A sorting method of variable-diameter pulsating liquid-solid fluidized bed

A fluidized bed and pulsating flow technology, applied in the field of separation, can solve the problems of poor separation effect of refractory coarse coal slime, narrow range of effective separation particle size, affecting production and economic benefits, etc., to achieve a solution to clean coal recovery rate Contradictions with the quality of clean coal, reducing backlash phenomenon, and reducing the effect of solid solvent concentration gradient changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing.

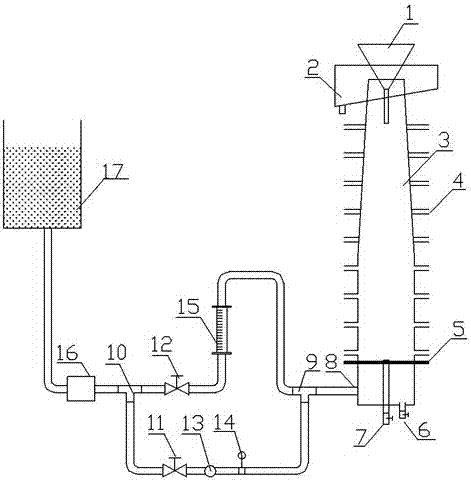

[0017] Such as figure 1 As shown, the variable-diameter pulsating liquid-solid fluidized bed separation method includes a variable-diameter disturbance bed sorter, a pulsating flow flow measurement and control system, a steady flow flow measurement and control system and a water pump 16; the variable diameter disturbance bed sorter An overflow weir 2 and a feeding funnel 1 are provided on the upper part of the variable-diameter cylinder 3, and the feeding funnel 1 is inserted into the inside of the variable-diameter cylinder 3 from the top of the variable-diameter cylinder 3, and a plurality of sampling measuring devices are arranged around the variable-diameter cylinder 3. The pressure port 4 is provided with a turbulence plate 5 inside the variable diameter cylinder 3 near the bottom surface. The bottom of the variable diameter cylinder 3 is provided with an underflow por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com