A box-type bridge assembly structure and installation method

An installation method and bridge technology, applied in the direction of bridges, bridge parts, bridge materials, etc., can solve the problems of restricting the span and service life of bridges, unsuitable concrete quality assurance, complicated stress structure, etc., so as to improve vehicle speed and drive comfort. It is beneficial to technical operation and saves construction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

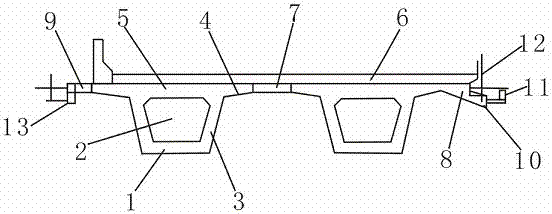

[0023] Embodiment: A box-type bridge assembly structure, including a concrete box girder 1, the concrete box girder 1 is in the shape of an inverted trapezoid, and an inverted trapezoidal hollow interlayer 2 is provided inside the concrete box girder 1, and the concrete box girder 1 is in the shape of an inverted trapezoid A support beam 3 is formed between the beam 1 and the hollow interlayer 2, and a wing beam 4 is fixedly installed on both sides of the concrete box girder 1, and the support surface 5 is formed on the top of the wing beam 4 and the concrete box beam 1, and on the support surface 5 is provided with a concrete pouring layer 6, which is connected by concrete floor joints 7 between adjacent concrete box girders 1, and the concrete box girders 1 at both ends are fixedly installed with cantilever beams 8 and butt-joint beams 9 respectively, and the cantilever beams 8 is composed of a suspension column 10, an anti-slip clamping beam 11 and a docking standard rod 12,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com