A spiral ascending flow type liquid-solid fluidized bed separation equipment and method

A fluidized bed and upflow technology, which is applied in the field of liquid-solid fluidized bed separation equipment, can solve the problem that the bottom flow control cannot be completely tracked in real time, the automatic detection and control system is not perfect, and the processing capacity of the disturbed bed sorter is large, etc. problems, to achieve the effect of reducing the phenomenon of heavy medium backlash, solving the separation efficiency and drug consumption, and reducing the gradient change of solid solvent concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

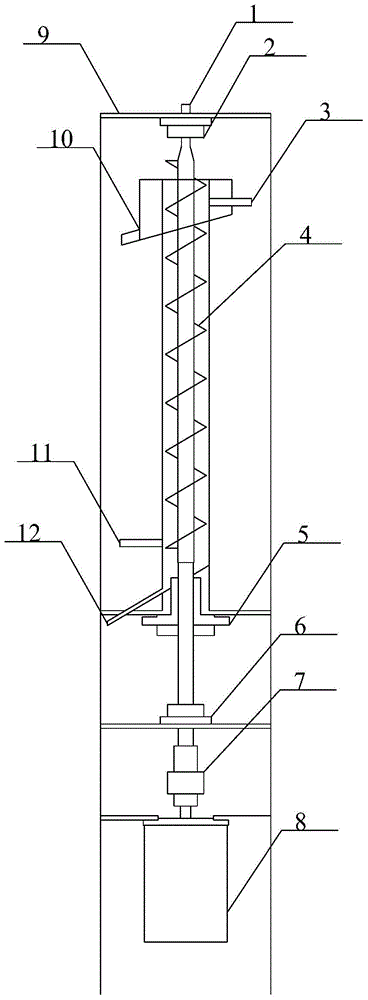

[0019] figure 1 As shown, the spiral ascending flow type liquid-solid fluidized bed separation equipment of the present invention is mainly composed of a transmission shaft 1, a bearing 2, a feed pipe 3, a spiral blade 4, a packing seal 5, a bearing 6, a shaft coupling 7, an electric motor 8. Rack 9. Composed of sorting columns. The column body of the sorting column is made of plexiglass, and the motor is composed of a three-phase asynchronous motor with variable frequency speed regulation and a variable frequency speed regulator. The sorting column is arranged on the top of the frame 9, and the motor 8 is arranged on the bottom of the frame 9. The transmission shaft 1 passing through the sorting column is arranged in the described sorting column, and the lower part of the transmission shaft 1 passes through the bearing 6, the coupling The shaft device 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com