Prestressed concrete wind power tower system and construction method thereof

A concrete and prestressed technology, which is applied to wind turbine components, wind engines, mechanical equipment, etc., can solve the problems of large space requirements in prefabrication plants, and achieve the effects of saving transportation costs, simple assembly work, and simplified prefabrication work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

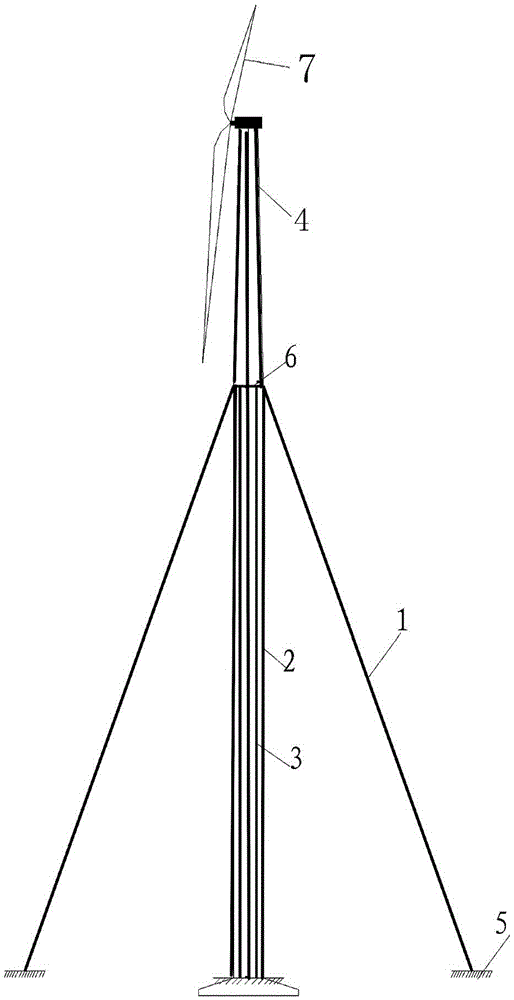

[0035] Such as figure 1 As shown, in this prestressed concrete wind power tower system, the upper end of the tower main body is connected to the wind power generator 7, which is characterized in that the tower main body consists of a concrete tower tube 2 at the lower part and a steel tower section 4 at the upper part The main body of the tower is fixed by a prestressed cable tie; the prestressed cable has a vertical prestressed bundle 3 arranged inside the lower concrete tower 2 and a vertical prestressed beam 3 arranged outside the lower concrete tower 2. The oblique prestressed cable 1; the upper end of the vertical prestressed beam 3 and the oblique prestressed cable 1 are anchored on the bottom flange 6 of the upper steel tower section, and the lower end of the oblique prestressed cable 1 is connected to the pullout The foundation 5 is fixedly connected, and the lower end of the vertical prestressed beam 3 is anchored to the base of the concrete tower 2 .

[0036] see ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com