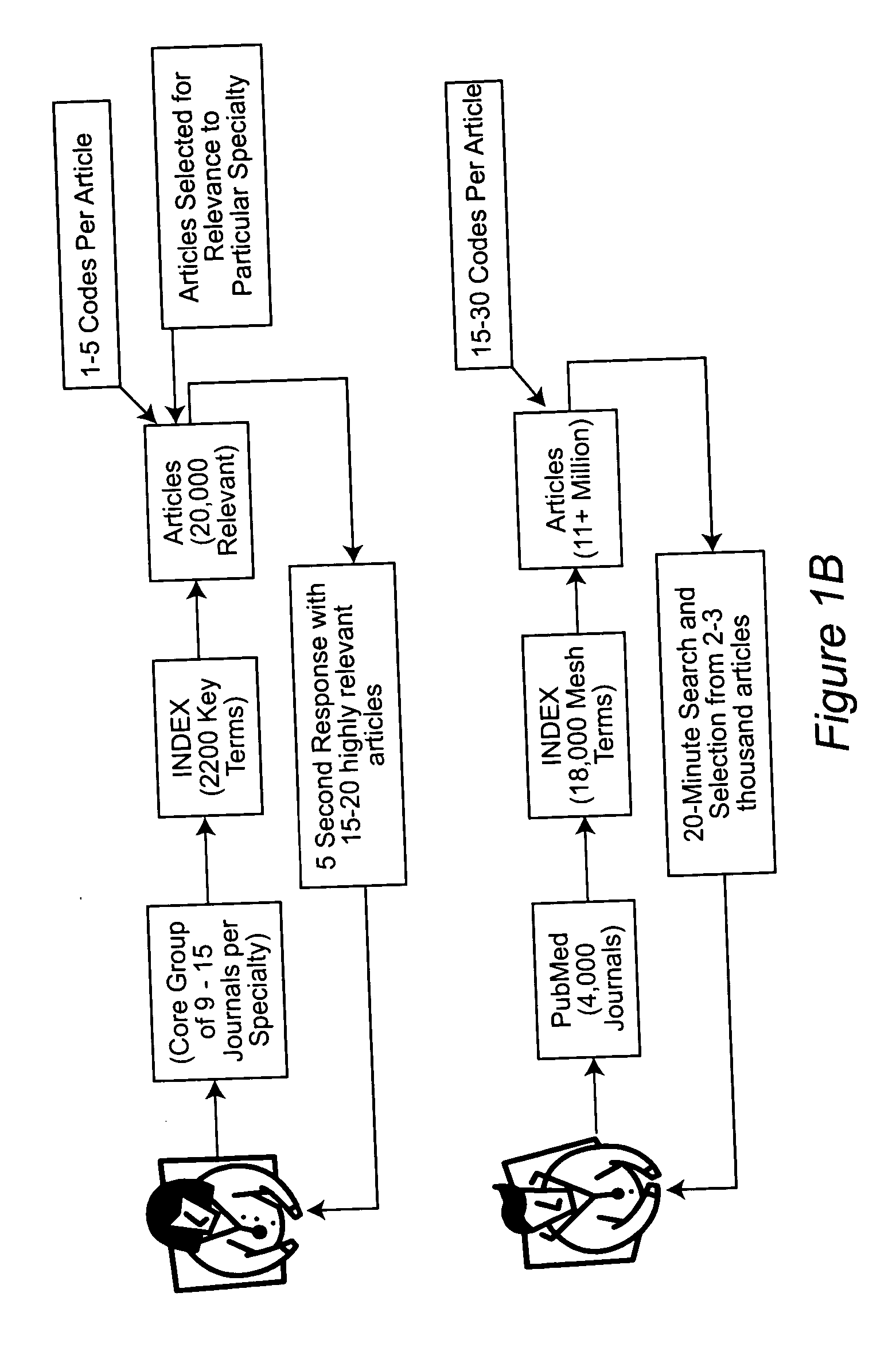

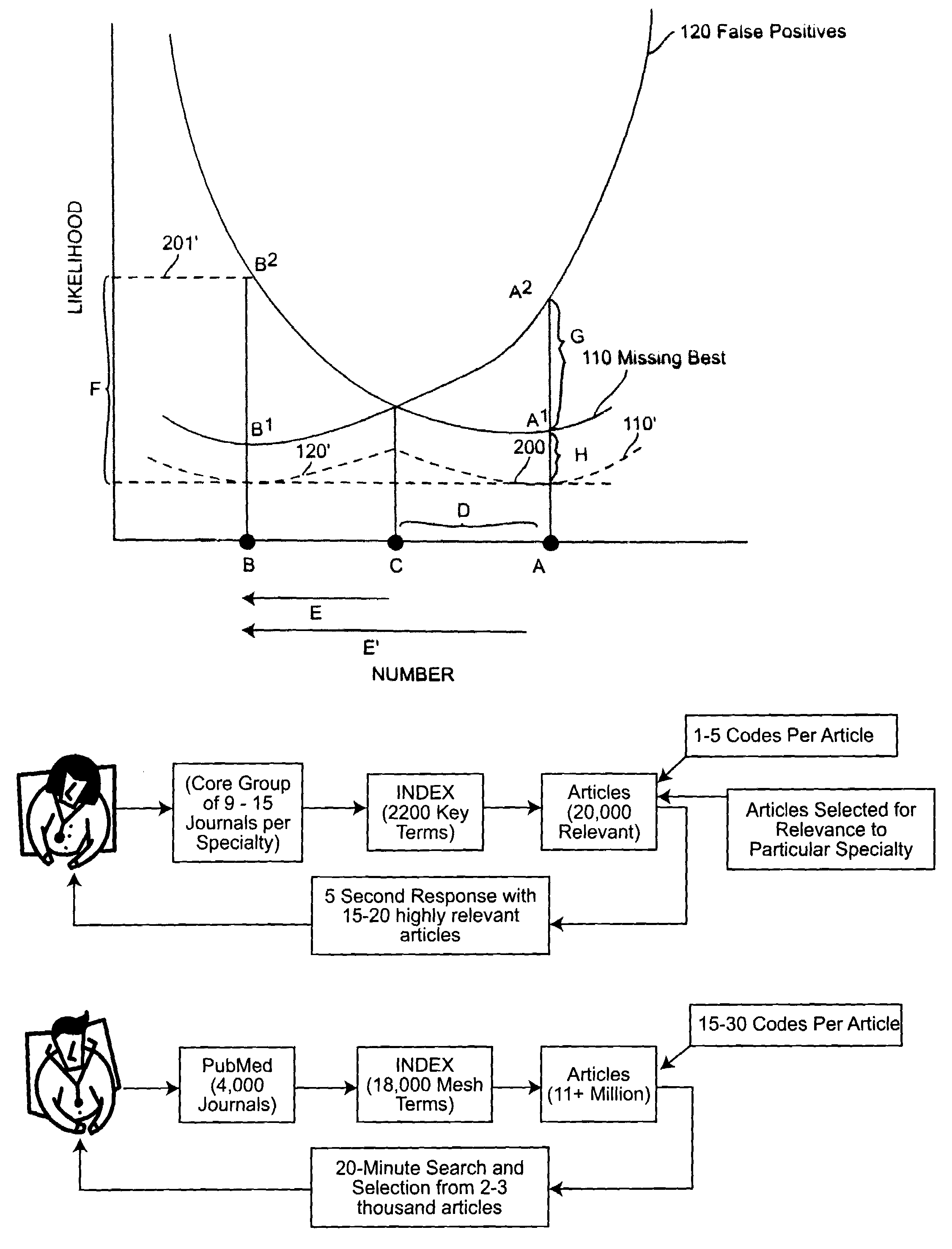

A customized, specialty-oriented database and index of a subject matter area and methods for constructing and using such a database are provided. Selection and indexing of articles is done by experts in the topic with which the database is concerned. As a result, articles are indexed in a manner that allows facile, rapid retrieval of highly relevant articles with few or no false positives with much reduced database maintenance cost through frugal limitation of number of documents in the database, number of terms in a Master Index, and number of codes assigned to each document. A thesaurus allows indexing and search in accordance with terminology familiar to different anticipated groups of users (e.g. doctors, patients, nurses, technicians, and the like). Key articles collections and rapid access to documents therein are also provided.

Owner:NELSON INFORMATION SYST

Database and index organization for enhanced document retrieval

ActiveUS7548917B2Quick searchRemove inclusionsMetadata text retrievalData processing applicationsDocumentation procedureKey articles

A customized, specialty-oriented database and index of a subject matter area and methods for constructing and using such a database are provided. Selection and indexing of articles is done by experts in the topic with which the database is concerned. As a result, articles are indexed in a manner that allows facile, rapid retrieval of highly relevant articles with few or no false positives with much reduced database maintenance cost through frugal limitation of number of documents in the database, number of terms in a Master Index, and number of codes assigned to each document. A thesaurus allows indexing and search in accordance with terminology familiar to different anticipated groups of users (e.g. doctors, patients, nurses, technicians, and the like). Key articles collections and rapid access to documents therein are also provided.

Owner:NELSON INFORMATION SYST

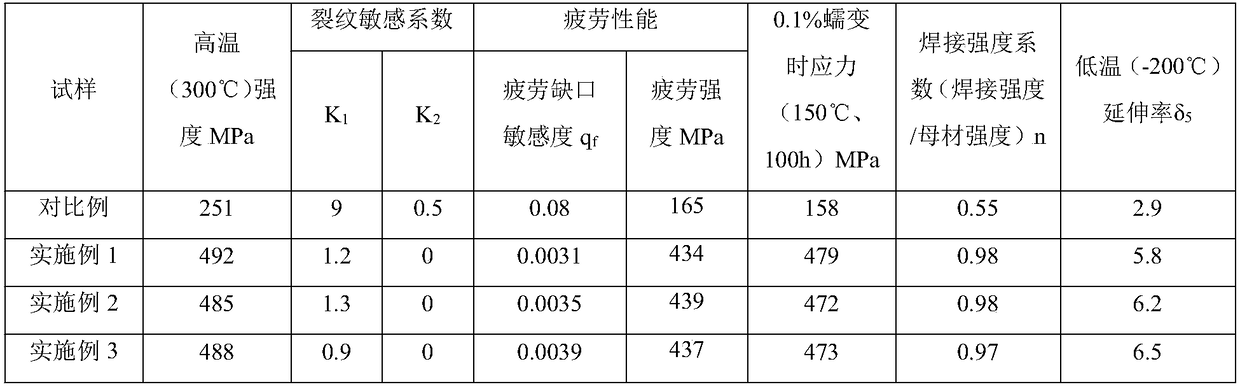

Aluminium alloy for vehicle hub and preparation method thereof

The invention provides an aluminium alloy for a vehicle hub and a preparation method thereof. The alloy comprises the following components by weight percent: 4.5-6.3% of Zn, 1.4-2.5% of Mg, 0.5-0.9% of Cu, 0.12-0.3% of Zr, 0.05-0.15% of Ti, 0.05-0.2% of Cr, 0.1-0.3% of Sc and the balance of Al. The preparation method of the aluminium alloy comprises the following steps: weighting raw materials, melting the raw materials except for magnesium blocks, adding a covering agent, then adding the preheated magnesium blocks, stirring, injecting nitrogen or argon to degas, filtering with a ported ceramic plate, reducing the temperature, standing for 20 minutes, and adopting a liquid forging mould and a liquid forging forming method to prepare the hub. The prepared vehicle hub has high strength, impact toughness and corrosion resistance; and the mechanical properties of the aluminium alloy hub can be ensured, the production cost can be reduced and the large-scale production of the hub is easy to perform.

Owner:ZHEJIANG GKO ALUMINUM

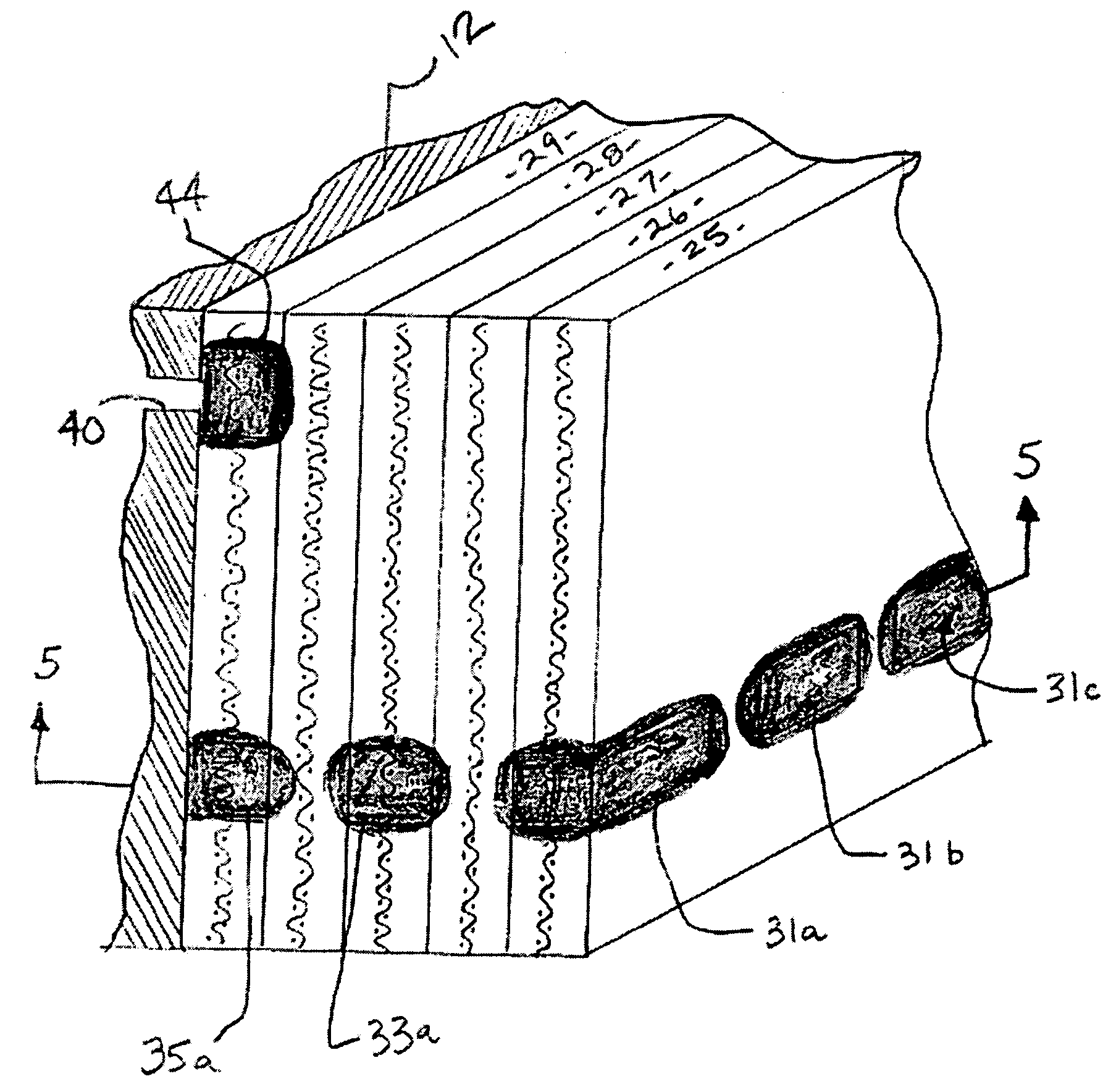

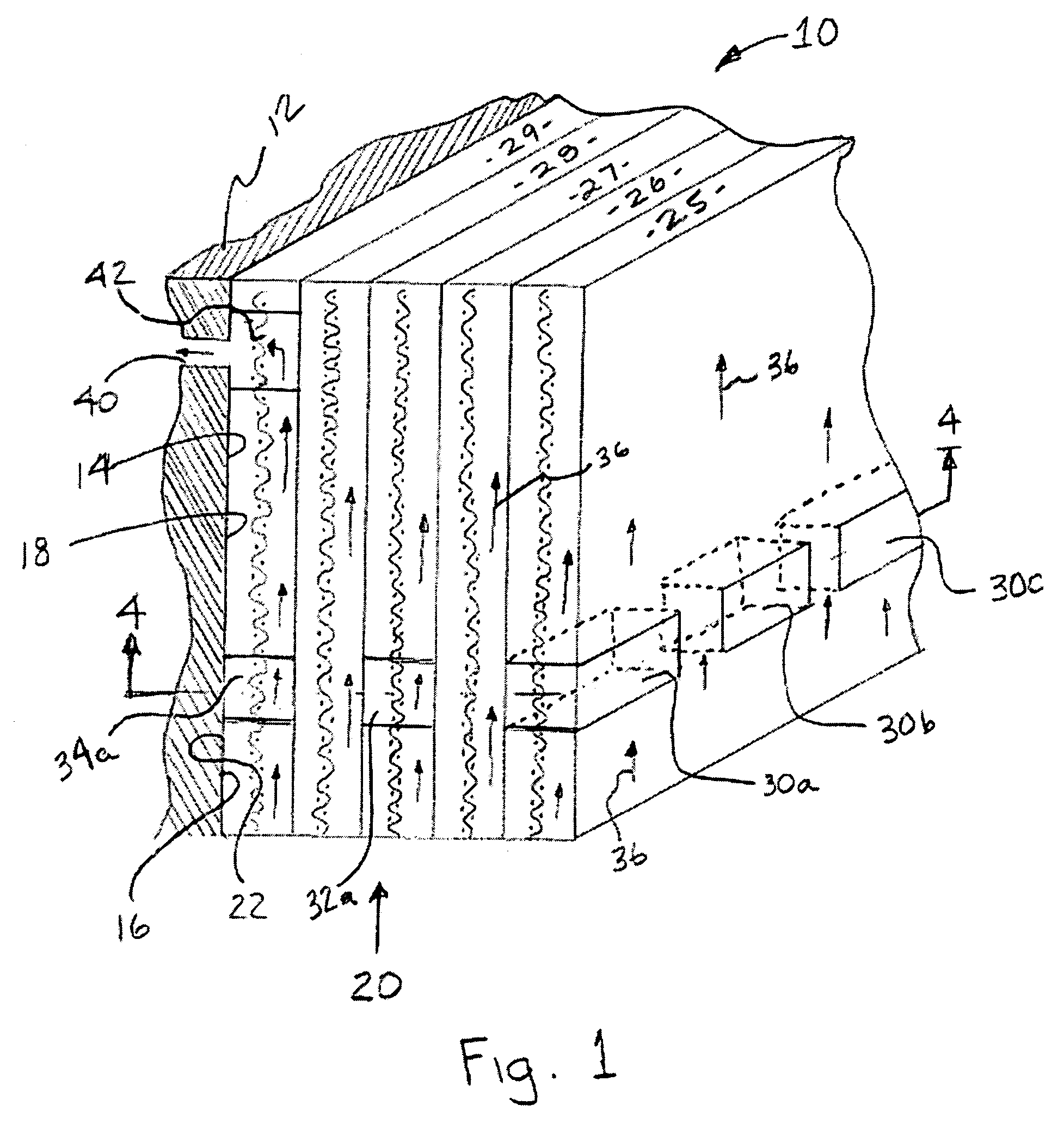

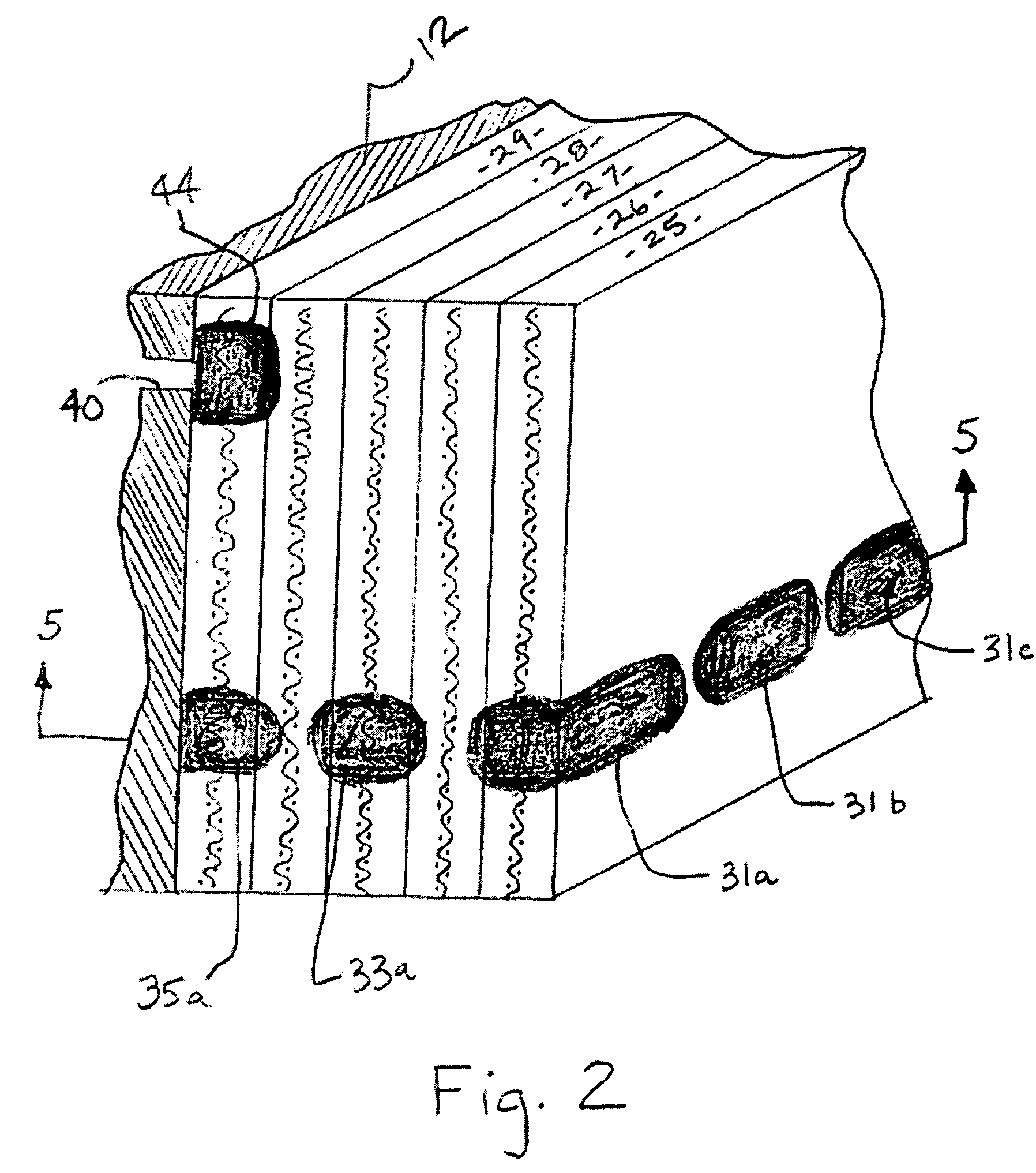

Control of resin flow during molding of composite articles

InactiveUS7255549B2EliminatePrevent from flowConfectioneryWood working apparatusComposite materialFiber

The flow of resin during the molding of composite articles is controlled by forming areas of immobilized resin during the infusion of resin into the fibrous body. The immobilized resin is formed using an immobilization agent that interacts with the infused resin to form a high viscosity resin barrier that is effective in blocking the flow of non-immobilized resin. The barriers of immobilized resin are located within the fibrous body so as to control the flow of non-immobilized resin during the molding process to prevent or least reduce resin depletion and to selectively block resin flow from the mold.

Owner:HEXCEL COMPOSITES LTD (GB)

Database and index organization for enhanced document retrieval

ActiveUS20110184954A1Quick searchRemove inclusionsMetadata text retrievalDigital data processing detailsKey articlesSubject matter

A customized, specialty-oriented database and index. of a subject matter area and methods for constructing and using such a database are provided. Selection and indexing of articles is done by experts in the topic with which the database is concerned. As a result, articles are indexed in a manner that allows facile, rapid retrieval of highly relevant articles with few or no false positives with much reduced database maintenance cost through frugal limitation of number of documents in the database, number of terms in a Master Index, and number of codes assigned to each document. A thesaurus allows indexing and search in accordance with terminology familiar to different anticipated groups of users (e.g. doctors, patients, nurses, technicians, and the like). Key articles collections and rapid access to documents therein are also provided. Additional classifications may be applied to articles or documents and searched as an additional search criterion such as a potential use. The context of key word(s) included in the search query can be specified from the hierarchical list of key words without requiring additional classification of articles / documents. Search results may also be filtered and / or sorted based on components included in the articles / documents.

Owner:NELSON INFORMATION SYST

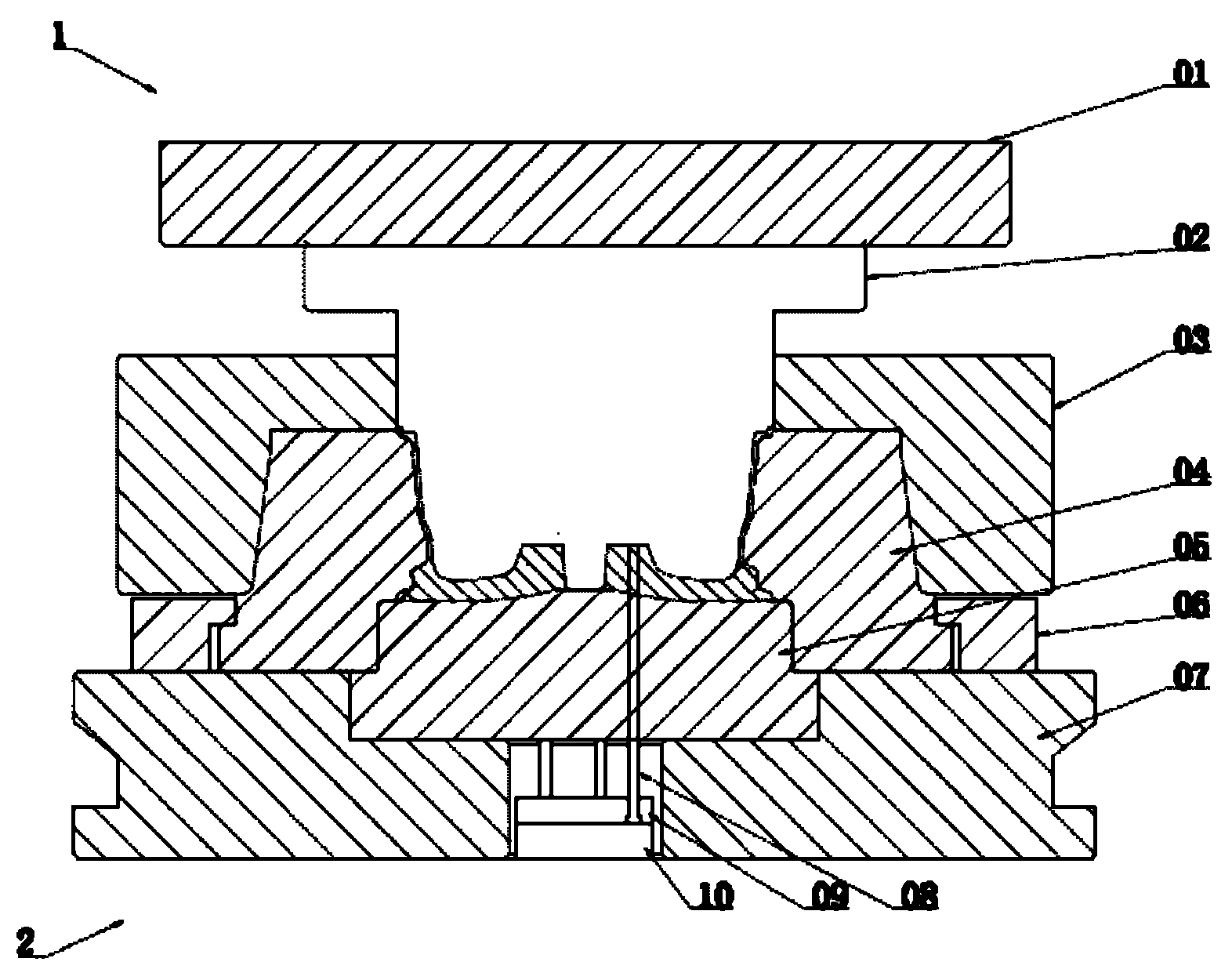

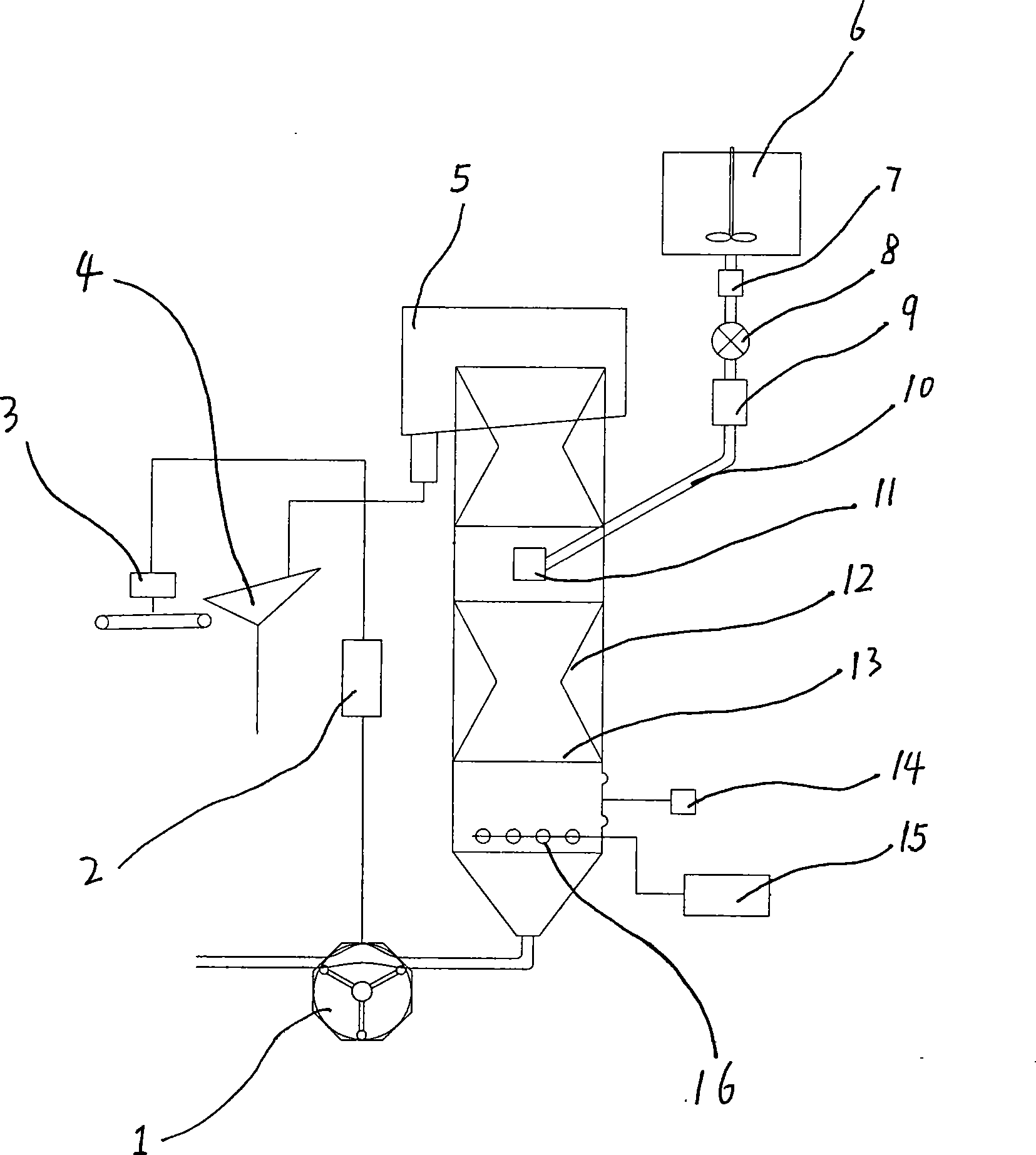

Sorting technology for coarse coal slurry damping pulsation interference bed

InactiveCN101543802AImprove loose stateReasonable flow distributionWet separationPeristaltic pumpEngineering

The invention discloses sorting technology for a coarse coal slurry damping pulsation interference bed. The sorting technology is formed by the mutual connection of an interference bed sorter, a feeding system, a peristaltic pump, a cleaned coal recovering system, and a water pump, and is characterized in that the inside of the interference bed sorter is added with a plurality of damping blocks and screens; the middle part of the interference bed sorter is connected with the feeding system to form a stable fluid bed; simultaneously, a diaphragm is additionally arranged on the lower part of the interference bed sorter and the upper part of a heavy product discharge port to generate a pulsating flow, so that particles with different densities gain the accelerating effect and retarding effect, and the leading action of the density on the separation effect is strengthened; the peristaltic pump is used for discharging heavy products, so that the processing capability of the equipment is improved; under the conditions of wide particle size range of the coarse coal slurry and heavy processing load, the good separation effect and high separation efficiency can also be achieved by the separation process.

Owner:HENAN POLYTECHNIC UNIV

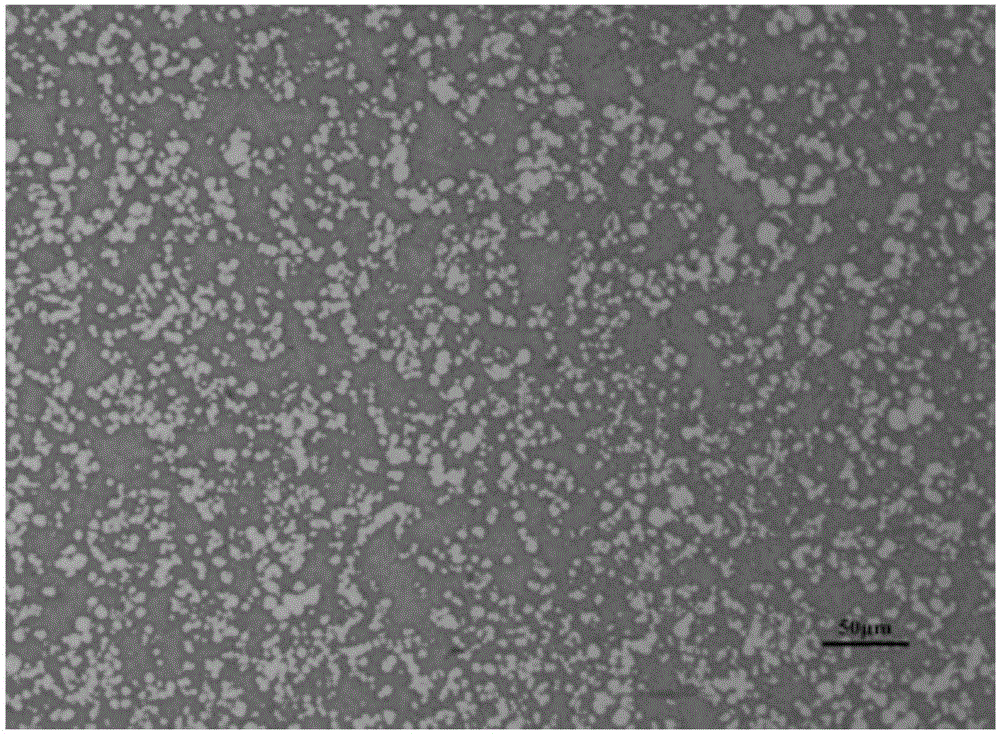

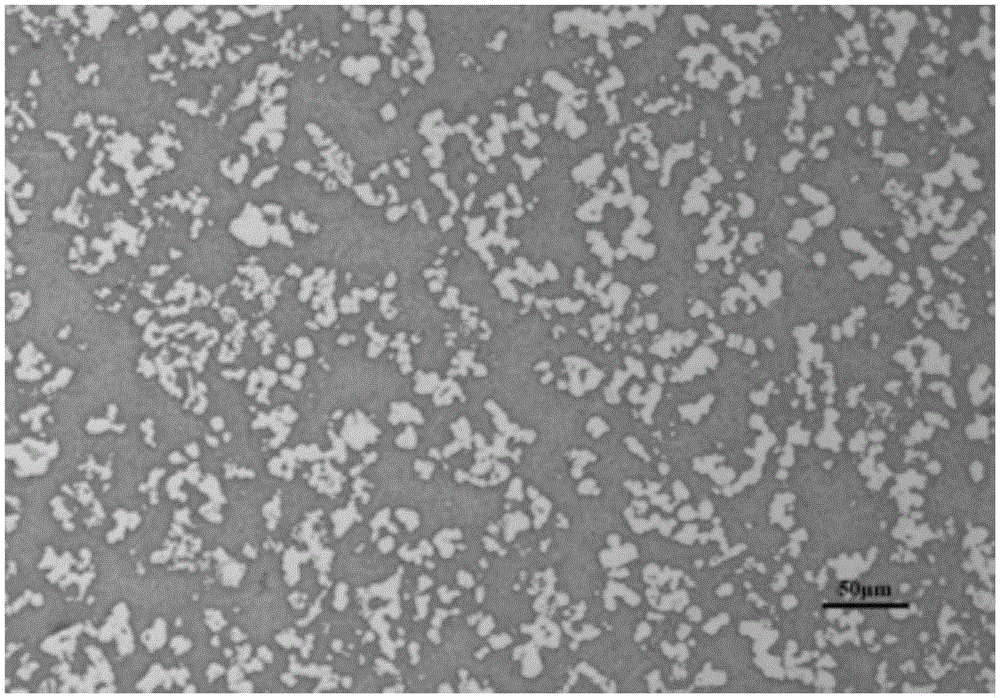

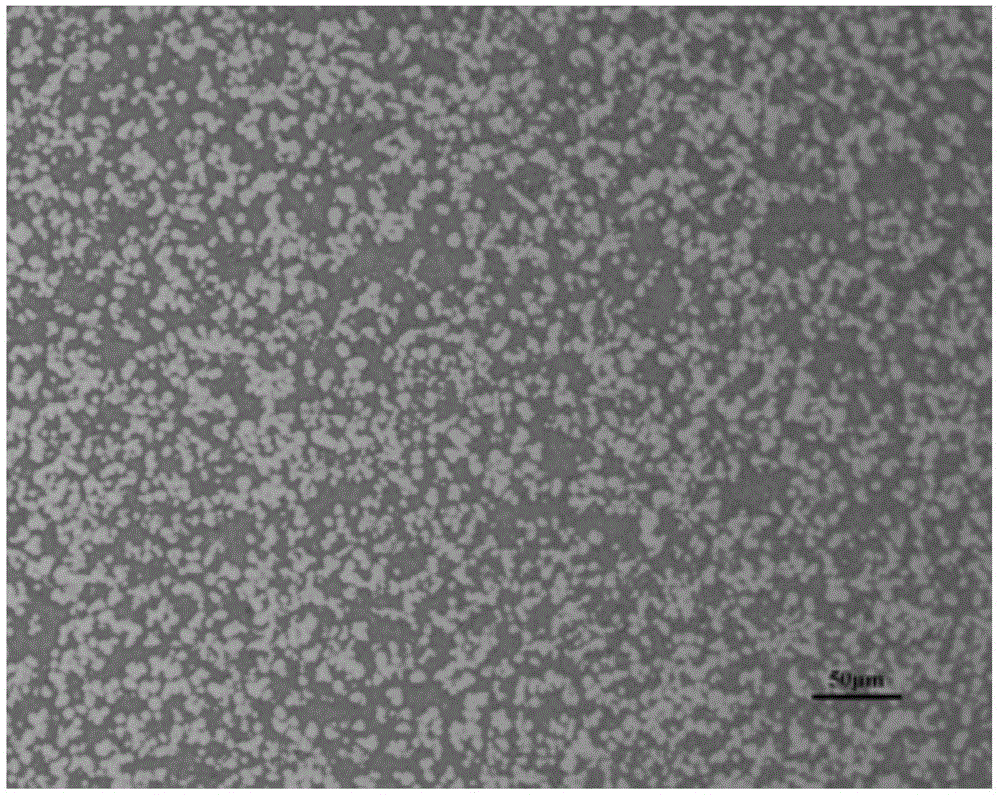

Ca and heavy rare earth Gd-containing die-casting heat resisting magnesium alloy and preparation thereof

The invention relates to a die-casting heat resistant magnesium alloy containing Ca and heavy rare earth element Gd and a preparation method thereof, pertaining to the metal material technical field. The components and weight percentage thereof of the alloy are: 3.0 to 8.0 percent of Al, 0.1 to 3.0 percent of Ca, 0.1 to 3.0 percent of Gd, 0 to 0.5 percent of Mn, lower than 0.02 percent of impurity elements and the rest is Mg. The preparation method of the alloy comprises the following steps: the materials are weighed, and industrial pure Mg is heated under the protection of the mixed gas of N2 and 0.2 percent of SF6; after Mg is wholly melted, industrial pure Al, industrial pure Ca and Al-Mn interalloy are added at the temperature of 650 to 680 DEG C, Mg-Gd interalloy is added at the temperature of 660 to 680 DEG C, the temperature is increased to 740 to 760 DEG C, and when the Mg liquid is cooled to 670 to 690 DEG C, the mixture carries out die casting. The preparation method of the invention has the advantages of low cost and high production efficiency, obviously increases the tensile strength, the yield strength, the elongation percentage and the creep resistance of the alloy at room temperature, and has excellent die-casting performance.

Owner:SHANGHAI JIAO TONG UNIV

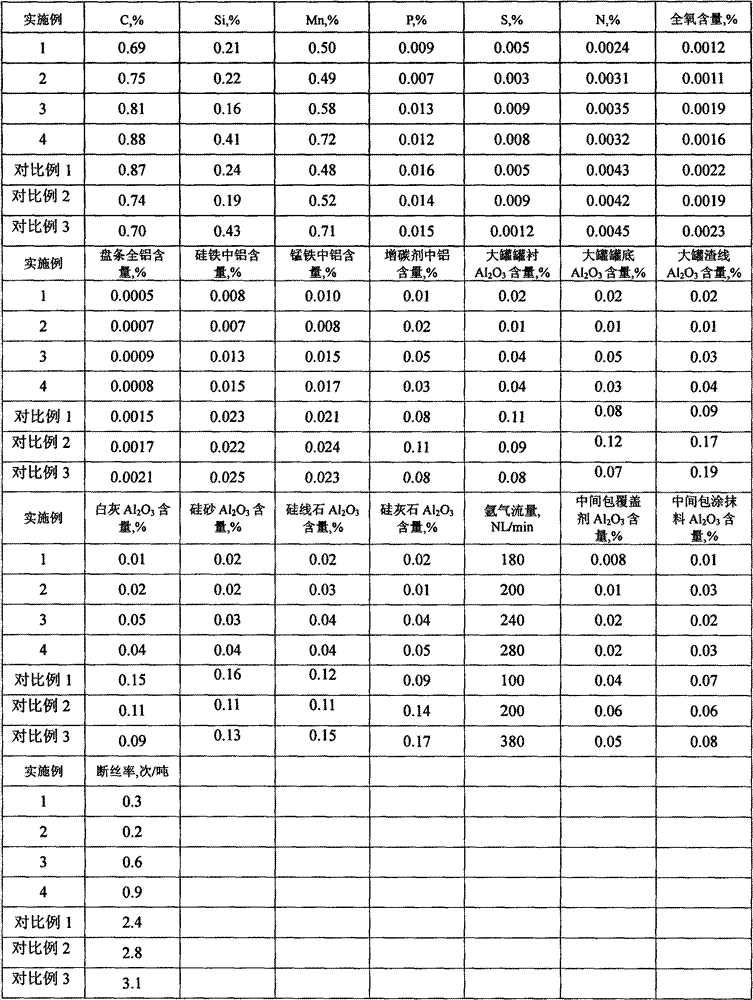

Wire rod for steel cord and its Al2O3 inclusion control method

The invention discloses a wire rod for steel cord and its Al2O3 inclusion control method. The wire rod for steel cord comprises 0.68-0.89wt% of C, 0.1-1.0wt% of Si, 0.35-0.80wt% of Mn, 0.015wt% or less of P, 0.010wt% or less of S, 0.004wt% or less of N, 0.002% or less of total oxygen, 0.0010wt% or less of total aluminum, and the balance Fe and inevitable impurities. The Al2O3 inclusion control method comprises the following steps: allowing the content of Si-Fe and Mn-Fe-Al used after converting to be not greater than 0.02% and the content of Al in a carburant to be not greater than 0.05%; allowing the content of Al2O3 in a refractory material at the pot liner, the pot bottom and the slag line of a large pot to be not greater than 0.05% in the refining process and the content of Al2O3 in lime, silica sand, sillimanite and wollastonite slagging materials to be not greater than 0.05%; allowing the large pot used in the molten steel refining to be special; completing the final deoxidation and component micro-adjustment of the wire rod for steel cord within 15min before the ending of an LF furnace refining; carrying out argon stirring treatment of the molten steel, wherein the argon flow is 150-350NL / min; and allowing the content of Al2O3 in a tundish covering agent to be not greater than 0.03% and the content of Al2O3 in a tundish coating to be not greater than 0.04% in the continuous casting process. The Al content in the wire rod for steel cord is not greater than 0.001% in the invention, so the Al2O3 inclusion in the wire rod is eliminated, and the fracture rate of the wire rod in the drawing process is reduced.

Owner:ANGANG STEEL CO LTD

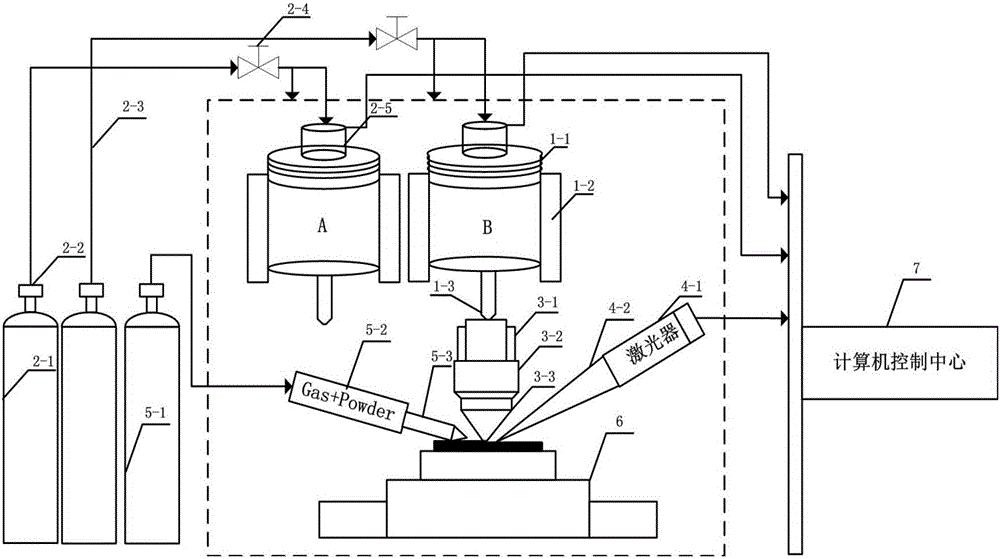

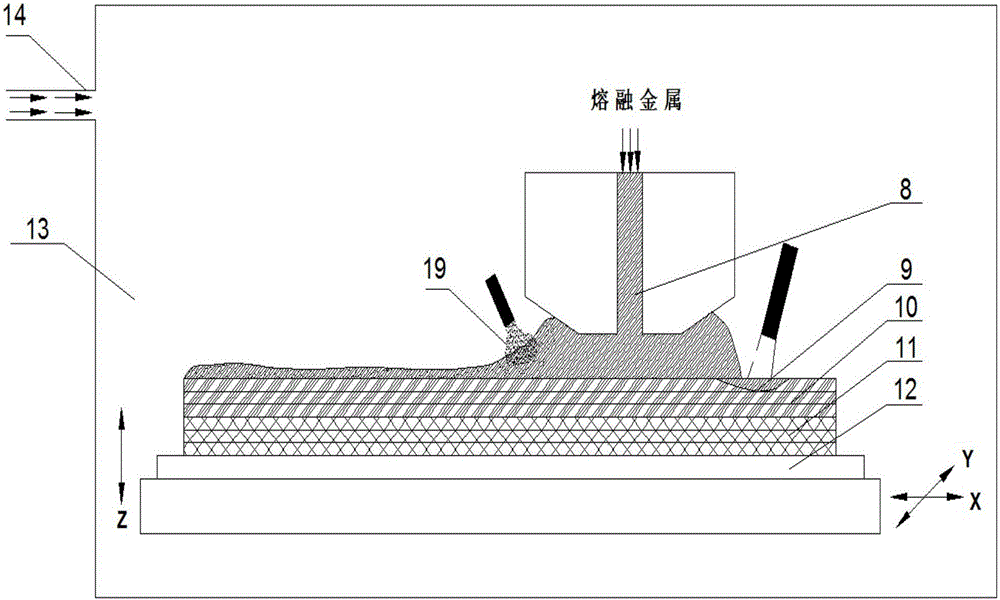

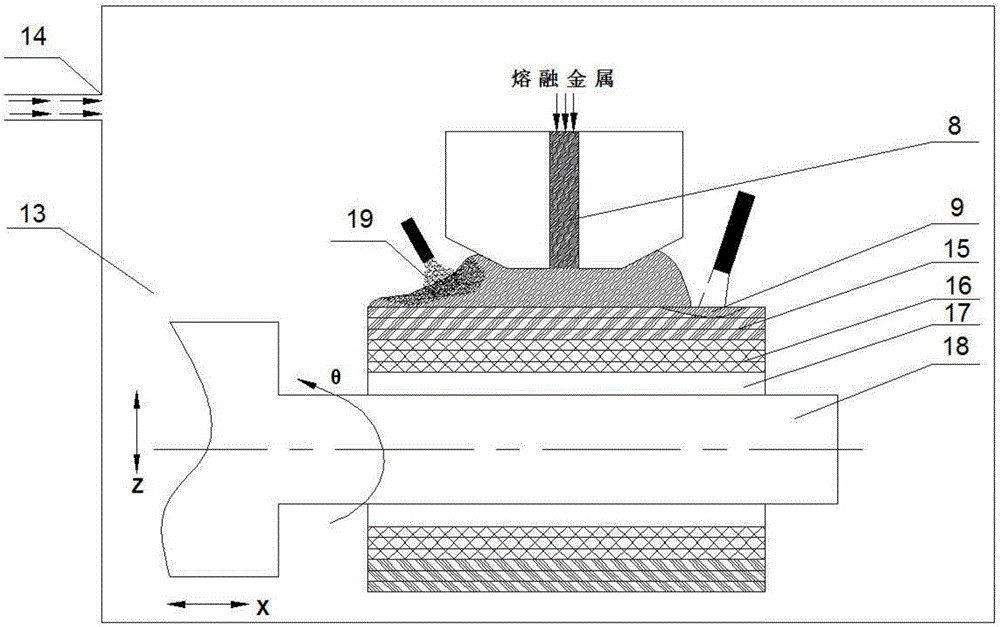

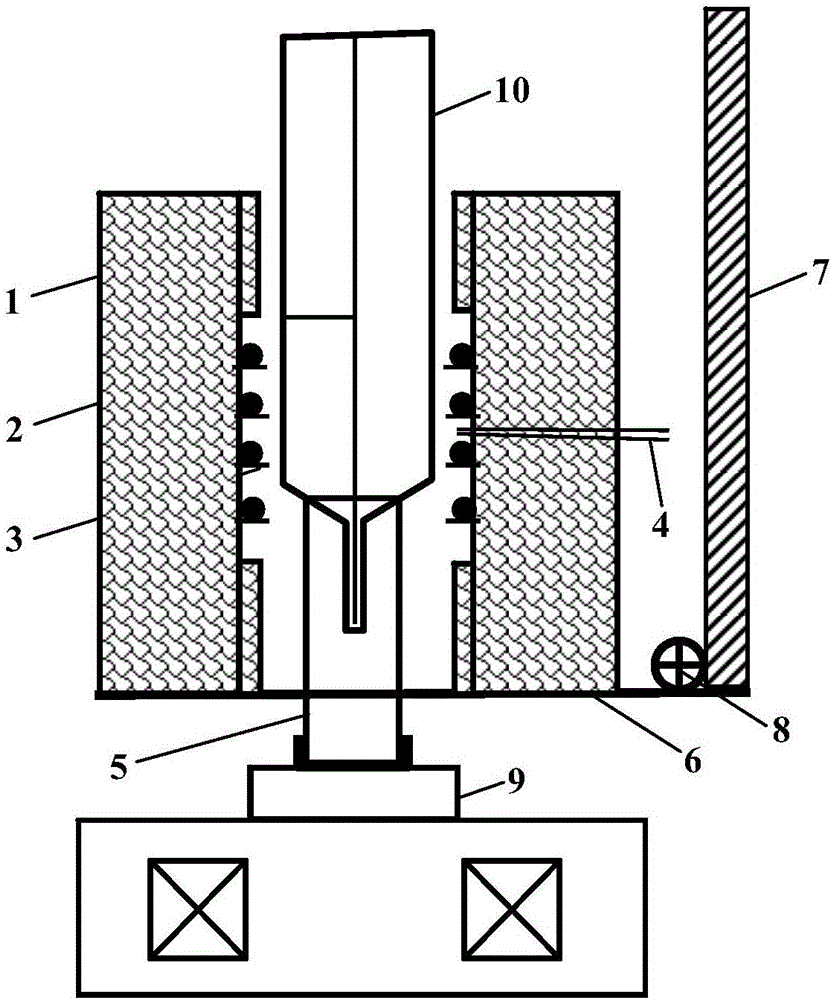

Molten coating forming device and method of metal material gradient components

InactiveCN105817626AEnabling Additive ManufacturingLow costAdditive manufacturing apparatusAtmospheric pressureAdditive layer manufacturing

The invention discloses a molten coating forming device and a method of metal material gradient components. The device comprises at least two metal smelting units, and further comprises an air pressure driving device, a molten coating head, a laser surface auxiliary remelting device, a powder feeder, a three-dimensional forming platform and an atmosphere protecting device; the air pressure driving device is connected with the metal smelting units through pipelines; the molten coating head is connected to the lower ends of the metal smelting units; the three-dimensional forming platform is arranged below the molten coating head; the laser surface auxiliary remelting device is arranged on one side of the three-dimensional forming platform; the powder feeder is arranged on the other side of the three-dimensional forming platform; and the metal smelting units, the molten coating head, the laser surface auxiliary remelting device, the powder feeder and the three-dimensional forming platform are all arranged in the atmosphere protecting device. The device can realize the added material manufacturing of part and gradient components with metal materials with high efficiency, high quality and low cost.

Owner:XI AN JIAOTONG UNIV

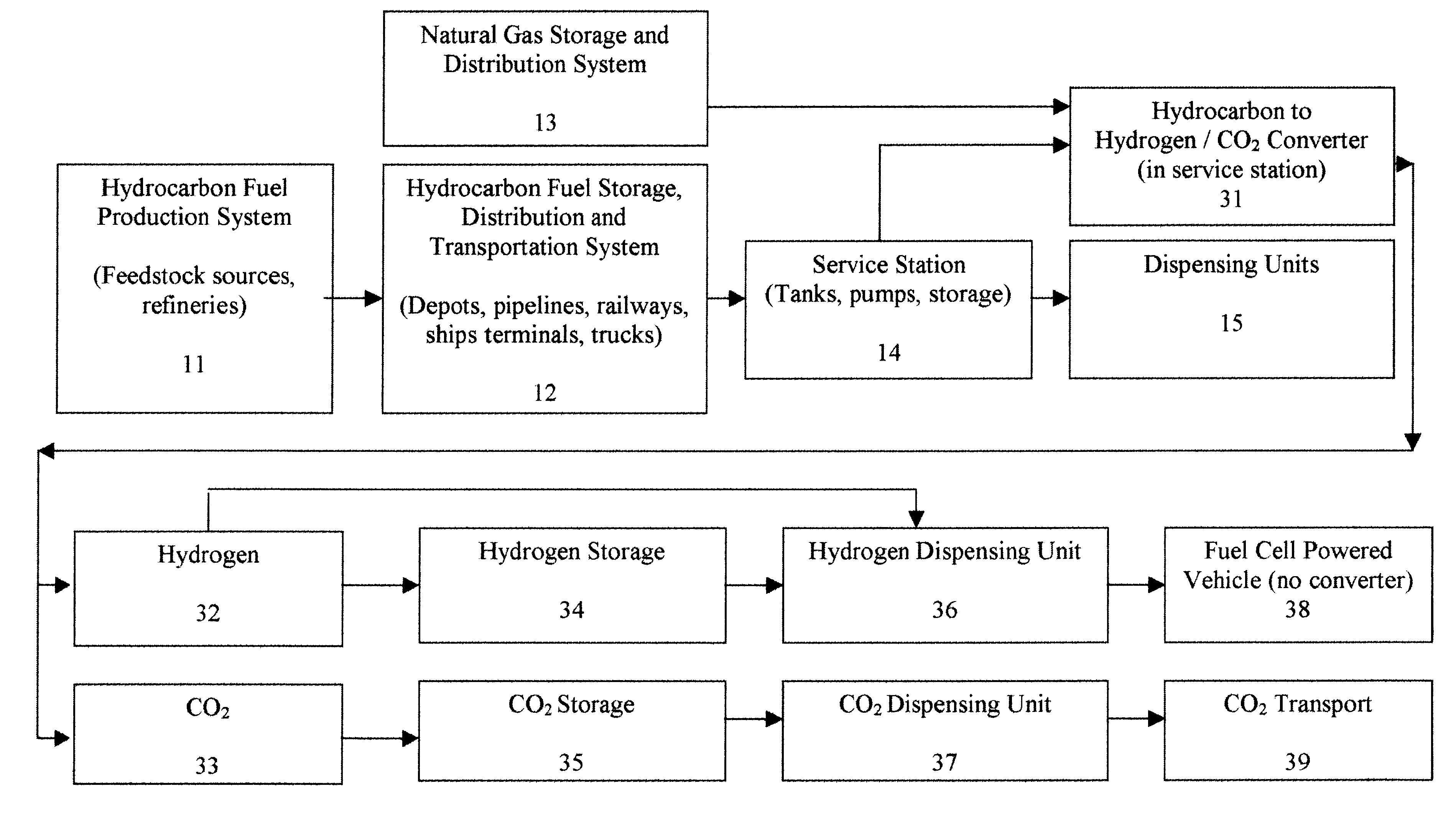

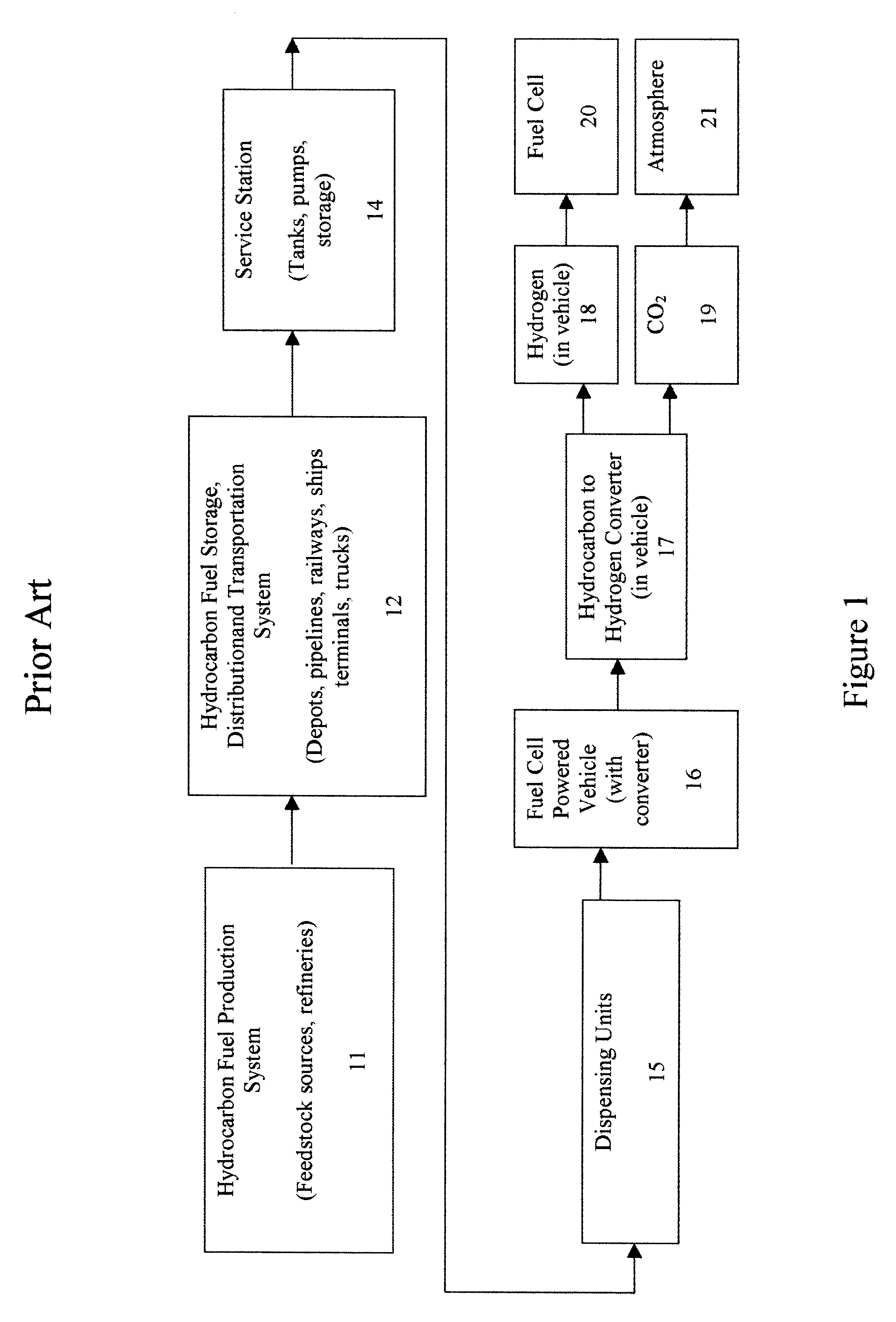

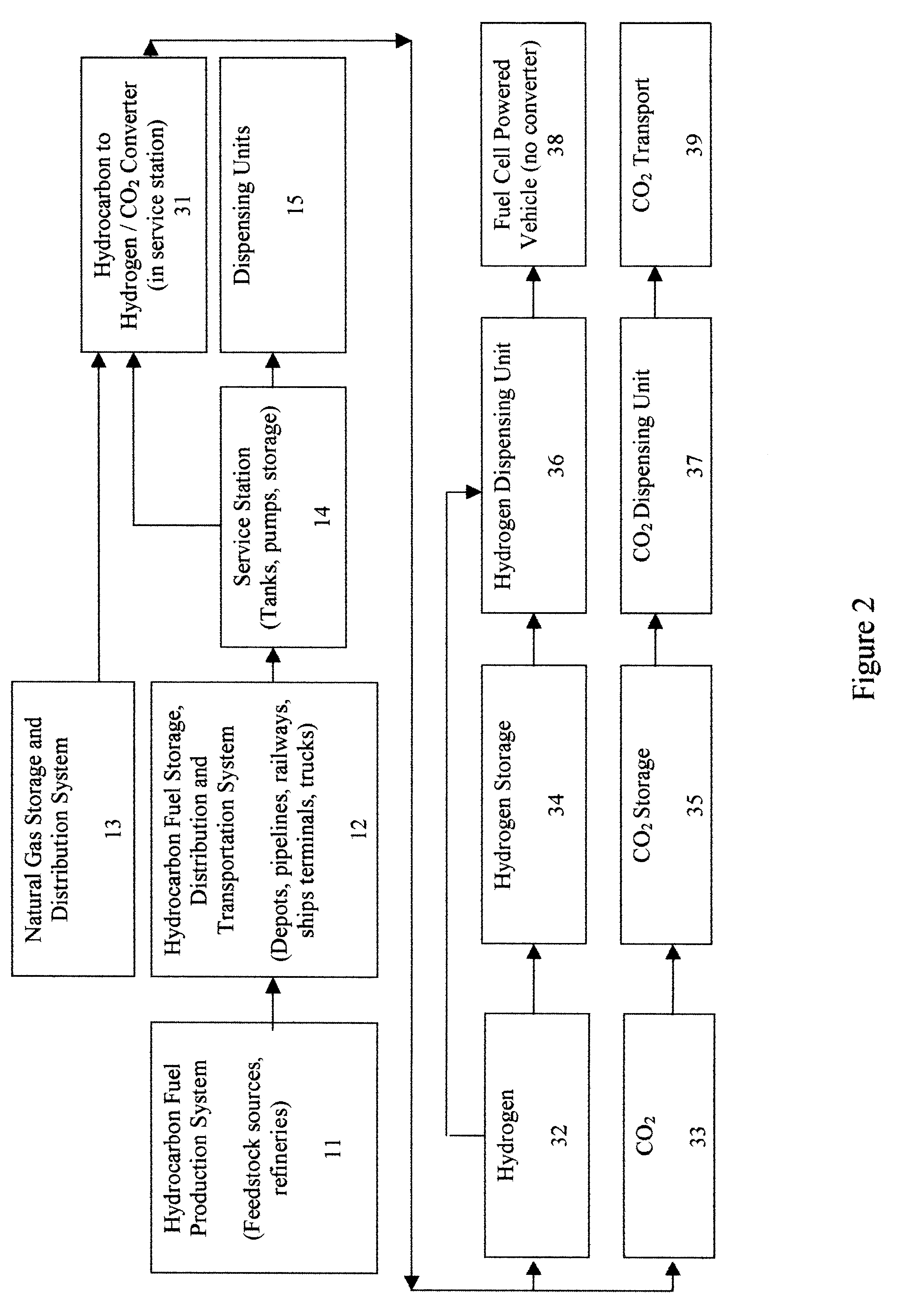

Apparatus and method for using the existing hydrocarbon distribution, storage and dispensing infrastructures for the production, distribution and dispensing of hydrogen

In order to provide hydrogen as a transportation fuel, service stations are provided with apparatus for performing the hydrocarbon to hydrogen conversion. The hydrocarbon product applied to the hydrocarbon to hydrogen converter can be distributed to the service station as gasoline / diesel fuel or as a separate hydrocarbon including natural gas. The hydrogen can be stored in a storage facility at the service station and dispensed to users as required. This distribution system eliminates the need for hydrocarbon to hydrogen converters in the each fuel cell powered automobile. This distribution system also eliminates the need for a separate dedicated hydrogen distribution system. In addition, the distribution of hydrogen can co-exist with the distribution of gasoline and diesel fuels providing for a convenient transition period. The carbon dioxide byproduct of the hydrocarbon to hydrogen conversion can be separately collected and forwarded to facilities requiring this material thus eliminating the emission of polluting gases if the hydrogen from hydrocarbon conversion done on each fuel cell powered vehicle.

Owner:SWANSON RICHARD ALLAN

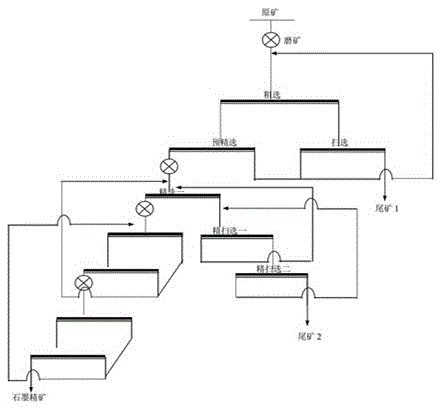

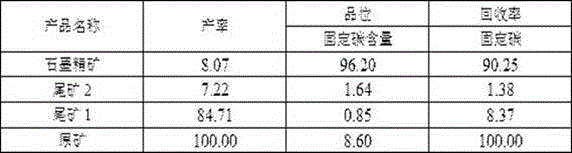

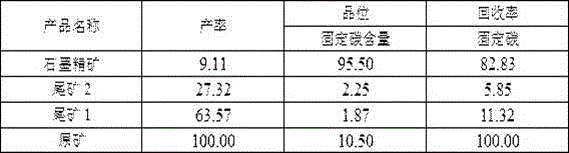

Beneficiation method of micro-fine particle graphite ores for producing high-carbon graphite

InactiveCN105457743AGood synergyEvenly dispersedFlotationGrain treatmentsCarbon graphiteOre concentrate

The invention provides a method for beneficiation of micro-fine particle graphite ores to obtain high-carbon graphite. According to the invention, with cooperation of creative and efficient reagent system and economical and environment-friendly beneficiation processes including crushing, grinding, flotation and regrinding, high-carbon graphite concentrate with fixed carbon content of over 95% is selected from micro-fine particle graphite ores with low content and difficulty in treatment, thus solving the difficulty that the high-carbon graphite concentrate cannot be economically and efficiently produced by adopting micro-fine particle graphite resources.

Owner:HUNAN RES INST FOR NONFERROUS METALS

Ultra-low aluminum steel and smelting method thereof

The invention belongs to the technical field of ferrous metallurgy and particularly relates to ultra-low aluminum steel and a smelting method thereof. The smelting method provided by the invention adopts a production route with the steps of deep removal of S and P by molten iron pretreatment, decarbonization by a converter, deoxidization and alloying of silicon manganese during tapping, deslagging by argon blowing, deep removal of O, S and P by ladle refining, micro-alloying of Ti, Ni, Mo, V and other elements, RH (Ruhstahl-Hausen) vacuum circulation degassing, soft argon blowing and full-protection casting; the prepared ultra-low aluminum steel has low content of harmful elements, particularly has low content of O and Al, can prevent the inclusion of brittle aluminum oxide and realize high impact-resistant and fatigue-resistant performances of the steel, and is suitable for application fields with relatively high requirements for fatigue and impact performances, such as high-speed track traffic and the like.

Owner:JIANGSU UNIV

Novel reinforcement technique of 6XXX aluminum alloy welding joint

InactiveCN103572180AIncrease densityImprove mechanical propertiesSolution treatmentUltimate tensile strength

The invention discloses a novel reinforcement technique of a 6XXX aluminum alloy welding joint, mainly solves the defects such as high cost, large equipment and noise, complex operation, workpiece damage, additional consumption of materials and energy, additional increment of workpiece weight and residual stress, reduction of workpiece plasticity and air hole mingling in the traditional reinforcement methods of the 6XXX aluminum alloy welding joint, and achieves the reinforcement effect to the 6XXX aluminum alloy welding joint. The technique comprises the specific operation steps of solution treatment, subzero treatment and ageing treatment. The technique has the advantages of simple technique, low cost, ideal reinforcement effect, energy conservation, environmental protection and largely improved strength and plasticity, can effectively solve the problems of air holes and mingling inside the joint, and has excellent industrial application prospect.

Owner:葛鹏

Database and Index Organization for Enhanced Document Retrieval

ActiveUS20150186364A1Quick searchRemove inclusionsMetadata text retrievalDigital data processing detailsDocumentation procedureSubject matter

A customized, specialty-oriented database and index. of a subject matter area and methods for constructing and using such a database are provided. Selection and indexing of articles is done by experts in the specialty with which the database is concerned. A thesaurus allows indexing and search in accordance with terminology familiar to different anticipated groups of users (e.g. doctors, patients, nurses, technicians, and the like) by translating search terms to a standard and limited list of topics; a limited number of which are assigned to each document / article and allowing the topics most likely to be relevant to be found. The search can be conducted based on the most relevant topic found or sequential searches can be performed based on topics most relevant to individual search terms or combined search terms and the search results combined on the basis of common topic classifications to leverage the benefits of document classification.

Owner:NELSON JOHN M

Method for preparing high-tungsten-content tungsten-zirconium alloy

The invention relates to a method for preparing high-tungsten-content tungsten-zirconium alloy. The method comprises the following steps that (1) powder is prepared and mixed, tungsten powder and zirconium-titanium powder are mixed and then pelletized, and the proportion, by weight, of the added tungsten powder is 50%-70%; (2) pressing and sintering are carried out, pressing is carried out through a cold isostatic pressing molding press, and pressure is relieved in a graded mode; degreasing sintering is carried out through a high-vacuum resistance furnace, peeling is carried out through finish turning, and a consumable electrode is obtained; and (3) consumable electric arc melting is carried out for at least one time to obtain the high-tungsten-content tungsten-zirconium alloy with uniform ingredients. The consumable electrode is prepared through powder metallurgy, the strength of the electrode is high, and the phenomenon of slag falling is avoided in smelting; the distribution state of tungsten and other elements in the electrode is well improved through powder sintering, the uniformity of ingredients and the structure of cast ingots is facilitated, and therefore the smelted-state tungsten-zirconium alloy with the tungsten content reaching up to 70% is obtained. In addition, through the consumable smelting process, the alloy can be purified, inclusions are eliminated, and the density and the toughness of the alloy are further improved compared with powder-metallurgy-state alloy.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

Preparation method of zinc selenide with high optical quality

ActiveCN101759161AHigh infrared transmittanceSmall absorption coefficientBinary selenium/tellurium compoundsAbsorption factorZinc selenide

The invention discloses a preparation method of zinc selenide with high optical quality, which belongs to the technical field of inorganic block body material preparation. The method comprises the following steps: putting zinc into a deposition furnace; pumping the vacuum; raising the temperature in a deposition chamber; using argon as carrying gas of reaction raw material gas; introducing H2Se gas and the argon into the deposition chamber through a mass flowmeter (the mol ratio of zinc to H2Se is between 0.8 and 1.2, the deposition reaction is carried out on the inner wall of the deposition chamber, and the zinc selenide begins to grow); maintaining the unchanged mol ratio of zinc to H2Se and the constant pressure in the furnace; carrying out deposition for 15 to 25 days; and then, lowering the temperature to the room temperature to obtain the zinc selenide with high optical quality. The invention effectively solves the problem of powder generation in the process of preparing the zinc selenide through chemical vapor deposition, the impurities mixed in products are eliminated, the materials have high infrared transmission rate and low absorption factor, and the optical quality is greatly improved.

Owner:GRINM GUOJINGHUI NEW MATERIALS CO LTD +1

Method of Producing Mixed Powder Comprising Noble Metal Powder and Oxide Powder, and Mixed Powder Comprising Noble Metal Powder and Oxide Powder

ActiveUS20110114879A1Inhibit aggregationAvoid grain growthOther chemical processesHydrazine compoundNitrogen

Provided are a method of producing mixed powder comprising noble metal powder and oxide powder, wherein powder of ammonium chloride salt of noble metal and oxide powder are mixed, the mixed powder is subsequently roasted, and ammonium chloride is desorbed by the roasting process in order to obtain mixed powder comprising noble metal powder and oxide powder, and mixed powder comprising noble metal powder and oxide powder, wherein chlorine is less than 1000 ppm, nitrogen is less than 1000 ppm, 90% or more of the grain size of the noble metal powder is 20 μm or less, and 90% or more of the grain size of the oxide powder is 12 μm or less. Redundant processes in the production of noble metal powder are eliminated, and processes are omitted so that the inclusion of chlorine contained in the royal water and nitrogen responsible for hydrazine reduction reaction is eliminated as much as possible. Consequently, the present invention aims to omit the drying process at a high temperature and thereby prevent grain growth and aggregation, and further eliminate the pulverization and classification processes in order to considerably reduce the production cost.

Owner:JX NIPPON MINING& METALS CORP

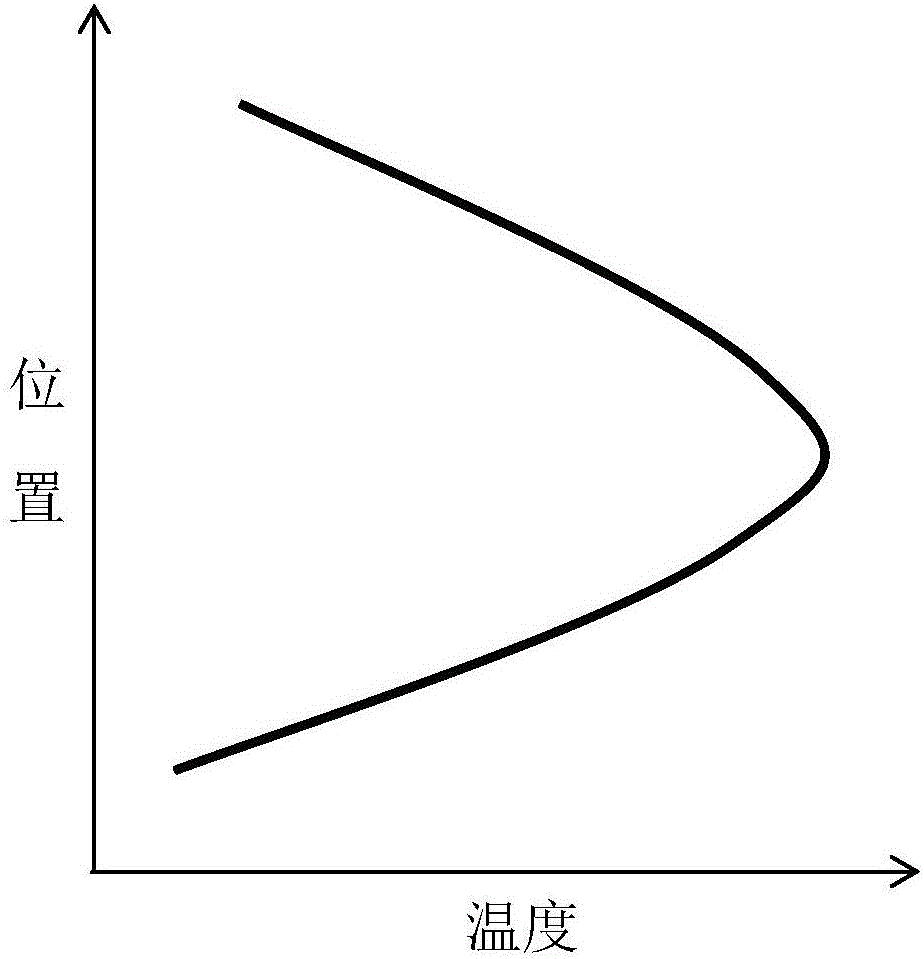

Vertically-movable furnace at short temperature zone and method for growing CdTe crystal by using same

InactiveCN106757369ASimple structureLow costPolycrystalline material growthFrom frozen solutionsEngineeringSingle crystal growth

The invention provides a vertically-movable furnace at a short temperature zone. The heating furnace only adopts a control system with an iron-chromium-aluminium electric heating wire and a thermoelectric couple, so that a furnace body is simple in structure and low in cost; the vertical height of a heating zone is easy in control, and a heating furnace at the short temperature zone is formed; in addition, since the furnace body is provided with openings at the top part and the bottom part, under the convection action of air, the temperature distribution of the heating zone in the vertical direction takes on a trend of gradual reduction from the middle to the upper side and the lower side so as to be beneficial to reducing the length of a melting zone, improving the zone refining effect of raw materials and reducing the content of impurities in crystals. Furthermore, a silicon carbide material is selected for a support of the heating furnace for supporting a quartz crucible, and the release of latent heat of crystallization on crystal growth interfaces is greatly promoted by utilizing high heat conductivity of silicon carbide, so that a micro-convex solid-liquid interface beneficial to single-crystal growth is obtained. CdTe crystal is grown by utilizing the heating furnace, so that the benefit for eliminating defects of Te precipitation, inclusion and crystal twinning and the like is achieved and the utilization rate of the CdTe single crystal is increased.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Aluminum alloy welding wire and manufacturing method thereof

ActiveCN108262576AReasonable alloy compositionEasy to organizeWelding/cutting media/materialsSoldering mediaNiobiumCerium

The invention relates to an aluminum alloy welding wire and a manufacturing method thereof. The aluminum alloy welding wire is prepared from the following elements in percentage by weight: 0.01 percent to 0.15 percent of iron, 0.01 percent to 0.12 percent of silicon, 0.01 percent to 0.1 percent of copper, 0 percent to 0.009 percent of scandium, 0.02 percent to 0.22 percent of manganese, 4.5 percent to 5.5 percent of magnesium, 0 percent to 0.009 percent of chromium, 0.01 percent to 0.18 percent of zinc, 0 percent to 0.003 percent of titanium, 0.001 percent to 0.03 percent of lithium, 0.001 percent to 0.01 percent of boron, 0 percent to 0.02 percent of vanadium, 0.005 percent to 0.009 percent of zirconium, 0.002 percent to 0.009 percent of cerium, 0.001 percent to 0.008 percent of yttrium,0.0001 percent to 0.002 percent of nickel, 0.0001 percent to 0.008 percent of strontium, 0.0001 percent to 0.009 percent of ytterbium, 0.0003 percent to 0.002 percent of neodymium, 0.0001 percent to 0.03 percent of niobium, and the balance aluminum. Compared with the prior art, according to the aluminum alloy welding wire and the manufacturing method thereof provided by the embodiment of the invention, the performance and the quality of the aluminum alloy welding wire can be remarkably improved, and the manufacturing cost of the aluminum alloy welding wire is comprehensively reduced.

Owner:江苏豪然新材料有限公司

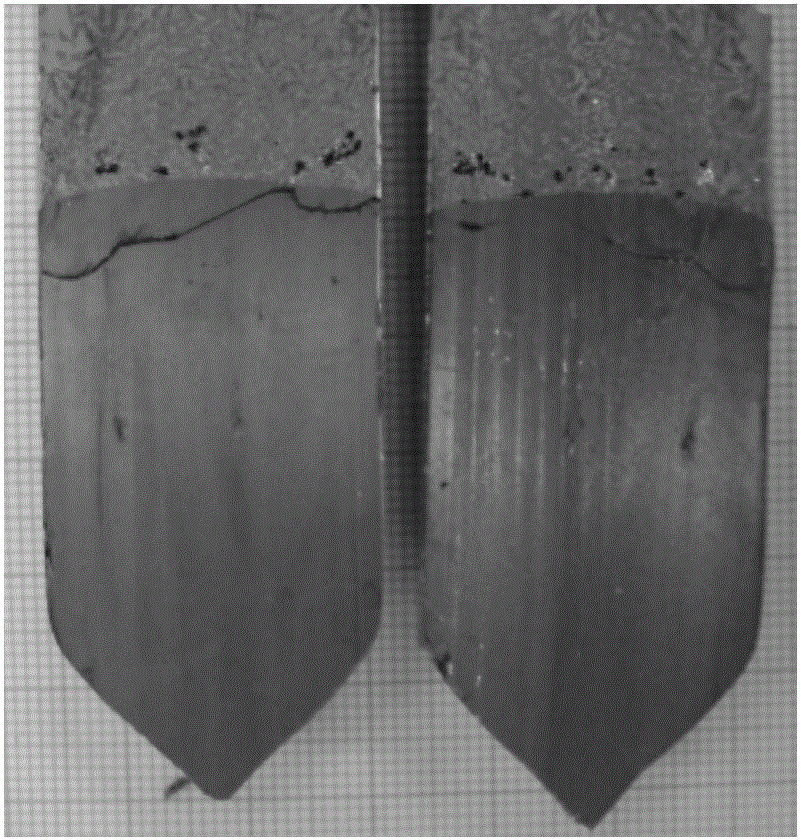

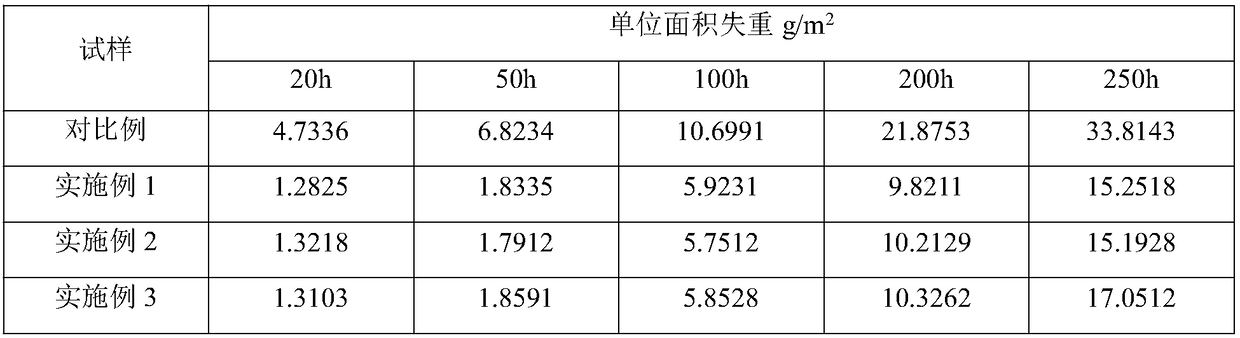

High-heat-capacity Os containing magnesium bath alloy for lead bath replacement

InactiveCN108467927APrevents flash evaporation and oxidationEliminate Flux InclusionsFurnace typesHeat treatment furnacesMagnesium alloyHeat treated

The invention discloses high-heat-capacity Os containing magnesium bath alloy for lead bath replacement and a machining technology thereof. The high-heat-capacity Os containing magnesium bath alloy comprises, by weight, 1.2-1.8 wt.% of Ba, 0.4-0.8 wt.% of Os, 1.0-1.5 wt.% of Mn, 0.4-0.8 wt.% of Sc, 0.2-0.3 wt.% of Sm, 2.0-4.0 wt.% of Co and the balance Mg. The magnesium bath alloy is adopted to replace lead bath alloy for heat treatment, an obtained troostite steel wire can have good comprehensive performance after drawing, the required mechanics index is provided for a finished steel cord, and meanwhile, the occurring frequency of the situation that the steel cord is broken in the production process is decreased.

Owner:GUANGZHOU YUZHI TECH CO LTD

Non-nickel low-chromium austenite 0CR13Mn14CuN stainless acid-resistant steel

InactiveCN101250670AGood for low temperature dephosphorizationImprove toughnessMinor elementLead smelting

The invention relates to a nickel-free low-chrome austenite 0Cr13Mn14CuN acid-resistant stainless steel, which is characterized in that the main chemical components comprise C<=0.08%, Si<=1.00%, Mn13.0%-15.0%, Cr12.0%-14.0%, Cu 1.0%-2.0%, N 0.15%-0.25%, P<=0.035% and S<=0.030%. The invention is new steel, which is tested to be austenite metallurgical structure through engineer tests for few decades, and the chemical components, acid resistance, corrosion resistance, oxidation resistance and mechanical property all reach the technical standard of stainless steel, in particular to minor element which is added, and crystal grain is led to be refined, toughness of steel is increased, and the functions of deoxidizing, desulfurizing, eliminating non-metal impurity in steel, preventing intergranular corrosion and the like. The cid-resistant stainless steel utilizes manganese and nitrogen to replace expensive nickel, which leads smelting cost to be lower more than 60%, and can be applied in producing acid-resistant stainless seamless steel pipes, various round bars, sheet material and acid-resistant stainless steel casting which is minutely casted.

Owner:陆平

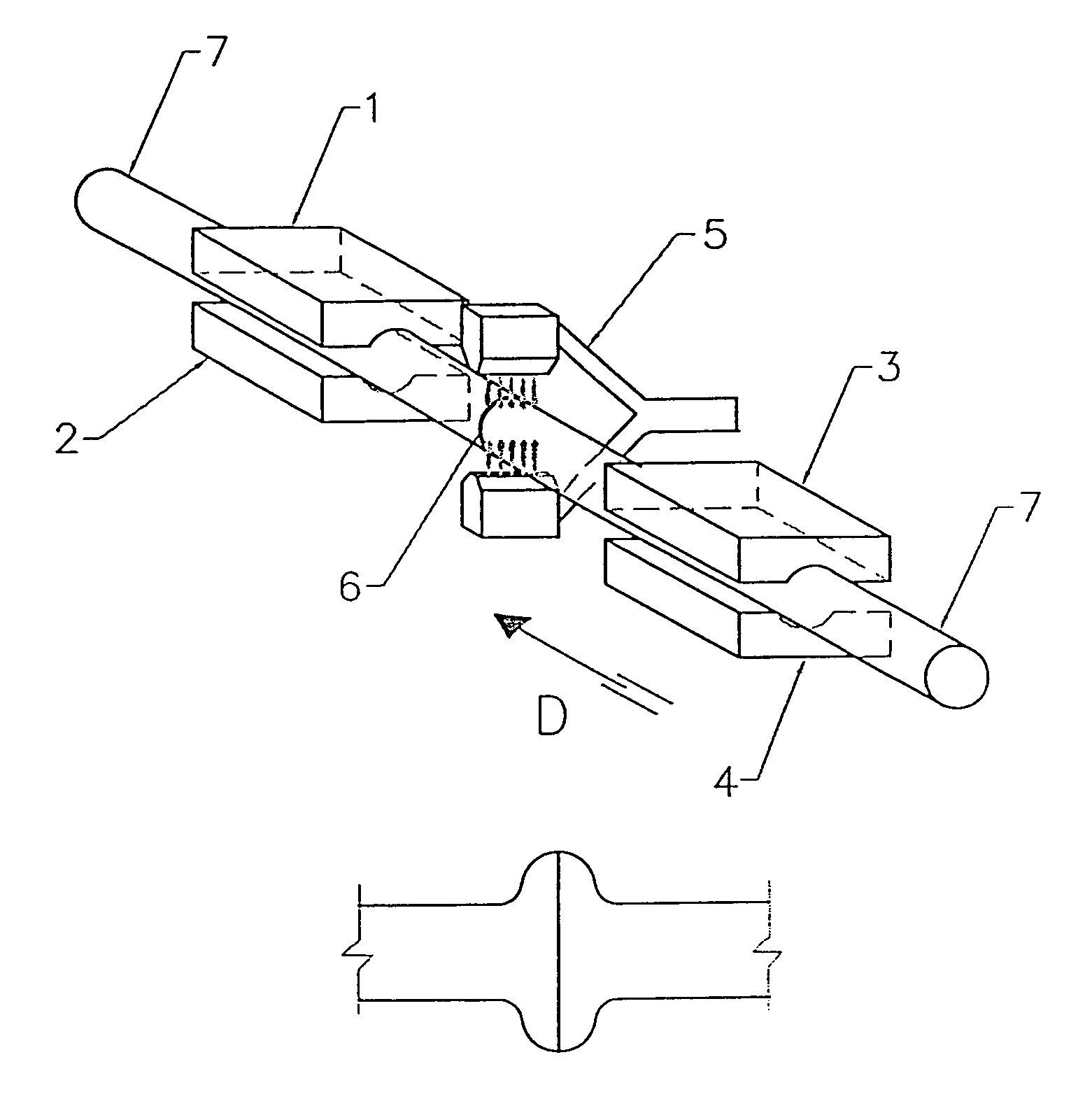

Method of joining coiled sucker rod in the field

InactiveUS7234627B2Small and less-expensiveRemove inclusionsWelding/cutting media/materialsMetal working apparatusAxial pressureEngineering

A method of joining coiled sucker rod in the field. In its most basic form, the method includes a first step of placing abutting ends of sucker rod in face to face relation. A second step involves positioning a gas burner in proximity to the abutting ends of sucker rod and heating the abutting ends with a hydrocarbon gas flame while applying axial pressure to force the abutting ends together. A third step involves continuing heating and applying pressure until a weld is formed with a bulge formed above the weld which is at least one third of the diameter of the welded rod. A fourth step involves keeping the pressure constant until the weld cools.

Owner:BOSTIK KAREL

Anti-corrosion aluminum alloy pipe and preparation method thereof

The invention provides an anti-corrosion aluminum alloy pipe and belongs to the technical field of aluminum alloy materials. The composition elements of the aluminum alloy pipe comprise, by mass, 0.05-0.1% of Si, 0.15% of Fe or the less, 0.01% of Cu or the less, 0.8-1.0% of Mn, 0.2-0.4% of Mg, 0.01% of Zn or the less, 0.01-0.05% of Ti, 0.05% of the other elements or the less and the balance Al. According to the anti-corrosion aluminum alloy pipe, through adjustment of components and change of the technique, the anti-corrosion performance of the aluminum pipe can be effectively improved while the 3003 aluminum pipe strength is met, and the service life of a product is prolonged.

Owner:JIANGSU ASIA PACIFIC LIGHT ALLOY TECH CO LTD

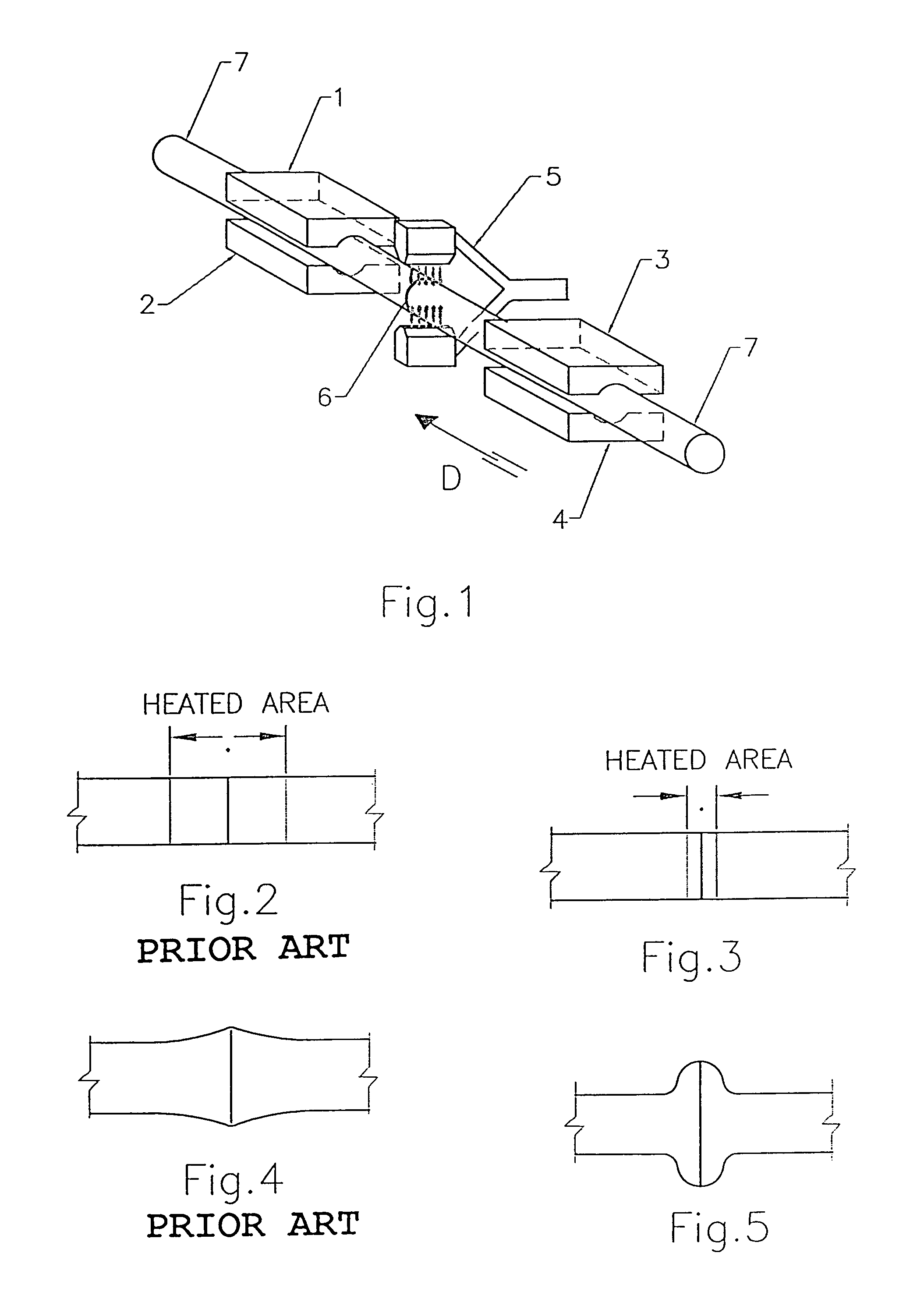

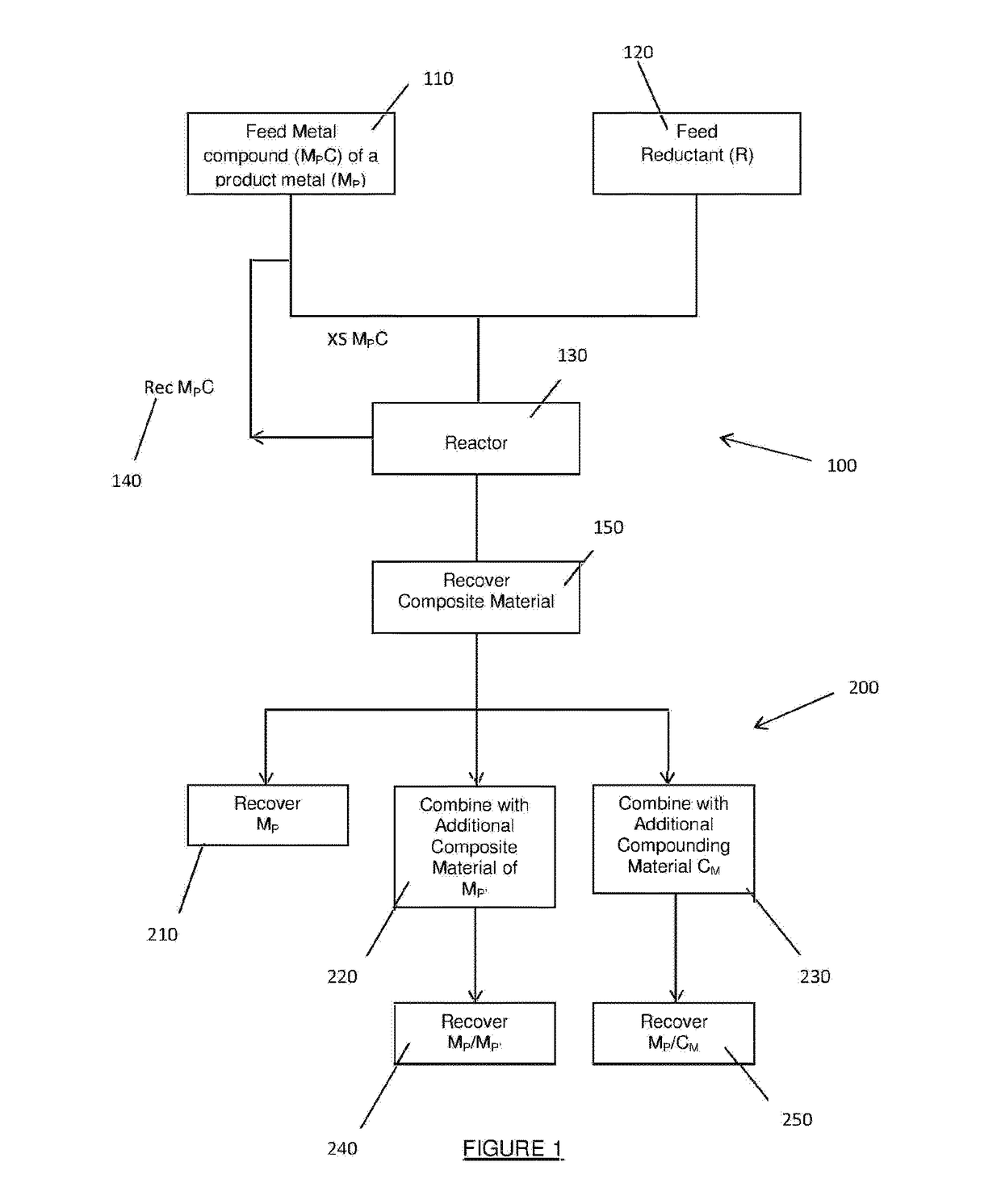

Method for production of a composite material using excess oxidant

ActiveUS9840753B2Remove inclusionsImprove corrosion resistanceProcess efficiency improvementOxidation-Reduction AgentOxidation state

A method of producing a composite material comprising: supplying a metal compound (MPC) of a product metal (MP) and a reductant (R) capable of reducing the metal compound (MPC) of the product metal (MP) to a reactor; forming a composite material comprising a matrix of oxidized reductant (R0) of the reductant (R), the product metal (MP) dispersed in the matrix of oxidized reductant (R0), and at least one of (i) one or more metal compounds (MPCR) of the metal compound (MPC) in one or more oxidation states and (ii) the reductant (R); and recovering the composite material from the reactor, wherein the metal compound (MPC) of the product metal (MP) is fed to the reactor such that it is in excess relative to the reductant (R).

Owner:COOGEE TITANIUM PTY LTD

Hard alloy and process for local laser coating of hard alloy

ActiveCN107760956ATightly boundHigh hardnessTransportation and packagingMetal-working apparatusLaser coatingThermal expansion

The invention discloses a hard alloy and a process for local laser coating of the hard alloy, belonging to the technical field of surface-hardening treatment of metal. The hard alloy comprises, by weight, 20 to 27% of Cr, 10 to 14% of W, 1.5 to 2.5% of C, 21 to 23% of Ni, 1% of Fe, 0.8 to 1% of Si, 1% of B and 1.5% of Re, with the balance being Co. The hard alloy is powdery and has a powder size of 40 to 200 [mu]m. The powdery alloy material used in the invention has good compatibility with a matrix material, the dilution rate of a cladding layer is small, and the thermal expansion coefficients of the two materials are almost same; through pretreatment and post-heat-treatment of a matrix and the cladding layer, temperature gradient is further reduced and internal thermal stress in the cladding layer is decreased, and thus, the phenomena of cracks and shedding of an alloy layer are avoided; therefore, the hard alloy overcomes the problem of infirm bonding between a coated alloy layer and matrix metal in the prior art and has the characteristics of high hardness and good wear resistance.

Owner:佛山铸昊机械设备有限公司

Preparation method of zinc selenide with high optical quality

ActiveCN101759161BSolve build problemsHigh infrared transmittanceBinary selenium/tellurium compoundsPhysical chemistryChemical vapor deposition

Owner:GRINM GUOJINGHUI NEW MATERIALS CO LTD +1

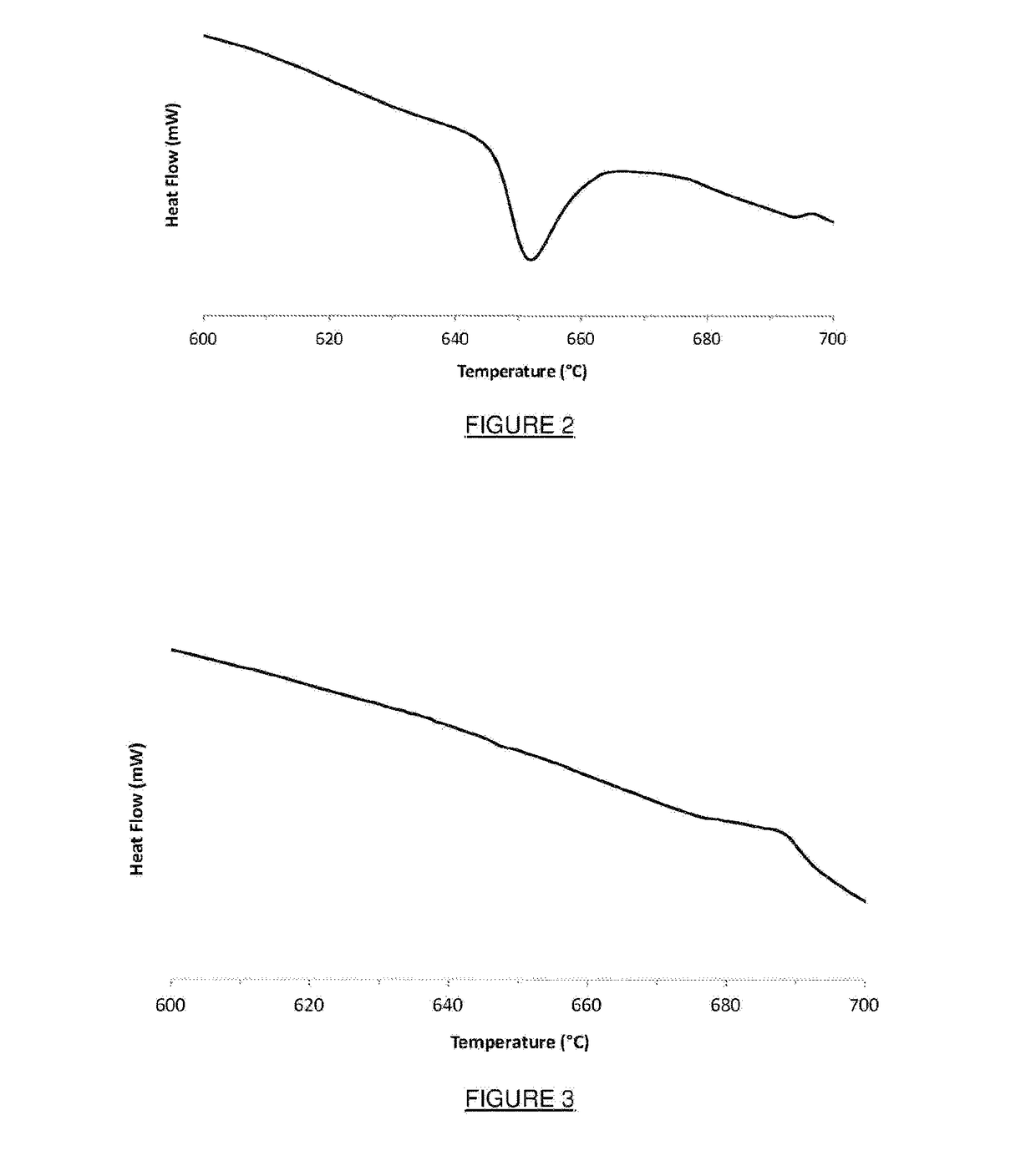

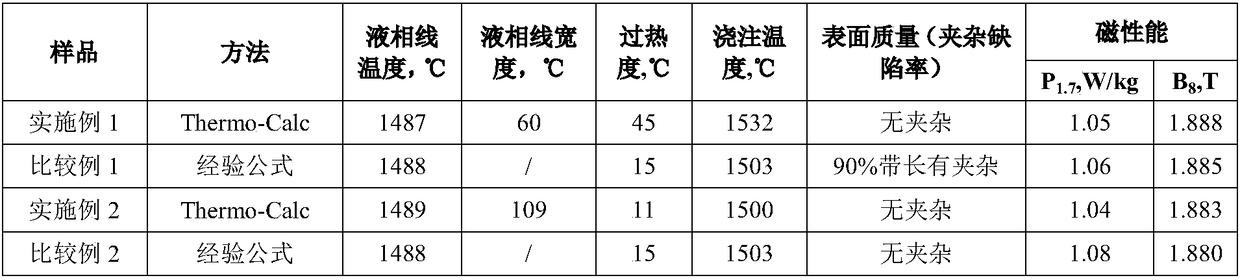

Production method of high-magnetic-induction-orientated silicon steel with low inclusion defect rate

ActiveCN108480587AControl the number of inclusionsRemove inclusionsManufacturing convertersAlkalinitySheet steel

The invention relates to a production method of high-magnetic-induction-orientated silicon steel with the low inclusion defect rate. The production method comprises the steps that smelting: argon blowing is conducted in the whole process of converter smelting; at the after-furnace end point of a converter, C is controlled to be less than or equal to 0.040%, P is controlled to be less than or equalto 0.011%, and S is controlled to be less than or equal to 0.005%; slag in the converting process has the alkalinity of 3.0-3.5 and the thickness less than or equal to 80mm; the slag is pushed off when steel tapping is finished; calculating the width of a liquid phase line of actual smelting components of high-magnetic-induction-orientated silicon steel; utilizing the calculated liquid phase linewidth result, controlling the superheat degree of molten steel in a tundish and controlling the temperature in the solidification process to be within 90-130 DEG C; and conducting electromagnetic stirring in the continuous casting process, conducting hot charging on a casting blank after continuous casting and controlling the temperature of the casting blank to be greater than or equal to 700 DEGC. The production method has the advantages that the width of the liquid phase line of the smelting components can be quickly and accurately calculated; the continuous casting technological parameters are reasonably designed according to the calculation result; the quantity of inclusions in a steel plate is effectively controlled; the finished steel rate is increased; the cost is saved; and wasteis reduced.

Owner:ANGANG STEEL CO LTD

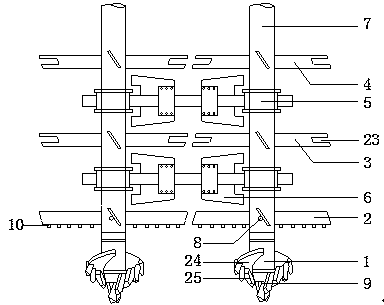

Double-shaft mixing drill with effect of eliminating soil adhesion

PendingCN110004924AReduce bending momentStir wellEarth drilling toolsDrilling rodsCement pasteScrew thread

The invention discloses a double-shaft mixing drill with the effect of eliminating soil adhesion and belongs to the field of pile foundation construction equipment. The double-shaft mixing drill comprises a drill body, mixing blades, a conversion device, a horizontal fixed connection device and a drill rod. The drill rod is a hollow cylindrical rod body, the internal side of the lower end of the drill rod is provided with internal threads, the drill rod is connected with the drill body in a thread mode and is welded with the mixing blades. The conversion device is connected with the drill rodin a buckling mode. The horizontal fixed connection device is connected with the conversion device through bolts. According to double-shaft mixing drill, pressure of an overlying soil layer and friction resistance in cutting soil body are effectively reduced, the problem that soil body which is loose due to stir around a mixing shaft rotates with a mixing shaft instrument, and further cement pastewhich is ejected from a whitewashing hole cannot be mixed with soft soil uniformly and quality of built-up pile is affected. Coating body of the drill body is eliminated through the double-shaft mixing drill, cement-mixed content, and mixing uniformity of the cement paste and soil is guaranteed, and returned quantity of the cement paste is reduced.

Owner:BEIJING ZHONGYAN DADI TECH CO LTD

Novel Re-contained lead-free magnesium bath alloy for troostite heat treatment

InactiveCN108342548AEliminate Flux InclusionsReduce pollutionQuenching agentsMechanical indexMagnesium

The invention discloses the novel Re-contained lead-free magnesium bath alloy for troostite heat treatment, and a processing technology thereof. The novel Re-contained lead-free magnesium bath alloy for troostite heat treatment comprises the ingredients of, by weight percentage, 1.5% to 2.0% of Ba, 0.4% to 0.6% of Re, 10.0% to 20.0% of Sn, 0.4% to 0.8% of Sc, 0.3% to 0.5% of Ce, 2.0% to 5.0% of Al, and the balance magnesium. By adopting the novel Re-contained lead-free magnesium bath alloy to carry out heat treatment instead of lead bath alloy, the obtained troostite steel wires can acquire the good comprehensive performance after being pulled, the needed mechanical indexes are provided for finished product steel cords, and less steel cords are broken in the production process.

Owner:GUANGZHOU YUZHI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com