Construction method of integrally poured building room

A construction method and building technology, which can be applied to buildings, building components, building structures, etc., can solve the problems of unsatisfactory seismic performance, unsatisfactory sealing performance, and difficulty in ensuring the overall strength of the building, and achieve high popularization and application value. Construction quality and efficiency, enhanced waterproofing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

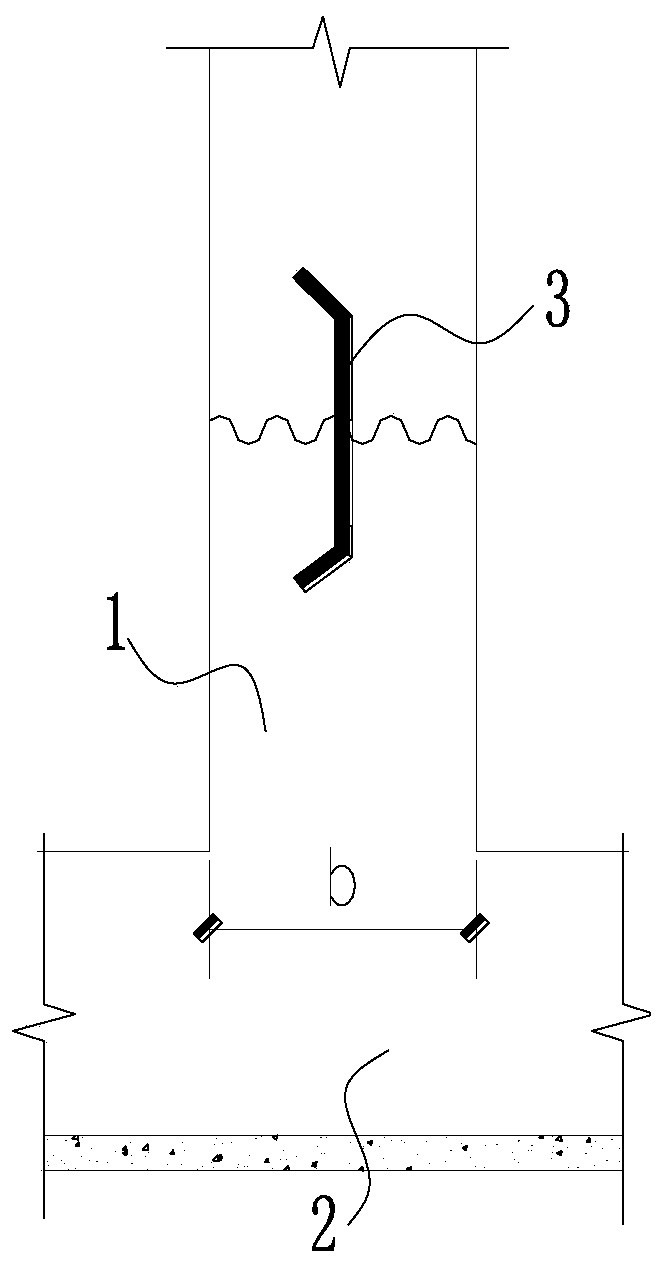

[0040] refer to Figure 1-6 As shown, the building construction method of integrated pouring, the specific steps include as follows:

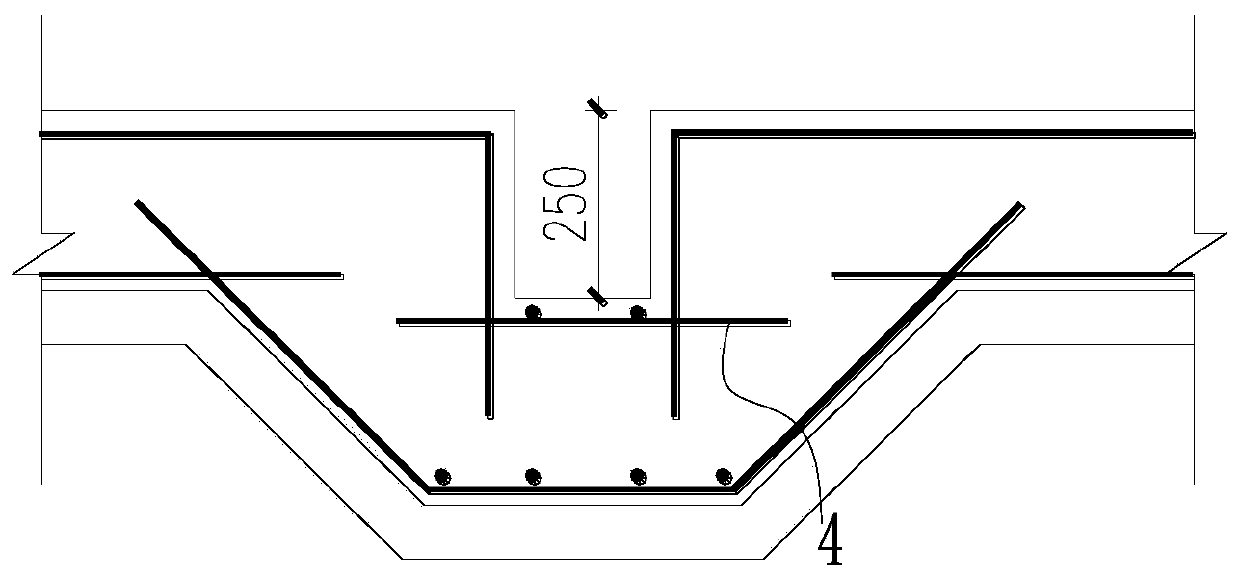

[0041] S1: Foundation treatment: clean up floating sand and silt in the site, use excavators and loaders to carry out mechanical excavation and leveling, and when the distance to the design elevation is 250m, manually level it and compact it with a road roller, and then pour concrete;

[0042] S2: Concrete pouring: After pouring large-volume concrete, moisture retention and temperature control measures should be taken within 10 hours. The temperature difference between the inside and outside of the concrete should not be greater than 25°C, and the temperature difference between the surface of the concrete pouring body and the atmosphere should not be greater than 20°C. The maintenance time is 14 days;

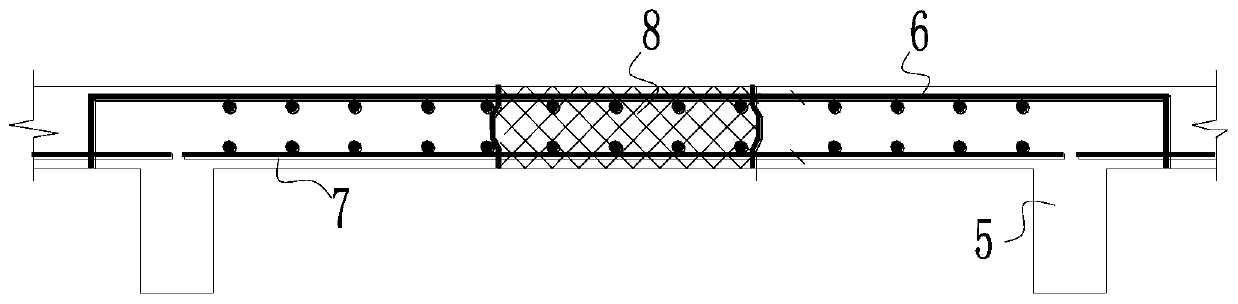

[0043]S3: Treatment of raft post-casting belts: a plurality of raft post-casting belts are evenly arranged on the foundation, and the bottom e...

Embodiment 2

[0054] refer to Figure 1-6 As shown, the building construction method of integrated pouring, the specific steps include as follows:

[0055] S1: Foundation treatment: clean up the floating sand and silt in the site, use excavators and loaders to carry out mechanical excavation and leveling, and when the distance to the design elevation is 280m, manually level it and compact it with a road roller, and then pour concrete;

[0056] S2: Concrete pouring: after pouring large-volume concrete, moisture retention and temperature control measures should be taken within 11 hours. The maintenance time is 16 days;

[0057] S3: Treatment of raft post-casting belts: a plurality of raft post-casting belts are evenly arranged on the foundation, and the bottom end of the raft post-casting belts is provided with a floor cushion 11 to form a good separation effect. The bottom floor cushion 11 Bottom plate steel bars 9 are arranged on the bottom plate steel bars 9, and the upper and lower part...

Embodiment 3

[0068] refer to Figure 1-6 As shown, the building construction method of integrated pouring, the specific steps include as follows:

[0069] S1: Foundation treatment: clean up floating sand and silt in the site, use excavators and loaders to carry out mechanical excavation and leveling, and when the distance to the design elevation is 300m, manually level it and compact it with a road roller, and then pour concrete;

[0070] S2: Concrete pouring: After pouring large-volume concrete, moisture retention and temperature control measures should be taken within 12 hours. The maintenance time is 20d;

[0071] S3: Treatment of raft post-casting belts: a plurality of raft post-casting belts are evenly arranged on the foundation, and the bottom end of the raft post-casting belts is provided with a floor cushion 11 to form a good separation effect. The bottom floor cushion 11 Bottom plate steel bars 9 are arranged on the bottom plate steel bars 9, and the upper and lower parts of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com