A force measurement device for a wind tunnel test model

A force measuring device and wind tunnel test technology, which is applied in the resistance, bending moment and torque component measurement device of the rigid model of the wind tunnel test, and the lift field. It can solve the problems of large cantilever, large bending moment, and balance range mismatch, etc., to achieve The effect of reliable test results, increased model size, and reduced thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

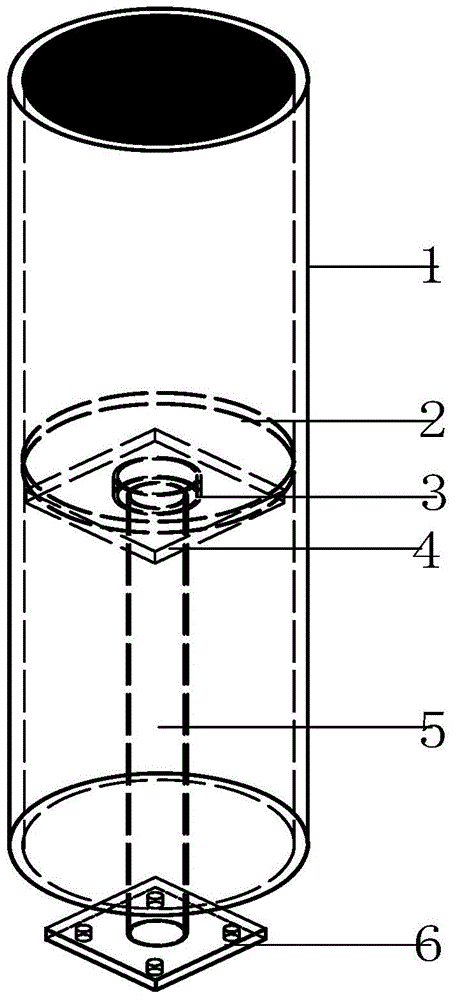

[0012] The specific implementation will be described below by taking the cylindrical model as an example in conjunction with the accompanying drawings and technical solutions.

[0013] When making the test model 1, fix and install the rigid partition 2 at an appropriate position inside it, rigidly connect the rigid partition 2 and the multi-component balance 3 through bolts (easy to disassemble), and rigidly connect the multi-component balance 3 to the balance through bolts On the support 4 (thickness 4-5mm, the plane size matches the balance), the balance support 4 is welded on the top of the circular steel pipe 5 (the diameter can be in the range of 3-5cm, and the wall thickness can be in the range of 2-5mm) , the other end of the steel pipe 5 is welded on the steel pipe base 6, and the steel pipe base 6 and the foundation can be connected by bolts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com