A new process for extracting gallium from Bayer mother liquor with chelating resin

A chelating resin and new process technology, applied in the field of gallium extraction, can solve the problems of resin gallium absorption capacity reduction, temperature rise, etc., and achieve the effect of eliminating the phenomenon of sharp temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

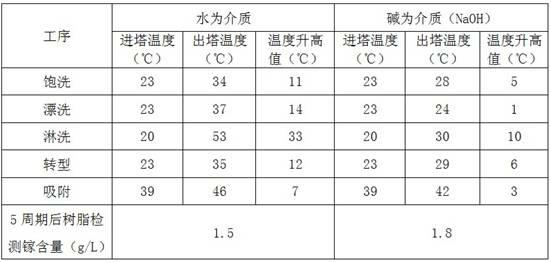

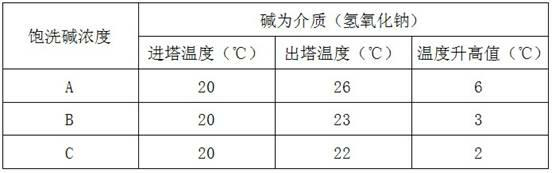

[0019] Under the same operating conditions, water and sodium hydroxide solution were used as media respectively to investigate the temperature change and resin adsorption capacity during each process.

[0020] Using water as the medium, the temperature changes during each process are as follows (wherein the temperature of entering the tower and the temperature of leaving the tower take the average value of the detection data in the whole process, and the following examples are all the same):

[0021] (1) Saturated washing: The resin volume of the saturated washing tower is 5m 3 , with a velocity of 2m 3 / h, the processing time is 2h. The solution entering the tower is water, the temperature of the water entering the tower is 23°C, and the temperature of the liquid exiting the tower is 34°C;

[0022] (2) Rinsing: The resin volume of the rinsing tower is 5m 3 , with a velocity of 2m 3 / h, the processing time is 2h. The solution entering the tower is water, the temperature o...

Embodiment 2

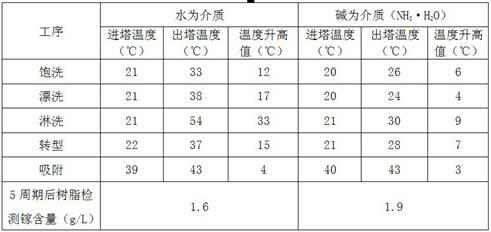

[0038] Under the same operating conditions, water and potassium hydroxide solution were used as media respectively to investigate the temperature change and resin adsorption capacity of each process.

[0039] Using water as the medium, the temperature changes during each process are as follows:

[0040] (1) Saturated washing: The resin volume of the saturated washing tower is 5m 3 , with a velocity of 2.5m 3 / h, the processing time is 2h. The solution entering the tower is water, the temperature of the water entering the tower is 21°C, and the temperature of the liquid exiting the tower is 35°C;

[0041] (2) Rinsing: The resin volume of the rinsing tower is 5m 3 , with a velocity of 2.5m 3 / h, the processing time is 2h. The solution entering the tower is water, the temperature of the water entering the tower is 23°C, and the temperature of the liquid exiting the tower is 36°C;

[0042] (3) Rinse: The resin volume of the single tower of the eluent tower is 5m 3 , with a ...

Embodiment 3

[0057] Under the same operating conditions, water and ammonia solution were used as media respectively to investigate the temperature change and resin adsorption capacity during each process.

[0058] Using water as the medium, the temperature changes during each process are as follows:

[0059] (1) Saturated washing: The resin volume of the saturated washing tower is 5m 3 , with a velocity of 2m 3 / h, the processing time is 2h. The solution entering the tower is water, the temperature of the water entering the tower is 21°C, and the temperature of the liquid exiting the tower is 33°C;

[0060] (2) Rinsing: The resin volume of the rinsing tower is 5m 3 , with a velocity of 2m 3 / h, the processing time is 2h. The solution entering the tower is water, the temperature of the water entering the tower is 21°C, and the temperature of the liquid exiting the tower is 38°C;

[0061] (3) Rinse: The resin volume of the single tower of the eluent tower is 5m 3 , with a velocity of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com