Double-shaft mixing drill with effect of eliminating soil adhesion

A technology of cohesion and biaxial mixing, which is applied in the direction of earthwork drilling, drill pipe, drill pipe, etc., can solve the problems affecting the quality of piles, cement slurry can not be uniformly mixed with soft soil, etc., to ensure the amount of cement mixed , Reduce the effect of bending moment and reduce the effect of returning slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The model pile mixing test was carried out on the miscellaneous filling site, the pile depth was set to 5m, and the cement-soil mixing method was used for construction. Two groups of tests A and B were set up, and each group was equipped with 3 specimens. Group A was the experimental group. Stirring drill bit of the present invention; B group is a control group, adopts the general stirring drill bit in the market, and concrete technology is as follows:

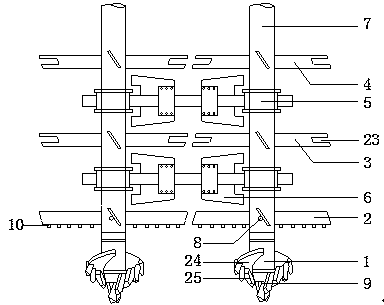

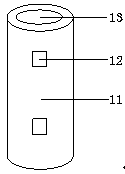

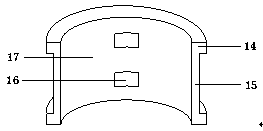

[0035] like Figure 1~8 As shown, a dual-axis stirring drill bit with the effect of eliminating soil bonding includes a drill bit 1, a stirring blade, a conversion device 5, a horizontal fixed connection device 6, and a drill rod 7; the drill rod 7 is a hollow cylindrical rod body, The inner side of its lower end is provided with an internal thread, the drill rod 7 is threadedly connected with the drill bit 1, and the drill rod 7 is connected with the stirring blade by welding; the conversion device 5 is connected with ...

Embodiment 2

[0052] When carrying out test piles at a certain construction site, set up a test pile, the more test piles that are added adopt the mixing drill bit of the present invention, the design regulation pile depth is 13m, adopt cement-soil mixing method construction, wherein, the soil layer of the site is:

[0053]

[0054] The specific techniques are as follows:

[0055] like Figure 1~8 As shown, a dual-axis stirring drill bit with the effect of eliminating soil bonding includes a drill bit 1, a stirring blade, a conversion device 5, a horizontal fixed connection device 6, and a drill rod 7; the drill rod 7 is a hollow cylindrical rod body, The inner side of its lower end is provided with an internal thread, the drill rod 7 is threadedly connected with the drill bit 1, and the drill rod 7 is connected with the stirring blade by welding; the conversion device 5 is connected with the drill rod 7 through buckles; the horizontal fixed connection device 6 is connected with the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com