Sorting technology for coarse coal slurry damping pulsation interference bed

A technology of pulsating interference and coarse coal slime, applied in solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of high-density fine particles entering the overflow tank and the reduction of sorting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

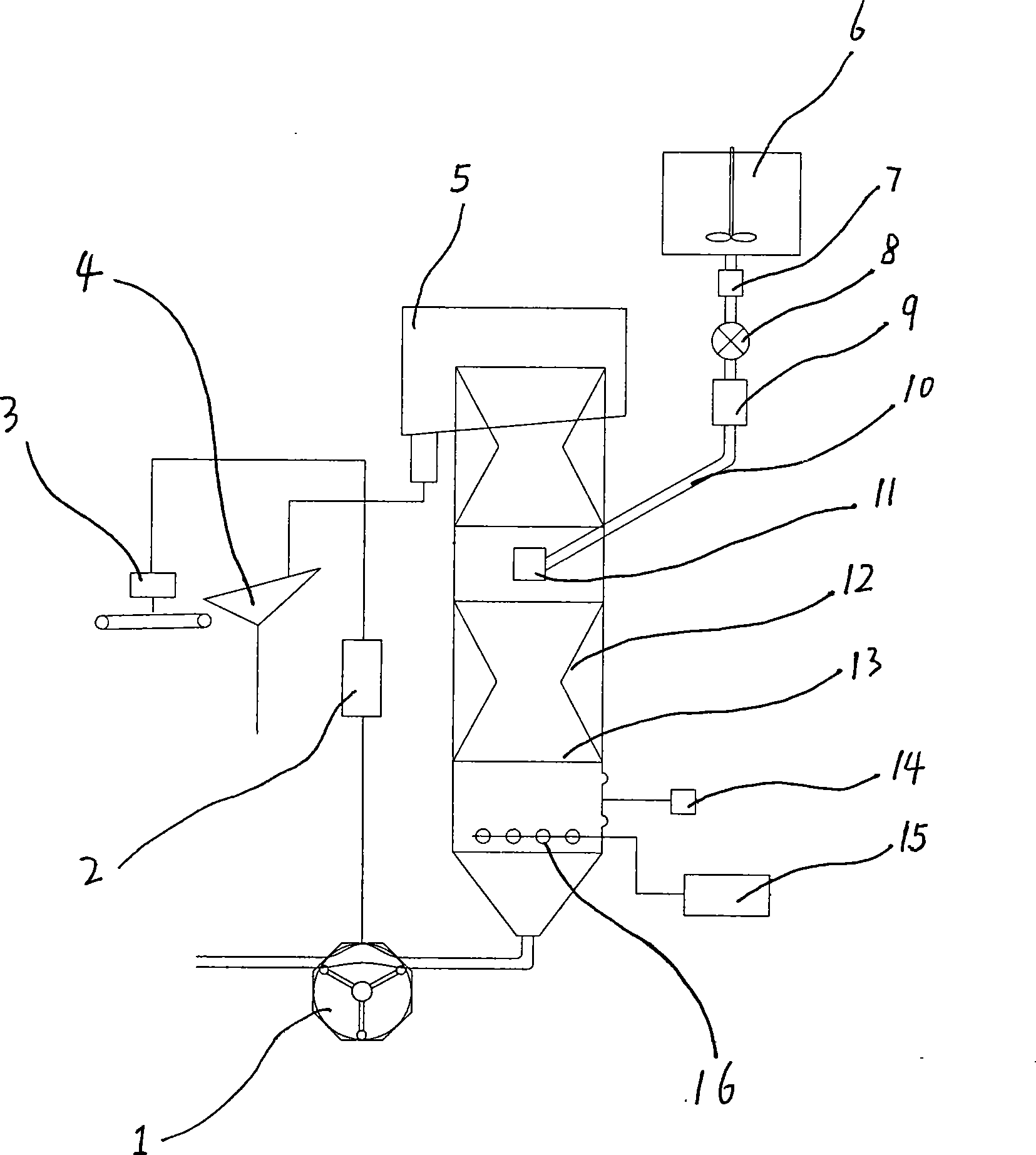

[0010] Such as figure 1 As shown, the present invention is formed by interconnecting an interfering bed separator, a feeding system, a peristaltic pump 1, a clean coal recovery system, and a water pump 15. The feeding system is composed of a mixing tank 6, a concentration meter 7, a flow meter 8, a valve 9, and a feeding pipe 10. The clean coal recovery system consists of a desliming screen 4, an ash analyzer 3 and a controller 2. The coal slurry is evenly stirred by the mixing tank 6, and then passes through an external feeding pipe from the middle part of the disturbance bed separator into the separation chamber of the disturbance bed separator, with concentration meters, flow meters and valves to realize automatic feeding. control. The interfering bed separator is divided into six parts, from top to bottom: clean coal overflow section, clean coal beneficiation section, fluidized bed layer section, tailing coal beneficiation section, pulsating water flow generation section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com